Water film dust removal utilizes the contact of dust-laden gas with the inner wall of the dust collector or other special components to create a water film through certain means. This film captures the dust, resulting in the purification of the gas. Such purification equipment is called a water film dust collector. These include impact water film, inertial (louver) water film, and centrifugal water film dust collectors.

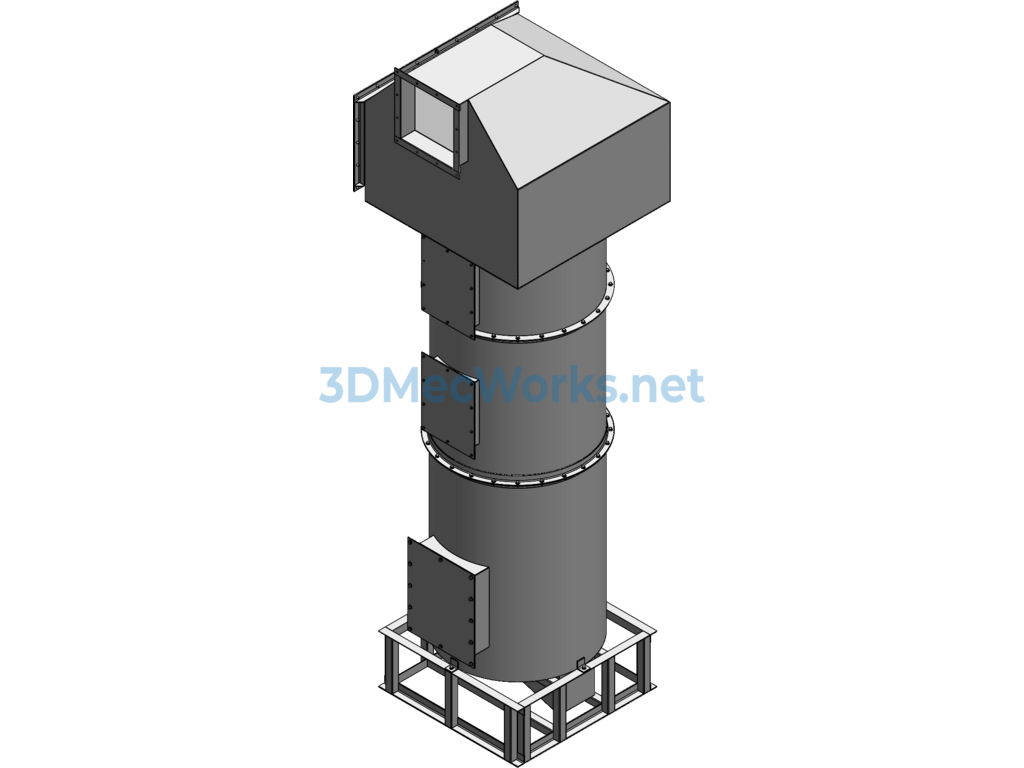

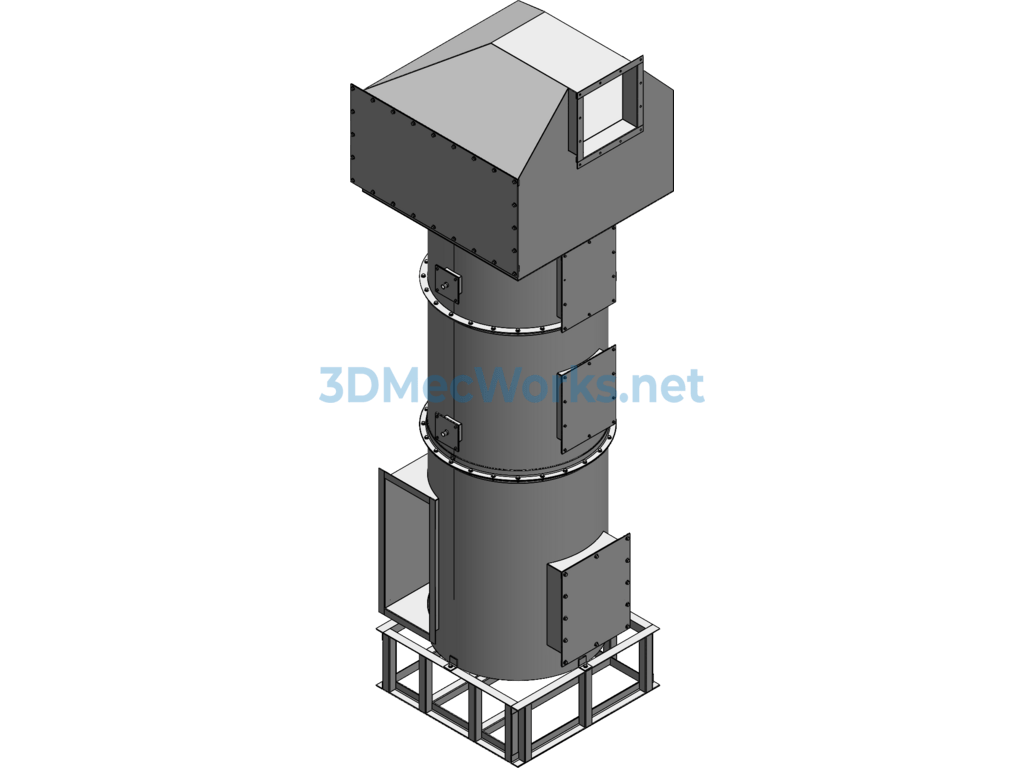

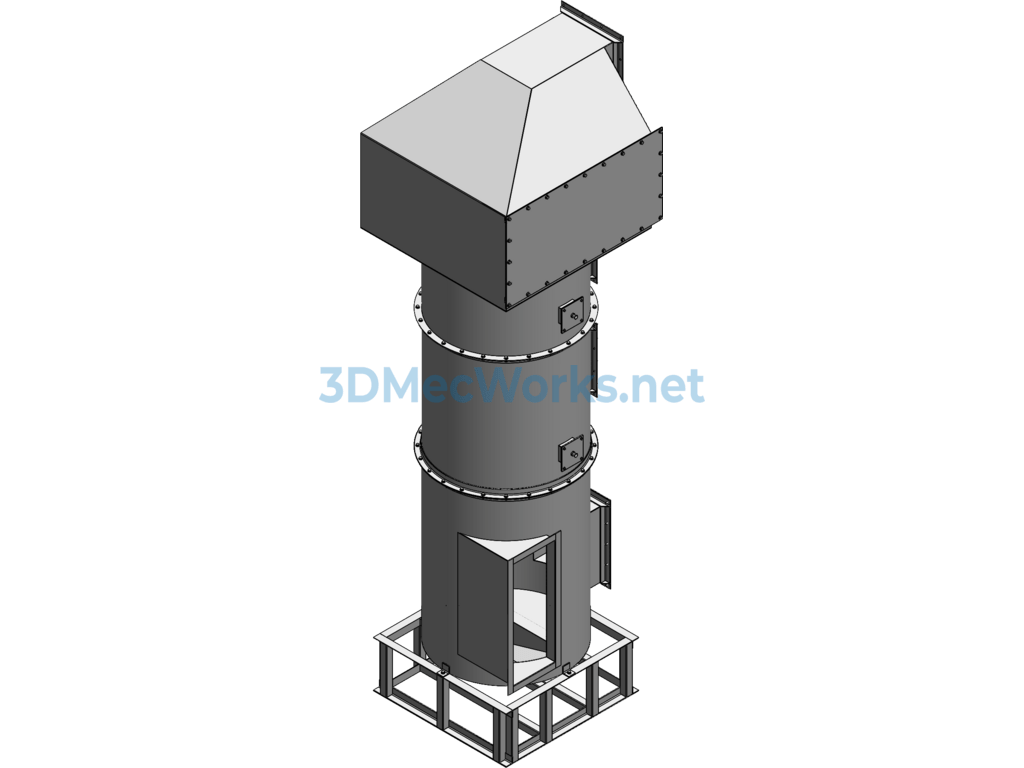

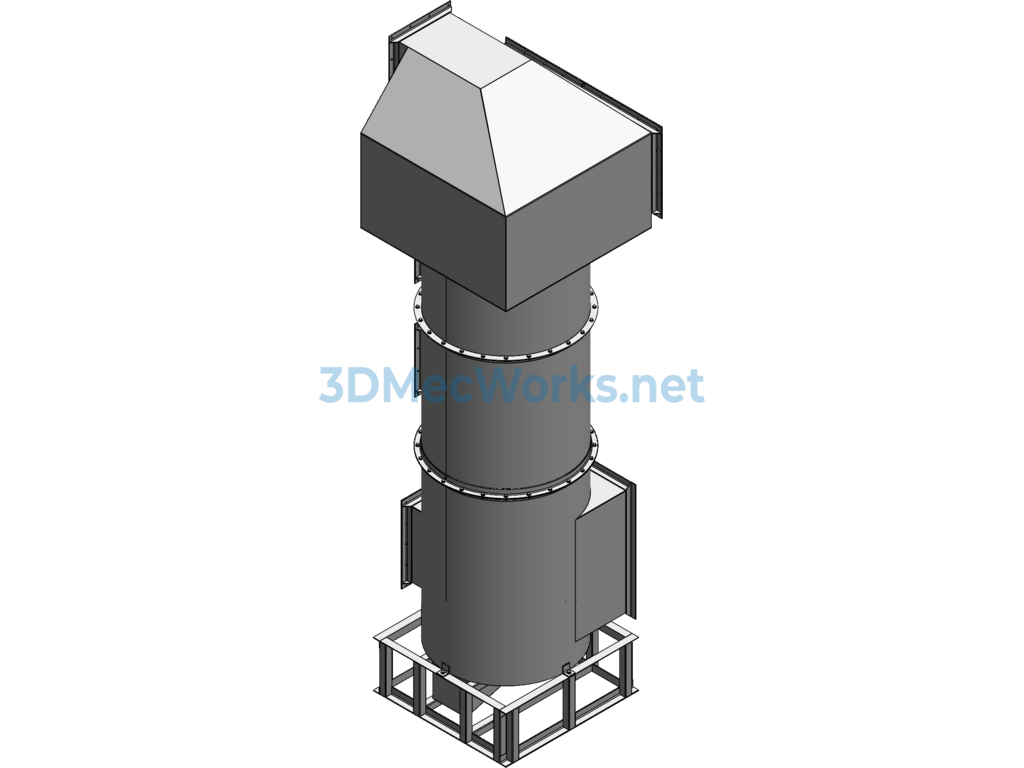

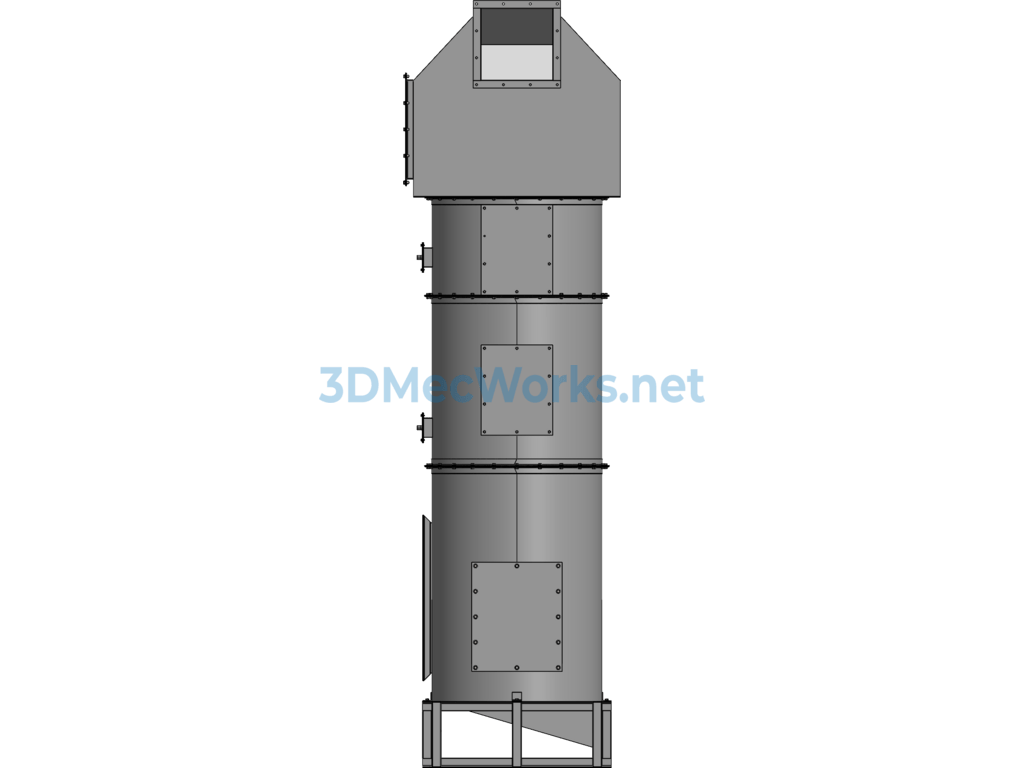

Dust-laden gas is introduced tangentially from the lower part of the cylinder, rising in a rotational motion. The dust particles are separated under the effect of centrifugal force and thrown toward the inner wall of the cylinder. Here, they are absorbed by the water film layer flowing along the inner wall of the cylinder. The dust, along with the water flow, is discharged through the dust outlet located at the bottom conical part. The water film layer is formed by several nozzles arranged at the upper part of the cylinder, which spray water tangentially onto the wall of the vessel. This ensures that a thin water film, rotating and flowing downward, constantly covers the inner wall of the cylinder, thereby enhancing the dust removal effect.

This type of wet dust collector has a simple structure, low metal consumption, and low water consumption. However, its disadvantages include a relatively large height, which complicates installation, and the occurrence of water carry-over during actual operation.

Specification: Water Film Dust Collector

|

User Reviews

Be the first to review “Water Film Dust Collector”

You must be logged in to post a review.

There are no reviews yet.