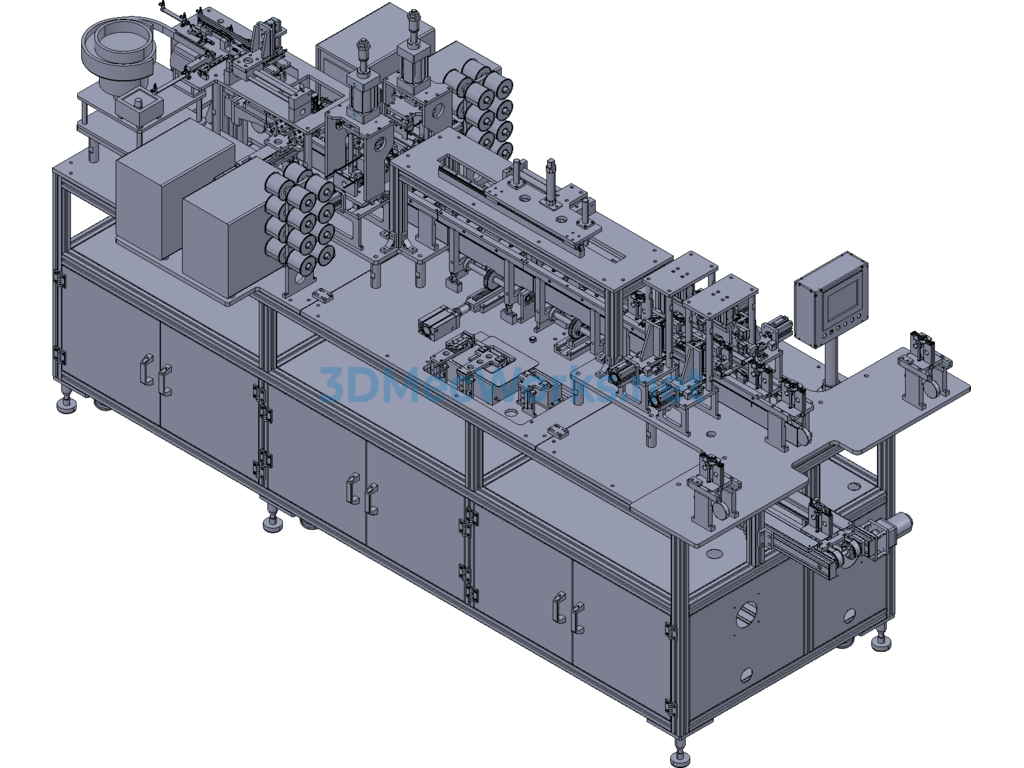

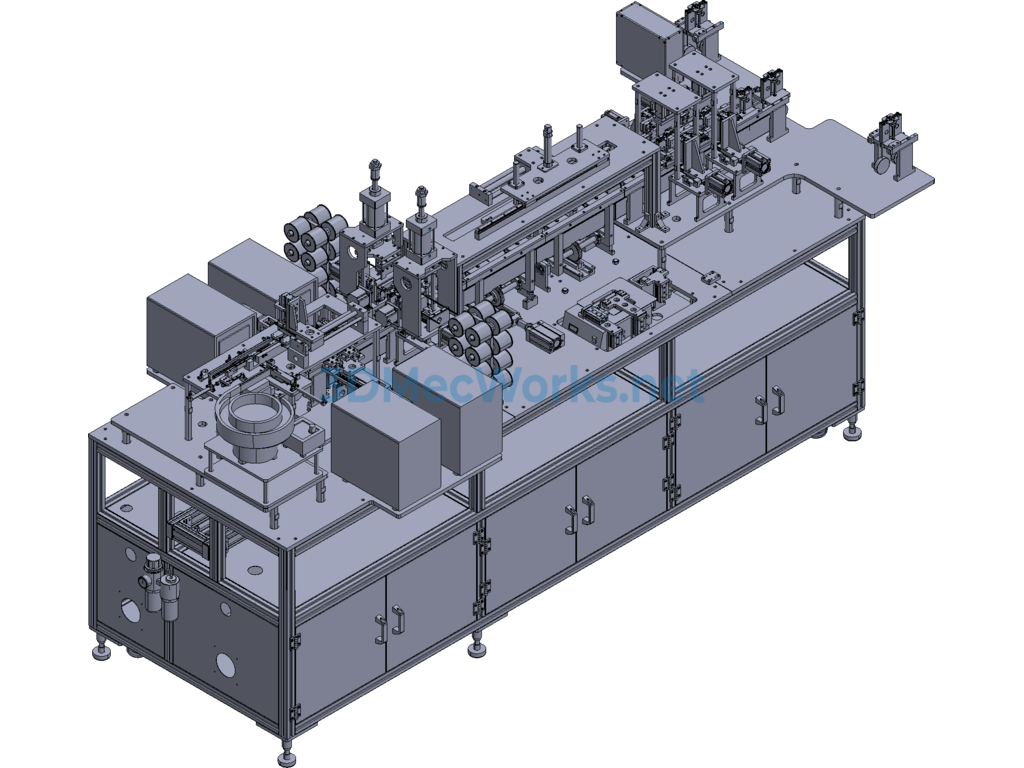

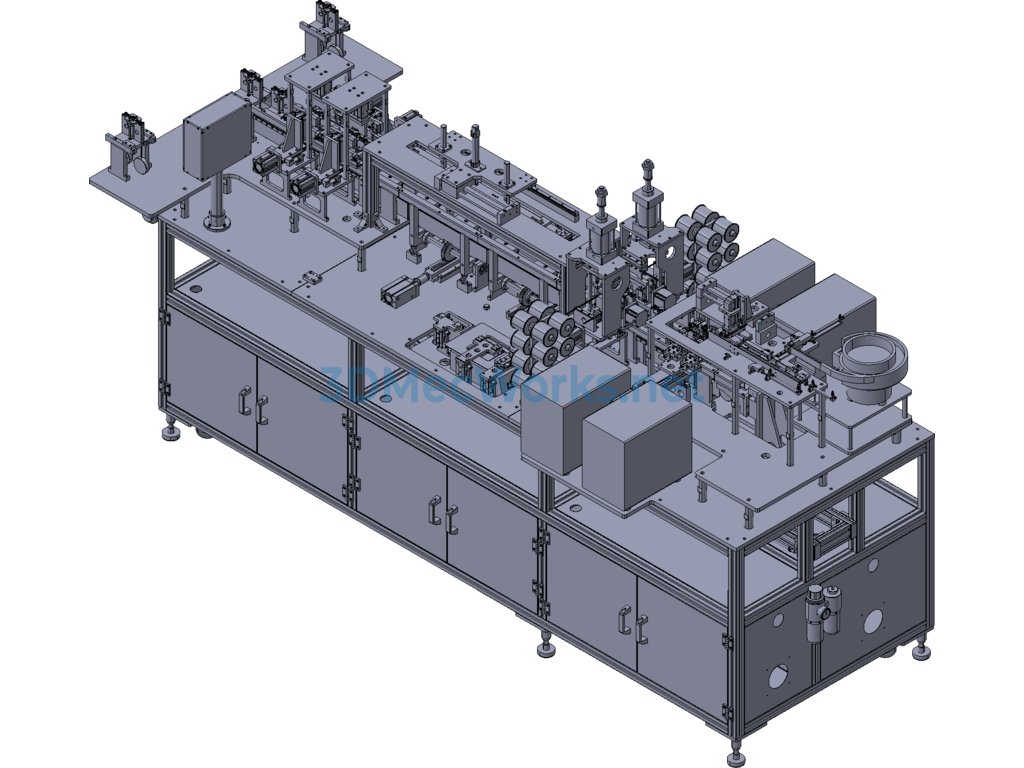

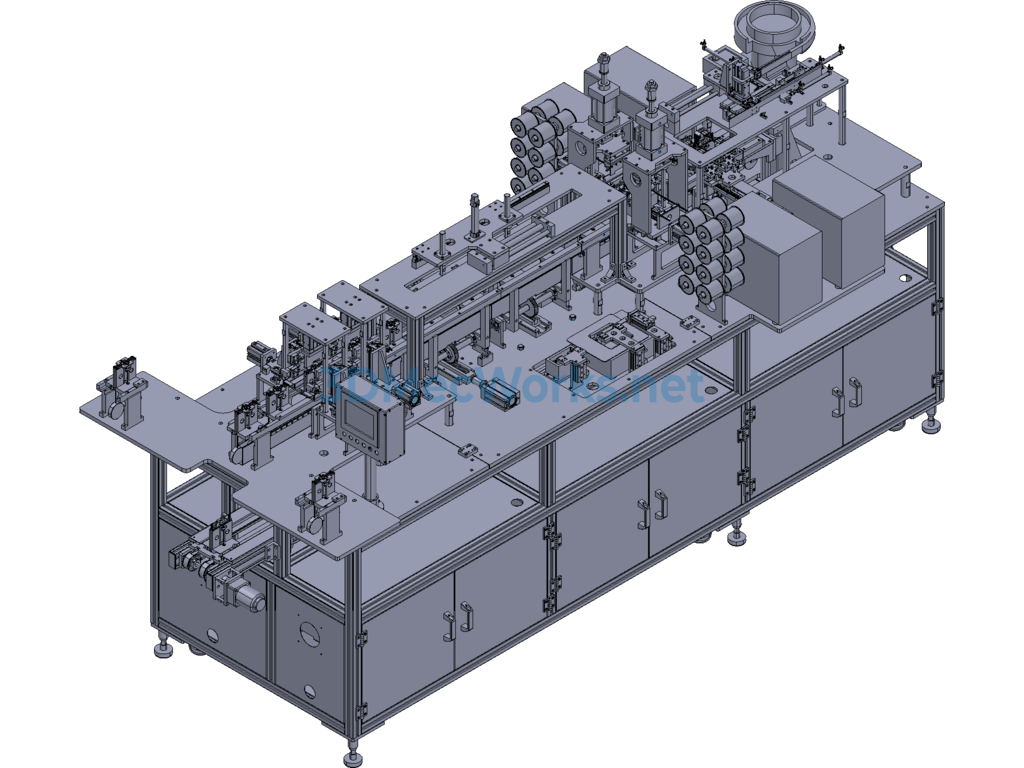

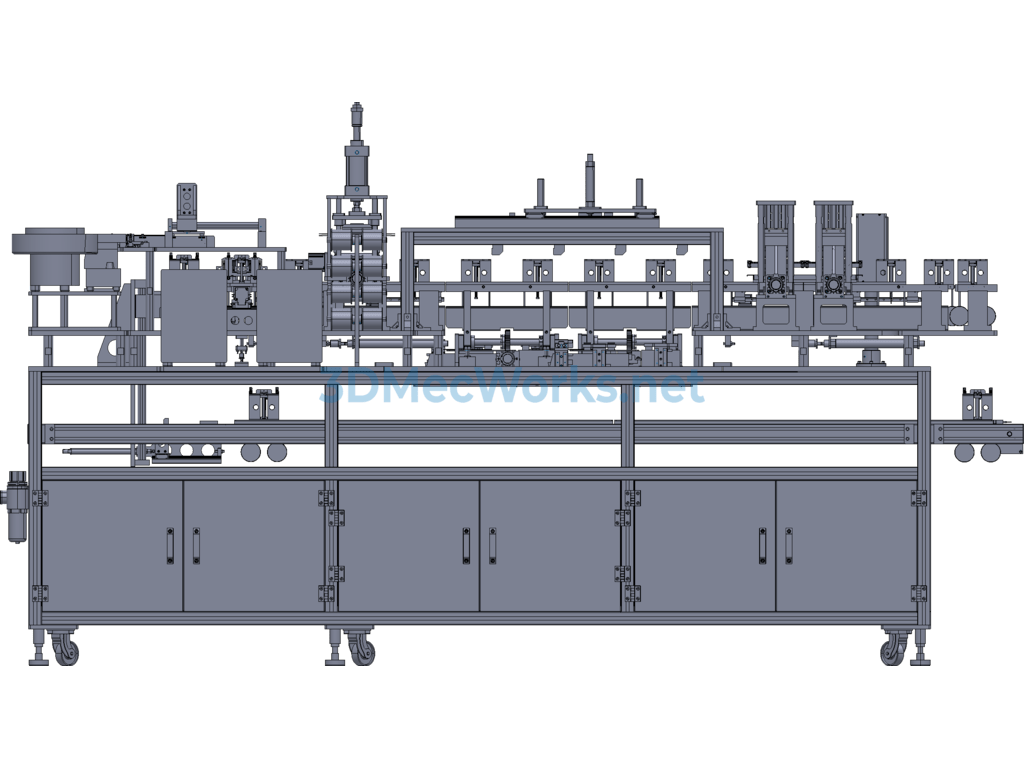

The cable is positioned and pushed into the chute through the fixture, using a pusher to successively transport it to stations such as: cutting, outer sheath stripping, flux spreading & tin dipping, tin pressing, welding, etc. Finally, according to requirements, the USB-3.0 connector is welded together with the cable, and the finished product is transported through the recovery mechanism to the staff’s position at the positioning table for continuous cycles. Efficiency evaluation: Actions such as (conductor cutting, outer sheath stripping, flux spreading & tin dipping, conductor tin pressing, connector sorting positioning, connector welding, etc.) are completed in approximately 10 seconds per cycle, producing 2 wires, with an estimated capacity of 720 pcs/h. USB-3.0 cable processing assembly line staffing: (1 person) with 1 person, checking cable positioning proficiency.

Specification: Usb-3.0 Cable Processing Production Line

|

User Reviews

Be the first to review “Usb-3.0 Cable Processing Production Line”

You must be logged in to post a review.

There are no reviews yet.