1. The furnace chamber uses imported alumina polycrystalline fiber materials, which have good insulation properties.

2. The heating element uses imported alloy wire 0Cr27Al7Mo2, with a temperature capability of up to 1000°C.

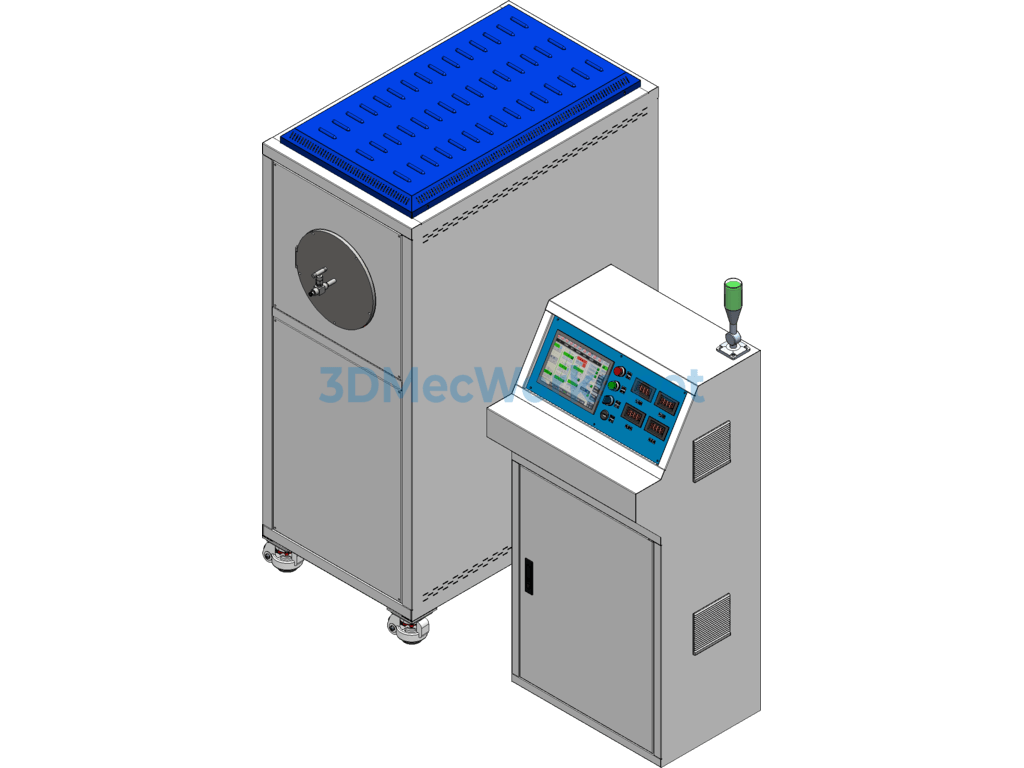

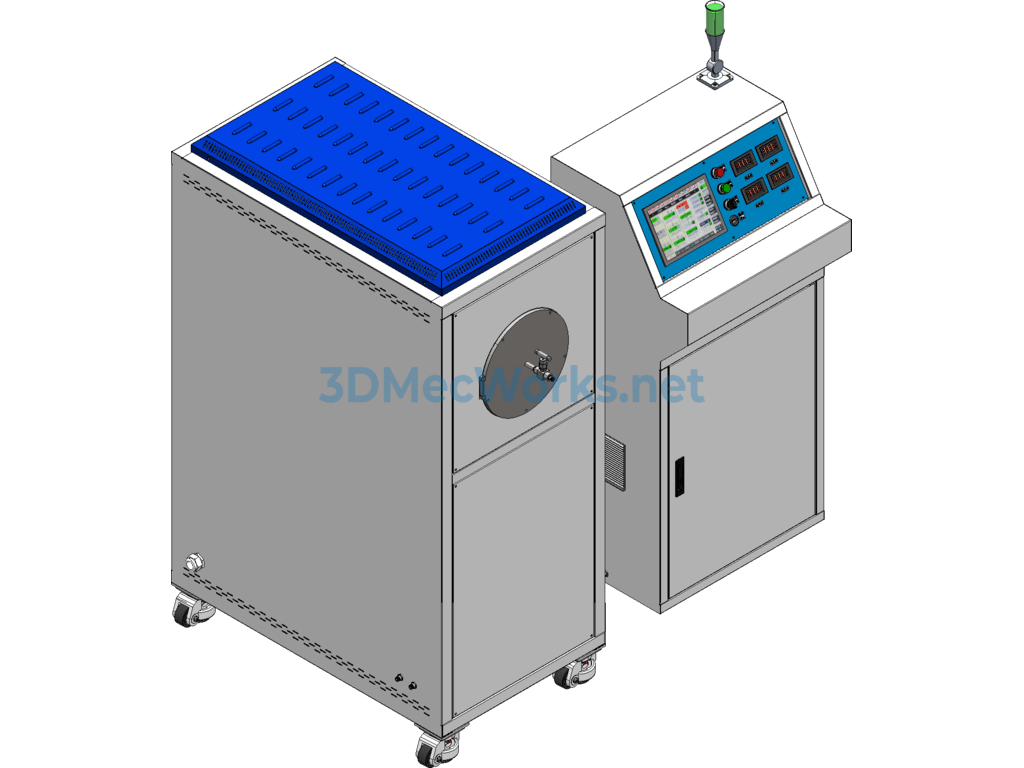

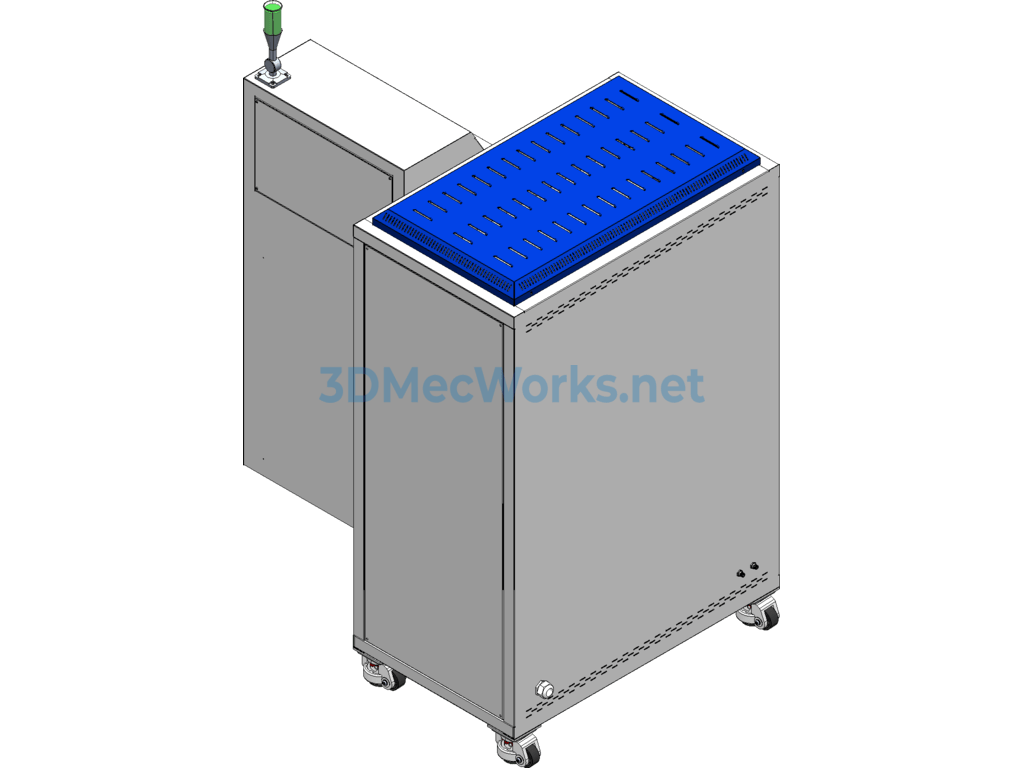

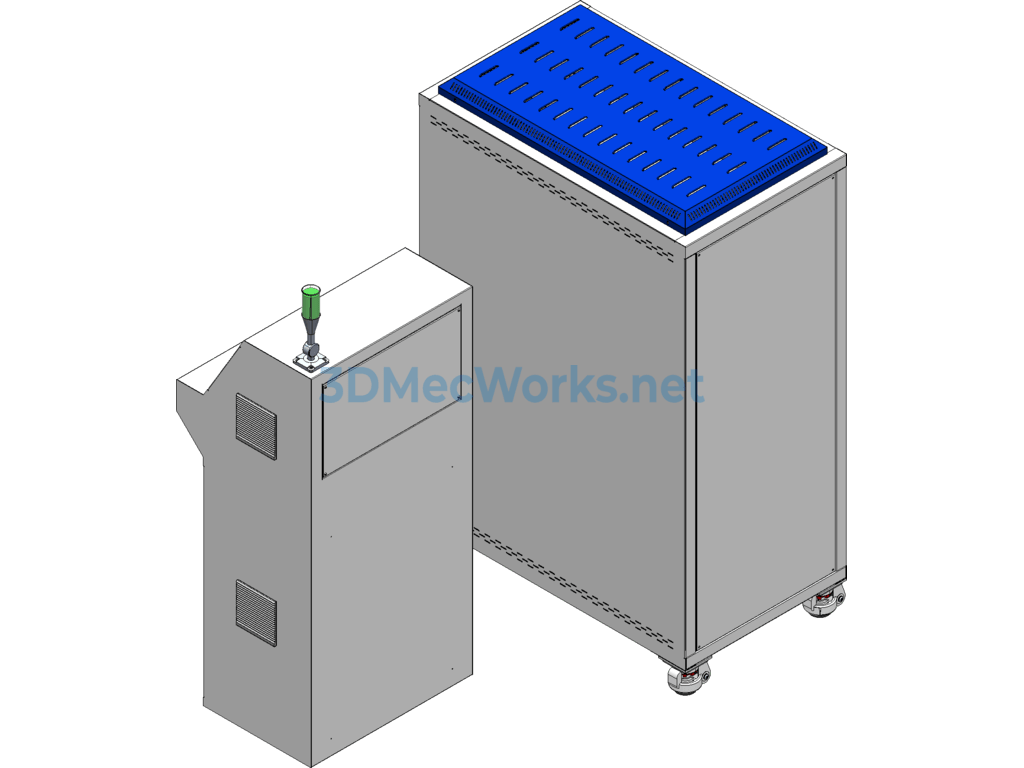

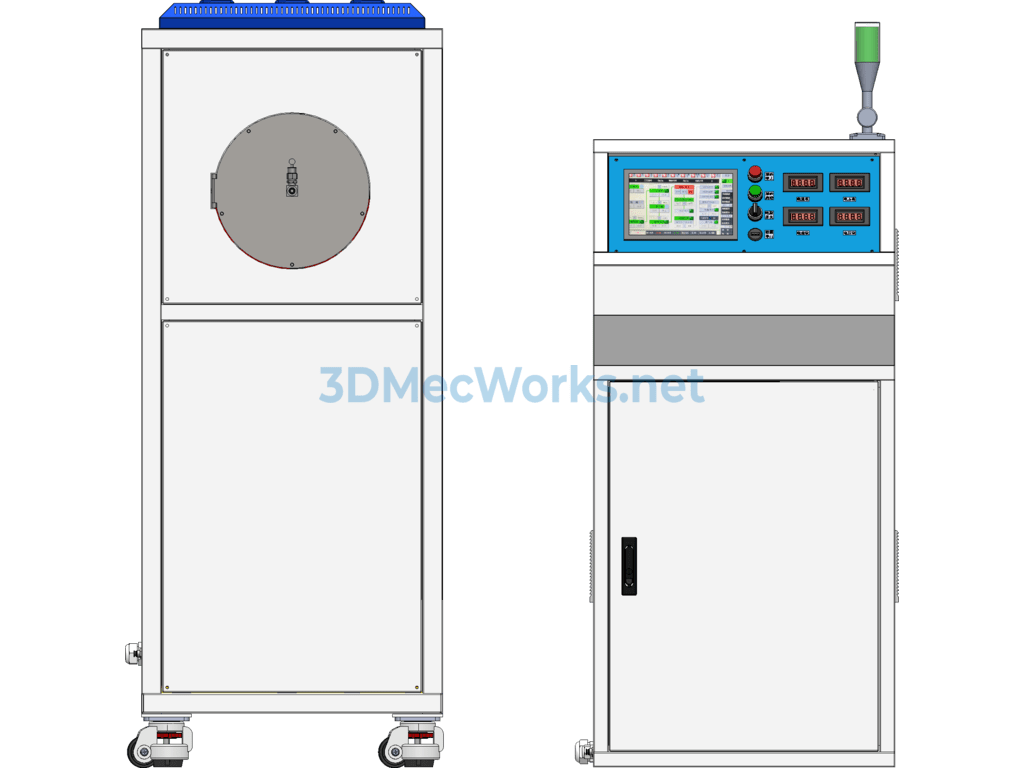

3. It adopts a double-layer shell structure combined with thermal induction technology, equipped with an air-cooling system to quickly reduce the surface temperature of the furnace.

4. The use of KF quick flange connections reduces the possibility of heating tube damage, making material placing and removing more convenient and efficient.

5. The top-opening furnace lid design allows real-time observation of heated materials and can rapid-cool, meeting experimental needs for rapid heating and cooling.

6. Smart PID control with self-tuning function and 30-segment programmable control allows setting 30 temperature rise and fall programs, achieving power loss-free operation.

7. Reserved quick vacuum and gas circuit interfaces, designed to work with our company’s vacuum and gas mixing systems; satisfying users’ experimental needs under different vacuum statuses and atmospheric conditions.

There are no reviews yet.