Lucia Hurley

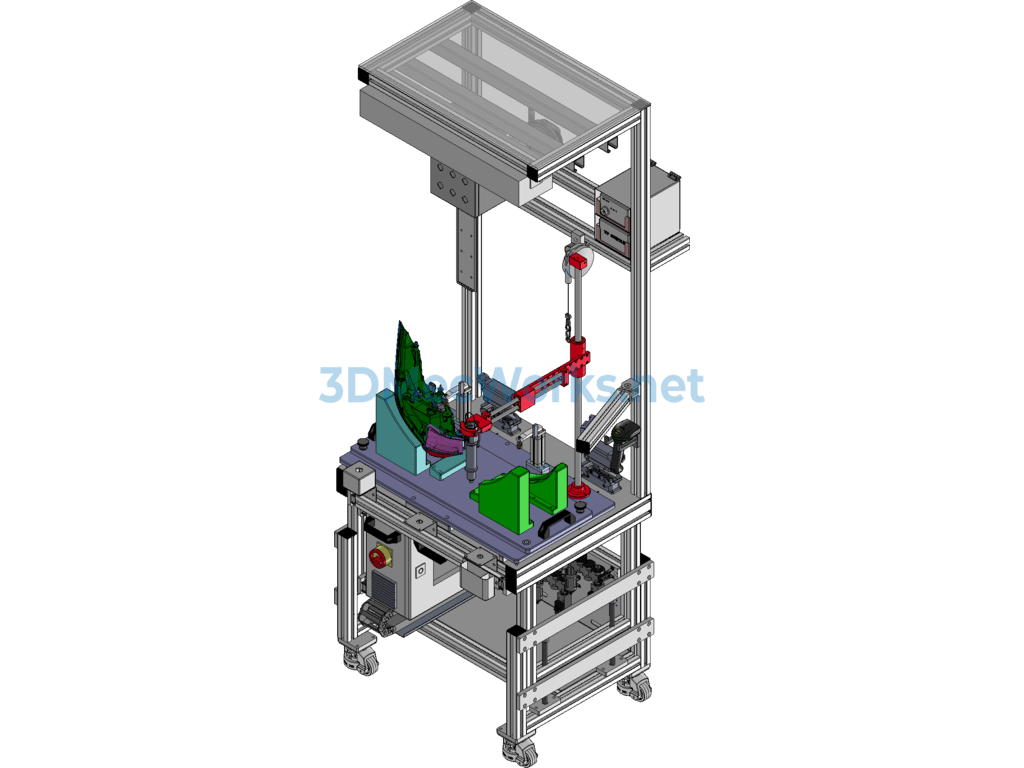

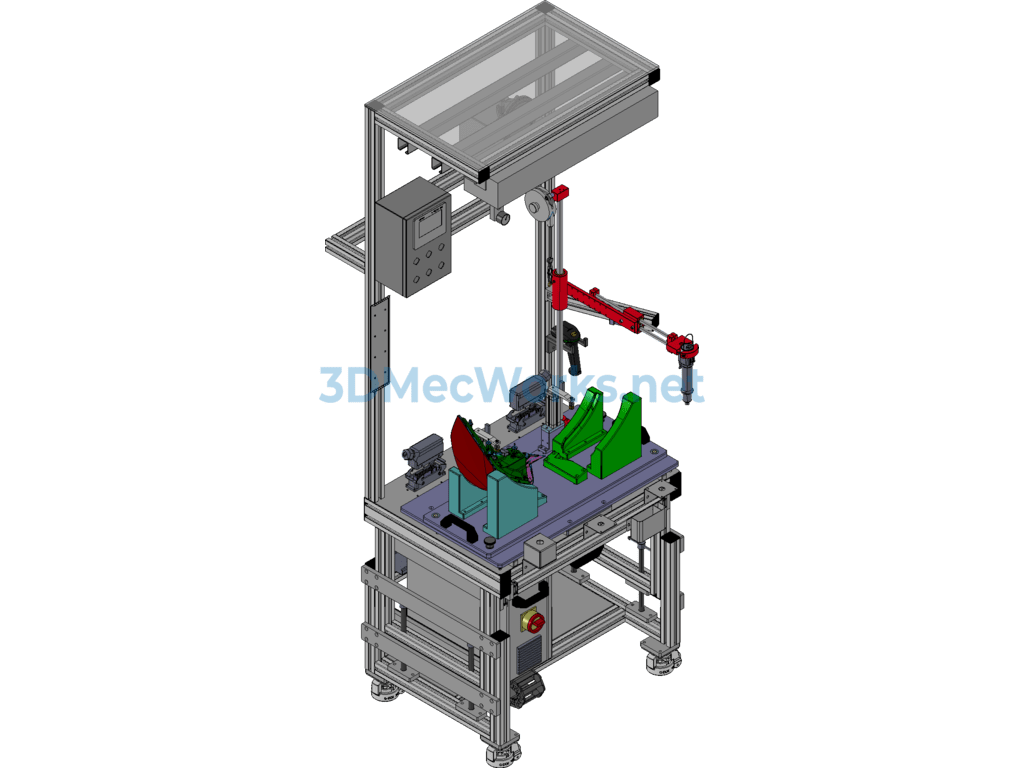

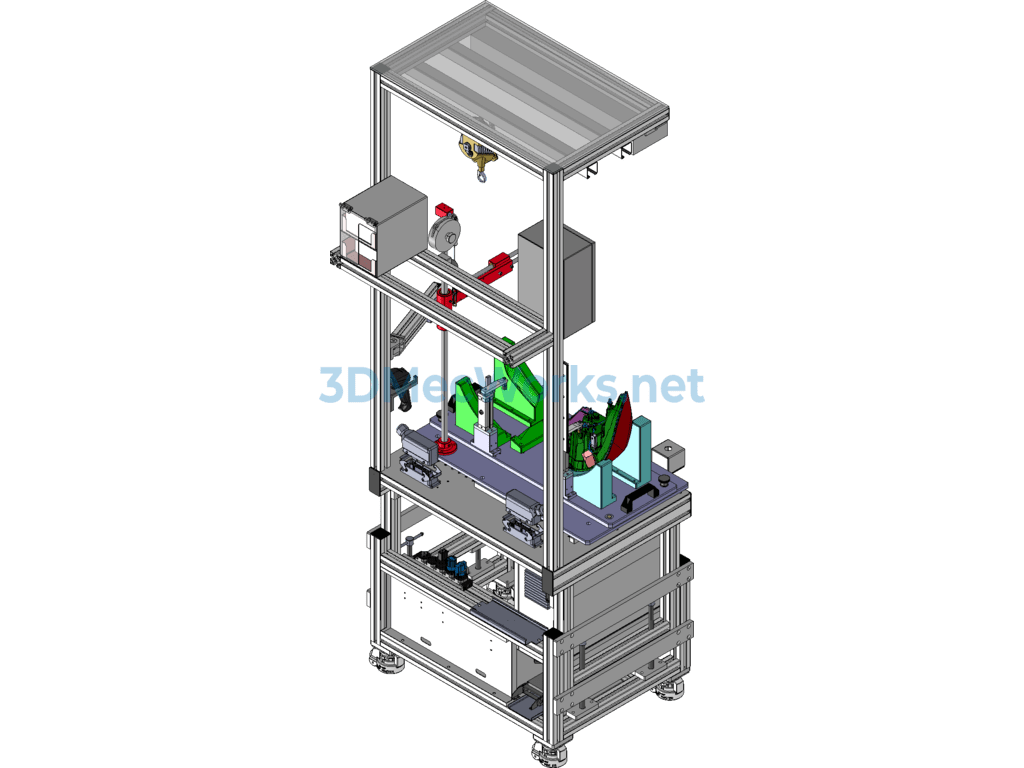

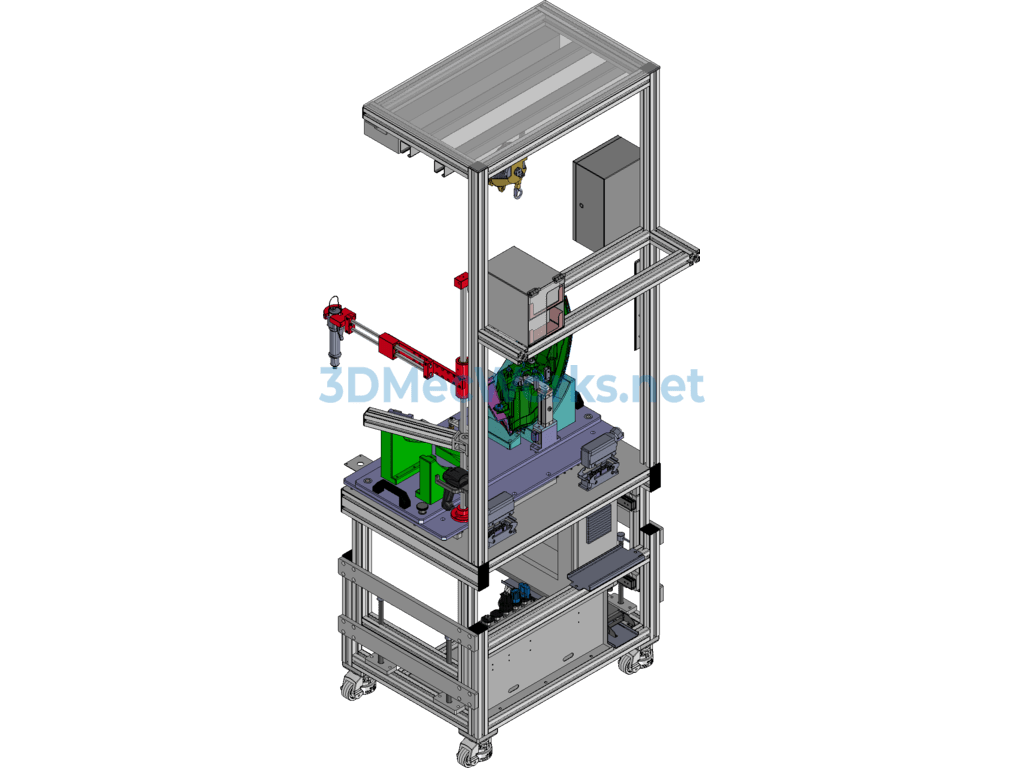

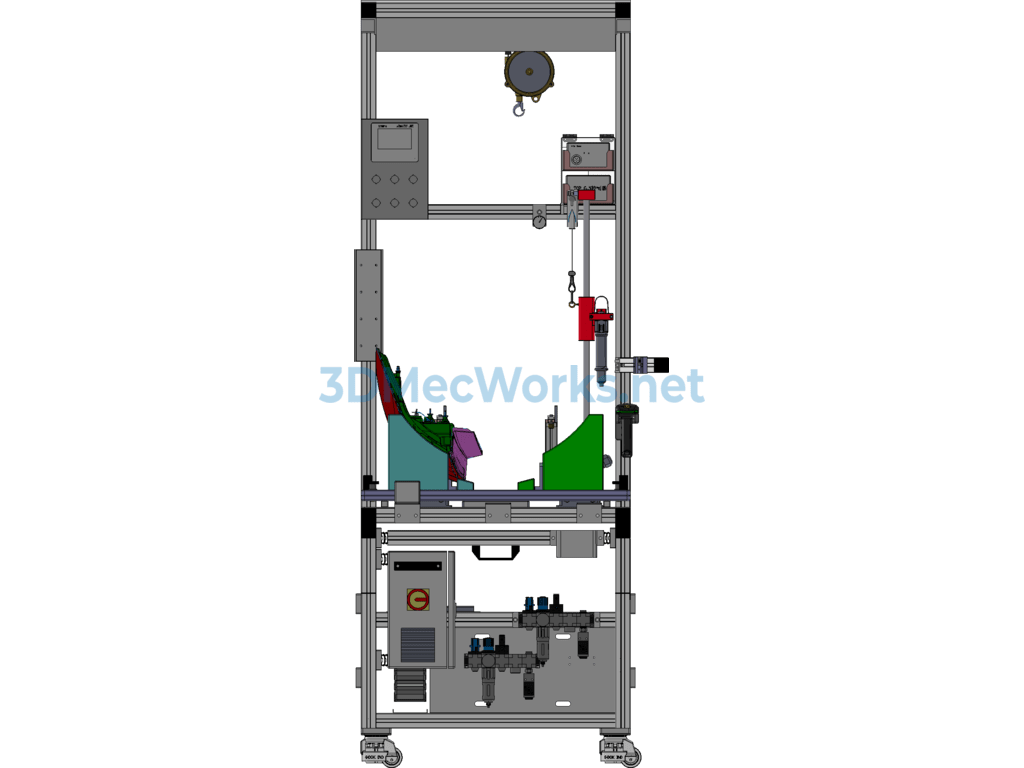

This is a set of equipment for producing car lights. It can complete the assembly of car lights (Fender and Trunk car lights) through electric and pneumatic drive along with manual operation. It is a non-standard equipment. (However, by changing the fastening tooling and operating PLC, other car light products can be produced. It is a very good reference material for those who need to design car light assembly equipment.) This set of equipment is divided into three stations. Station ST09 installs fixing screws, semi-transparent films, and gaskets onto the lamp shell. Station ST12 wraps protective film and scans labels. Station ST13 applies barcodes to the entire carton.

Operation procedure of Station ST09: 1. Place the semi-finished product onto the corresponding tooling, clamp the tooling to lock the product;

2. Take fixing screws and install them on the lamp shell;

3. Take the semi-transparent film and gasket and install on the lamp shell;

4. Remove the model and transfer to the next station.

Operation procedure of Station ST12: 1. Place the product onto the tooling;

2. Inspect appearance, clean, and punch;

3. Wrap the protective film;

4. Scan the label information.

Operation procedure of Station ST13: 1. Place the product on the work surface;

2. Inspect appearance, illuminate, and punch;

3. Pack into boxes;

4. Remove entire carton barcode from the barcode printer and attach it to the entire carton packaging.

Specification: Three-Station Assembly Line for Car Light Production Equipment

|

User Reviews

Be the first to review “Three-Station Assembly Line for Car Light Production Equipment” Cancel reply

You must be logged in to post a review.

There are no reviews yet.