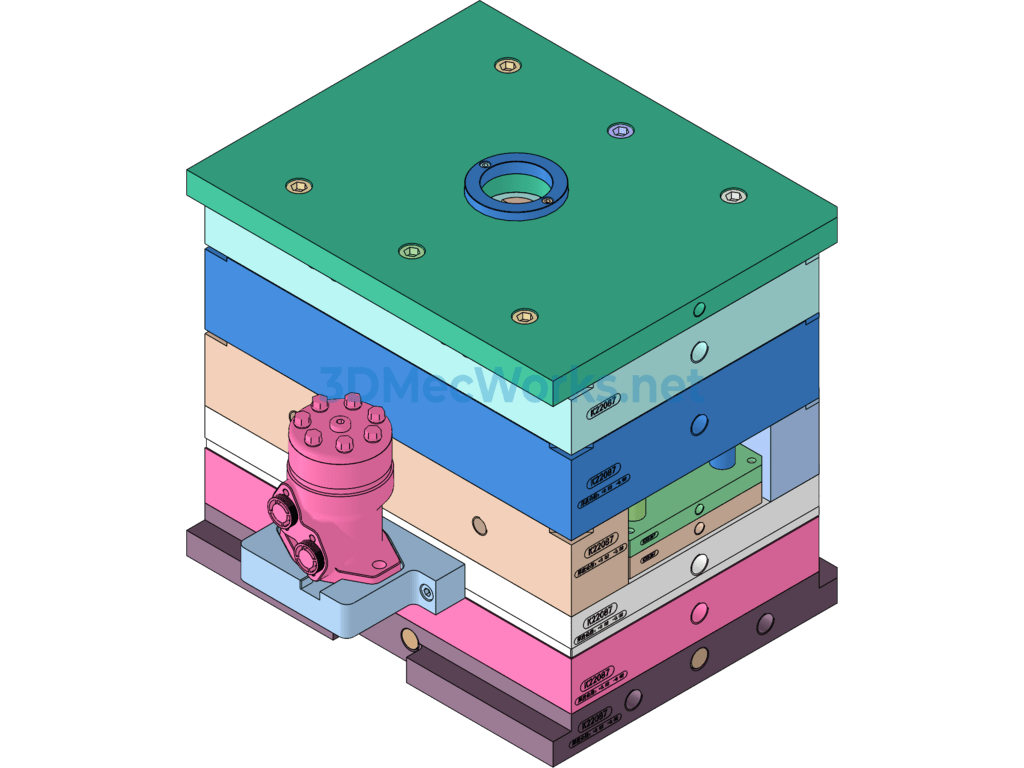

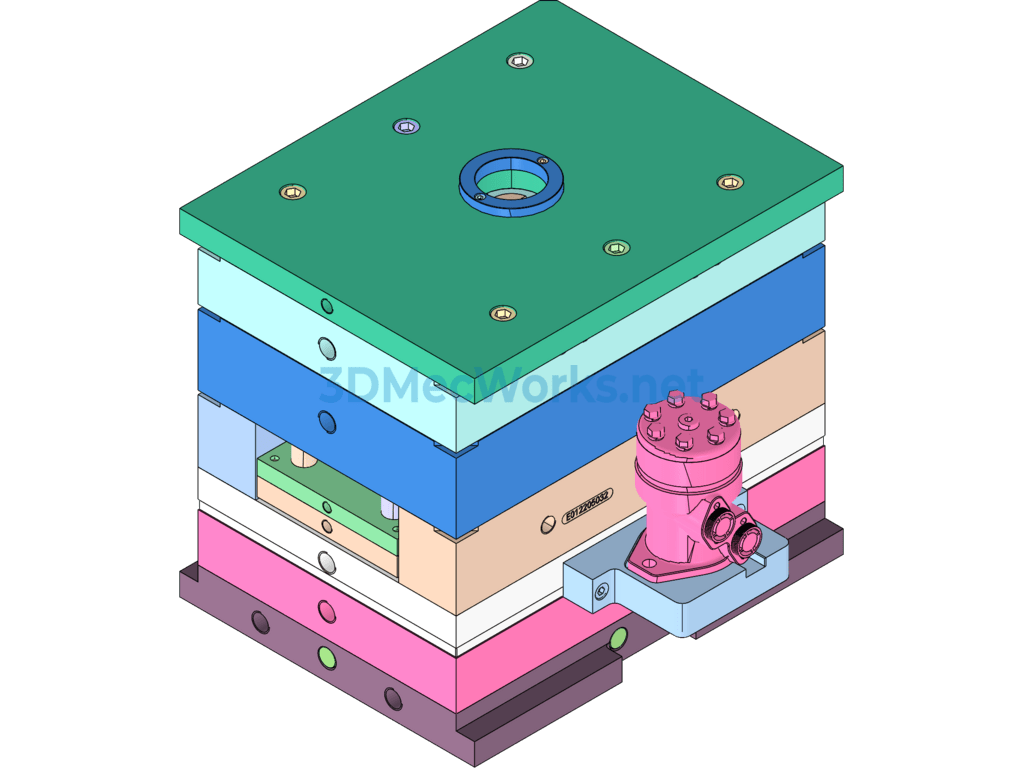

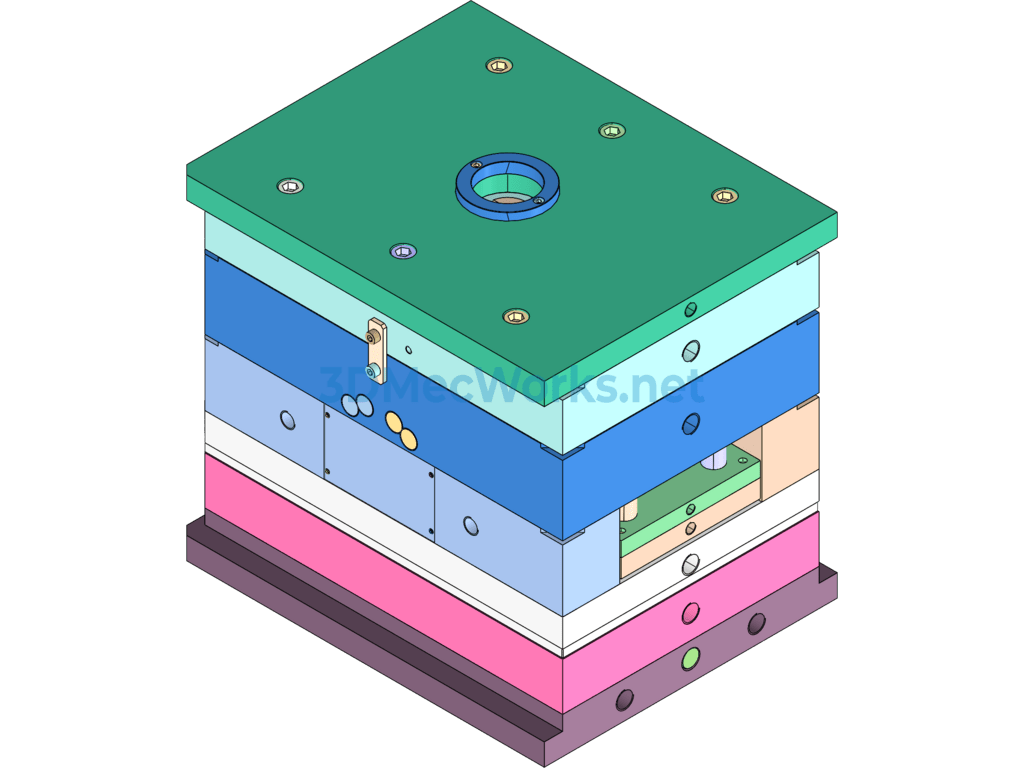

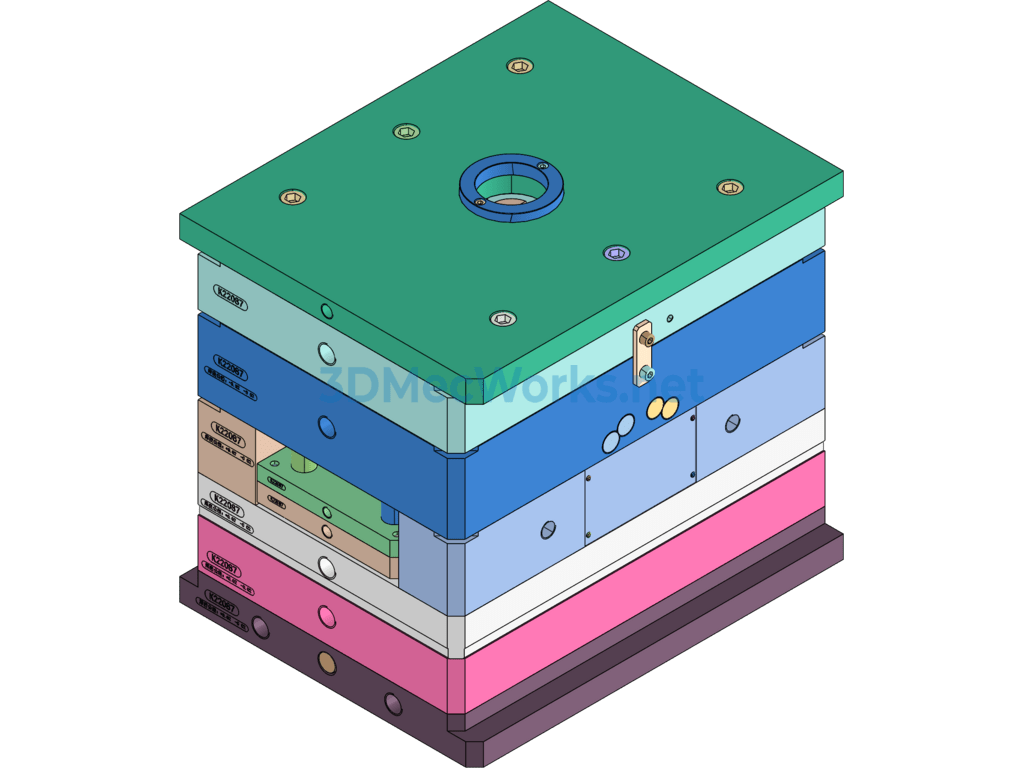

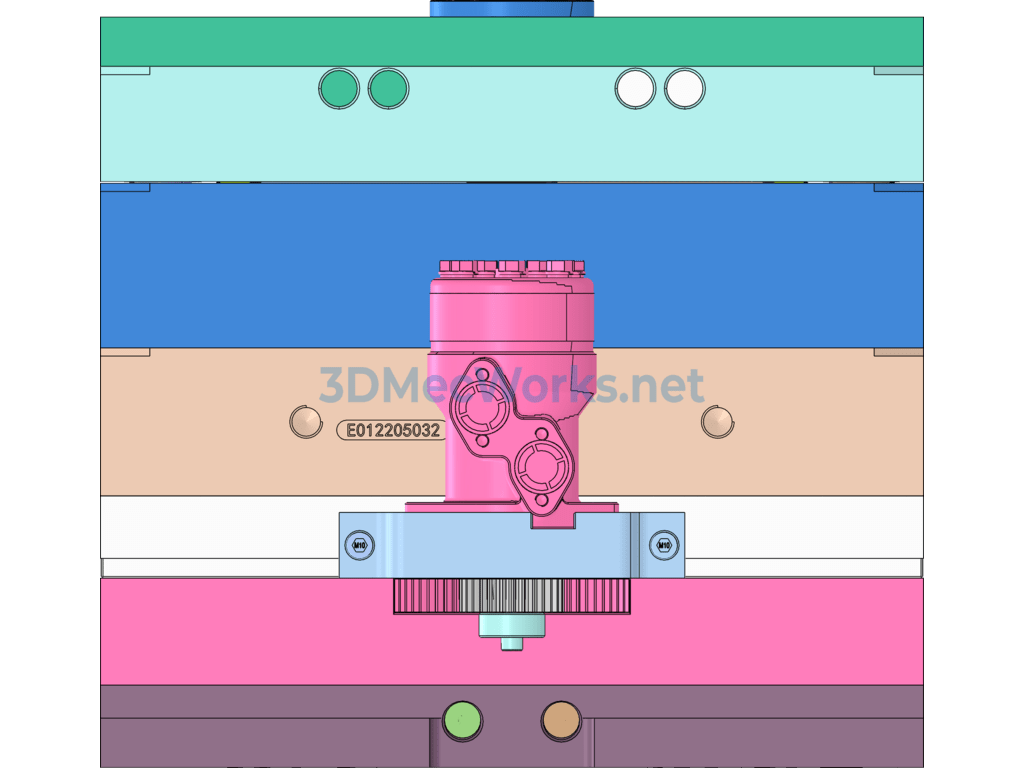

The model is a threaded injection mold design, with a four-cavity configuration, made of ABS material, using a large gate submarine runner for injection. The product’s internal threads use an oil motor for automatic de-threading. The mold operation is as follows: under the drive of a gear motor, the threaded core rotates; after the product is demolded upwards and the threads are completely disengaged, ejector pins are used to push it out. The threaded core is also cooled. The drawing structure is very clear and open for everyone to download and learn.

Specification: Threaded Knob Cover (threaded + Ejector Plate Ejection)

|

User Reviews

Be the first to review “Threaded Knob Cover (threaded + Ejector Plate Ejection)”

You must be logged in to post a review.

There are no reviews yet.