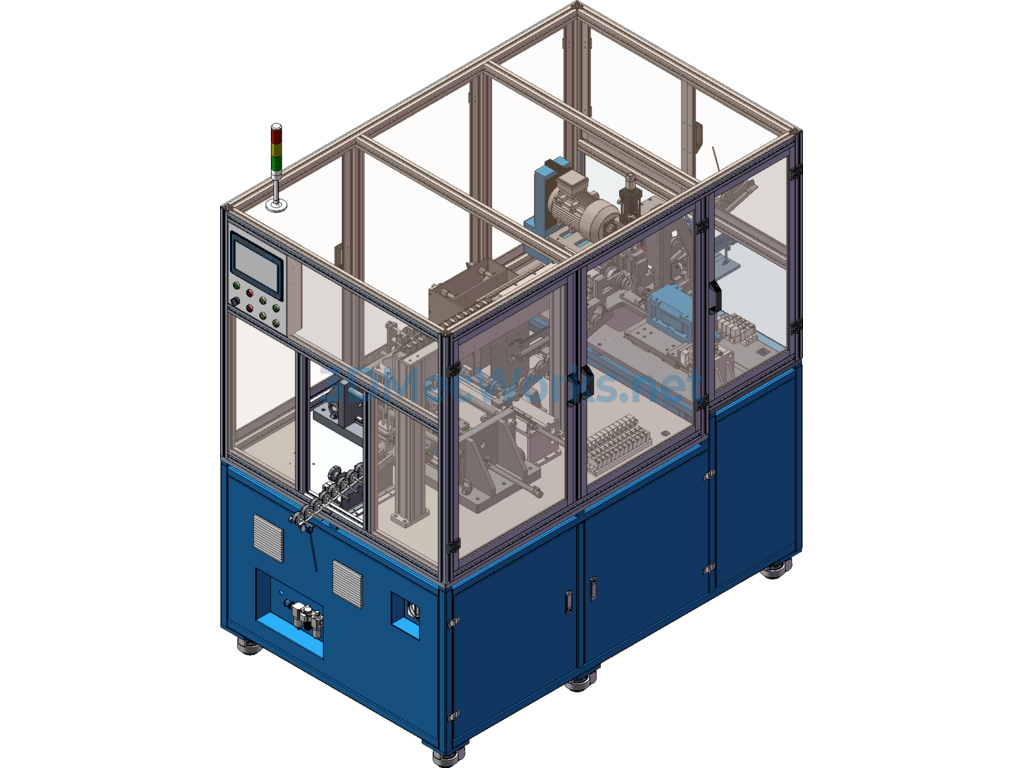

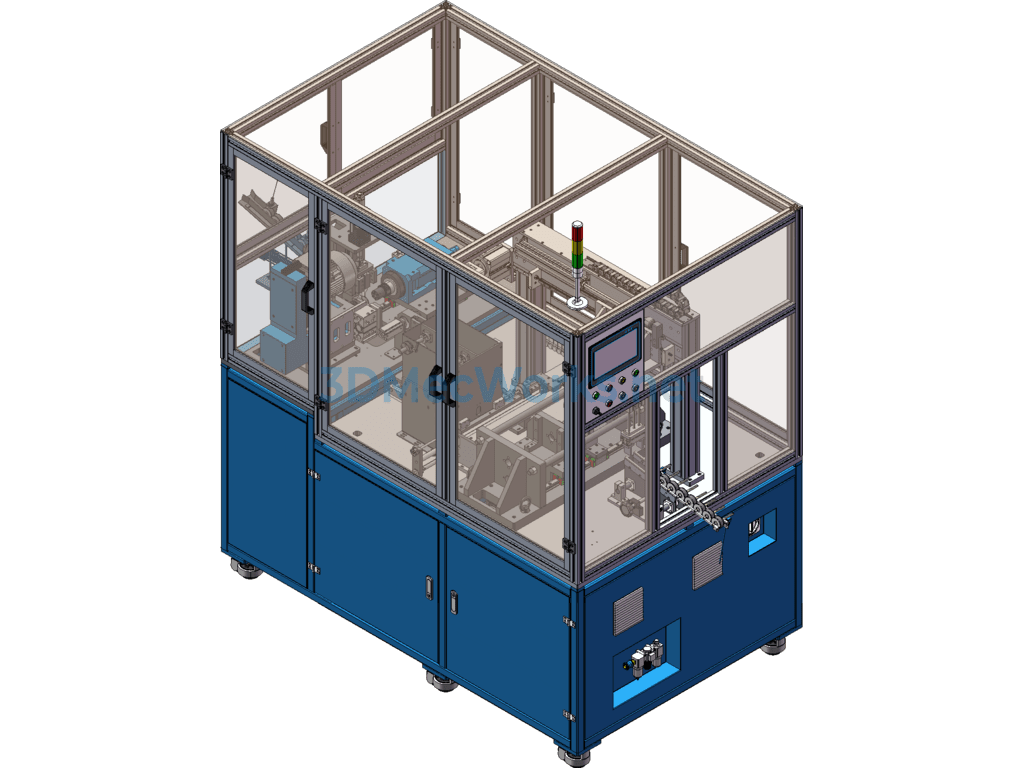

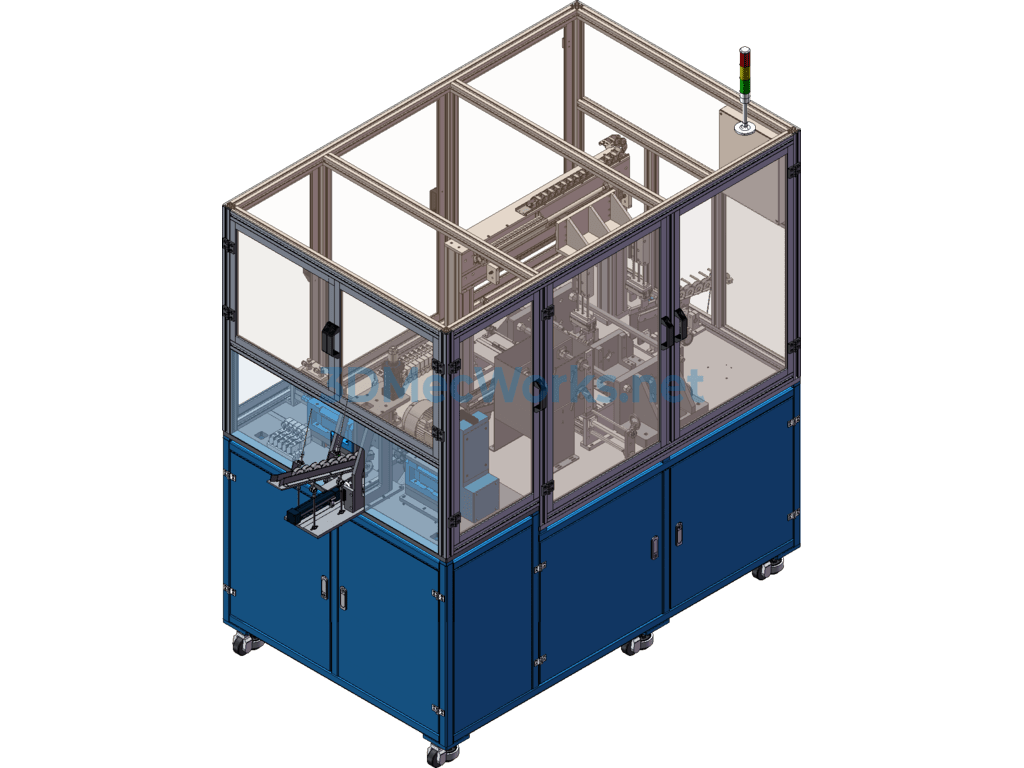

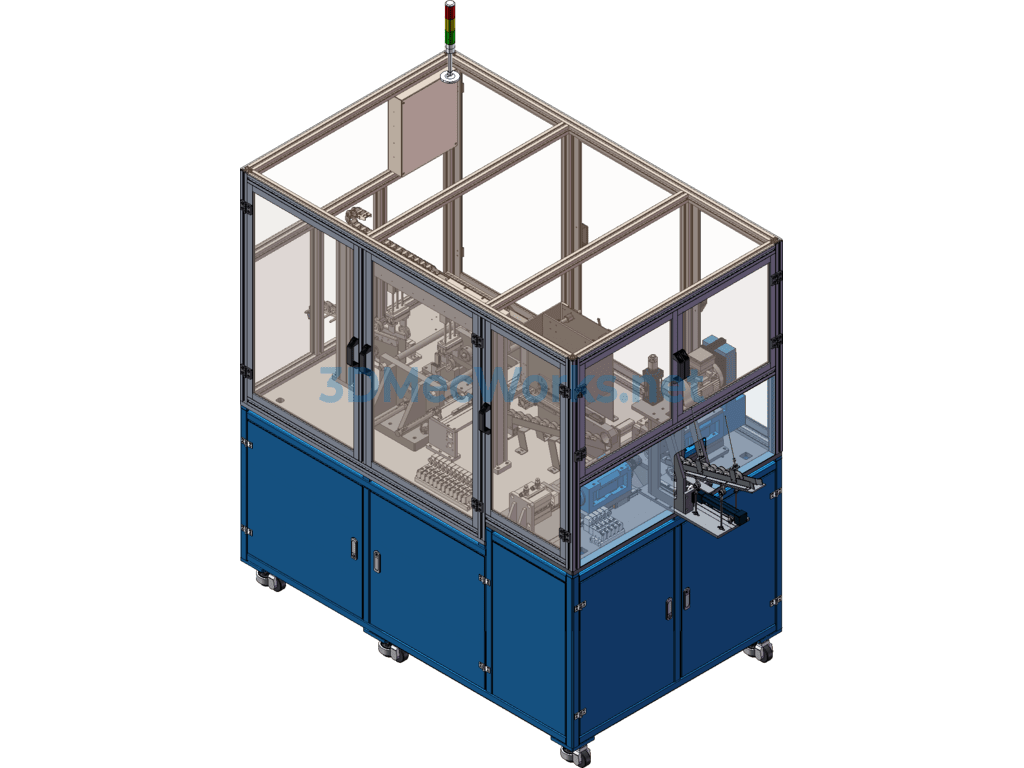

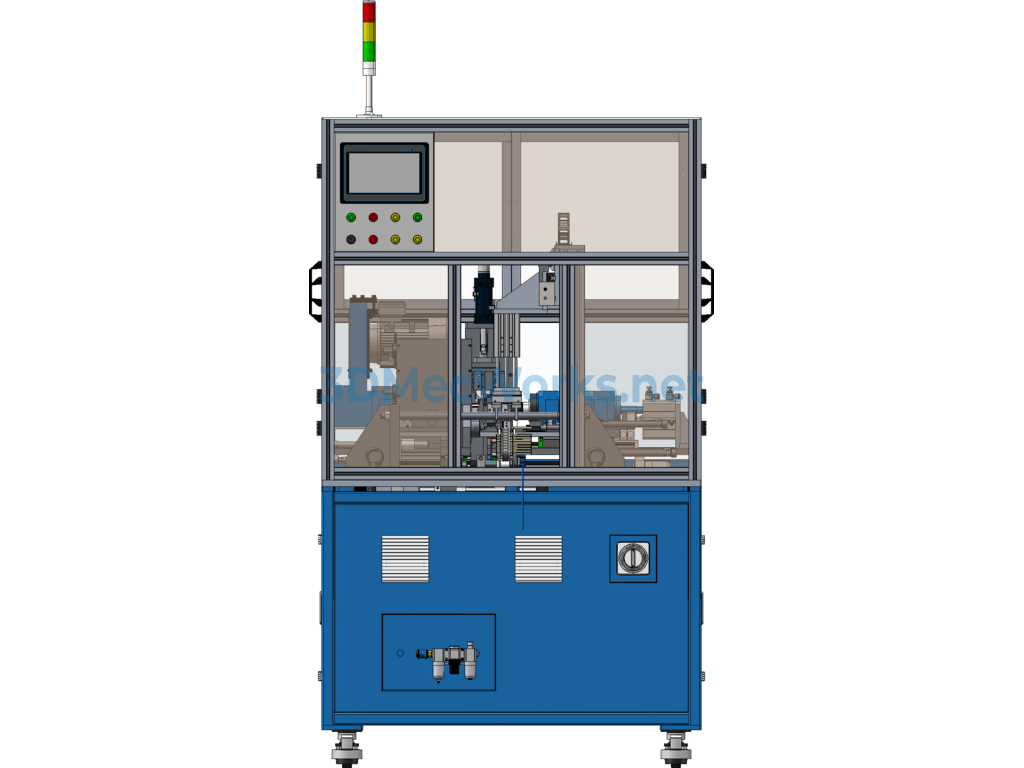

This equipment is used for rotor assembly production in the micro motor industry, primarily utilizing squirrel cage rotors of the 8042 series specifications. The entire machine extensively uses servo mechanisms. Equipment features include a chamfering mechanism to remove burrs and other debris produced during the die-casting of squirrel cage rotors, utilizing a power head mechanism. The rotor shaft storage mechanism has a large storage capacity, using a horizontal mechanism for shaft insertion. After the rotor is positioned with a pre-inserted shaft, the rotor shaft is then inserted into the rotor shaft hole. The transfer mechanism uses linear synchronous transfer and employs a pneumatic structure. The riveting section uses a 5-ton equivalent servo electric cylinder for riveting. The entire machine’s cycle time is controlled within 5 seconds, and the riveting depth and pressure are monitored in real-time through a pressure curve, with records saved.

Specification: Squirrel Cage Rotor Chamfering and Shaft Insertion Integrated Machine, Micro Motor Rotor Assembly

|

User Reviews

Be the first to review “Squirrel Cage Rotor Chamfering and Shaft Insertion Integrated Machine, Micro Motor Rotor Assembly”

You must be logged in to post a review.

There are no reviews yet.