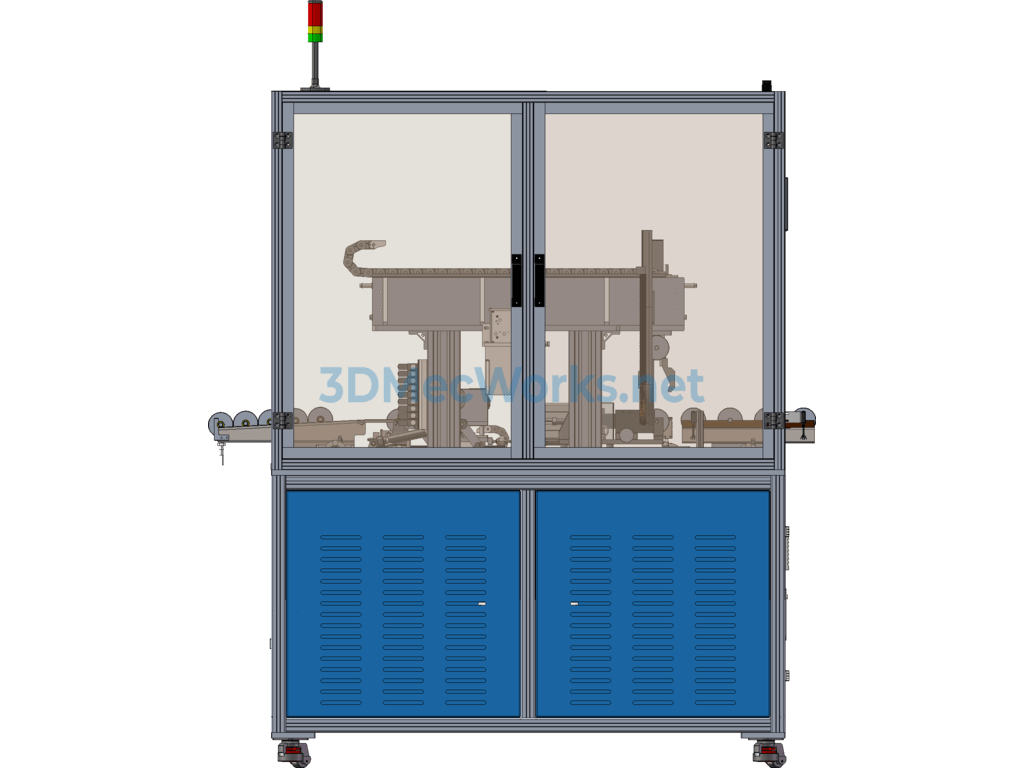

The rotor snap ring oiling integrated machine is used by squirrel-cage rotor manufacturers for rotor processing, with the main functions of assembling the rotor bearing position snap ring and applying anti-rust oil (light gold water) to the squirrel-cage rotor. The rotor is fed into the snap ring fixture by a feeding mechanism, and after the rotor bearing position snap ring is assembled in place, the pneumatic transfer mechanism sends the rotor to the anti-rust oil application station. At this point, the oiling roller is moved to the rotating shaft via the transfer mechanism to drive the rotor to rotate and apply oil. Upon completion, the connecting rod transfer mechanism sends the rotor to the unloading slide.

Specification: Snap Ring Assembly and Anti-Rust Oil Application Integrated Machine

|

User Reviews

Be the first to review “Snap Ring Assembly and Anti-Rust Oil Application Integrated Machine”

You must be logged in to post a review.

There are no reviews yet.