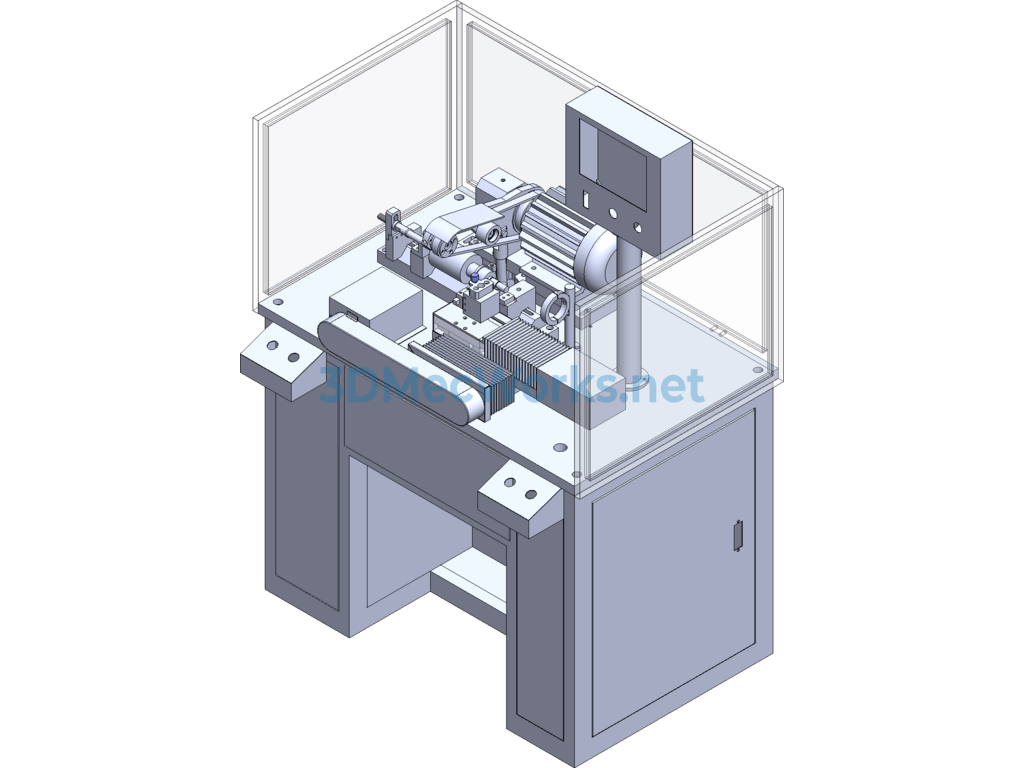

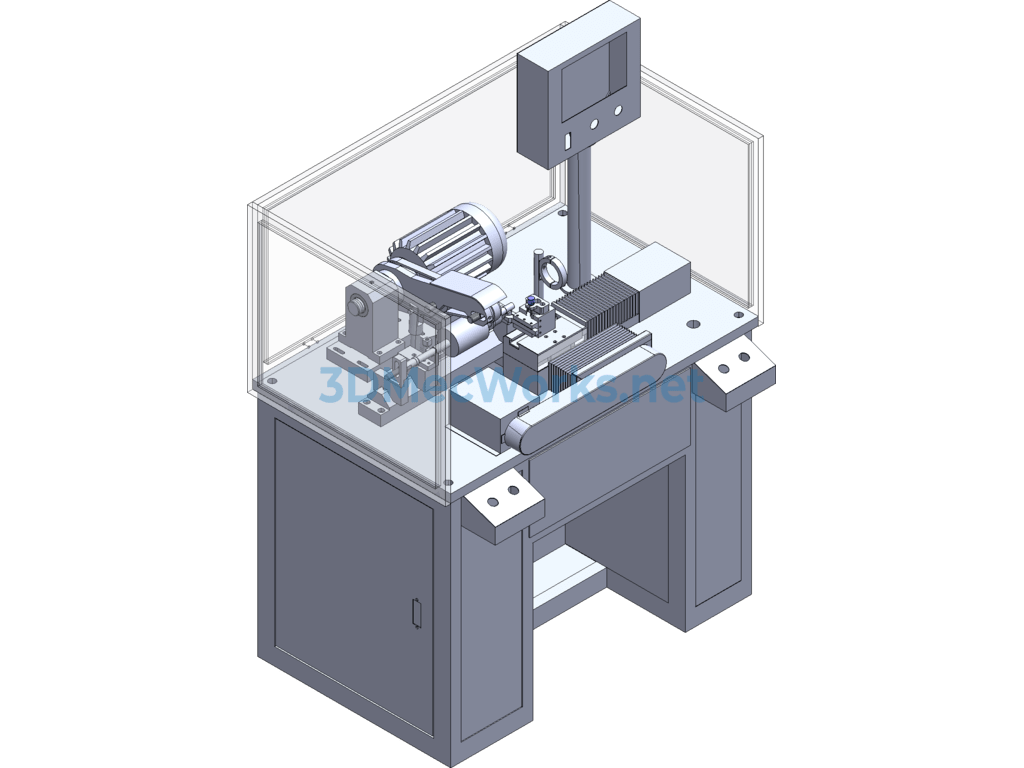

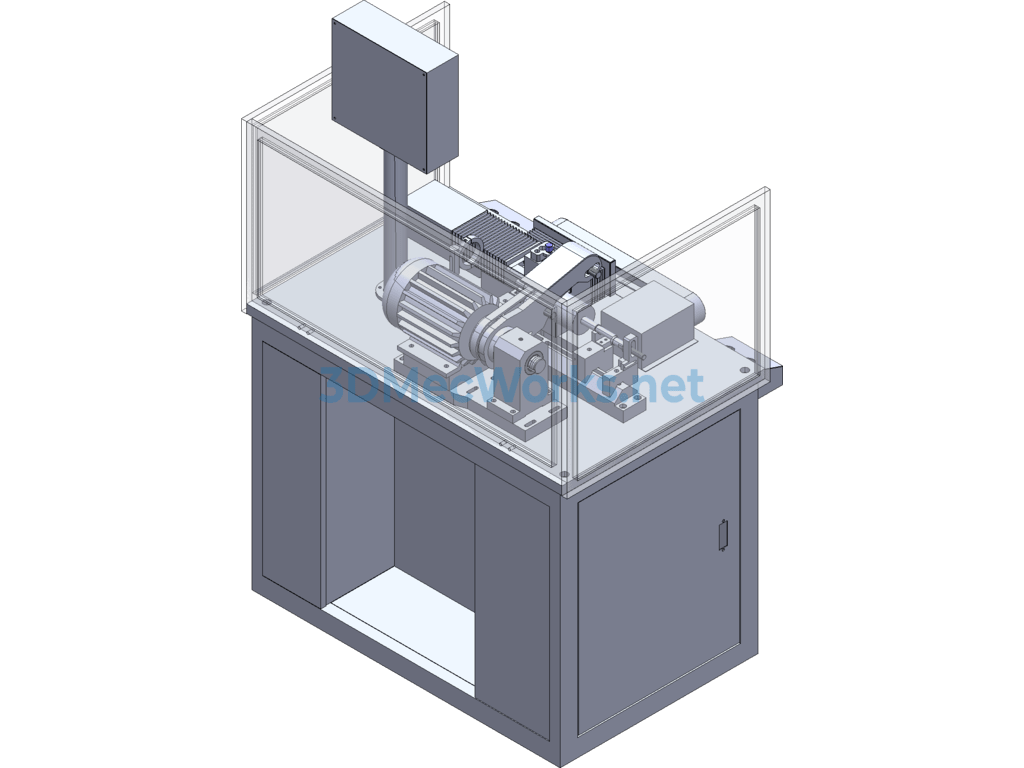

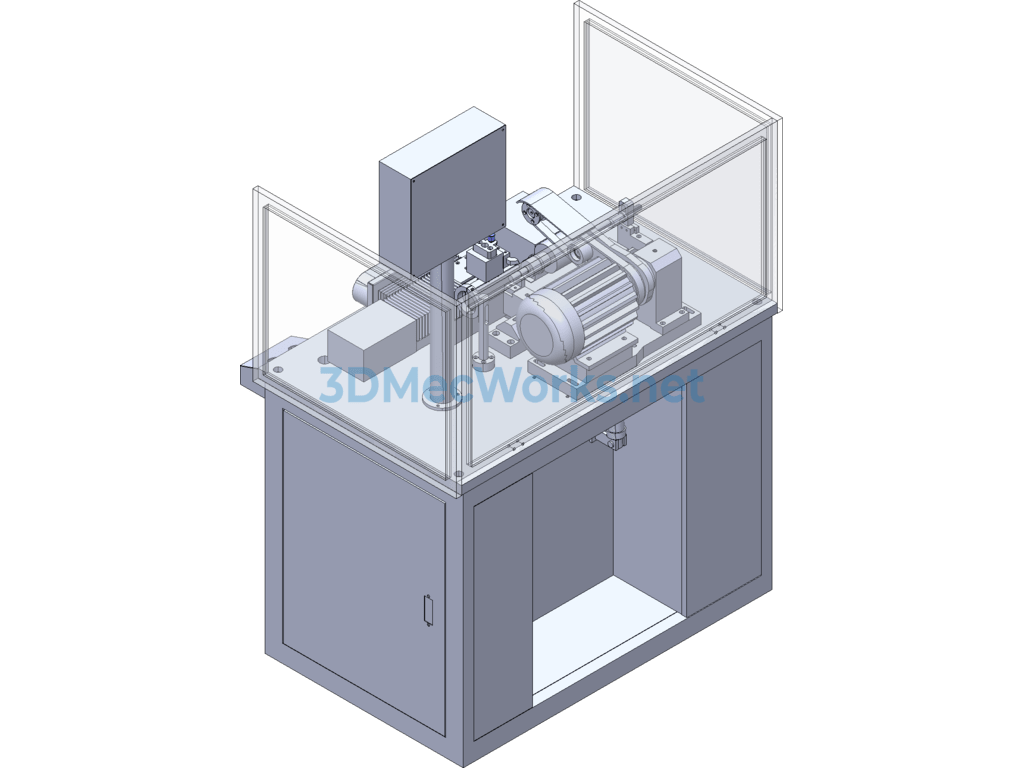

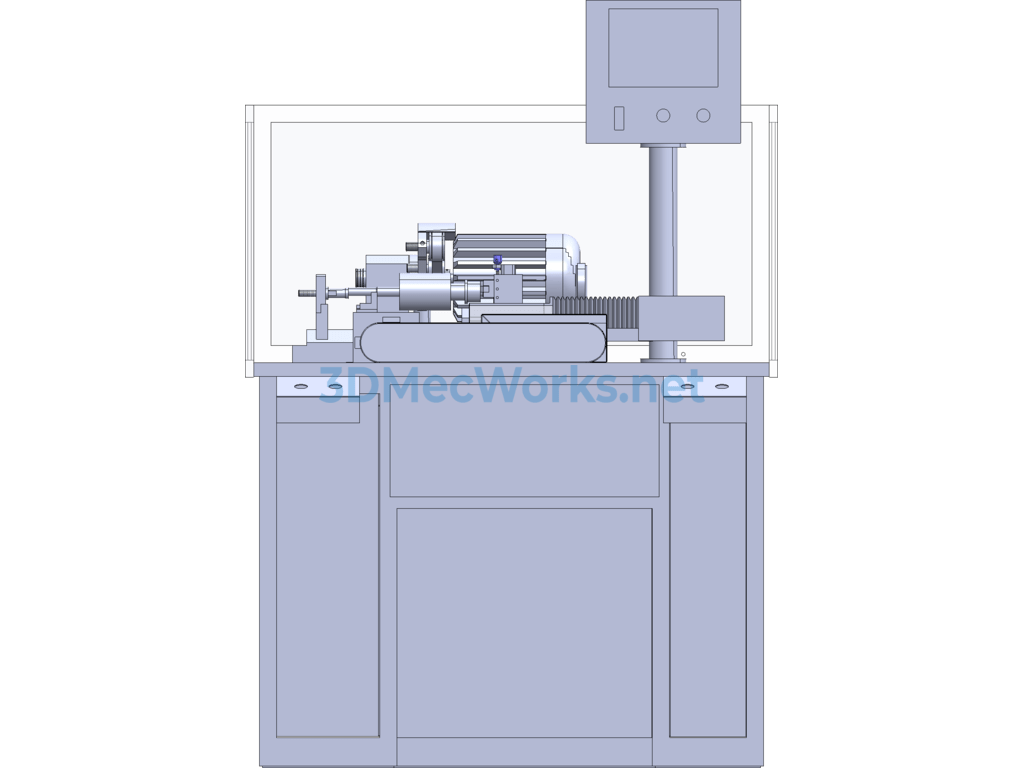

I. Performance and Features:

1. This machine is suitable for precise turning of the outer circle of commutators or rotor cores.

2. X and Y axes use imported brand (THK) precision ball screw guide rail transmission.

3. Durable grinding-grade diamond V-shaped frame with stable accuracy.

4. Equipped with Japanese PLC for program control and a touch screen, providing high system reliability.

5. X and Y axes are equipped with a Japanese servo system, ensuring stable turning accuracy and quality, and allowing for multiple cutting passes.

6. Optional chip removal and dust collection devices available.

II. Technical Parameters:

1. Turning part: Outer circle of rotor commutator;

2. Rotor core diameter: ≤Φ80mm;

3. Rotor shaft length: ≤270mm;

4. Rotor shaft diameter: Φ1.5~Φ15mm;

5. Commutator outer diameter: Φ4~Φ40mm;

6. Maximum machining length: ≤25mm;

7. Radial runout of processed commutator: ≤0.005mm;

8. Axial runout of processed commutator: ≤0.005mm;

9. Production efficiency: 10 seconds/piece (2 turning passes);

10. Input power: 3KW;

11. Air source pressure: 0.5~0.8MPa;

12. Machine dimensions: 900x700x1480mm;

13. Weight: 350kg;

14. Special customization available

Specification: Single-Blade Dual-Servo Precision Lathe Type Ⅰ 3d + Engineering Drawing

|

User Reviews

Be the first to review “Single-Blade Dual-Servo Precision Lathe Type Ⅰ 3d + Engineering Drawing”

You must be logged in to post a review.

There are no reviews yet.