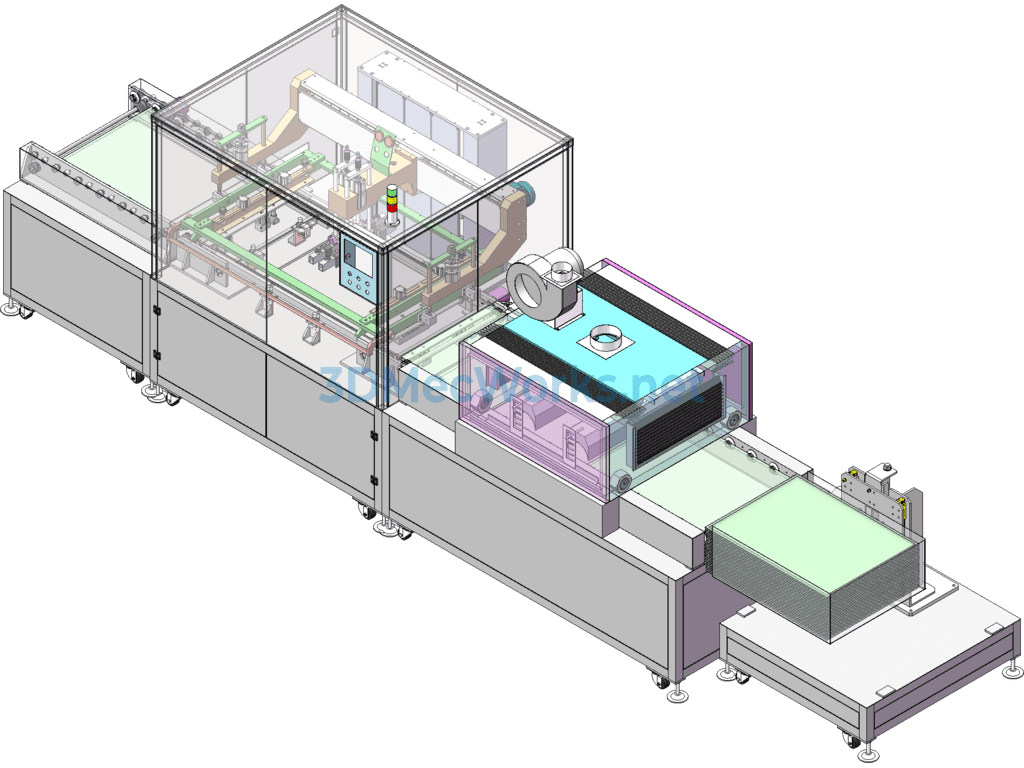

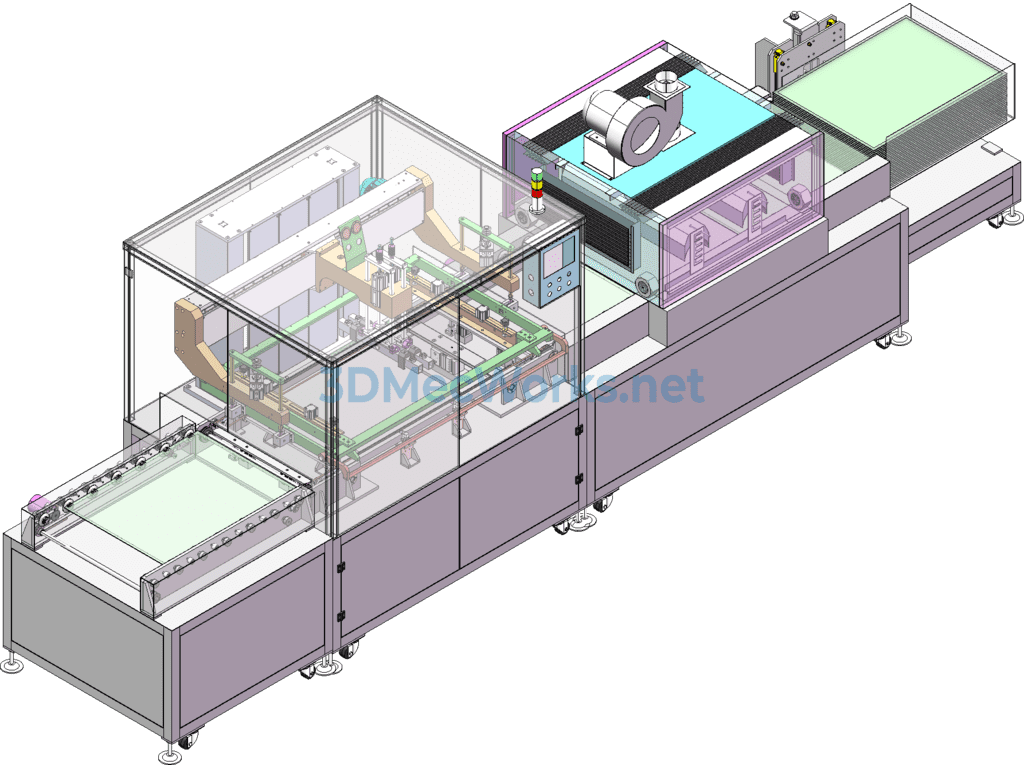

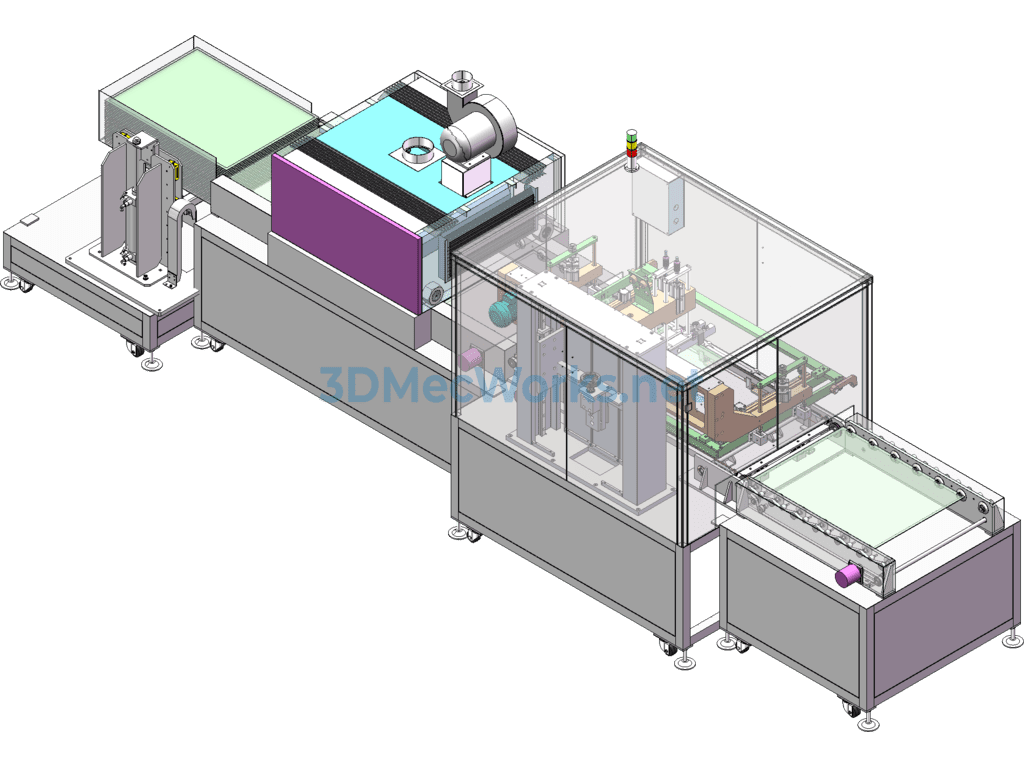

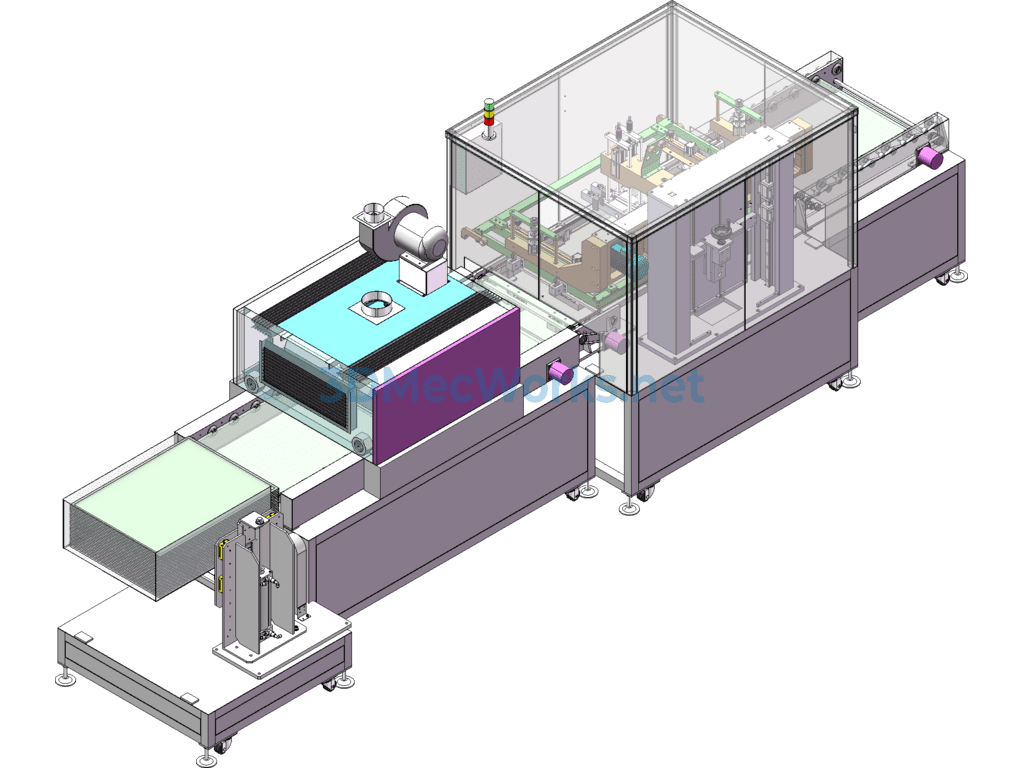

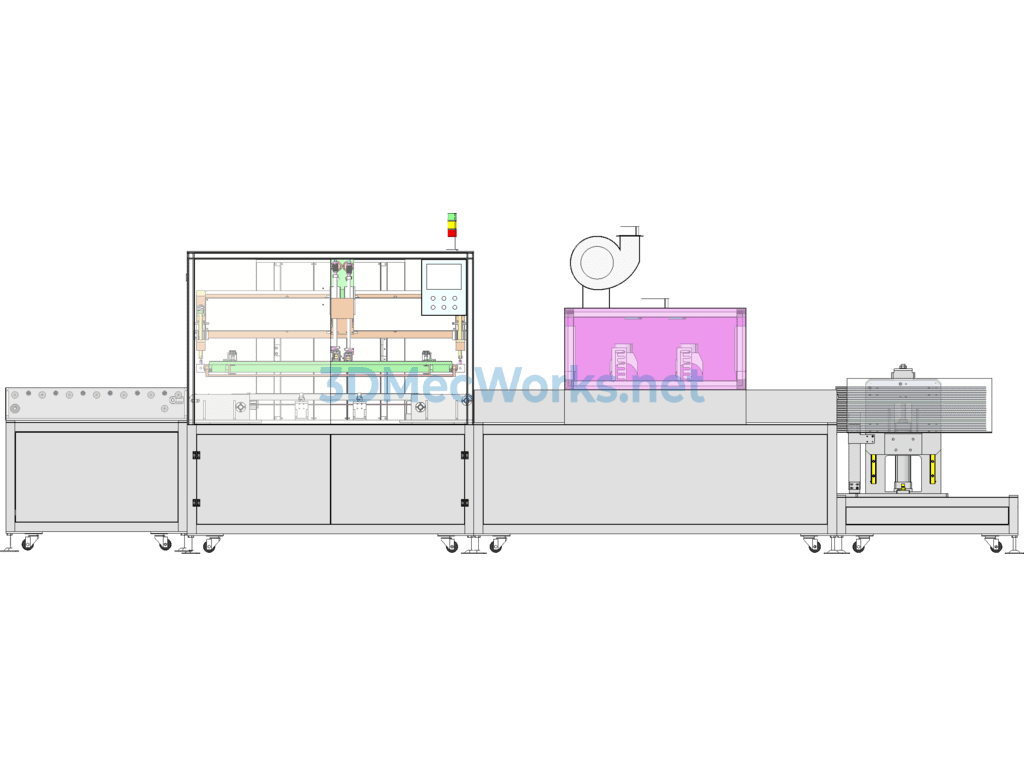

The main features of the fully automatic screen printing machine equipment include a 360° stop and rotating drum, ultra-high printing precision; LCD human-machine interface; 4-9mm adjustable network (distance between the screen and drum); pull-out screen frame for easier paper feeding status inspection and screen cleaning; centralized lubrication oiler controlled by PLC in the automatic screen printing machine ensures lubrication of the transmission parts, reducing damage to critical components and extending service life; the entire printing process is monitored by photoelectric sensors for empty sheets and skewed sheets, effectively reducing the scrap rate. Process flow: raw materials — automatic feeding (double-sided dust removal, protective film stripping, static elimination) — automatic printing (with positioning hole punching, inspection light) — automatic baking and rolling (automatic glazing, protective film, tape, release paper, etc.) — subsequent processes can achieve automatic die-cutting — finished product. Fully automatic operation requires only 1-2 people, and a complete set of fully automatic equipment requires only 15-20 square meters.

Specification: Silk Screen Printing Machine, Optimized Version

|

User Reviews

Be the first to review “Silk Screen Printing Machine, Optimized Version”

You must be logged in to post a review.

There are no reviews yet.