Davis Tanner

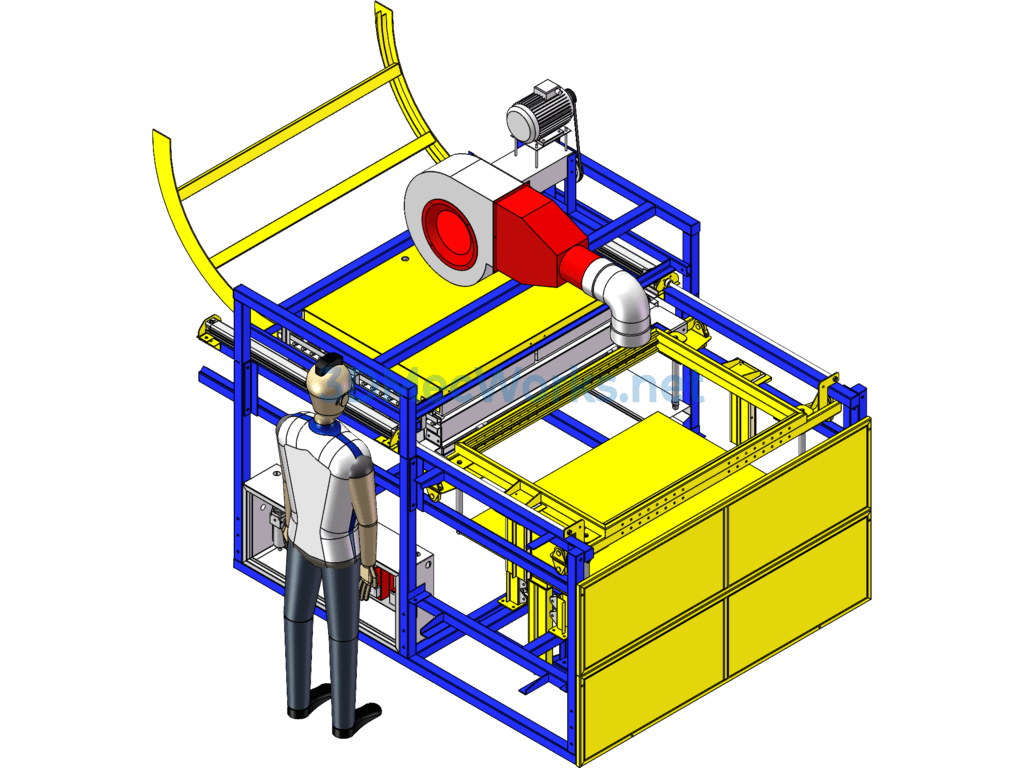

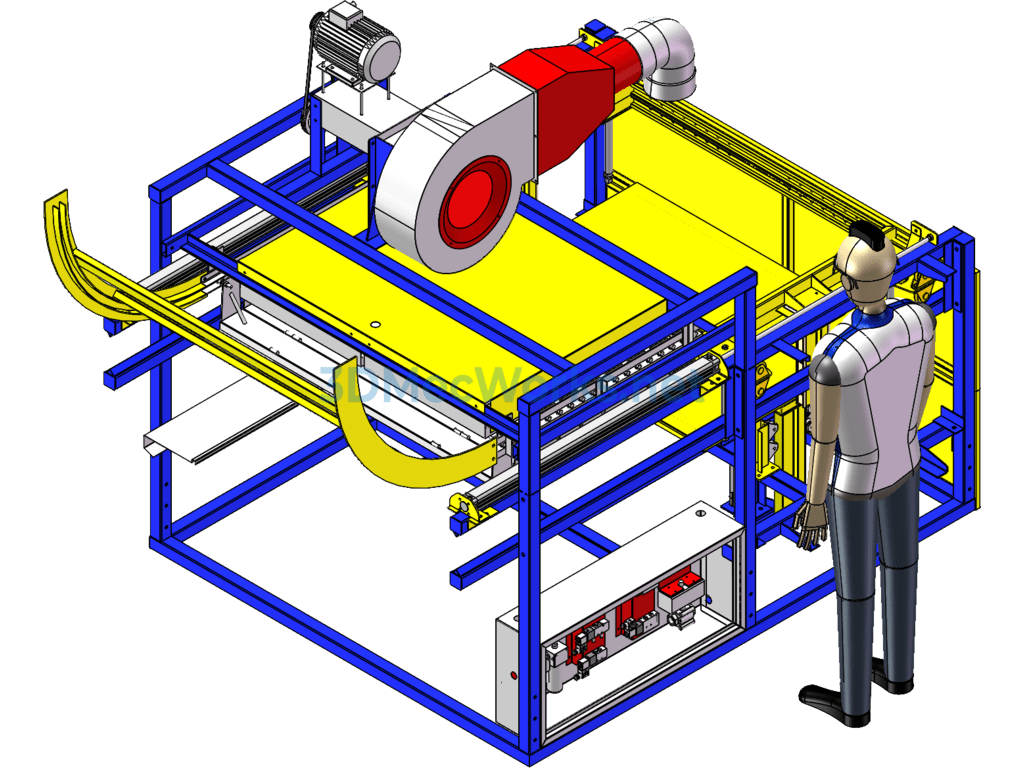

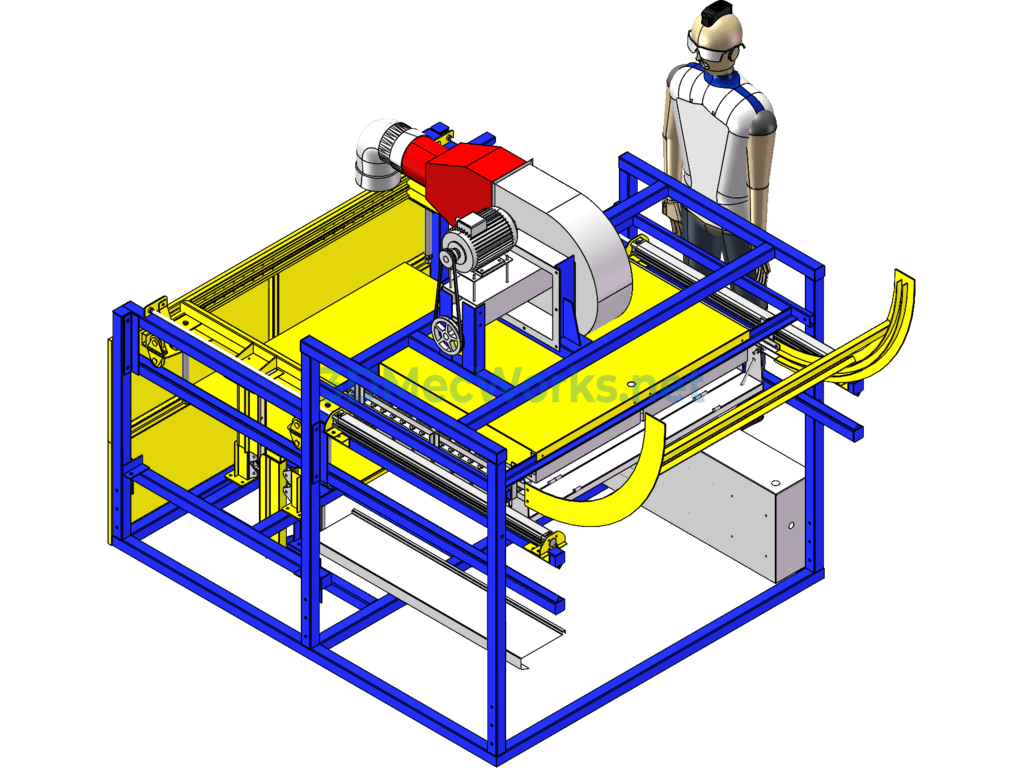

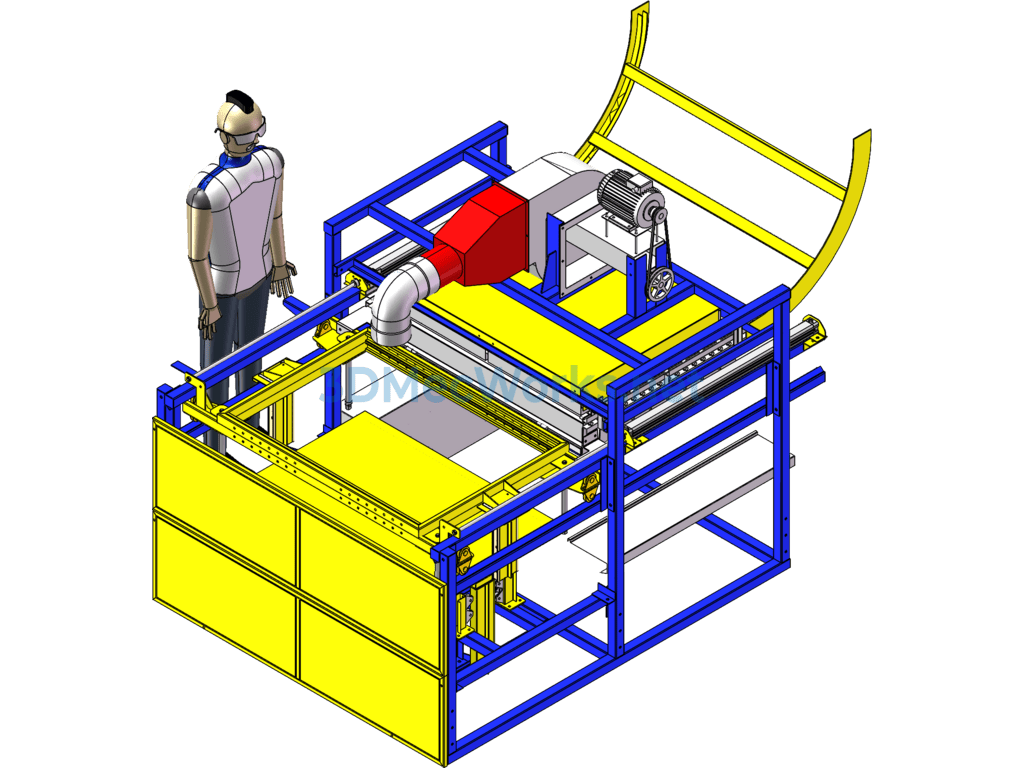

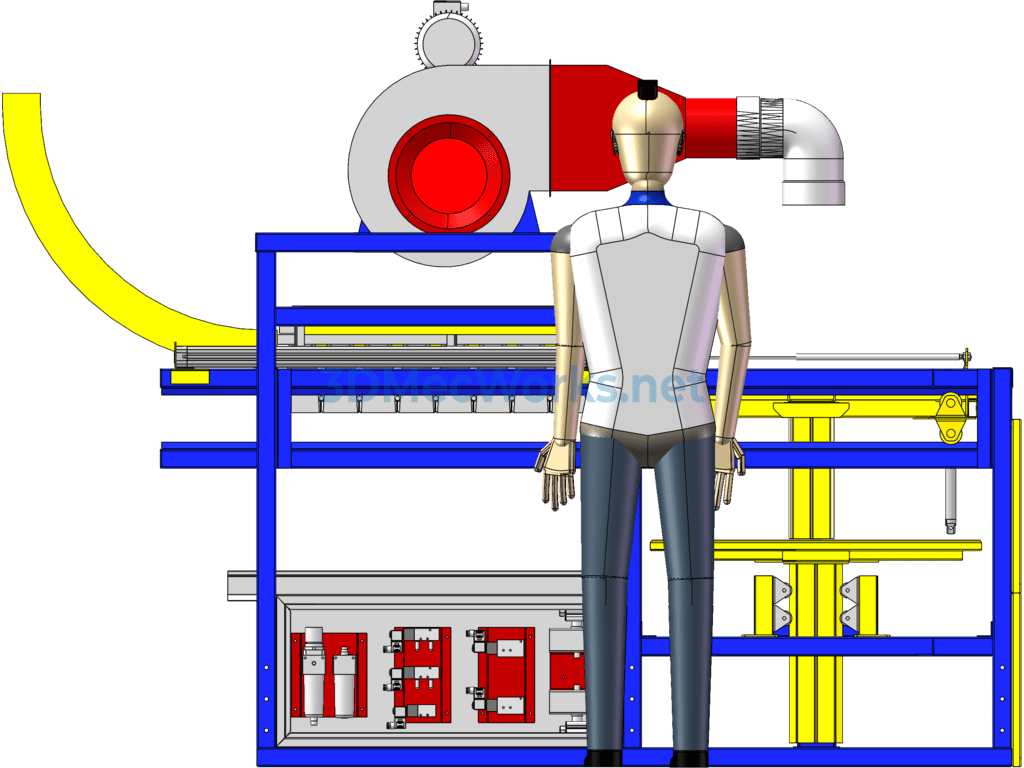

3D Model of Sheet Metal Forming Machine

Designed in Solidworks 2014, includes .sldasm and .sldprt source files. Welcome to download.

The sheet metal forming machine consists of a head unit, a tool carriage, a tailstock cone rack, a bed, and a transmission mechanism. Its main features include:

– The head unit has two spindles equipped with detachable bead rollers.

– The tool carriage and tailstock cone rack are each mounted on independent work track platforms.

– The tailstock cone rack includes a horizontal platform, while the head of the tailstock cone is equipped with detachable composite molds.

– The horizontal frame at the lower end of the tailstock cone rack features mechanisms for bending, seaming, and plane bead pressing.

– The vertical lifting mechanisms are designed on both the head unit rack and the tailstock cone rack.

– The head unit also incorporates an elastic displacement mechanism for the upper spindle.

As a result, this machine can replace multiple pieces of equipment used in sheet metal forming, allowing for the completion of multiple sheet metal forming processes on one machine. It is a flexible tool ideal for sheet metal forming.

The sheet metal forming machine equipment (actual production equipment) is a mature model utilized in real-world production environments. It is primarily suitable for processing self-made sheet metal parts, and while the mechanical structure design is relatively complex, this model is drawn very clearly. Welcome to download and learn.

Specification: Sheet Metal Forming Machine

|

User Reviews

Be the first to review “Sheet Metal Forming Machine” Cancel reply

You must be logged in to post a review.

There are no reviews yet.