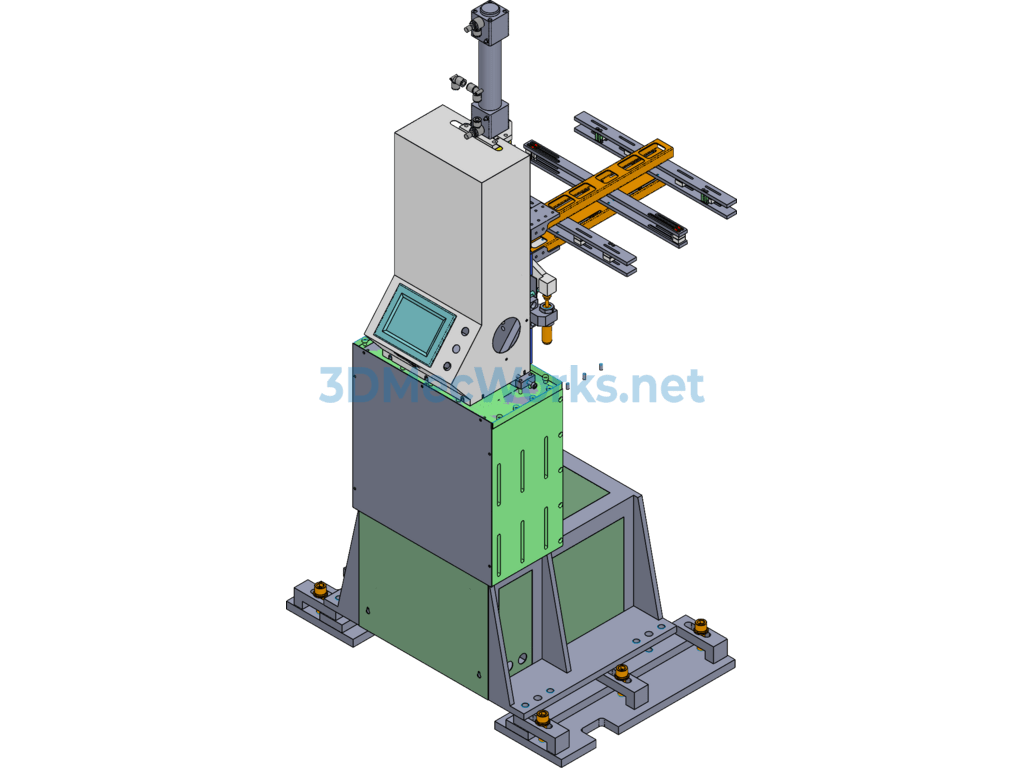

Separated Press Manipulator with 180-Degree Rotating Table 3D Model, ProE software design source files provided. Includes separated manipulator electrical diagram (.dwg), usage adjustment manual (.pdf), engineering drawings, and the BOM for purchased components. In short, a comprehensive set of materials for a horizontal transfer manipulator used in a press shop. Welcome to download.

This is a press manipulator with a rotating table, which flips the sheet metal 180 degrees and opens at the required station, waiting for the manipulator to pick up the material. The manipulator arm uses a speed-doubling mechanism composed of gear racks, and the Z-axis uses a servo motor paired with two balancing cylinders, with continuous air supply to the cylinders. This significantly reduces the load on the Z-axis motor. A special pressure-regulating valve is fitted to adjust the pressure so that the Z-axis can be easily turned by hand. The suction cups use a cushioning type, and the two arms require independent air route control. Designed with ProE, it has already been mass-produced in multiple units. If the flipping function is not needed, the position of the flipping table can be disabled at any time, and if multiple units form a punching line, the table may also not require a flipping function at that station, but an intermediary table is needed.

User Reviews

Be the first to review “Separated Stamping Robot With a 180-Degree Rotating Table”

You must be logged in to post a review.

There are no reviews yet.