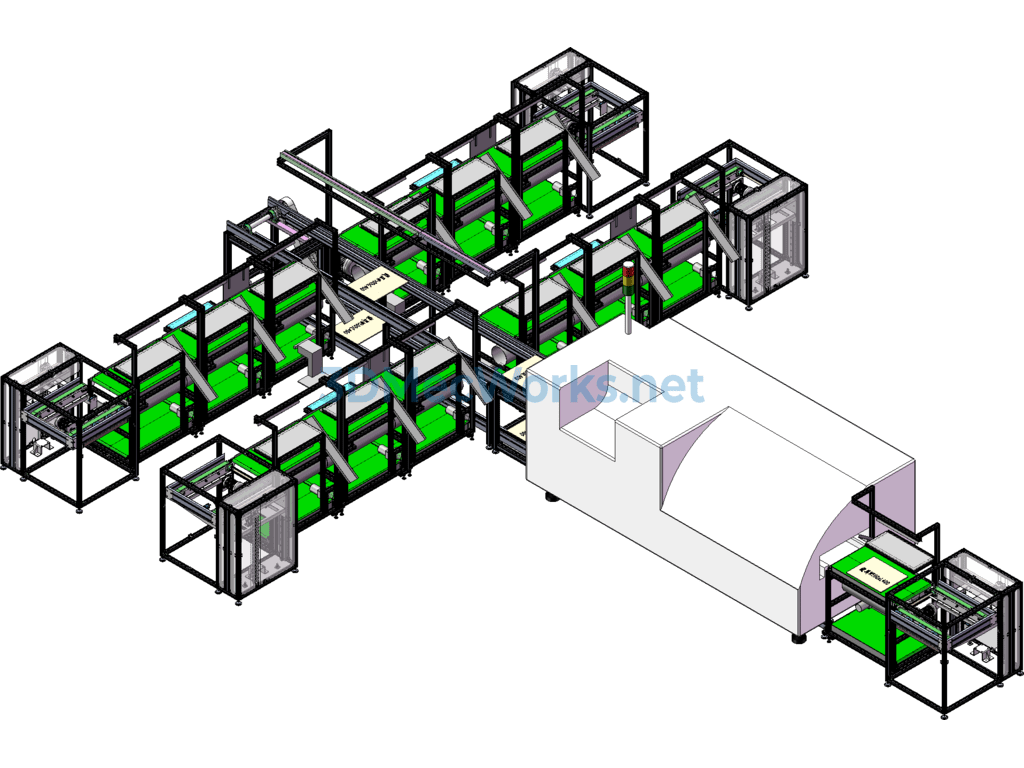

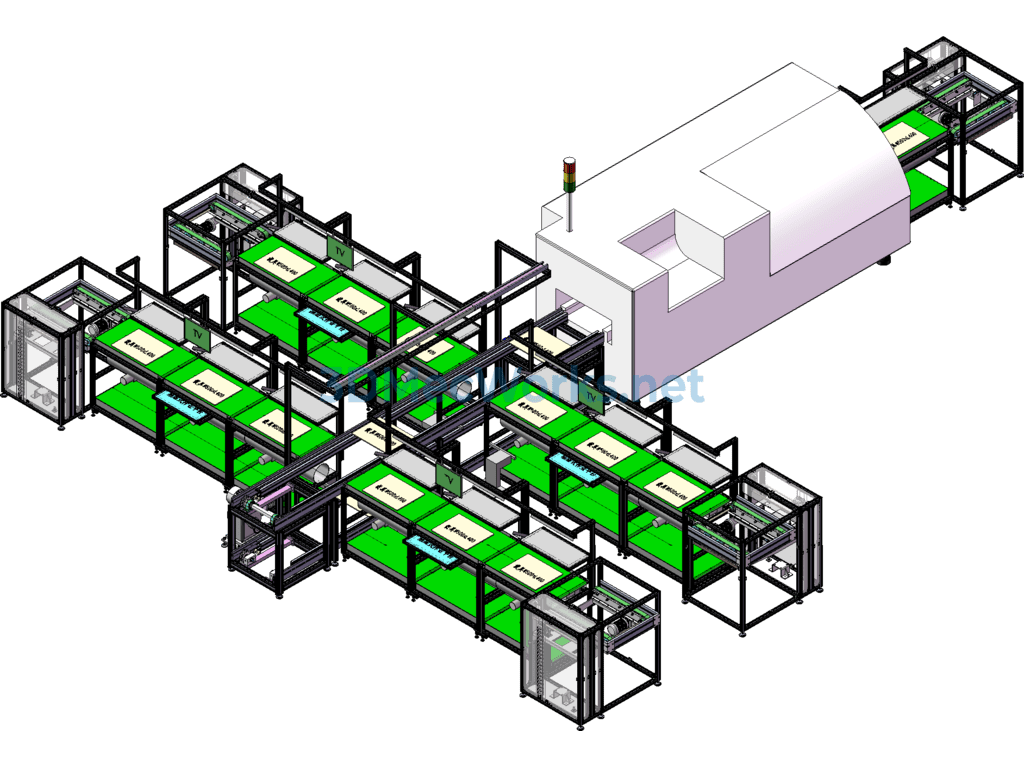

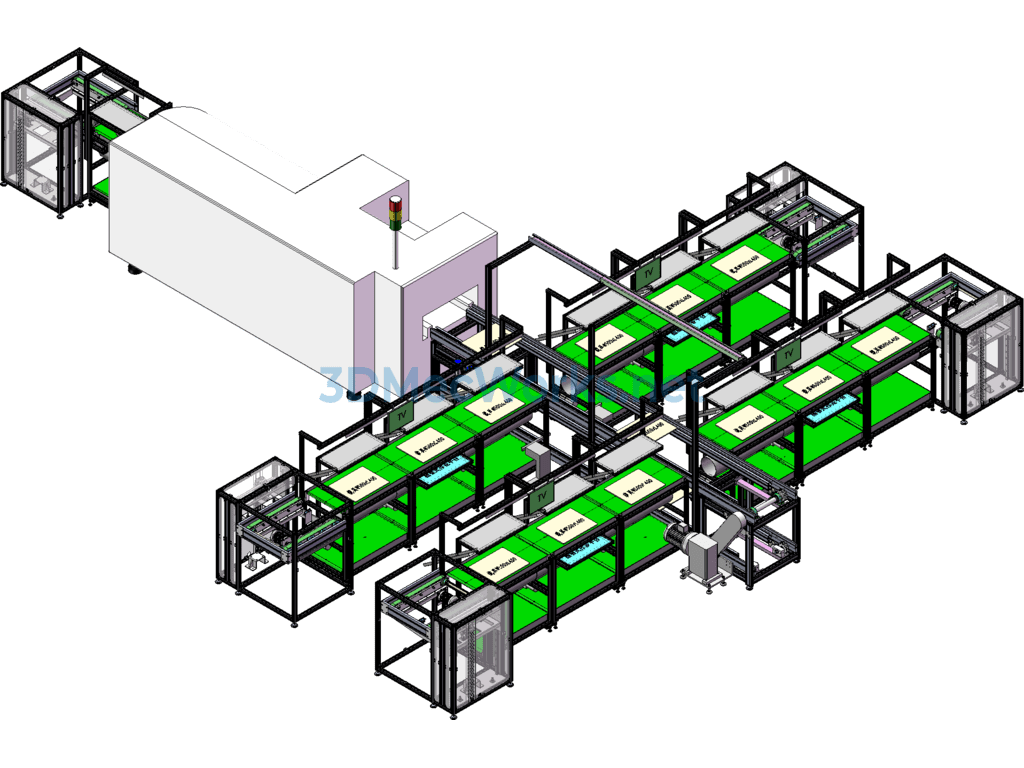

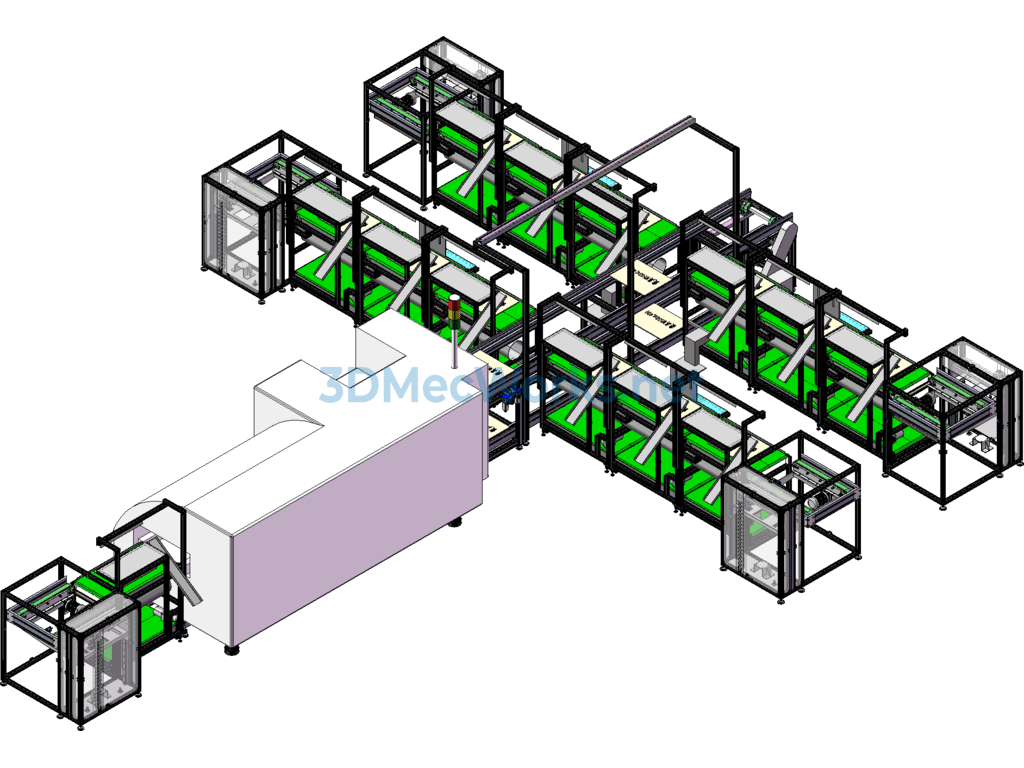

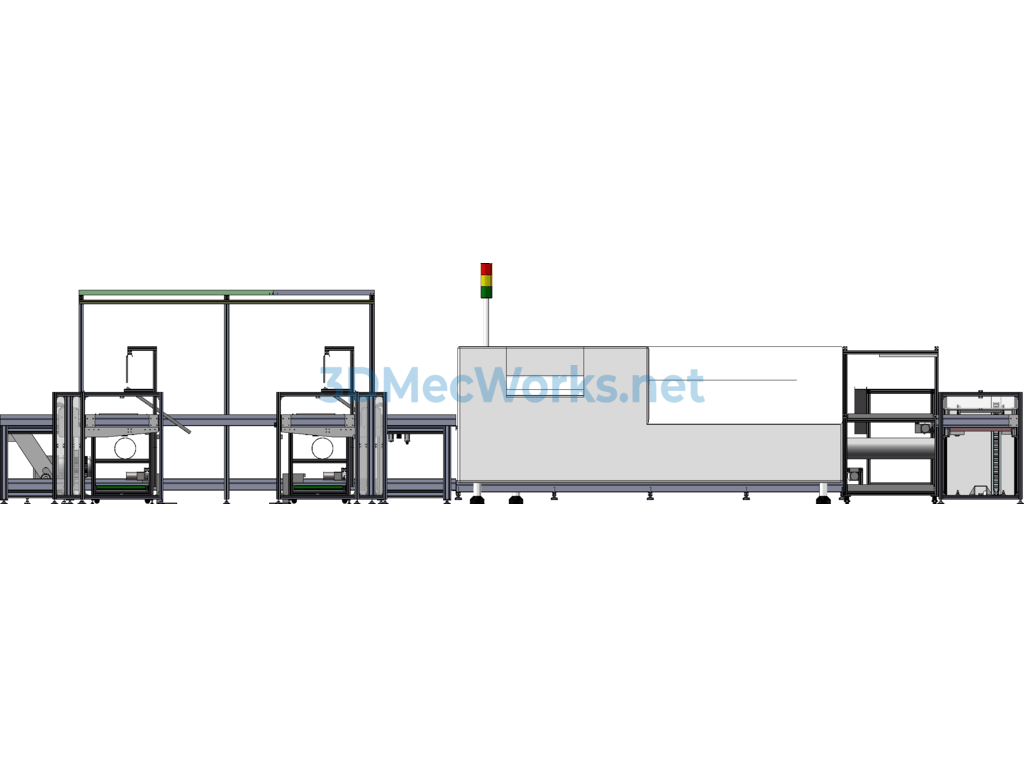

Plug-in Welding Production Line

1. Adopts wave soldering method, allowing multiple different types of PCBs to pass through the oven simultaneously.

2. Uses an upper and lower board-moving style.

3. After product welding, fixtures automatically return to their corresponding positions based on barcode types.

4. No moving action after plug-in completion, adopting a 90-degree angle between plug-in direction and pass-through direction.

5. Modular production line, allowing each branch line to combine freely when space is not limited.

6. Operation foot position has a protective cover to prevent fixture damage.

7. Double-layer design for plug-in material racks with recyclable plug-in material boxes.

8. Overall lampshade-style lighting is used.

9. Added exhaust piping integrated into the line, using splicable piping.

10. One workstation in each plug-in line includes a hideable work surface, allowing for dual plug-in/soldering functions.

11. Each plug-in workstation has a monitor displaying instruction cards.

Specification: Selective Soldering Production Line

|

User Reviews

Be the first to review “Selective Soldering Production Line”

You must be logged in to post a review.

There are no reviews yet.