This equipment achieves energy-saving effects through the secondary circulation of heat transfer oil for heating. This equipment is characterized by a high heat transfer coefficient, good performance, compact design, small volume, and minimal installation space requirements. According to the specific working conditions of the equipment, by adjusting the heat exchange area between the hot and cold media, the temperature distribution on the surface of the heat transfer elements can be altered, successfully avoiding low-temperature acid dew point corrosion. The minimum temperature difference required for heat transfer between media is small, allowing for the recovery of residual heat at low temperatures.

The heat pipe is fixed at a single point on the steam drum and freely suspended in the flue gas channel, allowing it to expand and contract with heat and cold without restriction, thereby avoiding stress damage and ensuring a long service life.

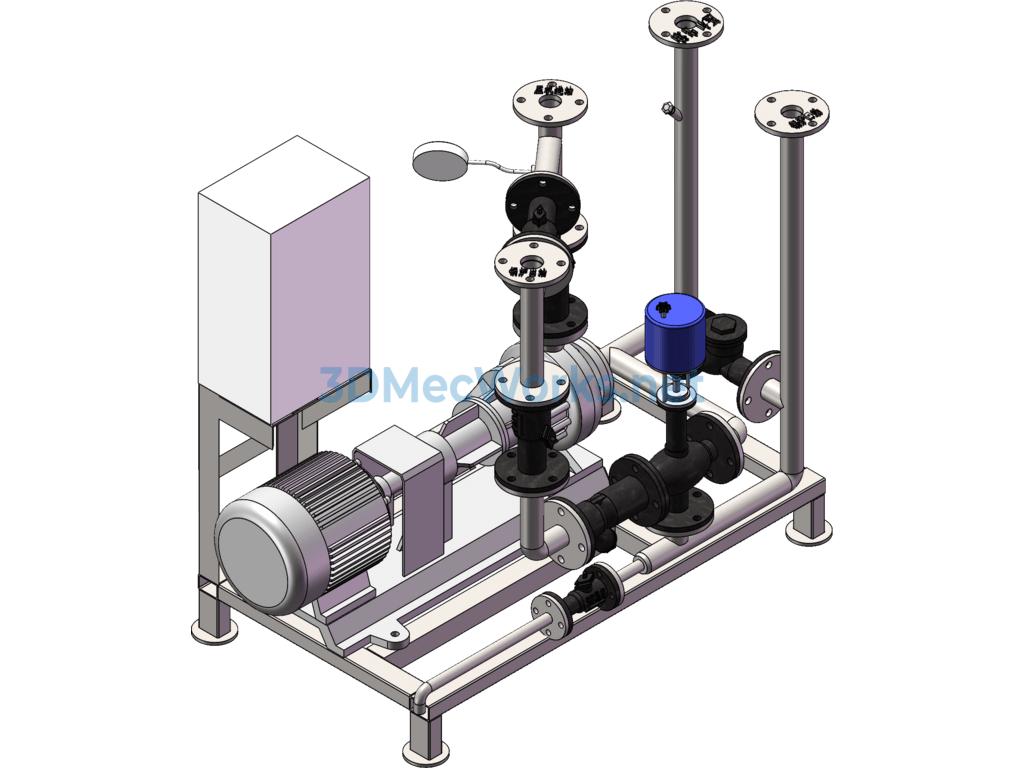

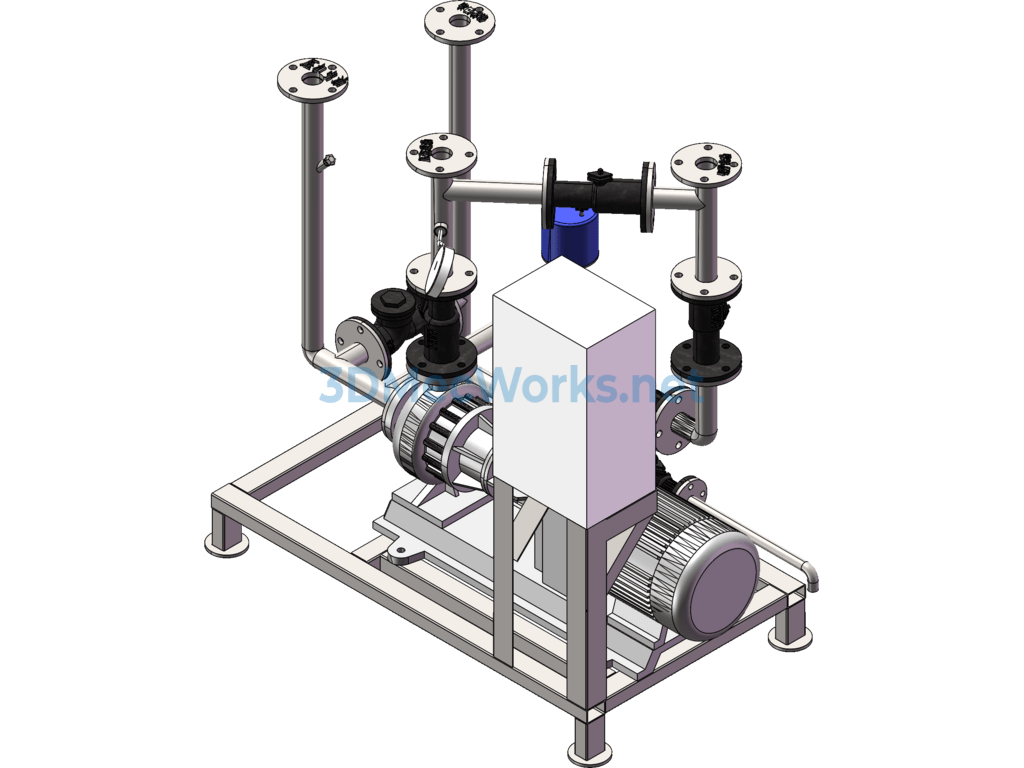

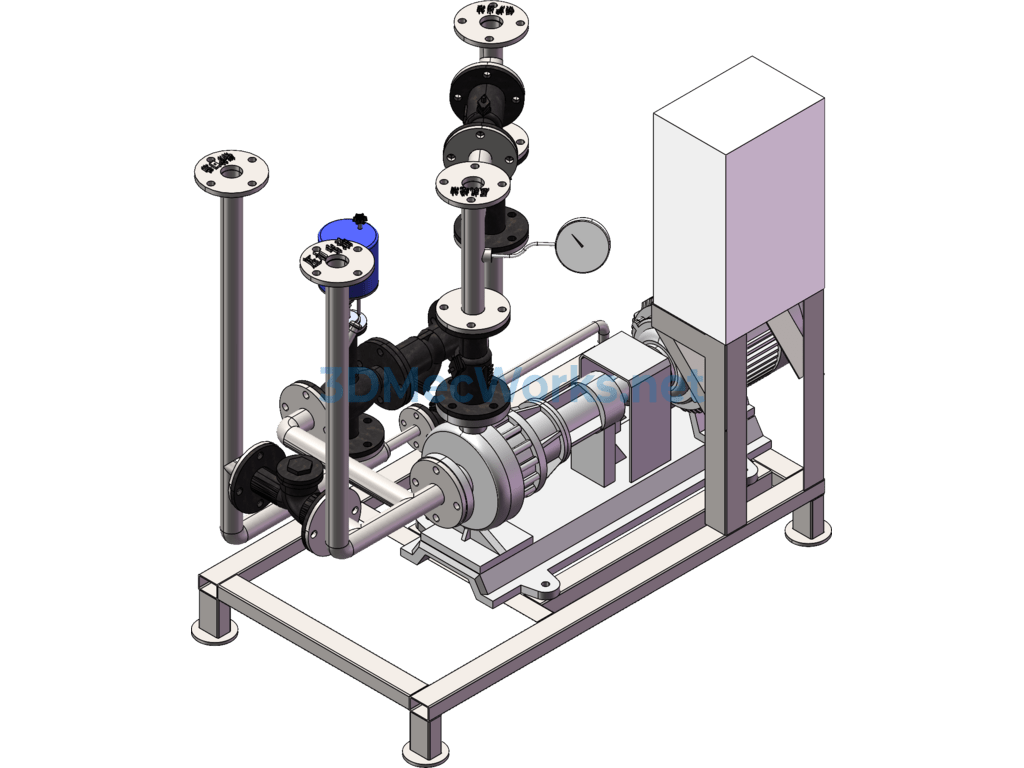

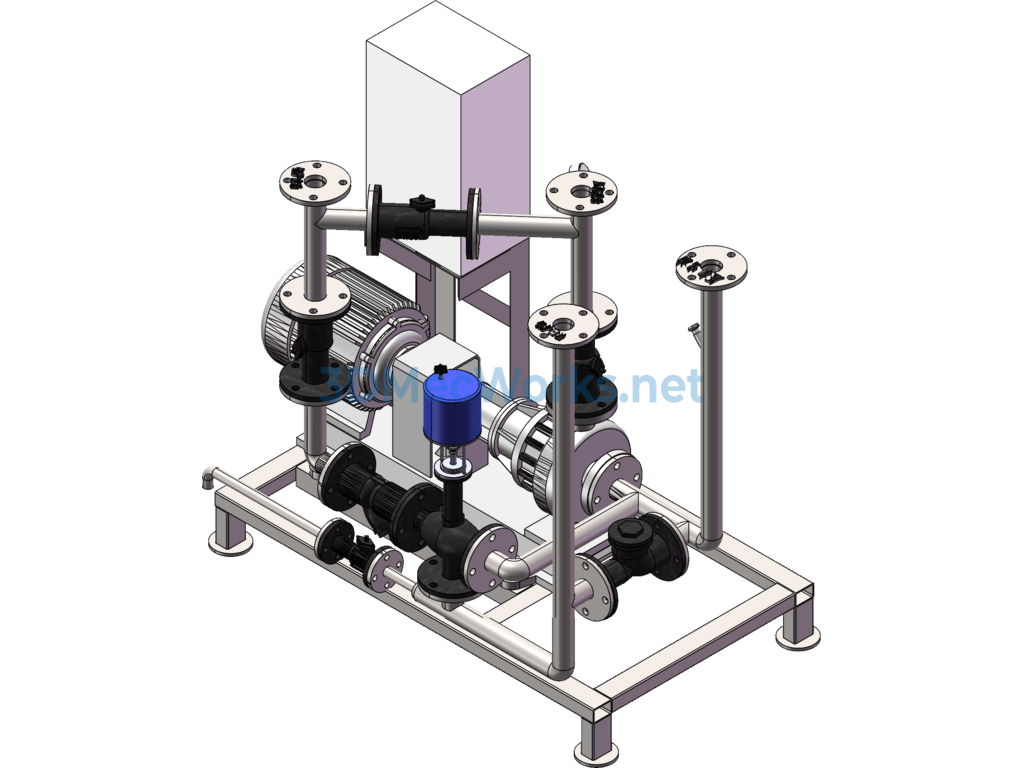

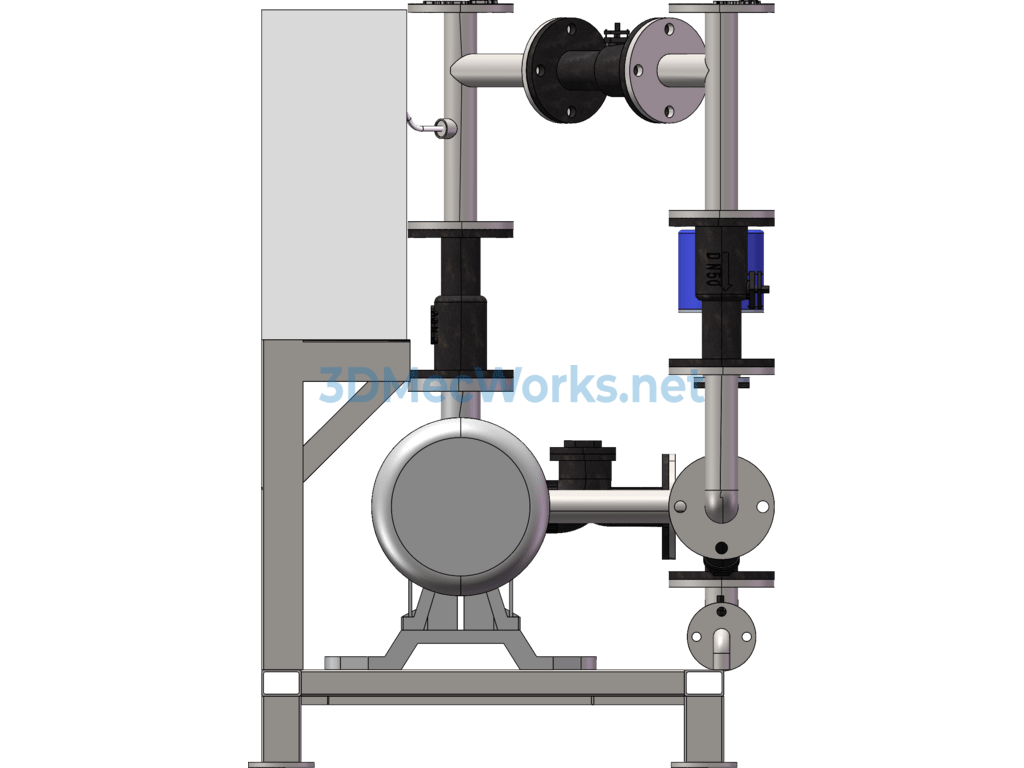

Specification: Secondary Circulation System of Heat Transfer Oil

|

User Reviews

Be the first to review “Secondary Circulation System of Heat Transfer Oil”

You must be logged in to post a review.

There are no reviews yet.