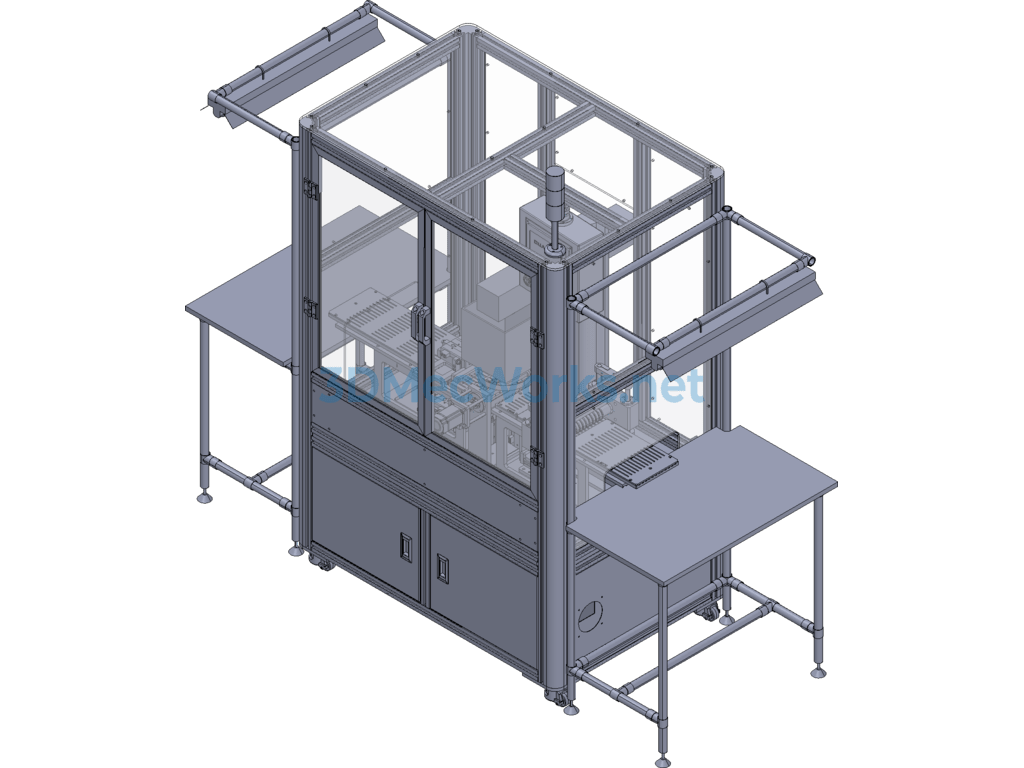

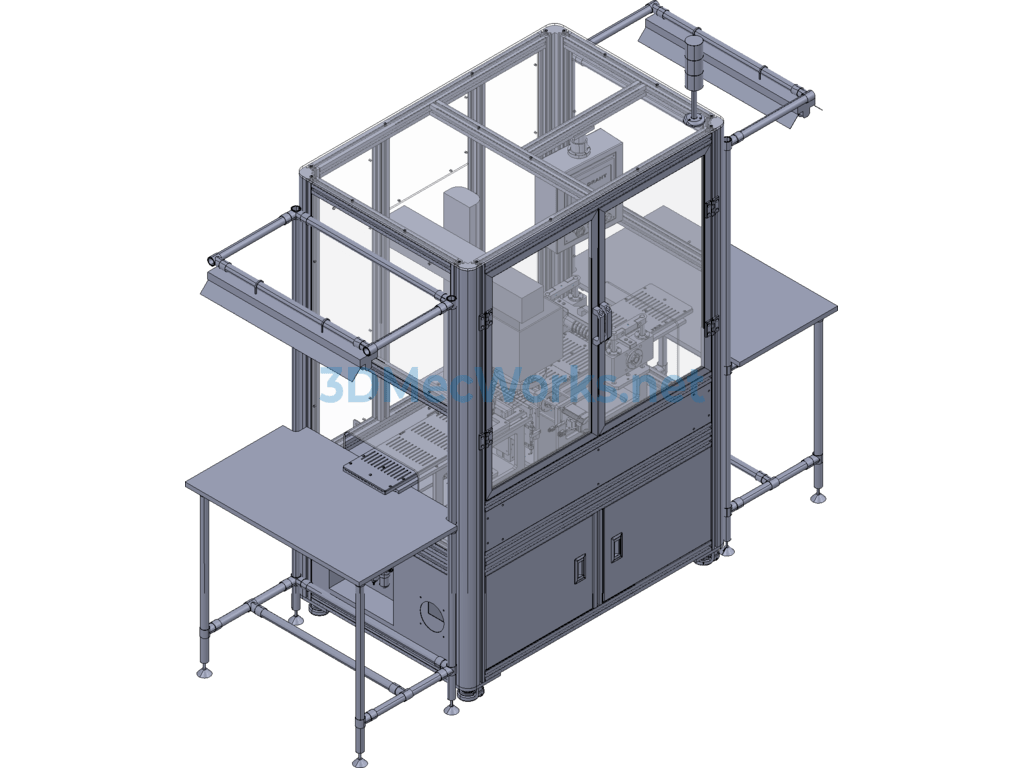

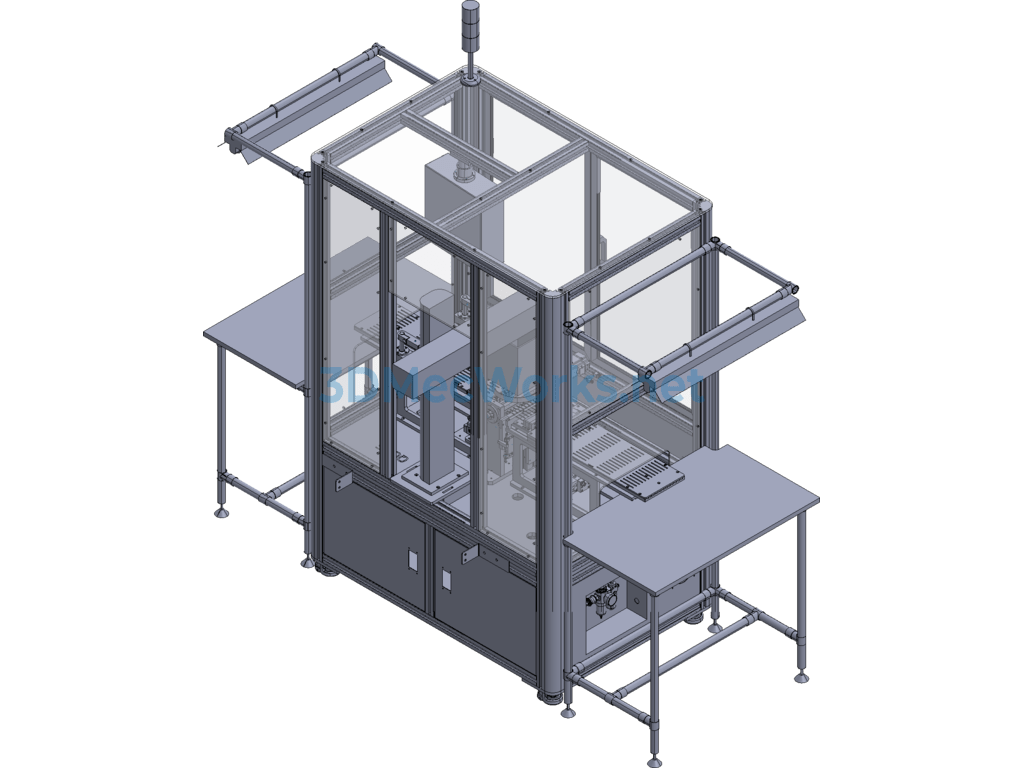

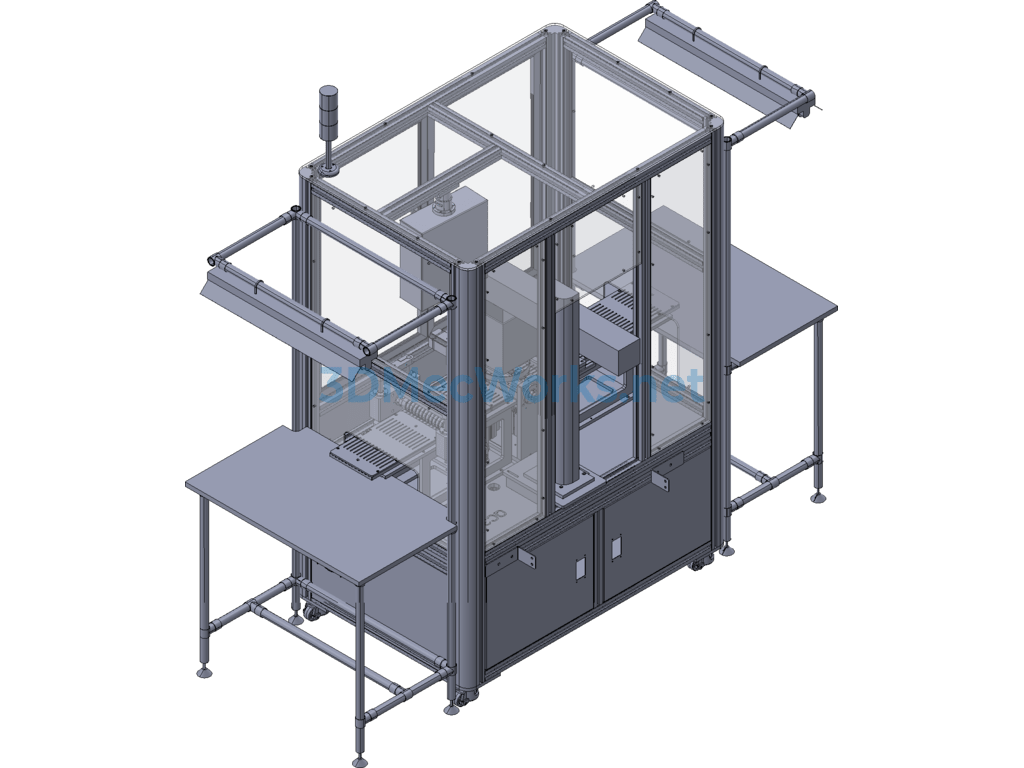

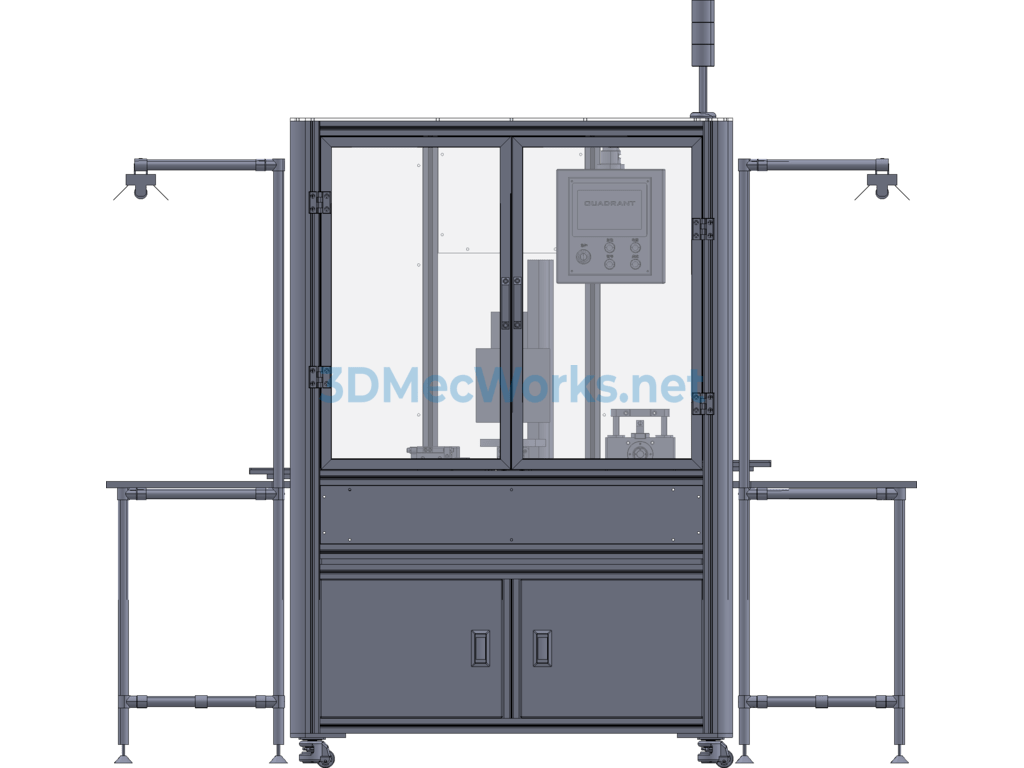

Laser Engraving Machine Equipment Function:

Loading and unloading through push-type magnetic steel loading and unloading mechanisms, with a rotating mechanism added in the middle to complete side marking operations and carrier transfers.

Equipment Structure:

Magnetic Steel Loading Mechanism: Uses a contoured linear pushing feeding to supply materials, with cylinder slide covers misaligned vertically, and cylinders driving push needles for loading.

Laser Engraving Equipment: Responsible for the product marking function.

Rotating Mechanism: A servo motor drives a sector-shaped drum, with magnets on the drum blades to ensure the fixture does not fall off.

Magnetic Steel Unloading Mechanism: Achieves unloading functionality through the cooperation of two cylinders.

Linear Feeding Mechanism: Ensures the stability of each feed through contoured linear pushing sheets.

Loading Sliding Mechanism: Misaligned baffles use a combination of epoxy board and SUS430 material, both ensuring the magnetic steel is in place and preventing misalignment and scratches.

Pushing Magnetic Loading Mechanism: Uses spring-loaded push pins to prevent scratches on the magnetic steel’s side.

Unloading Shifting Mechanism: Uses two cylinders to drive shifting sheets to realize the shifting function.

Shifting Mechanism: Moves the shifting sheet into the fixture slot, shifting the product onto the feed path.

Process Flow:

Step 1: Raise the magnetic mechanism cylinder to press the magnetic steel tightly;

Step 2: Move the magnetic mechanism cylinder horizontally forward to push in the magnetic steel;

Step 3: Linearly translate the misalignment warehouse upwards to separate the magnetic steel, while the end baffle holds the magnetic steel;

Step 4: Lower the magnetic mechanism cylinder back to position in preparation for the next fill;

Step 5: The feeding push pin pushes the magnetic steel on the misaligned board into the fixture;

Step 6: The rotating mechanism rotates 90° to position the magnetic steel marking face facing the marker for marking;

Step 7: After marking is completed, the rotating mechanism rotates the fixture to the unloading side;

Step 8: The magnetic steel unloading mechanism cylinder moves forward to the underside of the fixture;

Step 9: The magnetic steel unloading mechanism moves upwards into the fixture;

Step 10: The magnetic steel unloading mechanism cylinder moves back, shifting the product onto the feed plate to complete the unloading.

Specification: Rotary Laser Engraving Equipment, Automatic Loading and Unloading Marking Machine

|

User Reviews

Be the first to review “Rotary Laser Engraving Equipment, Automatic Loading and Unloading Marking Machine”

You must be logged in to post a review.

There are no reviews yet.