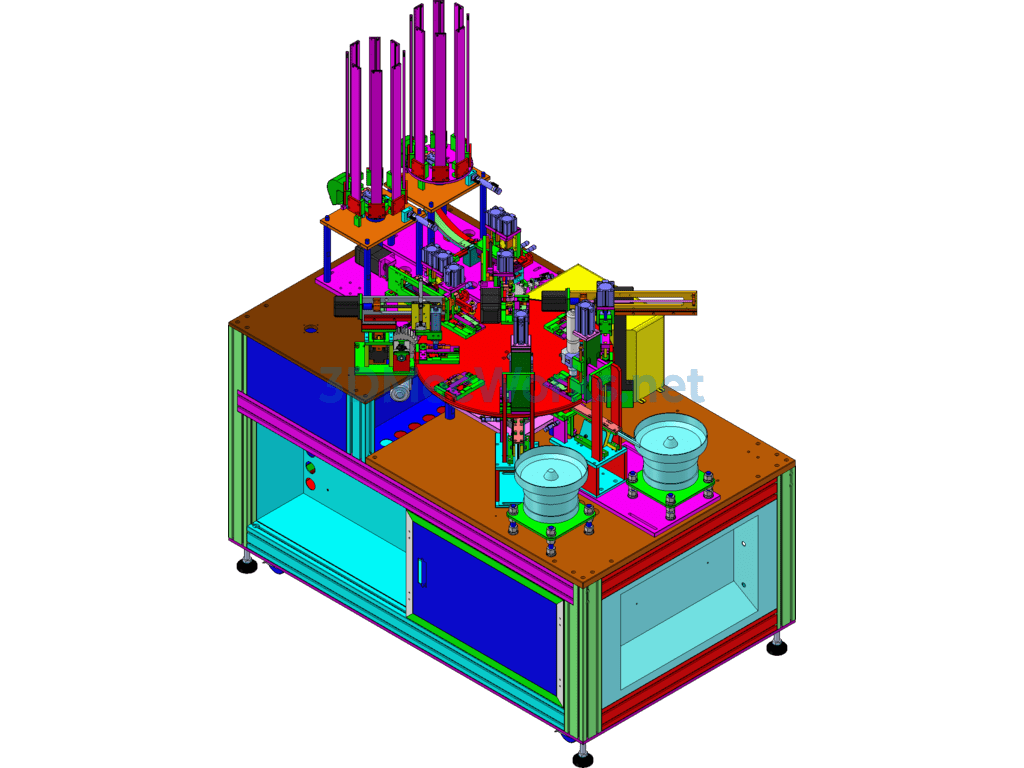

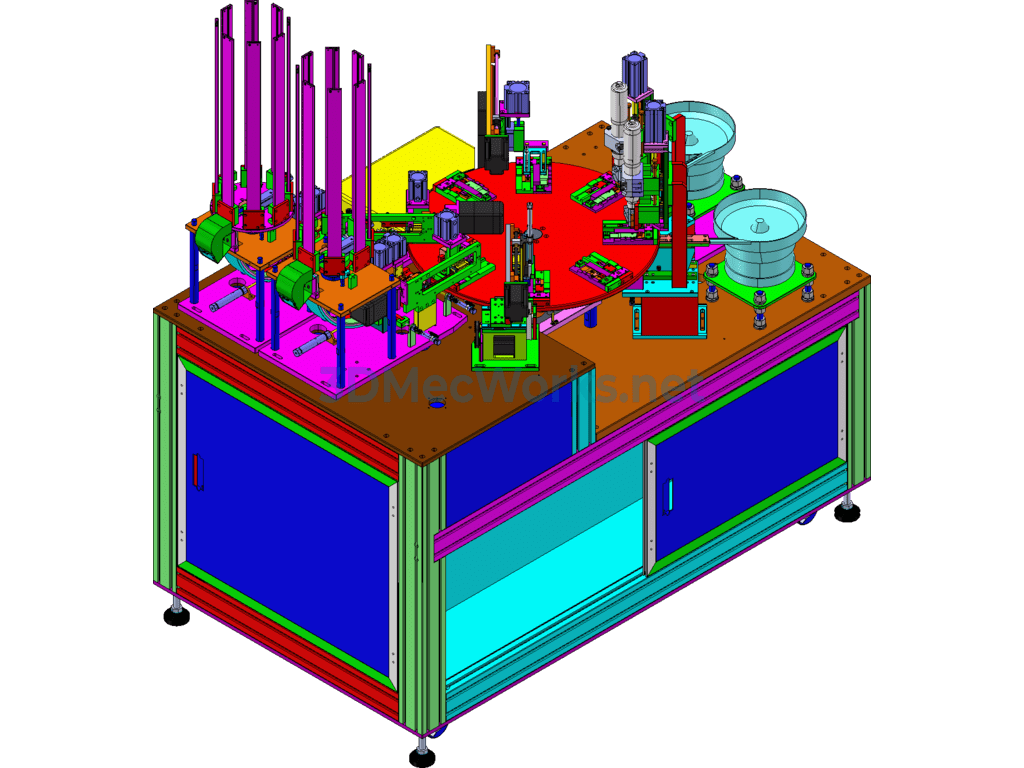

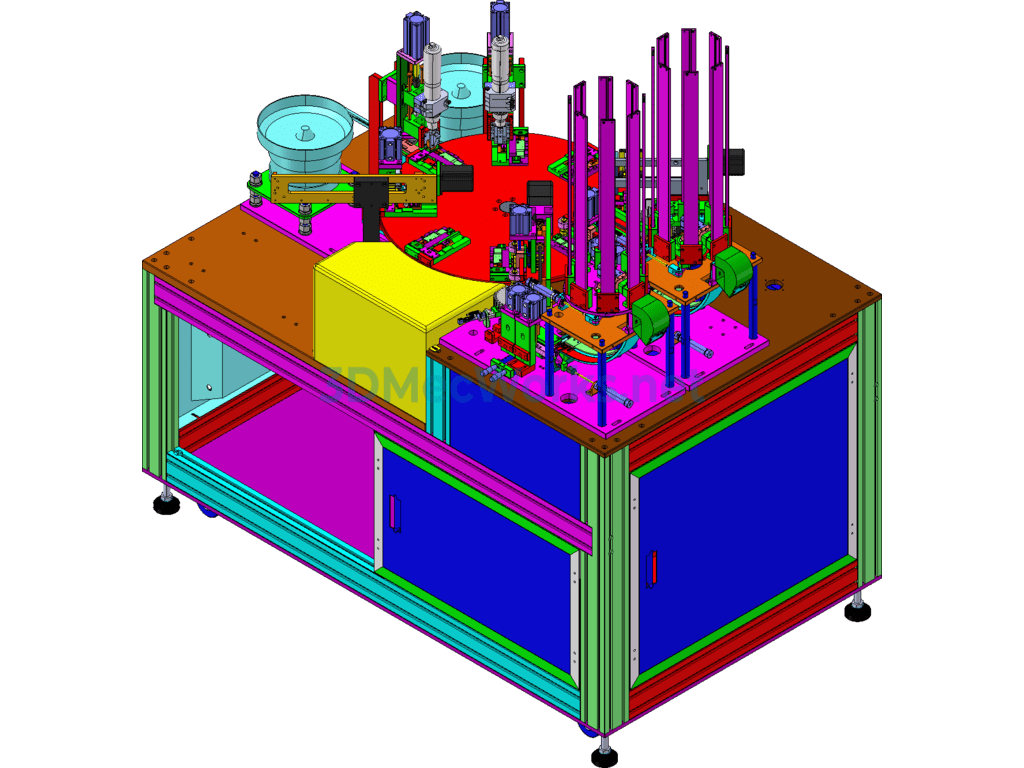

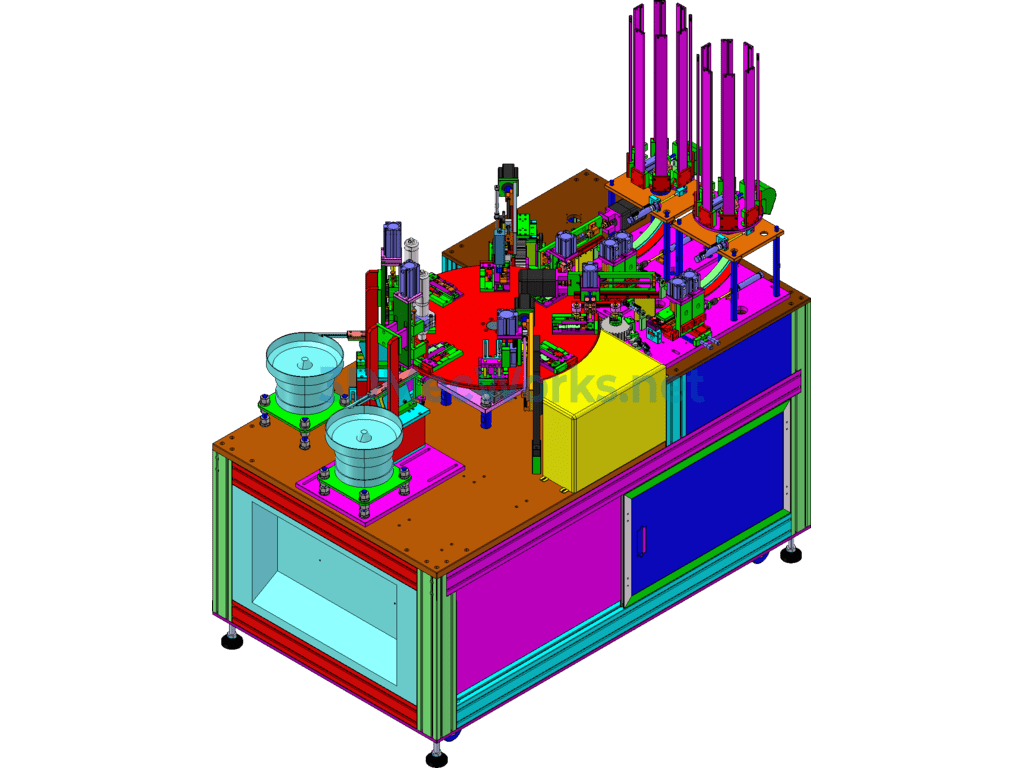

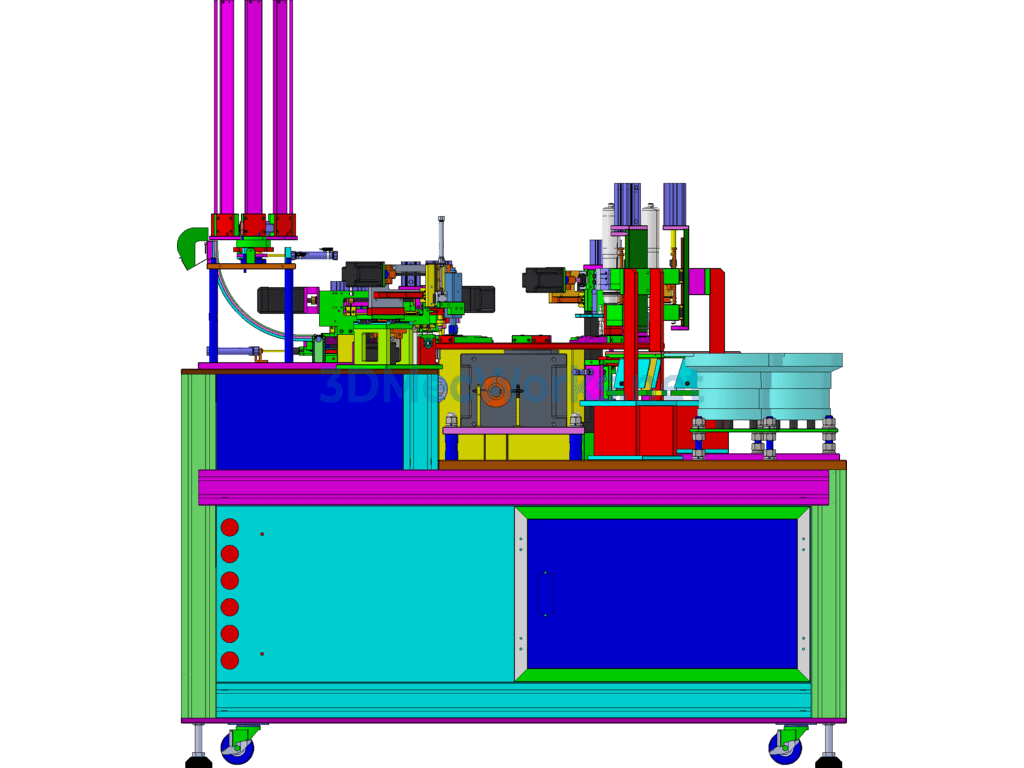

Disc-type Crystal-locking Heat Sink Assembly Machine A non-standard nut locking screw assembly device, the electrical system uses Japan’s Mitsubishi PLC control system, with Taiwan Weintek touch screen as the operation interface, which is intuitive and convenient. Debugging operations and fault feedback can be handled and resolved promptly, with stable operation, safety, and low failure rate.

This is a device for assembling crystal heat sinks, with parts to be assembled including crystal chip, heat sink, nut, and screws. First, the front-end feeding station sends out the crystal chips. The incoming material for these crystal chips is in tube form, with a common PVC tube filled with materials tube by tube. After the crystal chips emerge from the underfeed point, a screw rod material handling robot takes the material to the turntable for assembly. The drive for the turntable is rotationally driven by a divider. The feed for nuts is provided by vibrating plates, with two vibrating plates supplying material simultaneously. When the nut and crystal tube rotate to the same position, the screw-locking structure locks the heat sink and nut together. The final station is glue dispensing, as gluing is usually required for crystal heat sinks. After gluing, the discharge station finishes the process. The basic principle of operation for the entire equipment is like this. We hope everyone downloads and studies it a lot. Thank you. Disc-type Crystal-locking Heat Sink Assembly Machine Solidworks 2014 Design Source Files + STEP files provided.

Specification: Rotary Crystal Lock Heat Sink Assembly Machine (nut Lock Screw Assembly Equipment)

|

User Reviews

Be the first to review “Rotary Crystal Lock Heat Sink Assembly Machine (nut Lock Screw Assembly Equipment)”

You must be logged in to post a review.

There are no reviews yet.