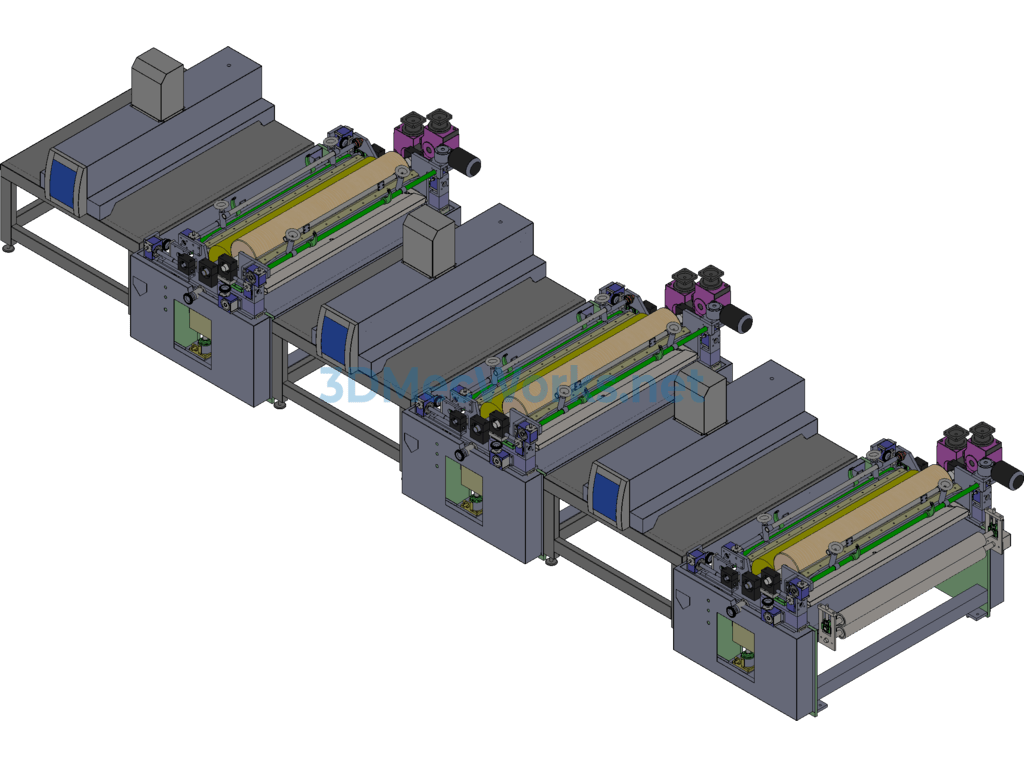

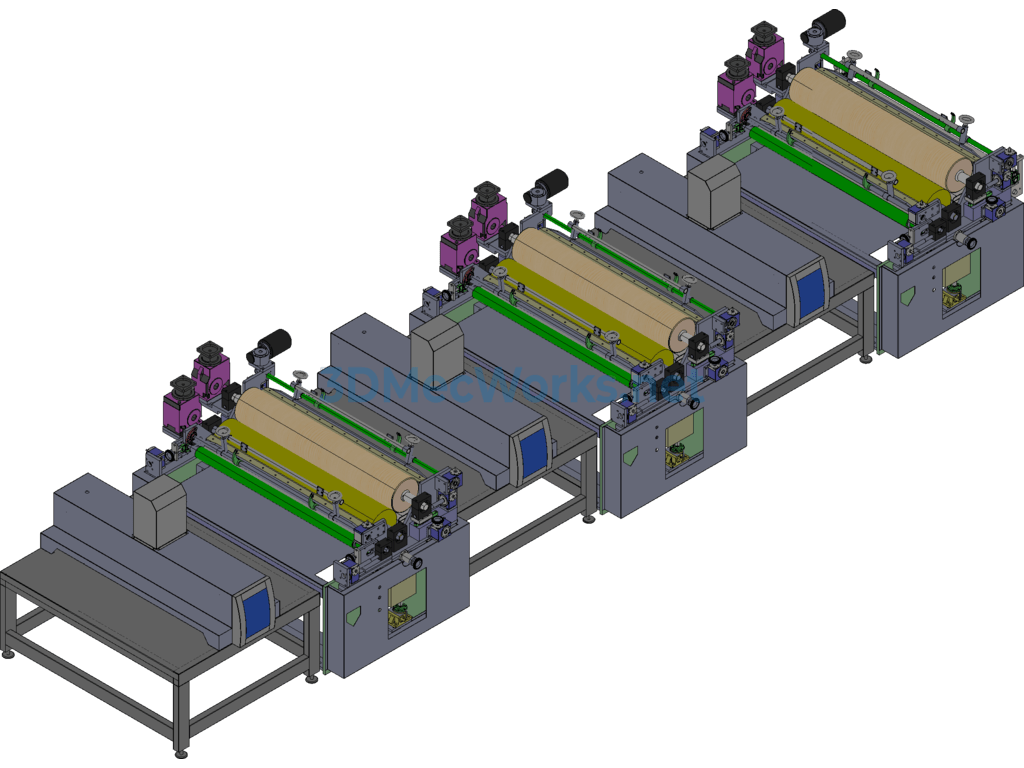

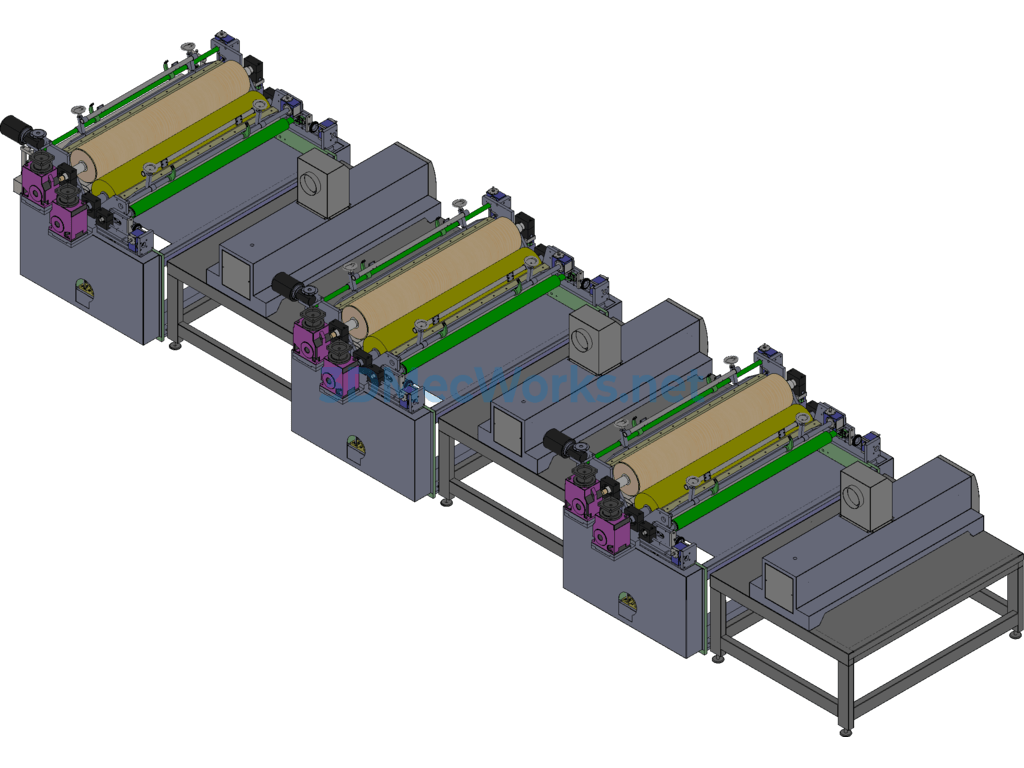

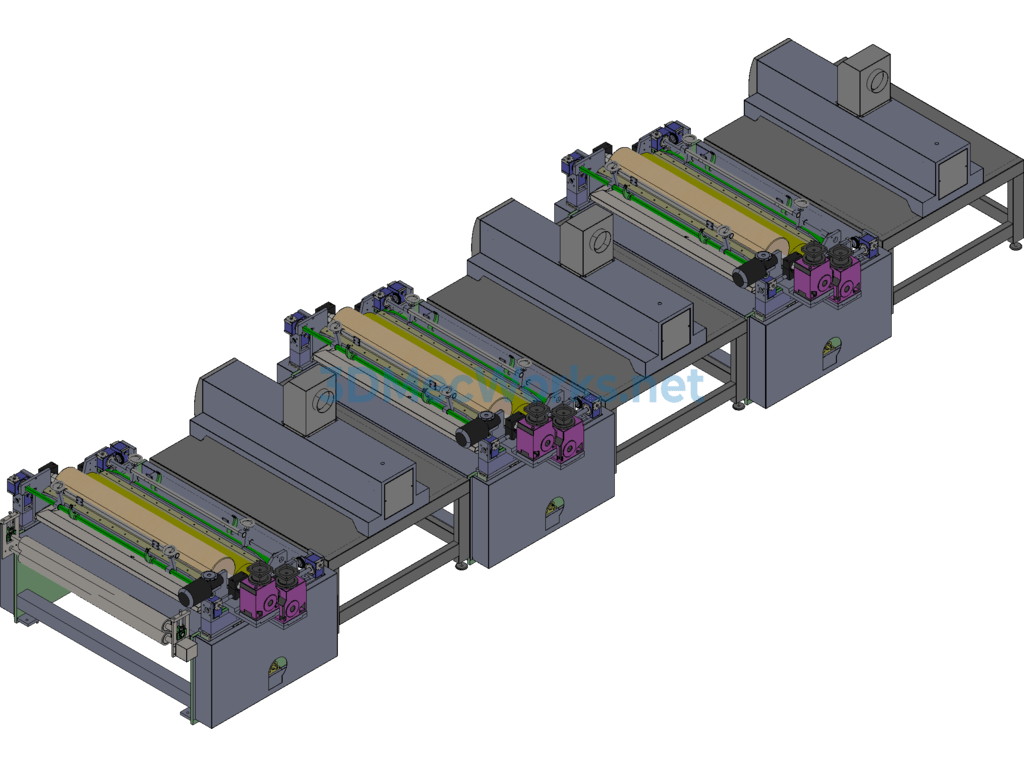

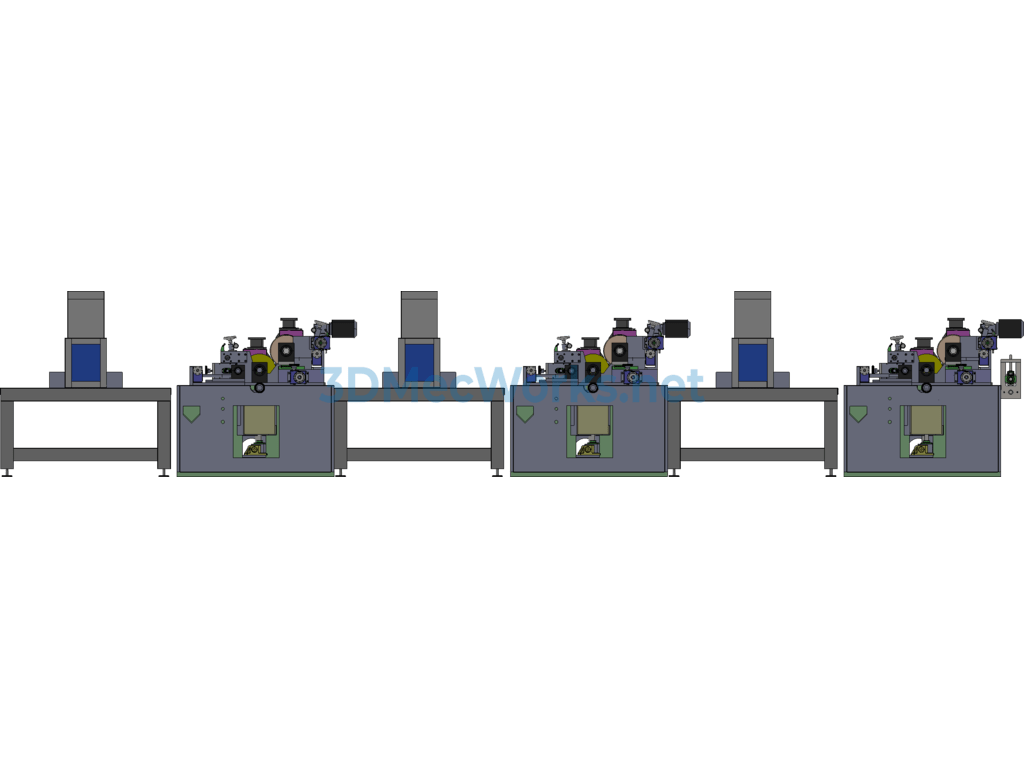

Suitable for the plate surface printing process of heavy steel rolls.

Frame structure: The frame and wall panels are precisely processed and annealed by large imported CNC milling machines from a whole 25 mm thick steel plate, providing higher assembly precision, more stability, and firmness without deformation.

Rubber roller mechanism: The rubber roller is made of imported PU rubber, with a roller diameter of Φ250mm, and the smooth roller with a diameter of Φ150mm. The roller surface has been finely processed, making it delicate and smooth. Rubber roller and smooth roller are equipped with quick-release scrapers and the angle is adjusted by a worm gear reducer, providing even painting and a smoother paint surface. Both ends of the rubber roller use bearing seats for quick replacement, reducing maintenance time. The driving force of the conveyor belt rotates at the balanced roller of the center line of the rubber roller, improving stability in transportation.

Lifting mechanism: The lifting of the rubber roller group is manually fine-tuned, with each group of rubber rollers guided by four sets of imported precision linear guides and slides without gaps, avoiding oscillation during coating, enabling high-speed and stable coating. It is convenient to adjust for different thicknesses of plates. Lifting is configured with a cylinder locking device to eliminate machine gap errors, and also has an instant lift function for wrongly placed thick plates, effectively protecting the damage of the rubber roller, making the coating more even and delicate.

Conveying mechanism: The conveyor table adopts a sander working table structure, making it more stable and allowing quick and easy belt replacement; this structure determines the oil tank design, which is installed reasonably and scientifically, making oil tank replacement and cleaning very convenient. During roller coating and cleaning, paint and cleaning solvents will not fall on the belt. The conveyor belt is made of imported high-strength PU belt, with an imported variable frequency speed regulation device for stable operation, resistant to various solvents, preventing delamination caused by chemical corrosion.

Drive part: The rubber roller, smooth roller, and conveyor belt are driven by independent imported motors, and stepless speed regulation is achieved by independent imported inverters, which is conducive to improving the painting quality and facilitating the equipment operation. By adjusting different speeds, the paint amount can be precisely controlled, enabling the workpiece to achieve the best surface smoothness and saturation.

Paint heating system and paint circulation: The paint barrel heating system is adopted, improving the stability of paint circulation and easily adjusting the viscosity of solvent-free UV coatings. Active oil is installed inside a two-layer stainless steel barrel, which gets indirectly heated through an electric heater with adjustable temperature functionality, aiding in paint heating. Optional mixers are available to stir the paint evenly.

Painting system and maintenance: The oil tank design is reasonable, making cleaning very convenient without dropping paint on the conveyor belt, and the belt replacement is very simple.

Specification: Roll Material 1320 Printing Machine

|

User Reviews

Be the first to review “Roll Material 1320 Printing Machine”

You must be logged in to post a review.

There are no reviews yet.