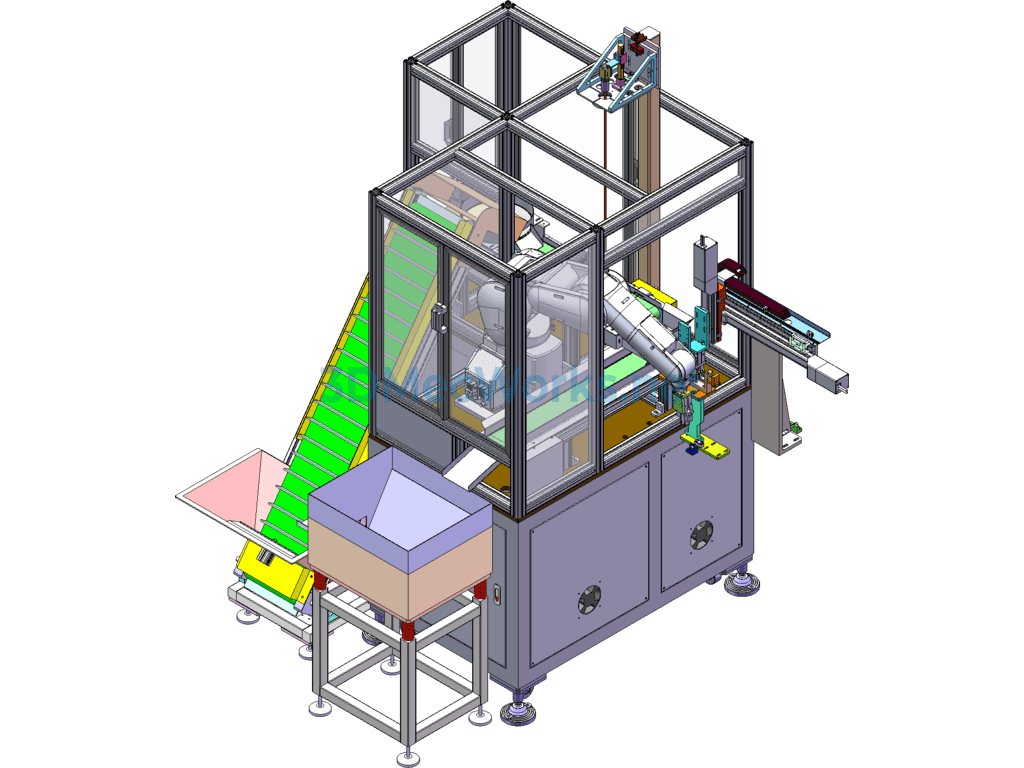

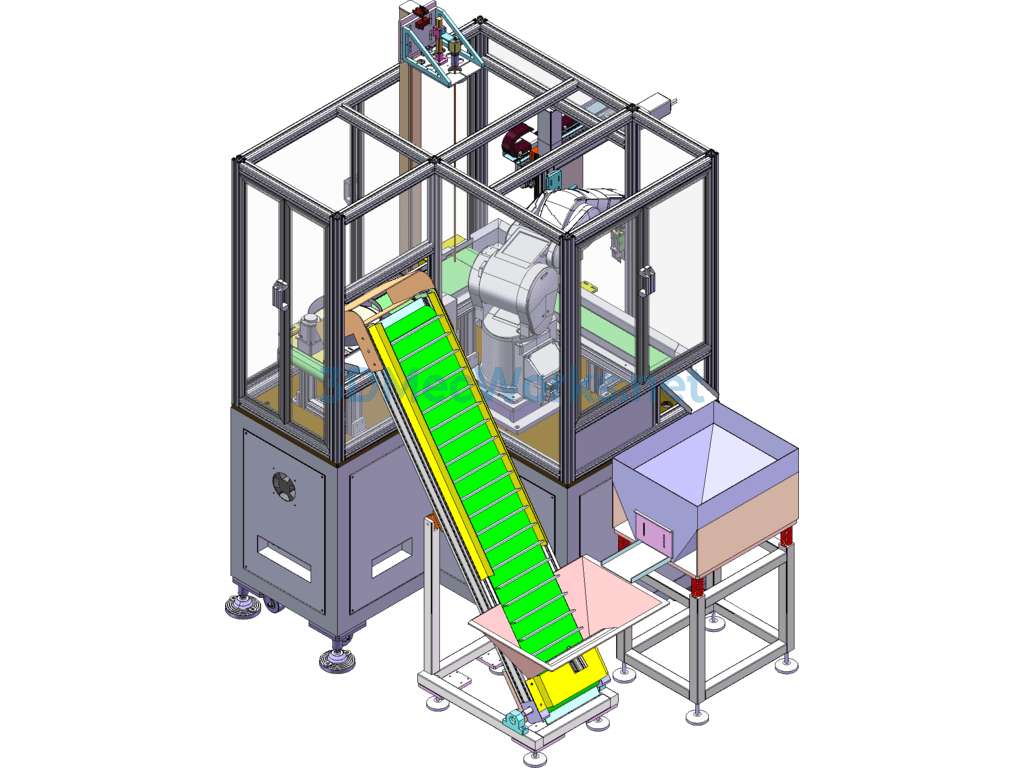

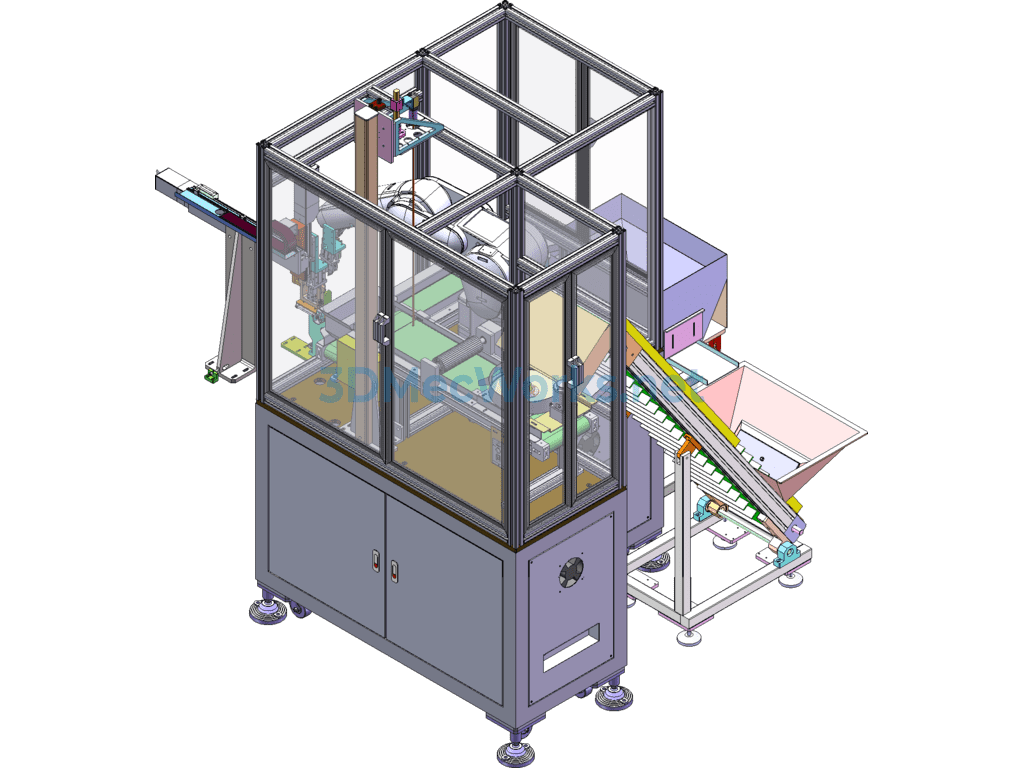

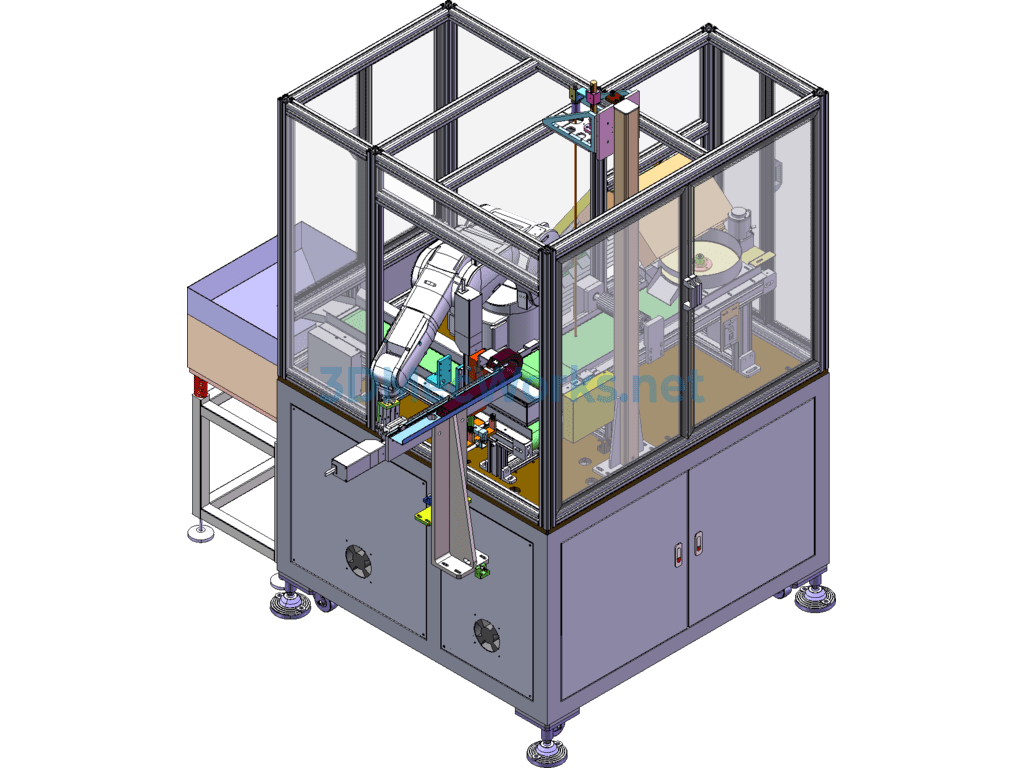

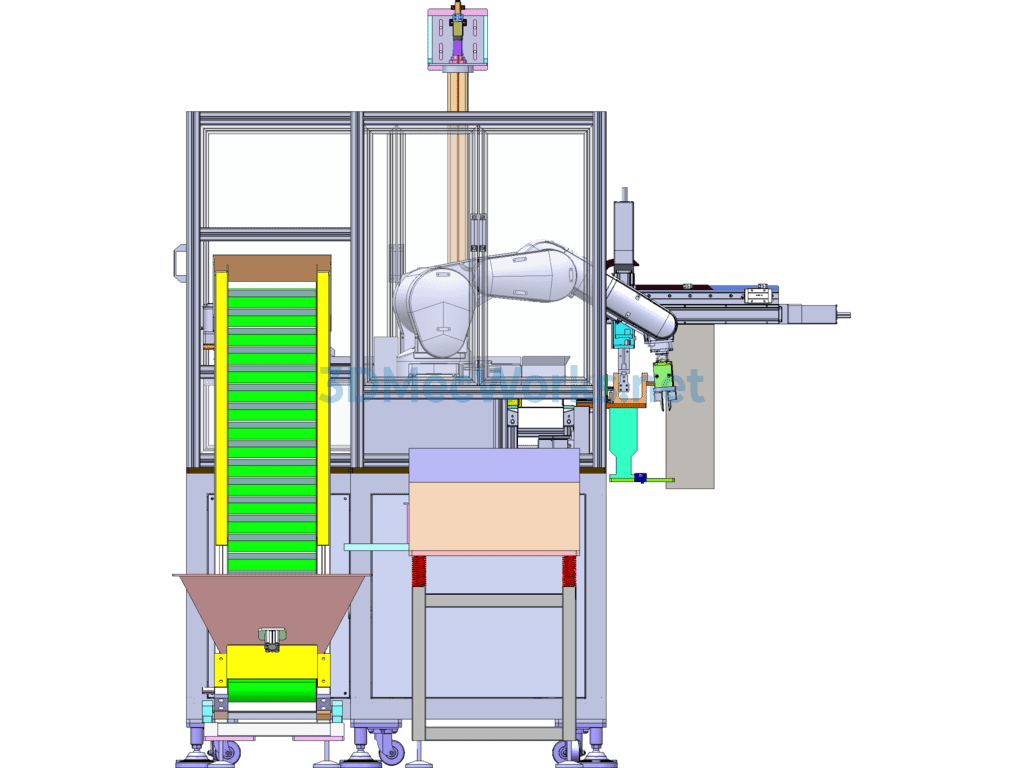

Manually pour the product into the hopper. The material is transported to the interior of the centrifugal disc device through a circulating lifting assembly line. The centrifugal disc automatically sorts and discharges the material one by one. The individual discharge enters a dual-line differential assembly line, conveyed to the positioning area. After CCD (Charge-Coupled Device) photography locates the product position, a robotic arm with an air gripper grabs the product and places it inside the equipment. Unidentified products are recirculated into the loading hopper.

Specification: Robotic Arm Automatic Loading Equipment

|

User Reviews

Be the first to review “Robotic Arm Automatic Loading Equipment”

You must be logged in to post a review.

There are no reviews yet.