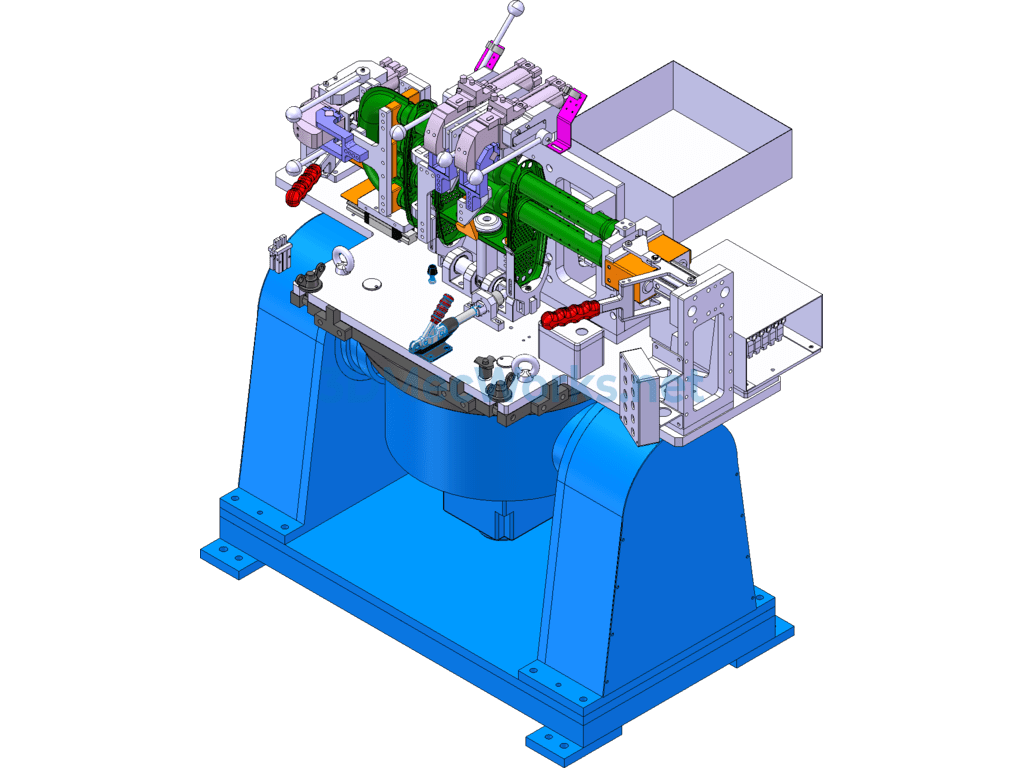

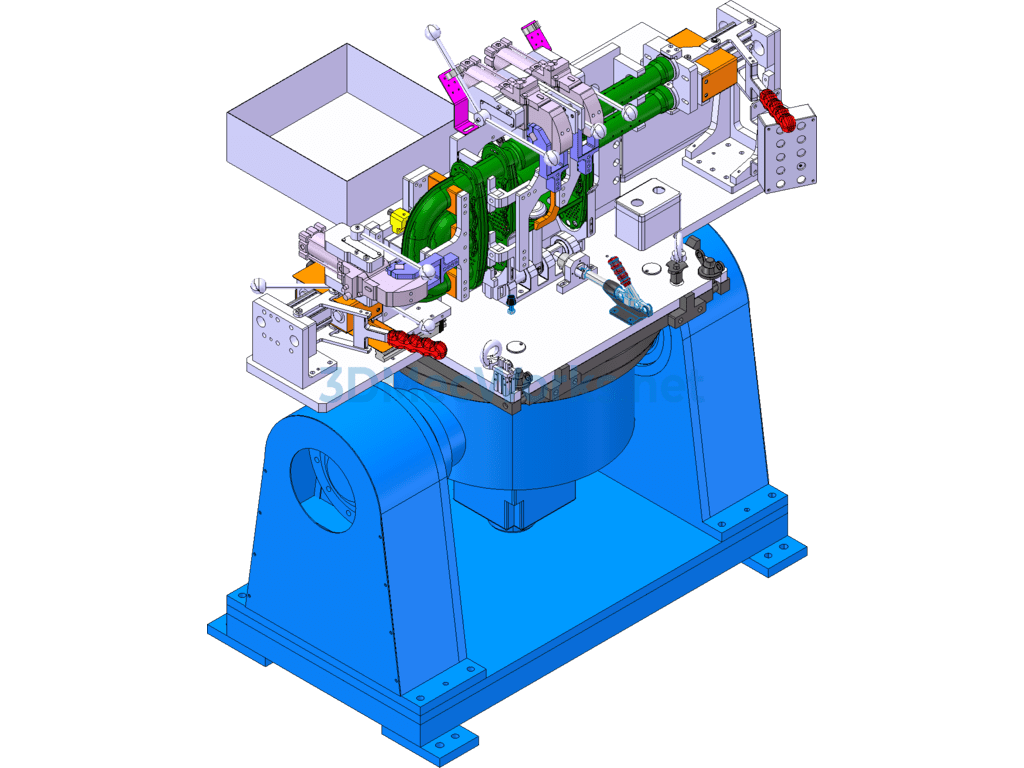

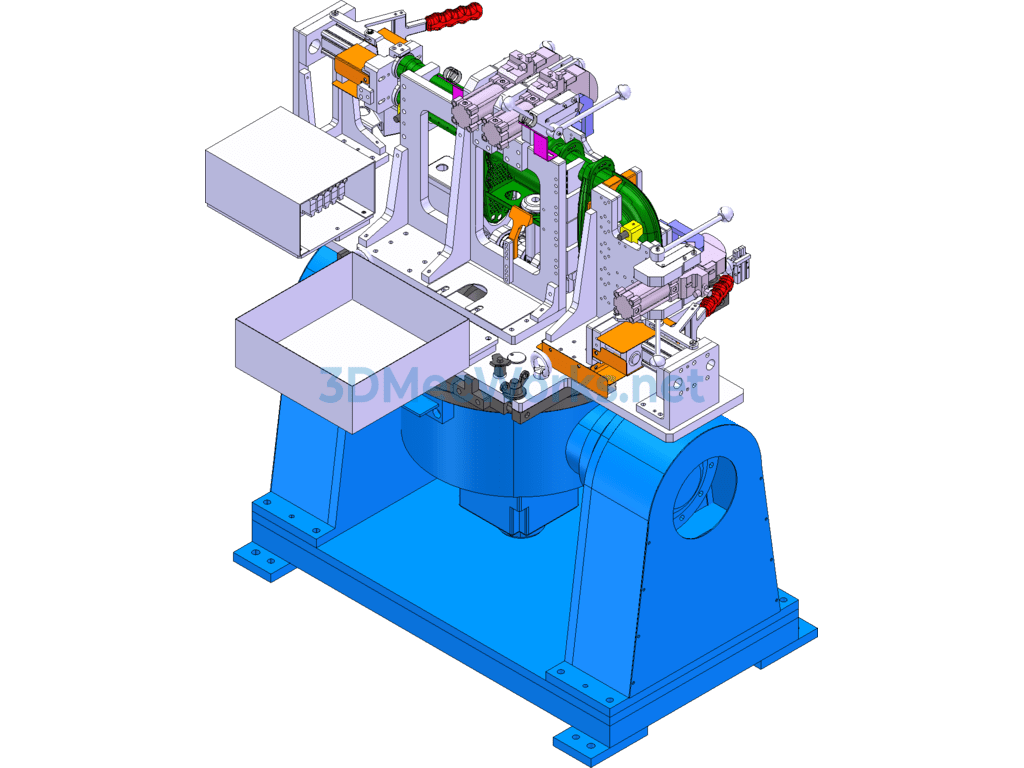

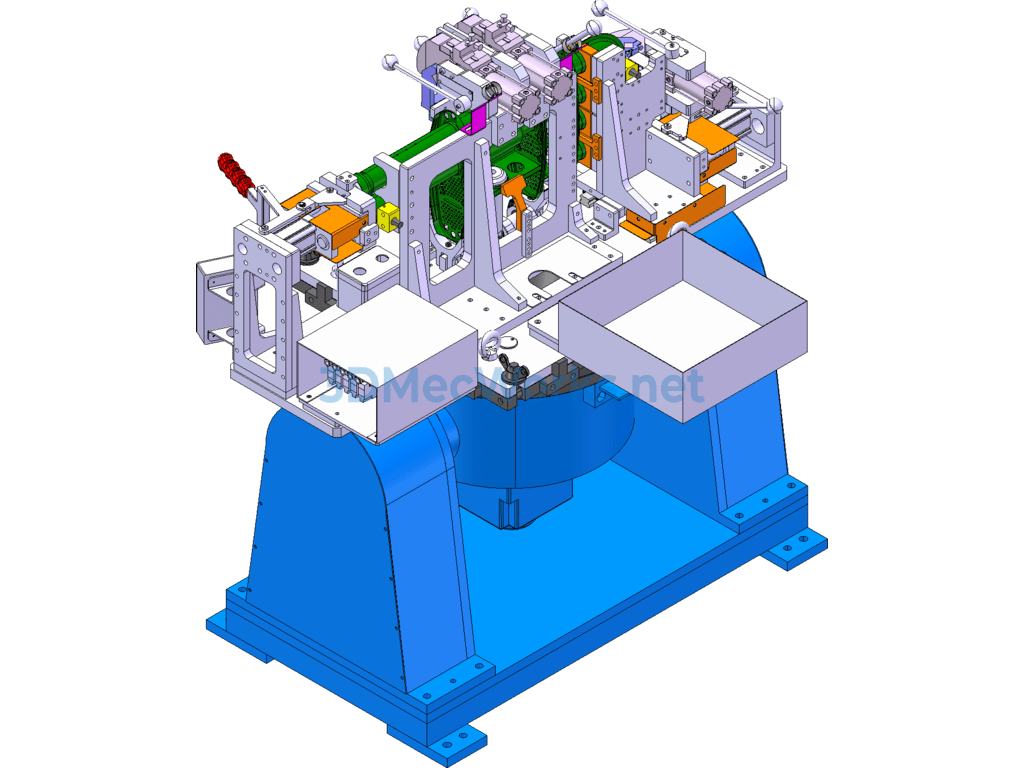

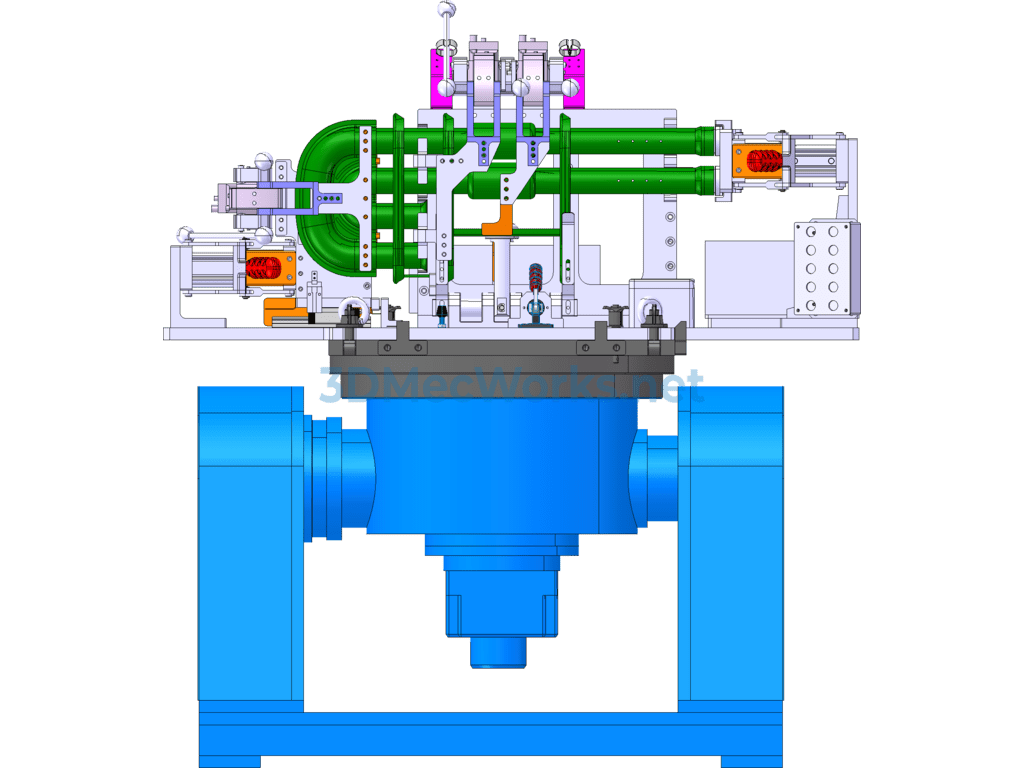

Robot Positioner Welding Fixture

1. The lifting of the welding platform is achieved through a T-shaped lead screw driven by a motor on the column, which has a self-locking function to ensure it won’t fall during a power outage.

2. The welding platform flips by a motor driving rotary support which causes the platform to flip. When double columns are working, the motor on the right column does not work and disengages from the rotary support. When each column is used separately, the gear on the right column engages with the rotary support to drive the table to rotate.

3. The right column can be rotated manually, and once rotated into position, it can be secured by tightening bolts, allowing it to be used as an independent welding flip positioner.

Specification: Robot Positioner Welding Fixture

|

User Reviews

Be the first to review “Robot Positioner Welding Fixture”

You must be logged in to post a review.

There are no reviews yet.