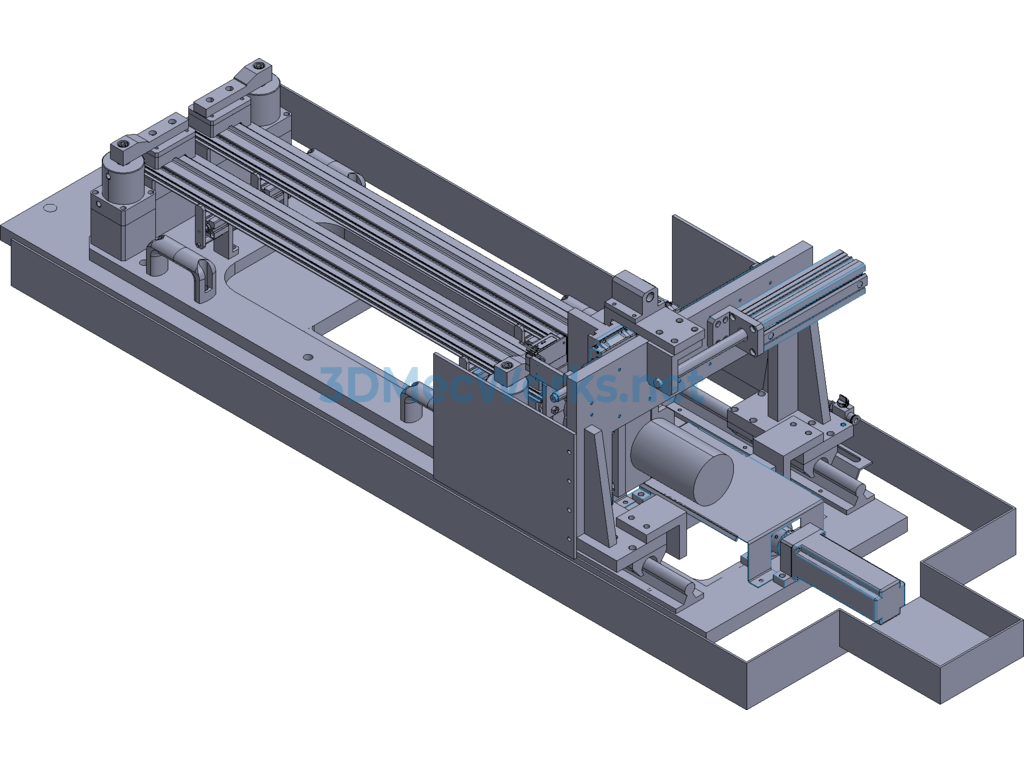

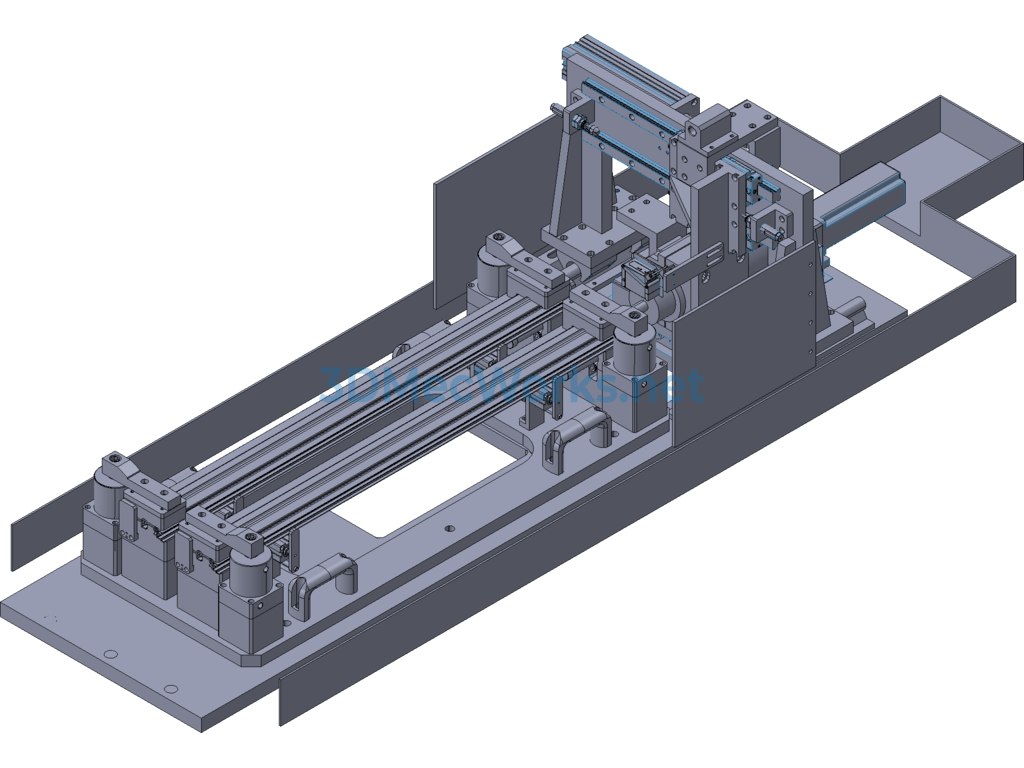

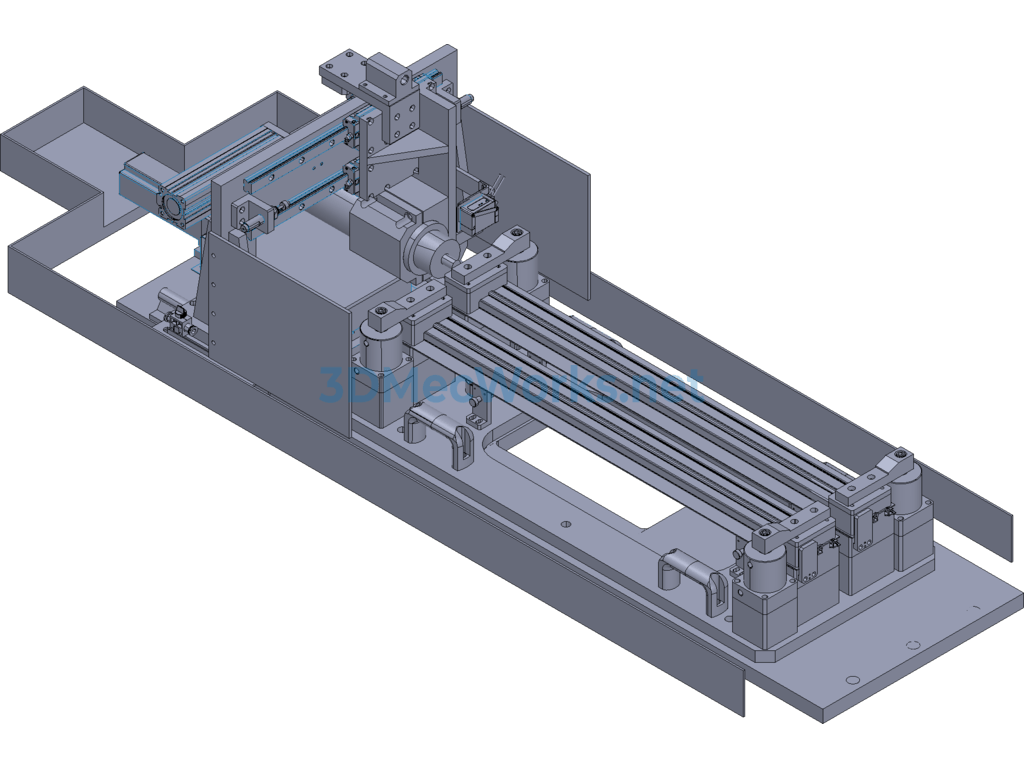

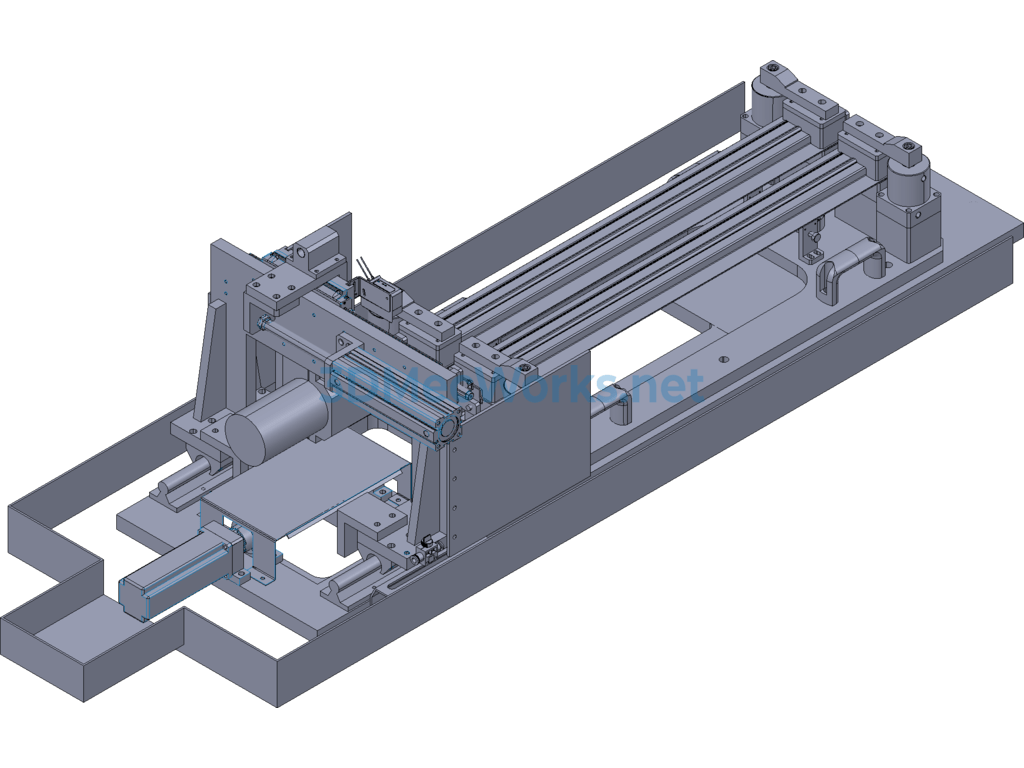

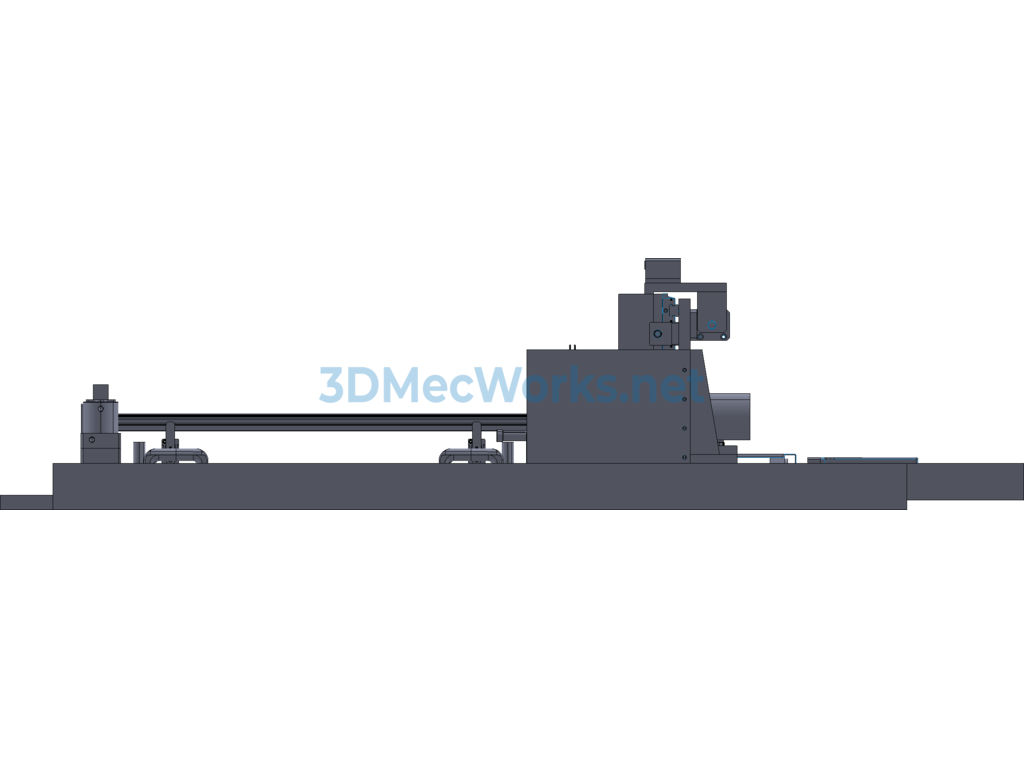

This is a technical modification of an engraving machine by adding an additional head, enabling simultaneous chamfering of the skylight guide rail and reaming of cable holes, thereby reducing the original two processes to one. To meet the load-bearing and strength requirements of the original machine’s moving slide rail, the load-bearing plates of the entire machine’s structural components are processed using 704A super-hard aluminum material, and force deformation analysis was conducted, with results meeting the requirements.

The entire structure is designed and analyzed using CREO, and is now converted to STP format for direct opening. The drilling main engine uses a 2.2KW electric spindle, with an ER16 CNC collet capable of clamping 6-10mm diameter tool handles, combined with a fiber optic sensor to achieve effective compensation for length deviation of the guide rail. The tooling part adopts Airtac rotary cylinders with a delicate and compact structure.

Now shared for learning and exchange.

Specification: Retrofit and Install Machine Head for Engraving Machine

|

User Reviews

Be the first to review “Retrofit and Install Machine Head for Engraving Machine”

You must be logged in to post a review.

There are no reviews yet.