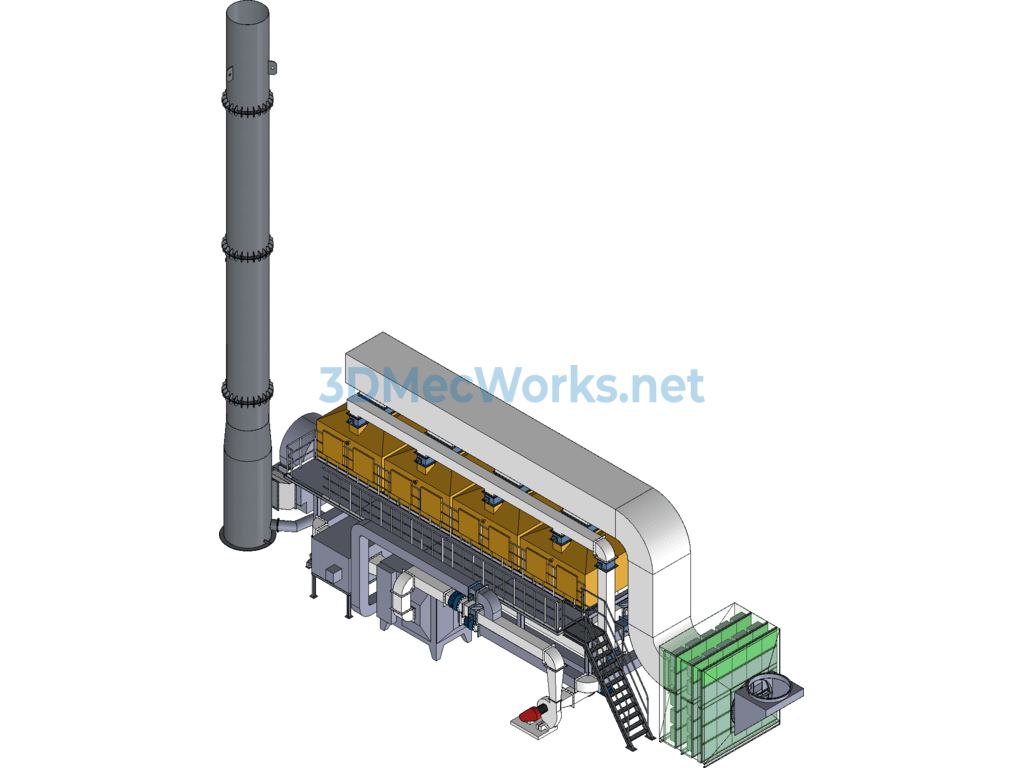

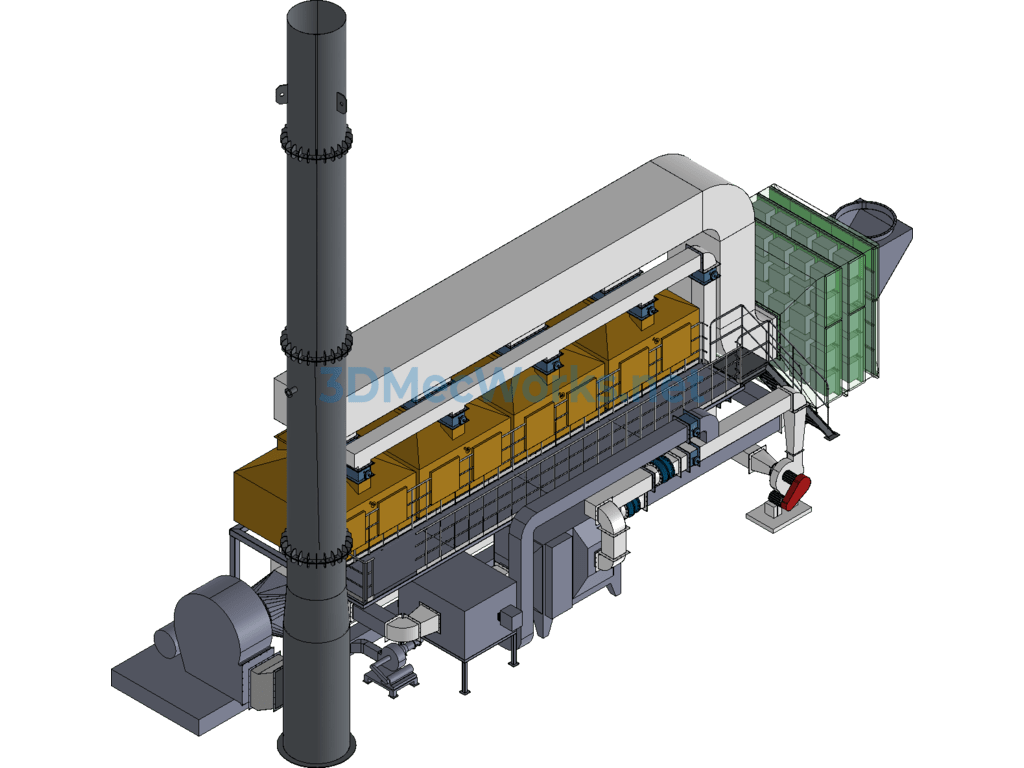

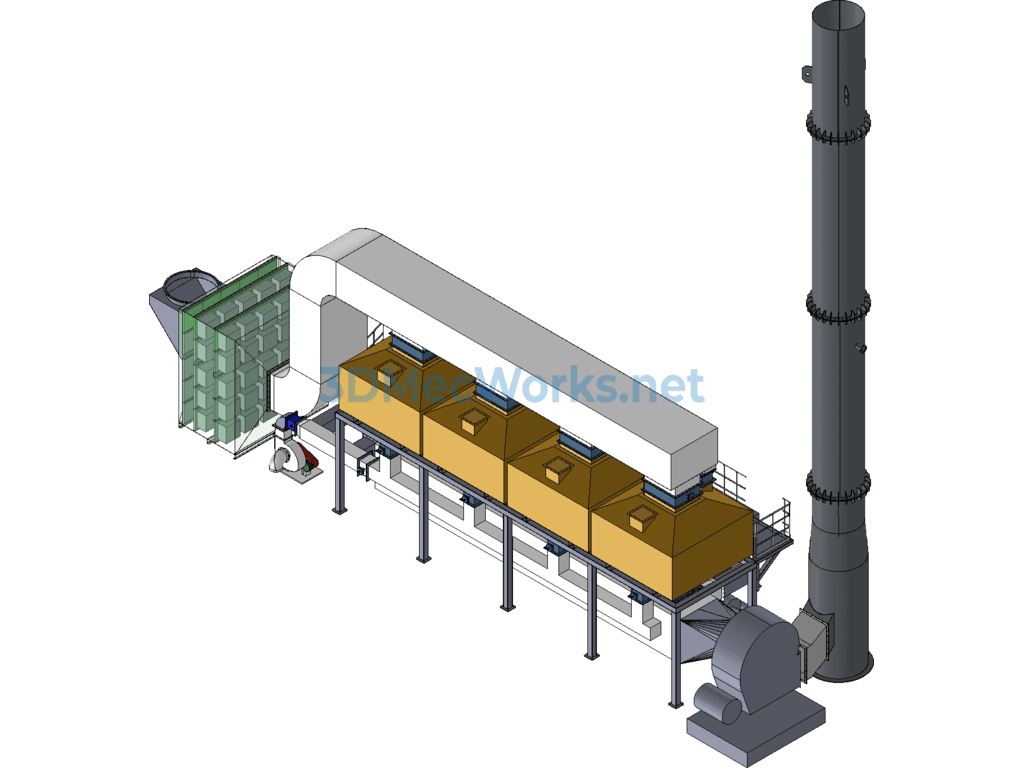

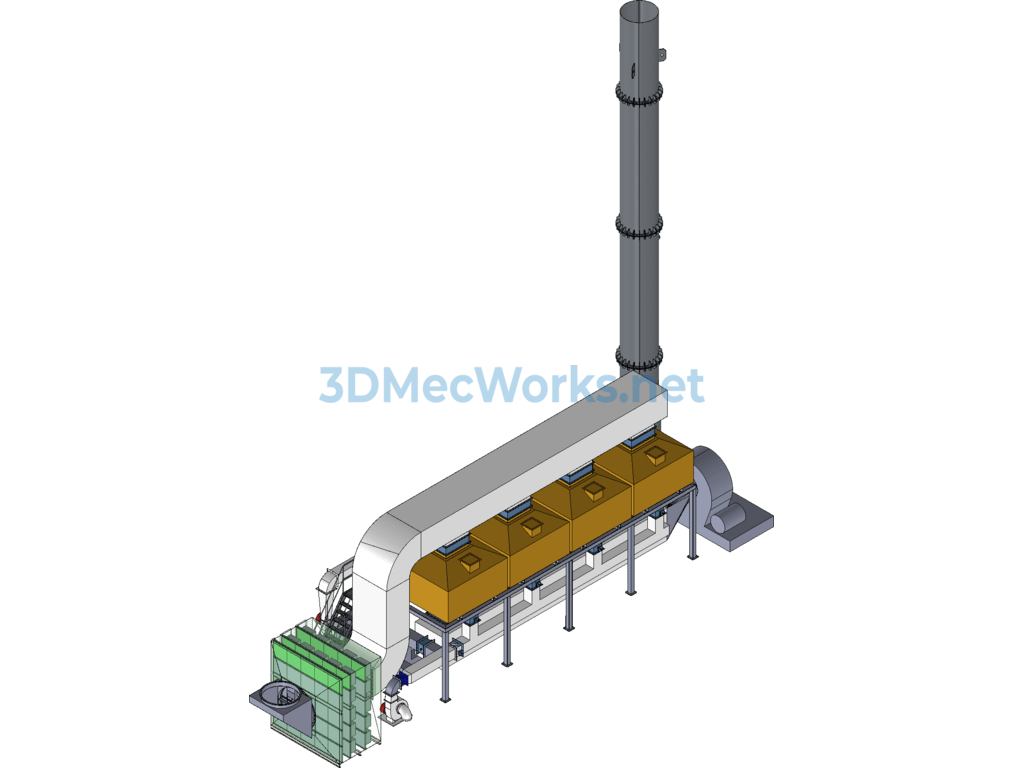

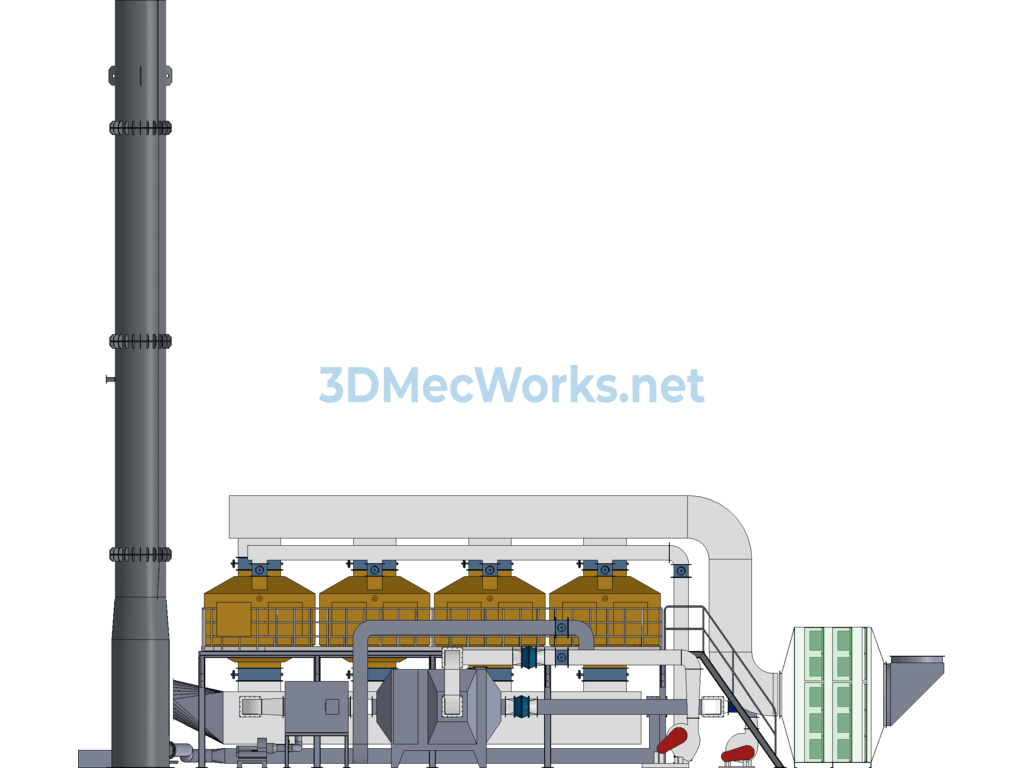

VOCs Exhaust Gas Treatment Device Design Drawing of Activated Carbon Adsorption, Desorption, and Catalytic Combustion Device. 3D Drawing of Activated Carbon Adsorption + Desorption, with an adsorption capacity of 40,000m3/h and a desorption capacity of 1,000m3/h, adopting a working mode of three towers for adsorption and one tower for desorption. The system diagram of the honeycomb activated carbon bed + catalyst catalytic oxidation combustion device includes the front-end filtration system, duct pipeline, fan, system chimney, valves, equipment ladders, platforms, supports, and individual equipment dimension drawings. The process is that when the adsorption bed is saturated, the main fan is stopped; the inlet and outlet valves of the adsorption box are closed. Each time the catalytic combustion furnace operates, it first runs empty for 40 minutes to heat up, then the desorption fan is started to desorb the adsorption bed. The desorption gas first passes through the heat exchanger in the catalytic bed, then enters the preheater in the catalytic bed. With the electric heater, the gas temperature is raised to about 220°C, then passes through the catalyst, where the organic substances burn under the action of the catalyst, and are decomposed into CO2 and H2O to achieve the purpose of exhaust gas purification.

Specification: Rco Activated Carbon Adsorption Desorption and Catalytic Combustion Equipment

|

User Reviews

Be the first to review “Rco Activated Carbon Adsorption Desorption and Catalytic Combustion Equipment”

You must be logged in to post a review.

There are no reviews yet.