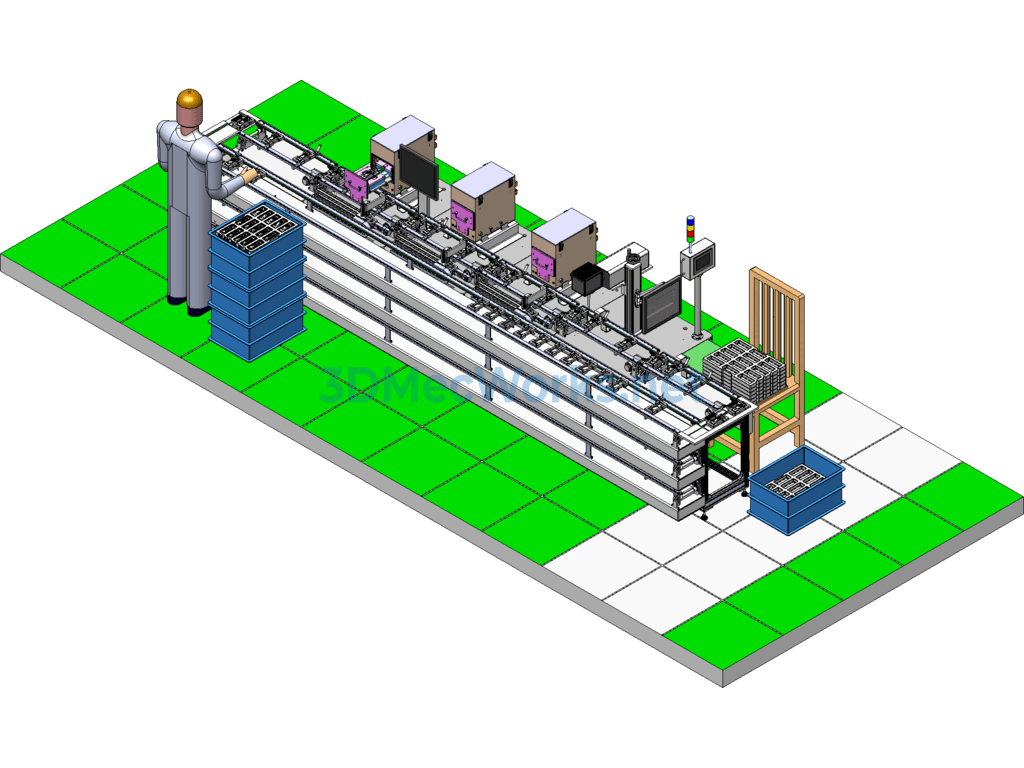

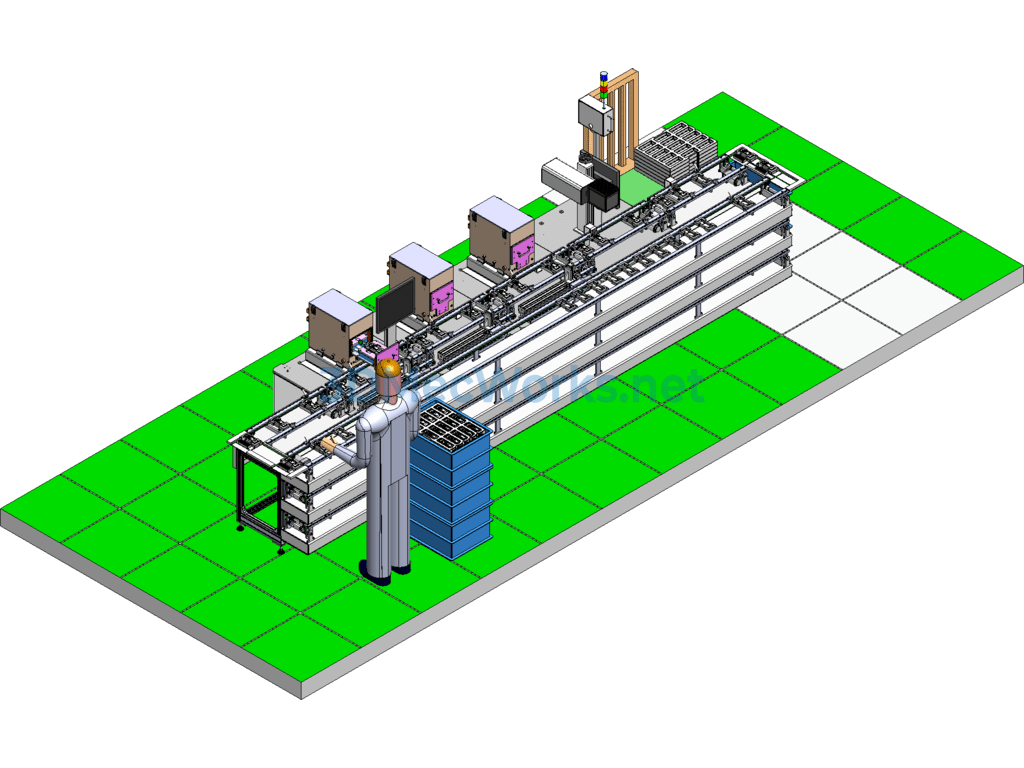

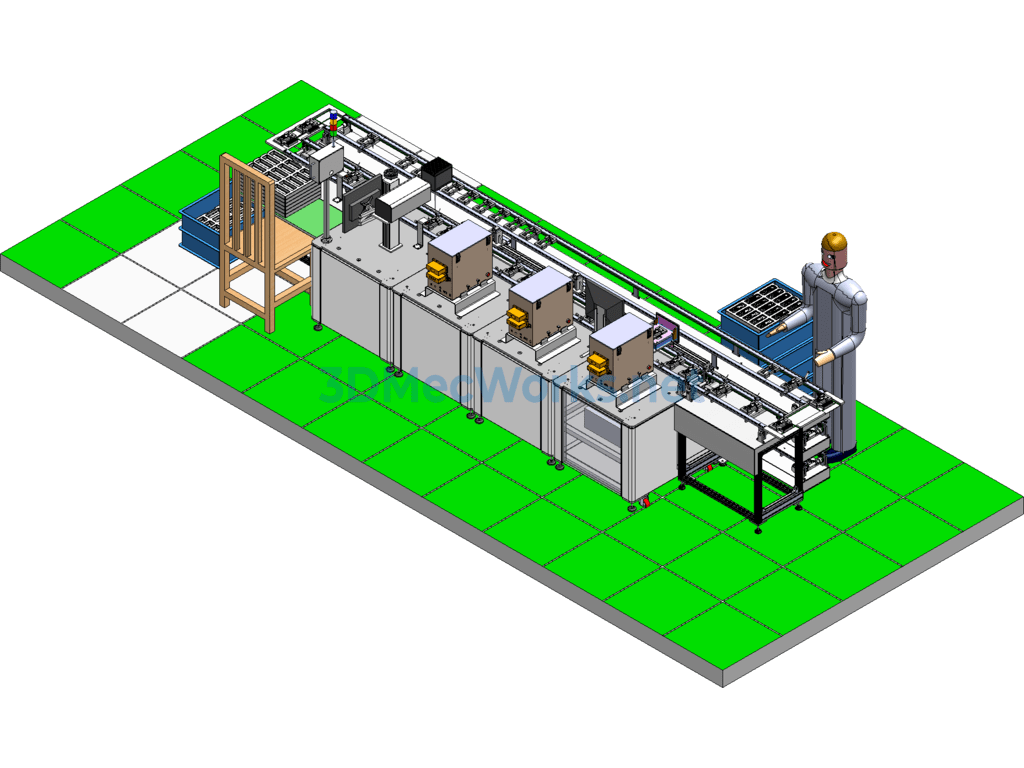

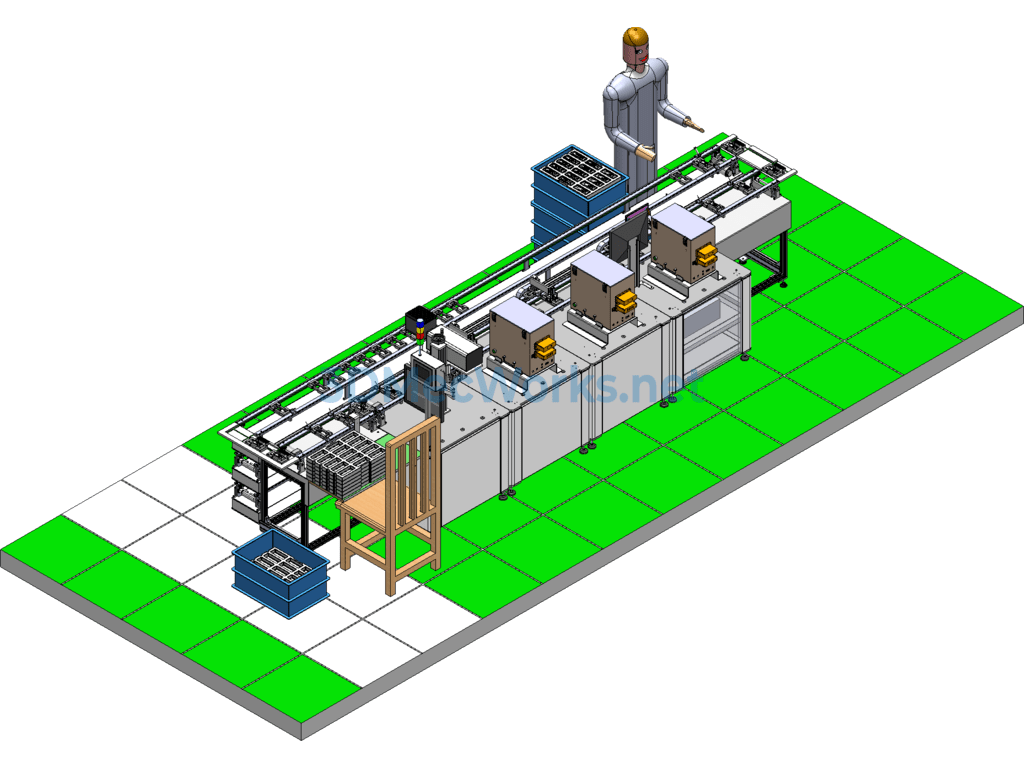

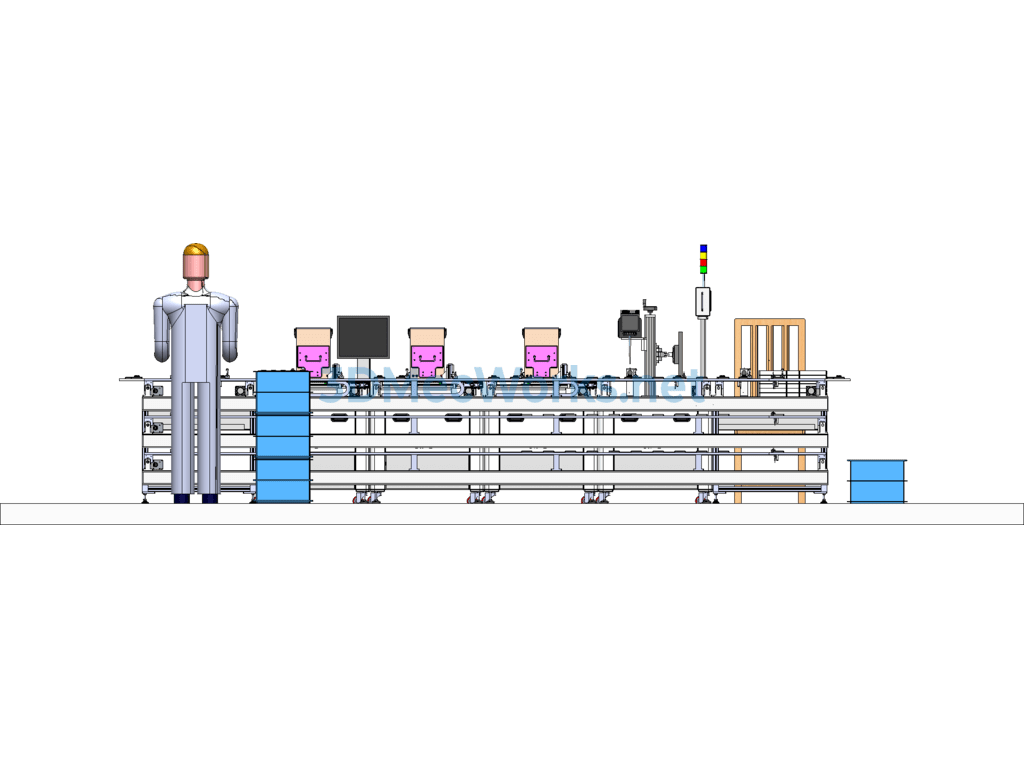

The Radio test line equipment replaces the manual loading and unloading actions in the M8 Radio test process with a conveyor line and automation mechanism, thereby realizing automated operations at the M8 Radio test station, saving labor, increasing efficiency, and reducing the production line footprint.

The M8 Radio product is transferred to a fixed area in front of the test station by a transfer box and manually loaded: placing the product into the conveyor line tray. The tray carries the product through the storage line temporarily for an hour. (The tray is designed with a foolproof function to prevent the product from being placed in reverse.) After the tray is conveyed out of the storage area, it sequentially goes through STEP1, STEP2, STEP3 for testing, STEP4 for laser marking, STEP5 for manual barcode labeling, and at the same time, products are collected into corresponding empty Trays labeled Pass or Fail.

Infrared code reading is required at all five stations of the test line.

Specification: Radio Test Line Equipment

|

User Reviews

Be the first to review “Radio Test Line Equipment”

You must be logged in to post a review.

There are no reviews yet.