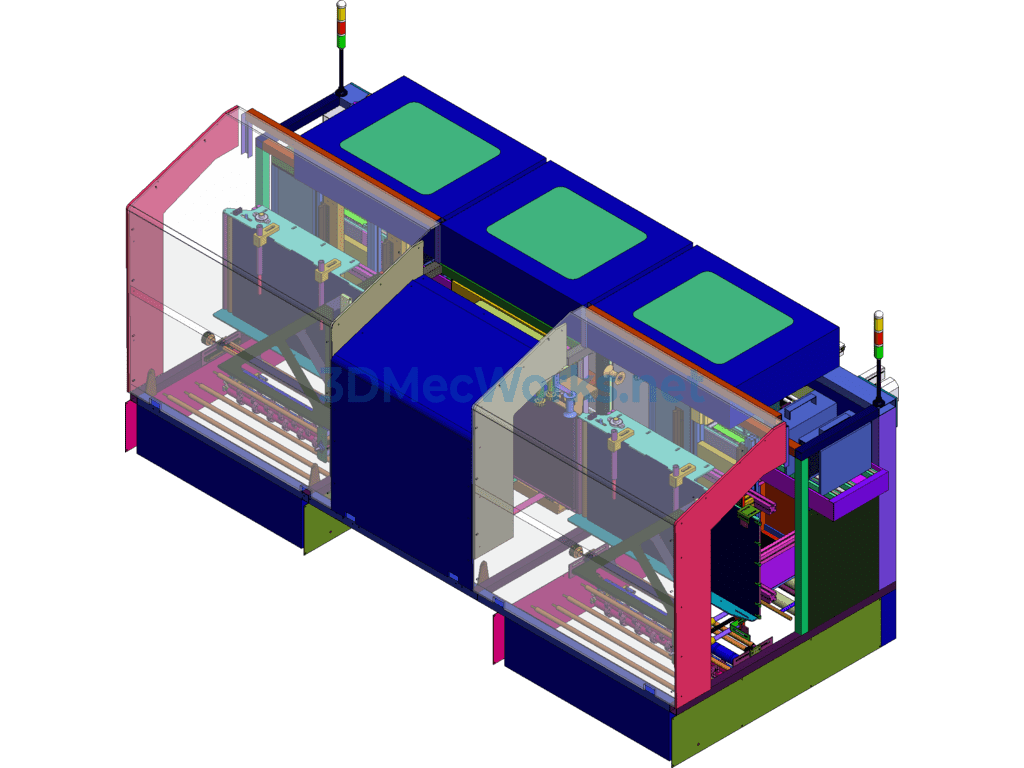

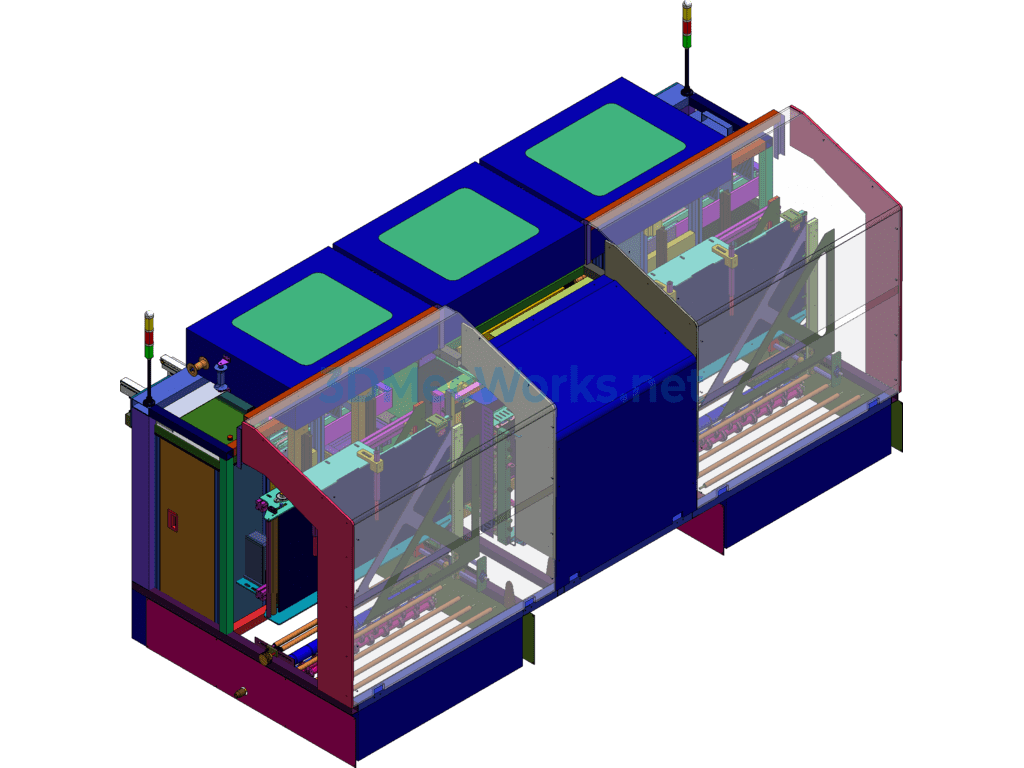

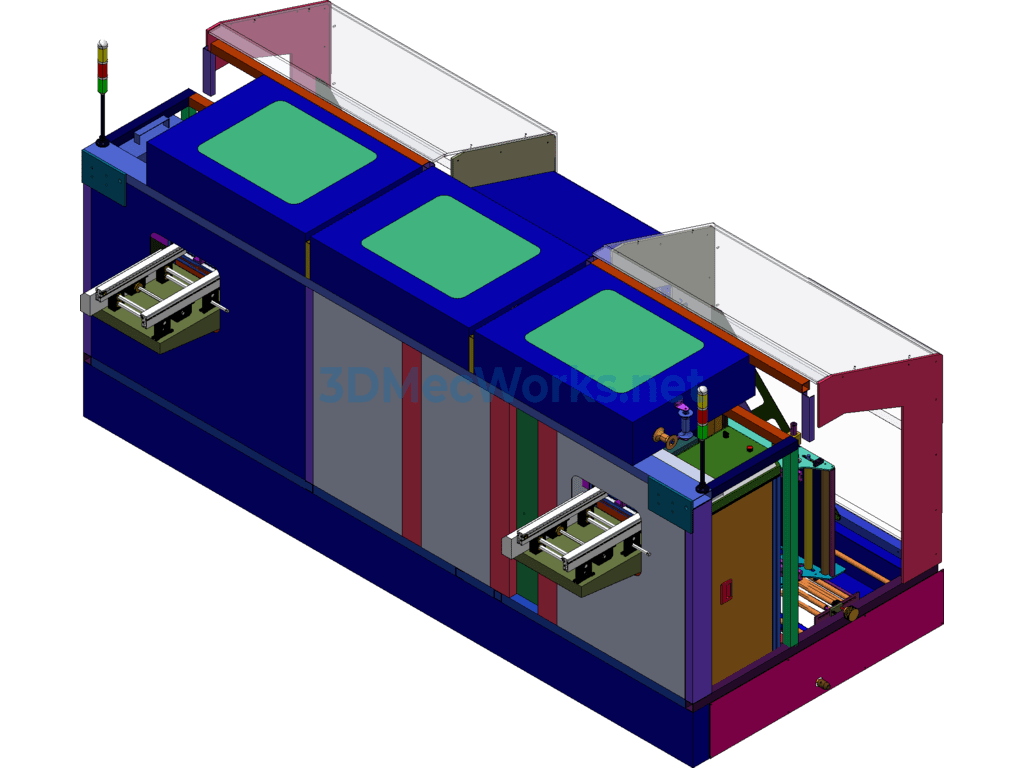

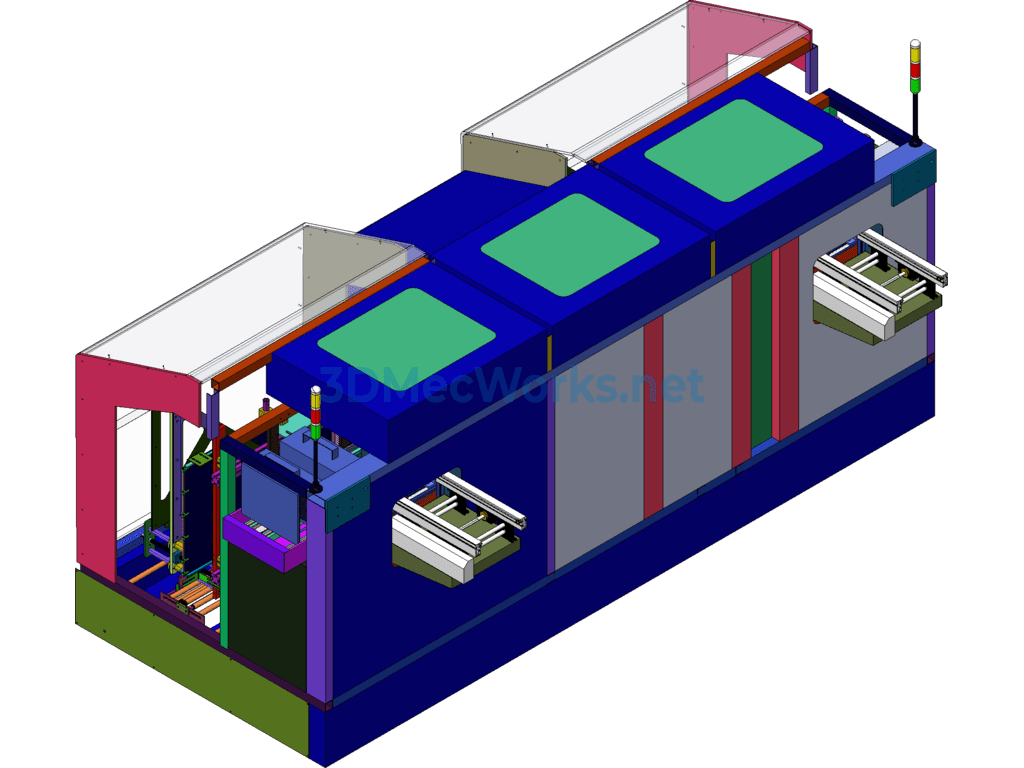

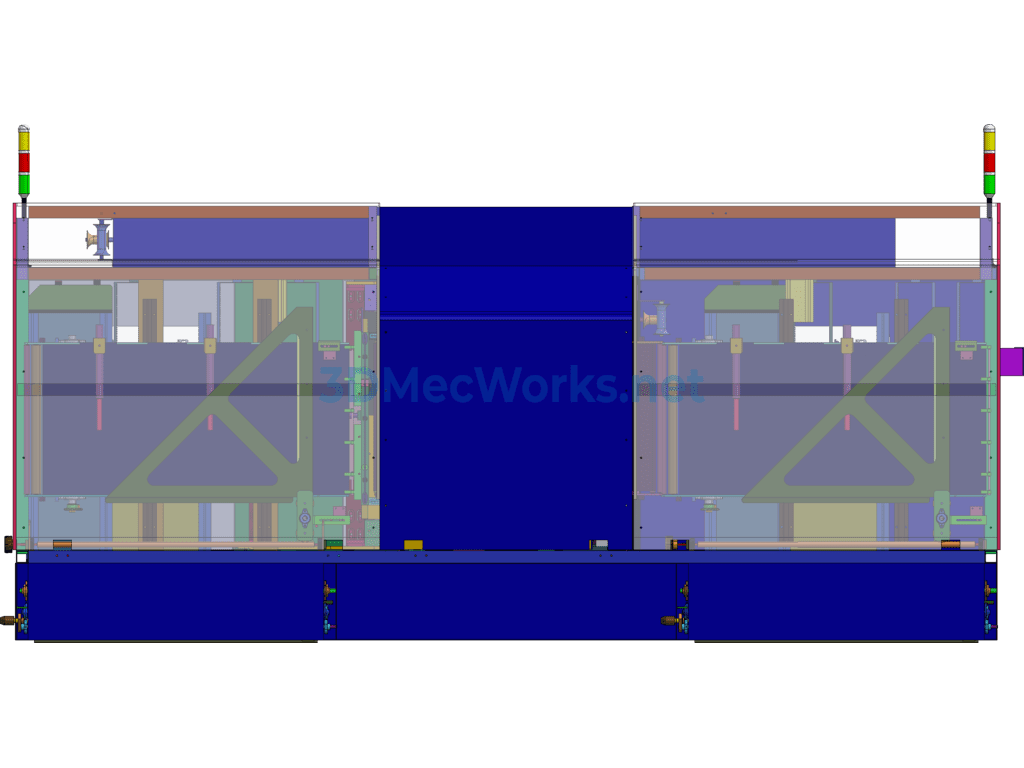

The mechanism of this equipment is designed using SW2016 and includes editable part features. Precision CNC winding controller wiring structure: external simply supported beam. Clamping mechanism: pneumatic powerful Morse long bearing span. Tension control: double row wheel with straightening tensioner. Wire diameter range (mm) 1.0-3.0, coil processing rotation diameter: 350mm, maximum speed (rpm): 140RPM, winding shaft number: 1, speed ratio 1:3, winding motor: 57 extended stepper motor, wiring width (mm): 210, power supply 220V/50HZ, floor-standing with base. High efficiency, stable performance, fully Panasonic servo motor control. Simply place the wiring and terminals to be produced in the specified position on the equipment, perform simple settings of product characteristics (wire specifications, product PIN number, product length, etc.) on the human-machine interface operation panel, press the start button, and the equipment can automatically complete the actions of wiring, feeding, dividing, cutting, peeling, feeding terminals, and crimping terminals according to the setting requirements, realizing continuous automated production. Includes STP and UG universal editable format.

Specification: Q16 Automatic Wiring Equipment a

|

User Reviews

Be the first to review “Q16 Automatic Wiring Equipment a”

You must be logged in to post a review.

There are no reviews yet.