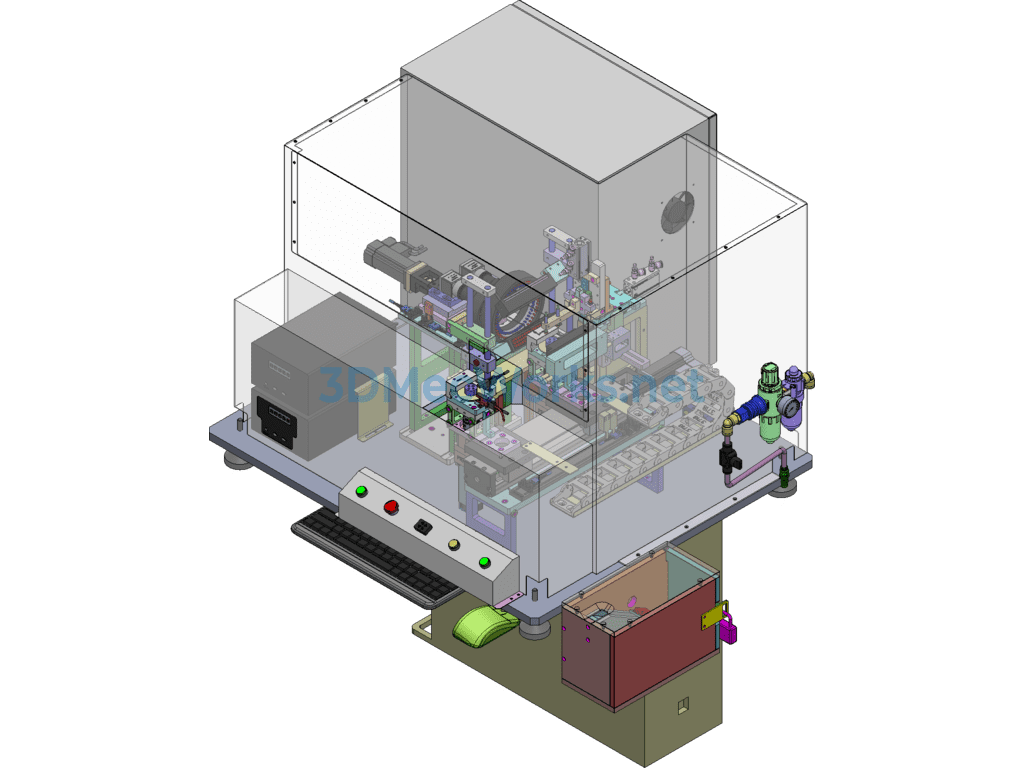

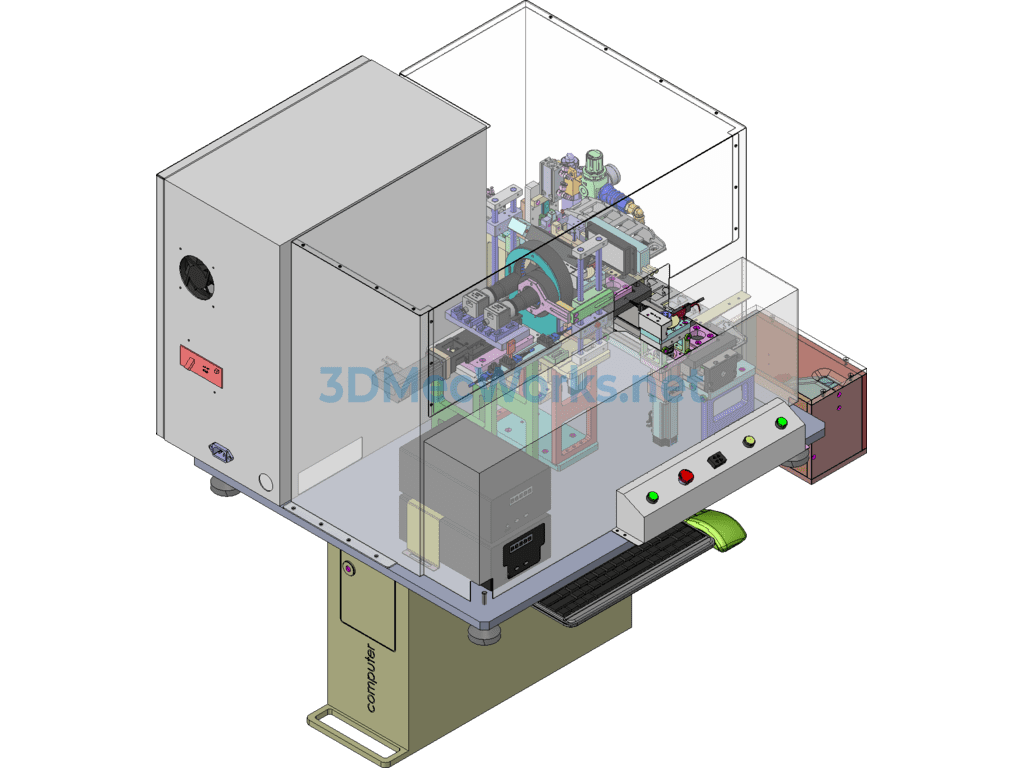

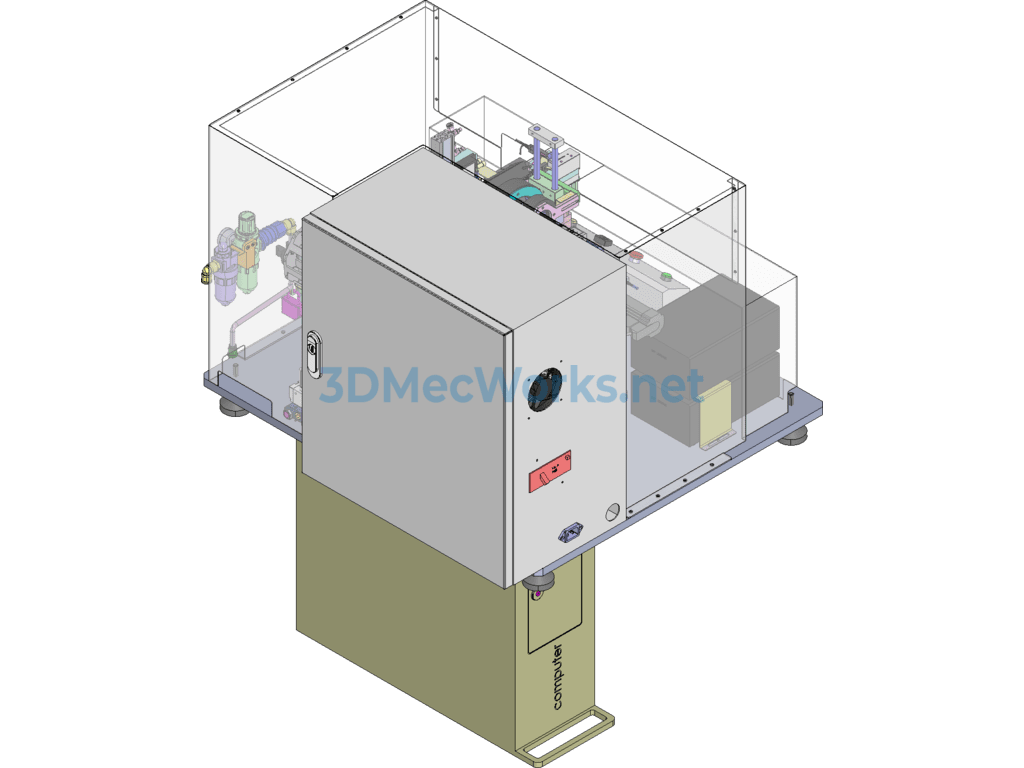

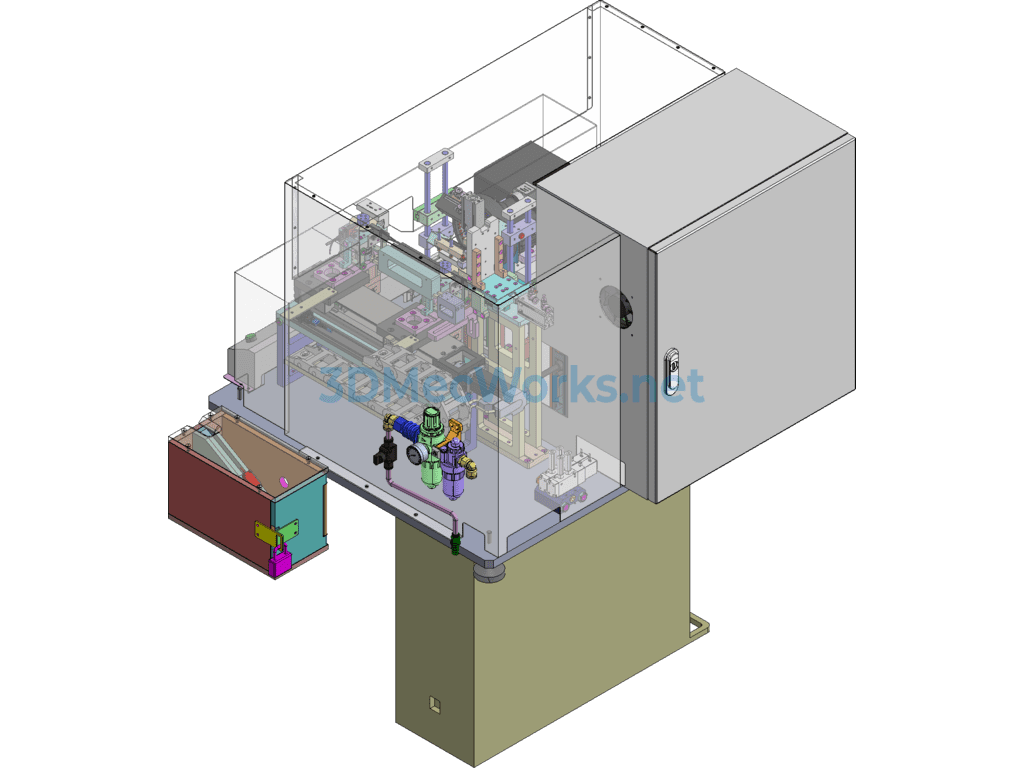

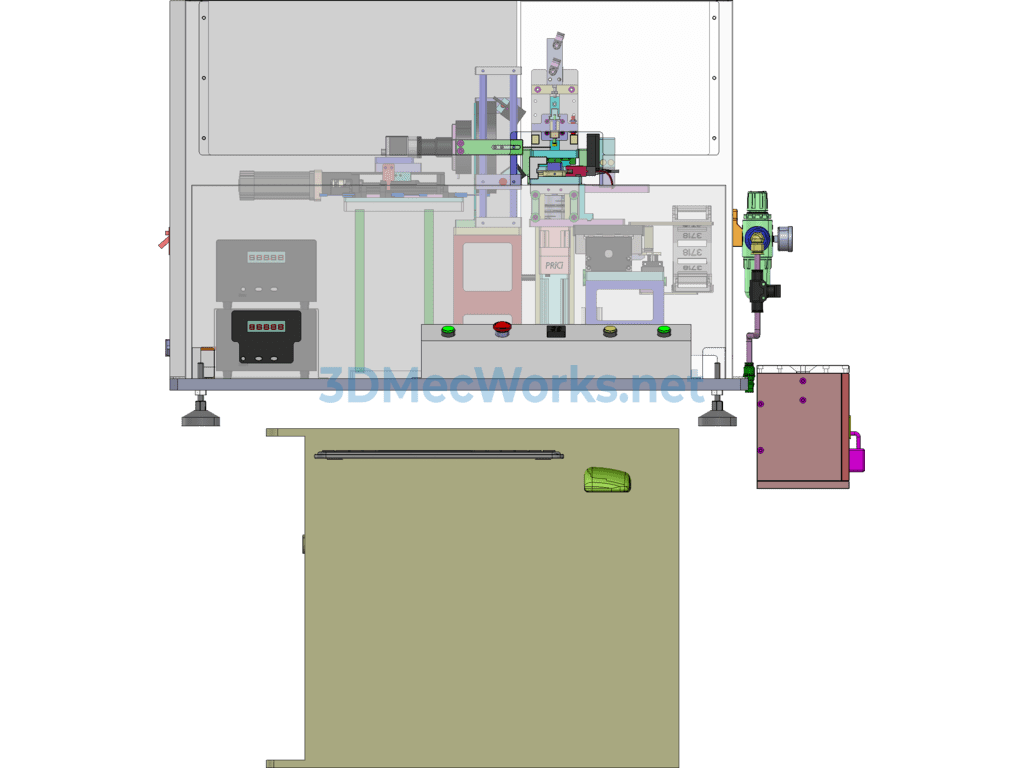

Overview of the Operating Process for Manufactured PIN Detection Equipment:

1. The product is manually loaded and positioned within the fixture to detect the 80 PINs of the product.

2. The product transfer module moves the fixture to the inspection station for positioning.

3. The CCD vision module checks whether the product PIN is installed correctly and detects defects.

4. Rotate to inspect the back side of the product after detection.

5. After completion, the product is manually removed.

Specification: Produced Pin Inspection Assembly Drawing (including Dfm, Bom)

|

User Reviews

Be the first to review “Produced Pin Inspection Assembly Drawing (including Dfm, Bom)”

You must be logged in to post a review.

There are no reviews yet.