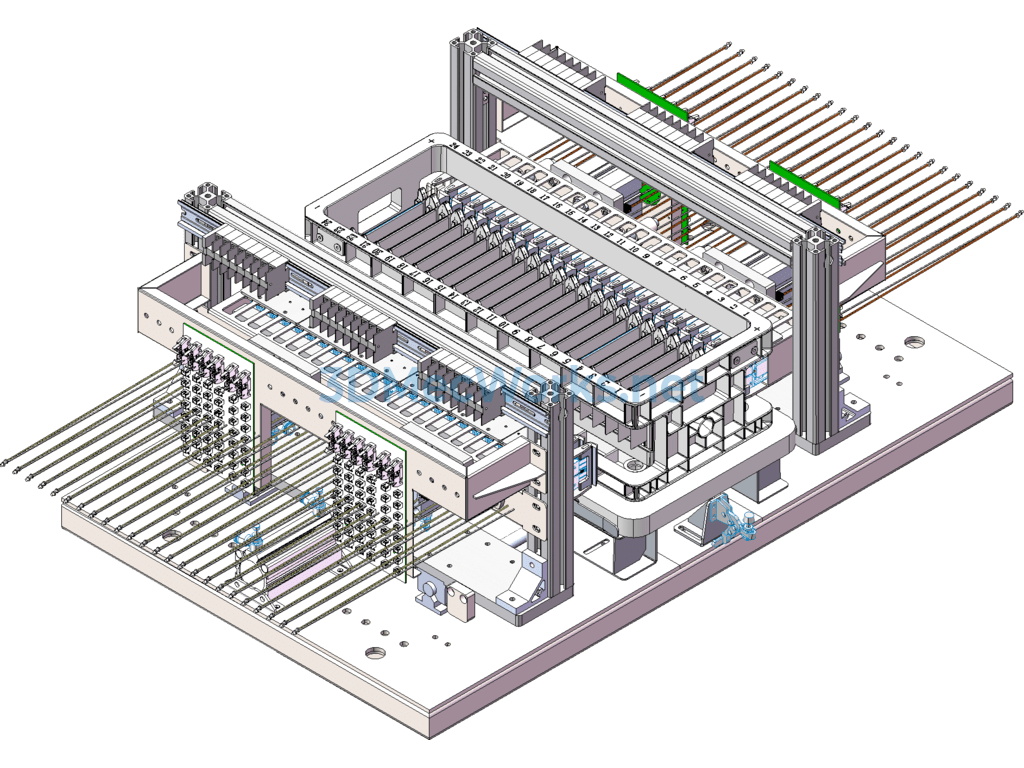

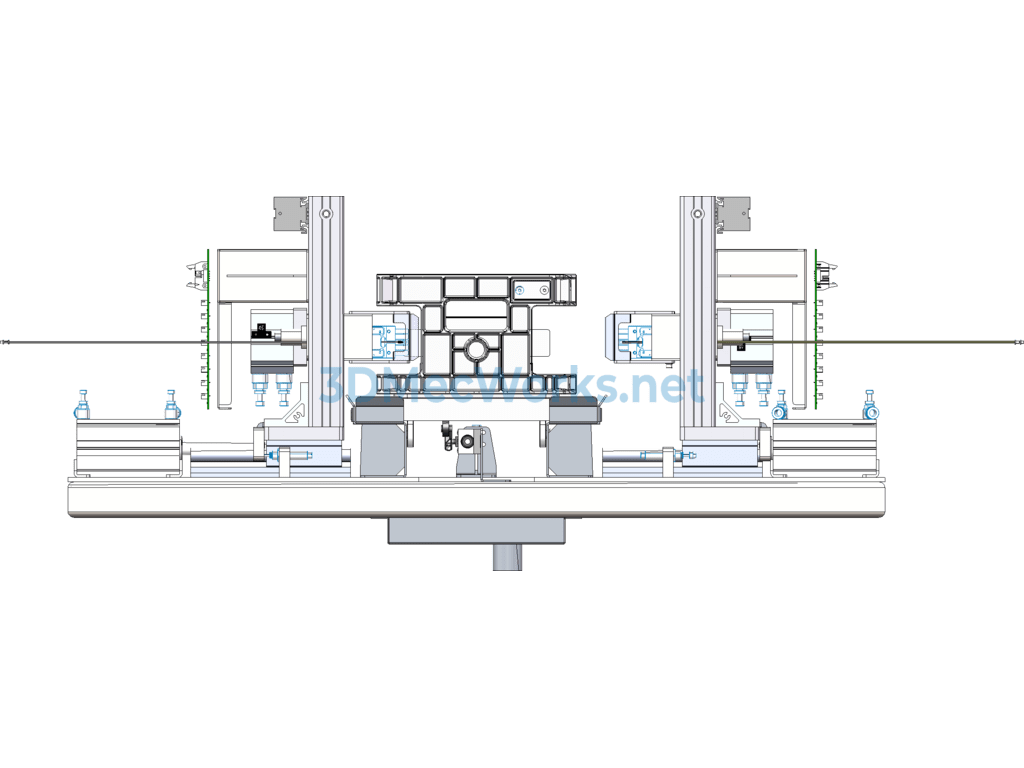

The soft pack battery fixture model is mainly used in soft pack battery processing equipment. Through special design, it completes the battery feeding and clamping function. The 3D design is clear and has strong practicality. This bed of needles structure is aimed at the automation of formation and capacity grading in the polymer (soft pack) battery workshop. The battery can have unilateral double tabs, two columns on the left and right, and four sets of units in the front and rear. The fixture employs a single pressing method, moving horizontally to the battery tray position. The front and rear clamps and stops apply force to press the battery tabs for charge and discharge. The solenoid valve is controlled by PLC to operate the cylinder, and the sensor controls the travel to the end position. The mechanical proximity switch senses the tray’s position. The fixture line connects to the terminal blocks, forming a modular structure with temperature sampling, smoke sensing alarm, and even fire protection design.

For prismatic lithium battery formation and capacity grading fixtures, the battery is handled using a constrained method. During the formation process, the battery body reduces expansion. The fixture part uses quick clamp operations, reducing labor intensity for personnel. The modular design enhances rationality and efficiency.

Specification: Pouch Cell Fixture, Tab Capacity Grading Fixture

|

User Reviews

Be the first to review “Pouch Cell Fixture, Tab Capacity Grading Fixture”

You must be logged in to post a review.

There are no reviews yet.