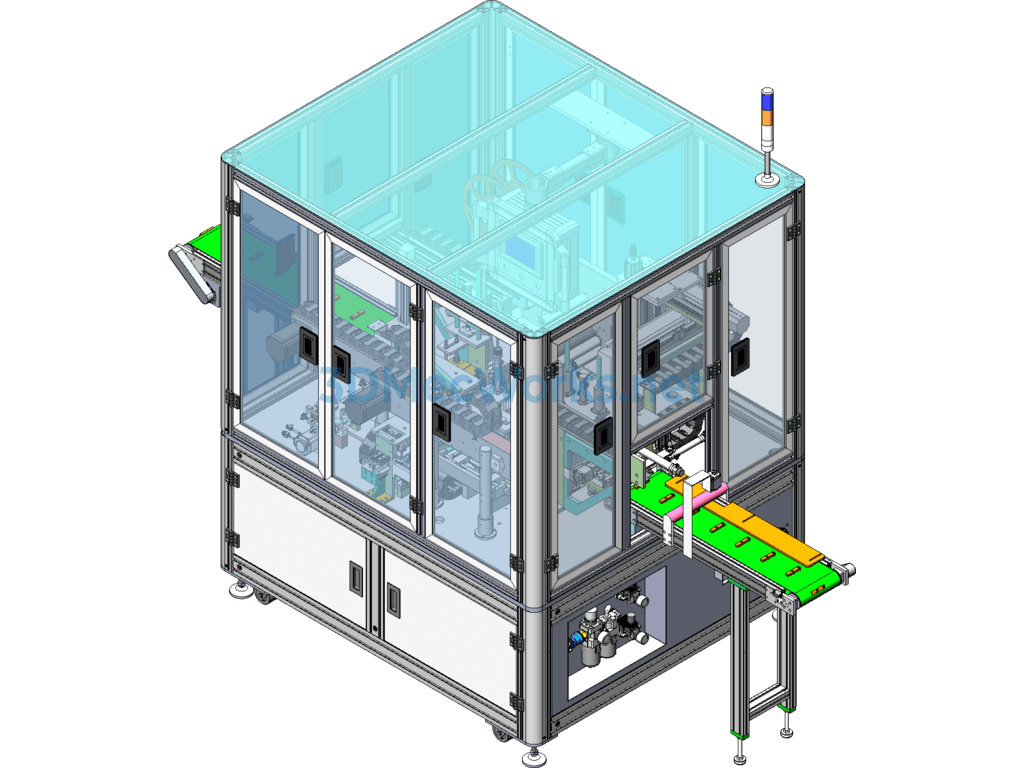

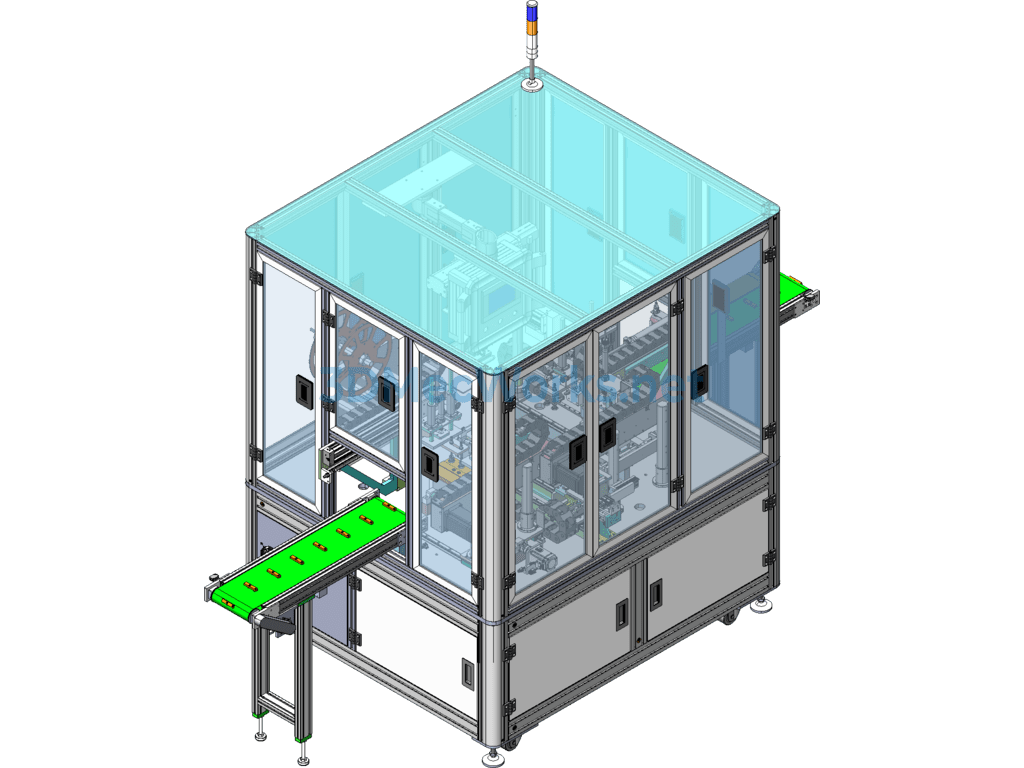

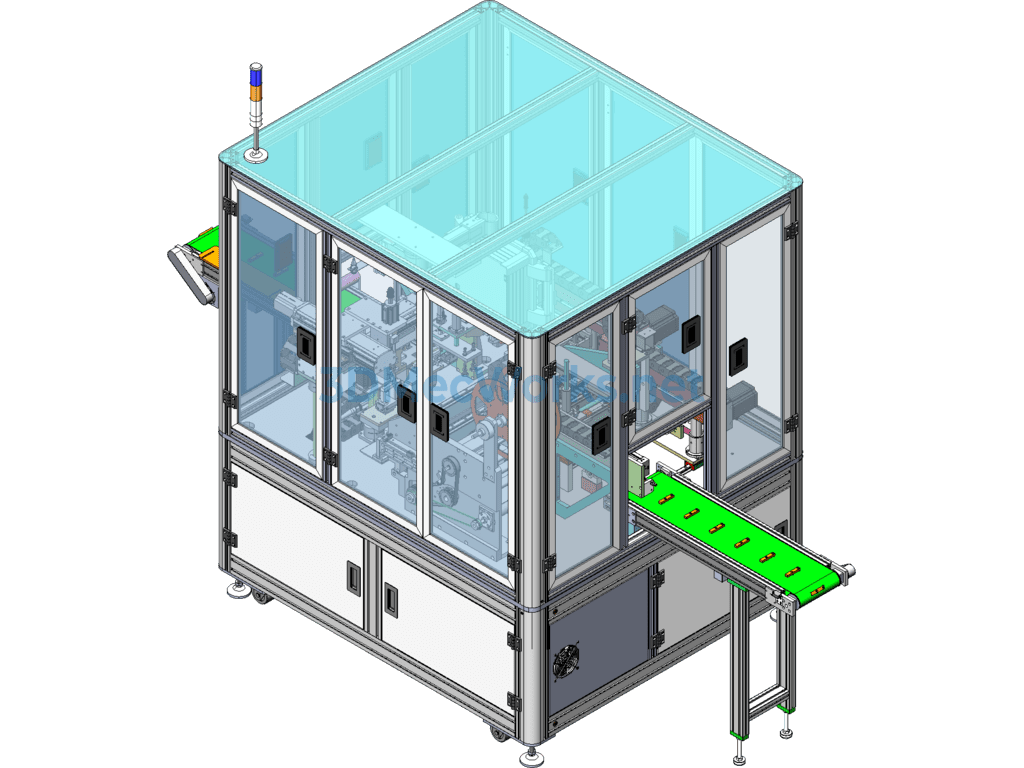

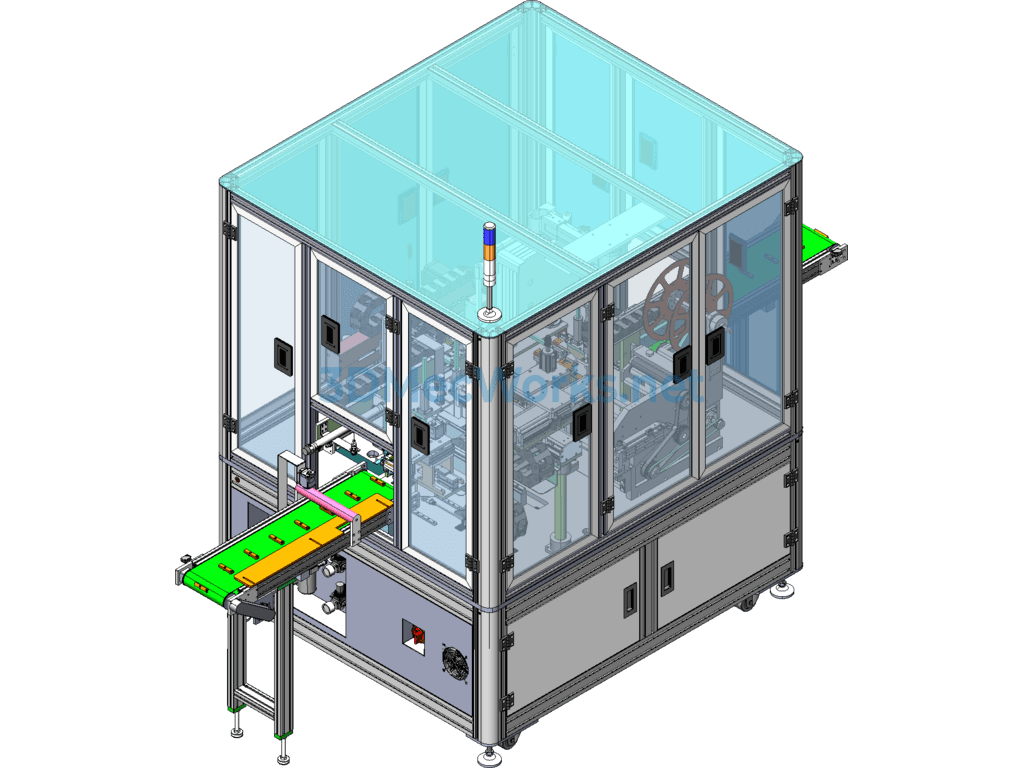

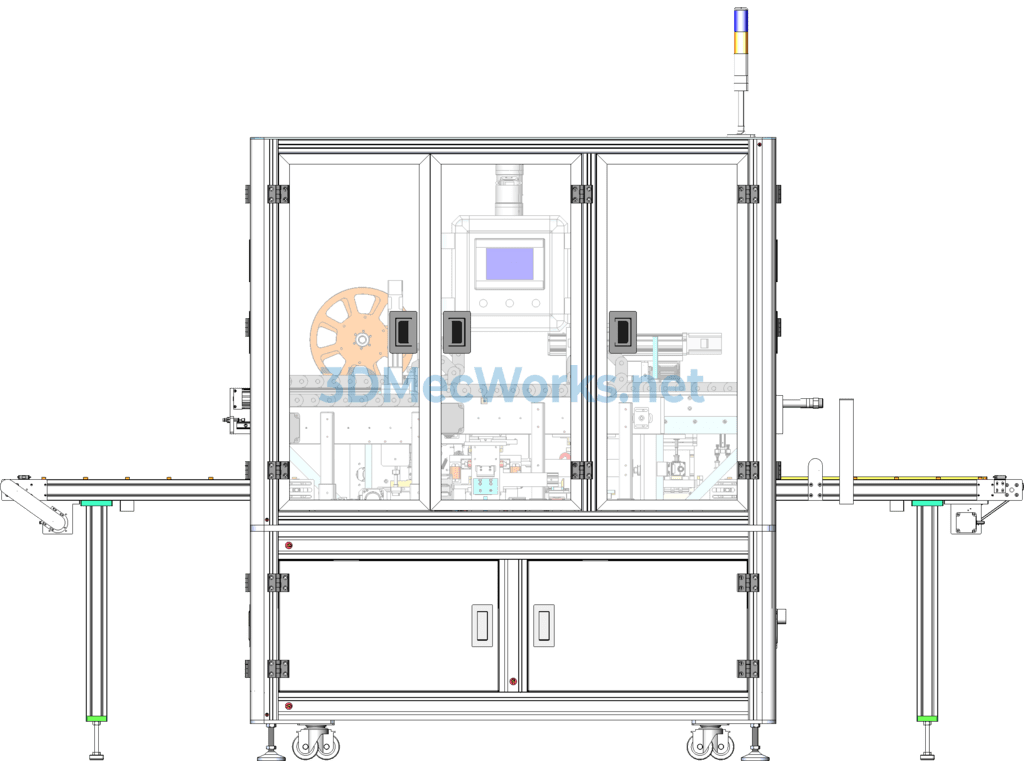

This equipment is dedicated to shaping, pressing glue, and labeling soft-pack polymer batteries. The operator manually places the battery on the production line and presses the start button, initiating the process of battery orientation testing at the CCD testing station. If the CCD inspection passes, the battery directly proceeds to the de-dusting mechanism and flows into the equipment. If the battery is incorrectly oriented, the equipment triggers an alarm, prompting the operator to correct the battery orientation and press the start button again. The battery then passes through the de-dusting mechanism into the equipment. The loading and unloading manipulator picks up the battery and places it in the shaping mechanism to process both sides of the battery, followed by another CCD inspection. The battery is then placed in a positioning and labeling fixture. The motor drives the fixture to move to the labeling position. The label supply feeder dispenses the label. The X, Y, Z, and W four-axis manipulator picks up the label, and the CCD performs a visual inspection of the label’s position. The information is transmitted to the system, which instructs the X, Y, Z, and W four-axis manipulator to correct any deviation. The manipulator moves to the labeling position and applies the label to the battery. The shaping station returns to its designated point. The labeling mechanism fixture releases, and the Z-direction cylinder pushes the battery upward. Rolling wheels on both sides wrap the battery, and the folding manipulator takes the battery to the folding station. First, the roller flattens the battery tab with adhesive. After the CCD visual inspection is OK, the tab edge is folded, followed by folding the bottom two tabs, and finally the bottom edge wrapping. After completion, the manipulator transfers the battery to the unloading production line. Designed with SOLIDWORKS 2018.

Specification: Polymer Battery Shaping and Labeling Machine

|

User Reviews

Be the first to review “Polymer Battery Shaping and Labeling Machine”

You must be logged in to post a review.

There are no reviews yet.