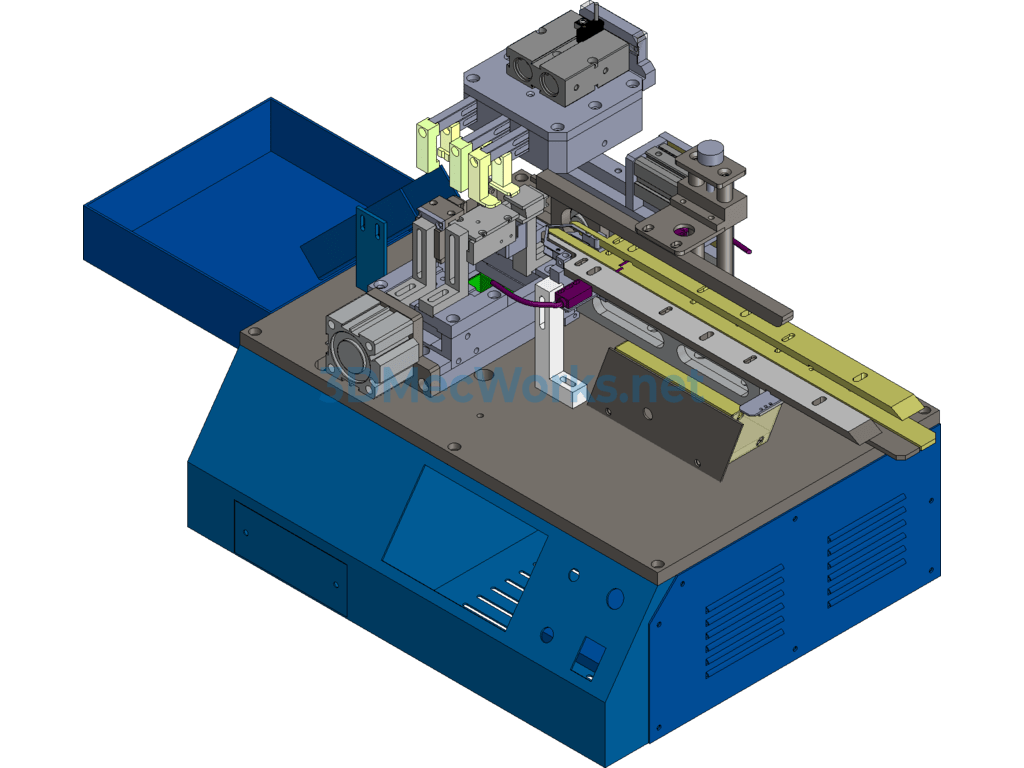

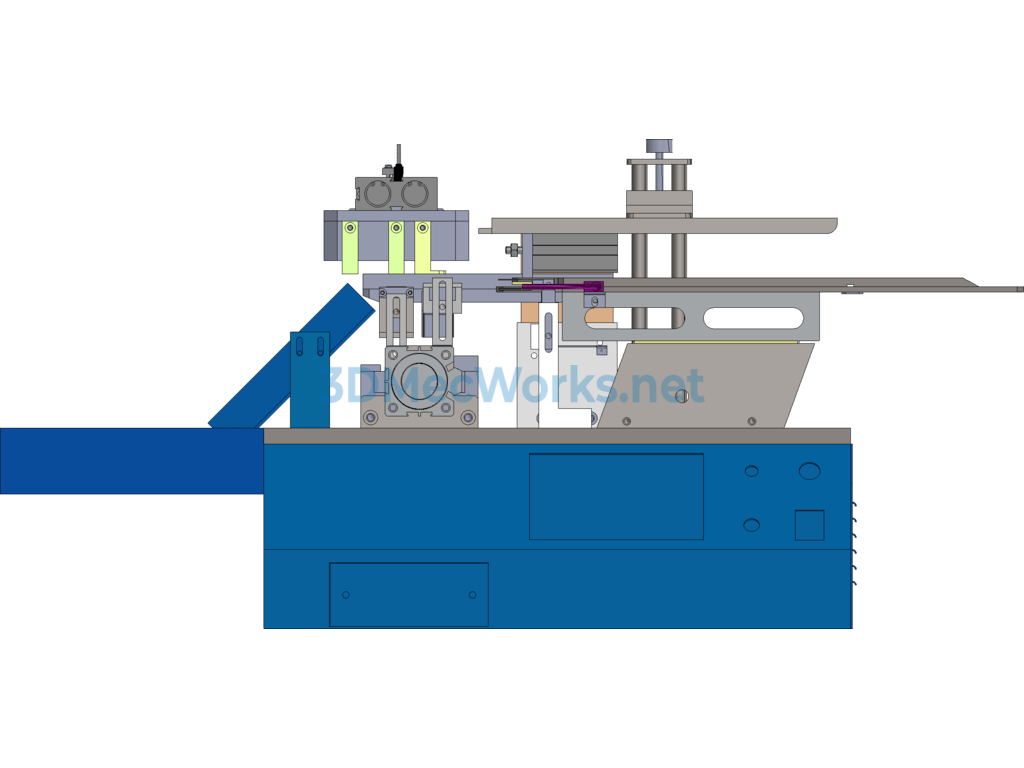

Pneumatic Bulk Capacitor Forming Machine Equipment Specifications

Power Supply: 110V/200VAC 60HZ/50HZ

Dimensions: L500 x W400 x H400mm

Speed: 4000pcs/h

Weight: 50kgs

Power: 60W

Air Pressure: 4-6kg/cm²

Equipment Features

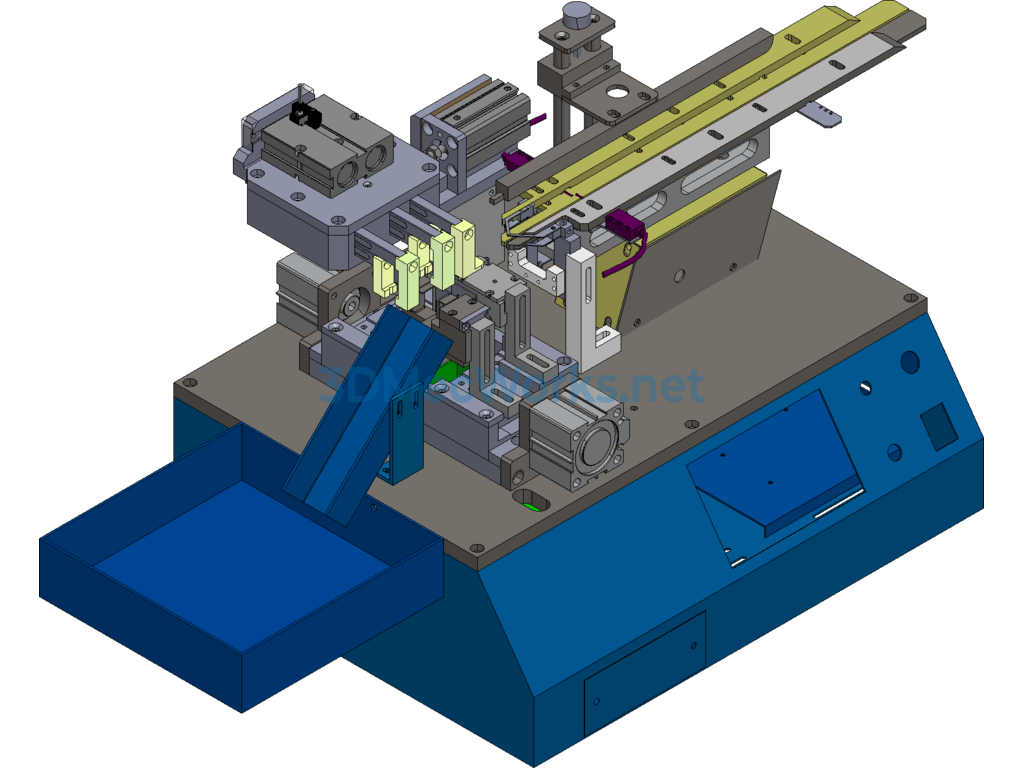

This machine adopts the Japanese Sanro PLC control system, equipped with a human-machine dialogue interface touch screen, featuring user-friendly design and simplicity of operation.

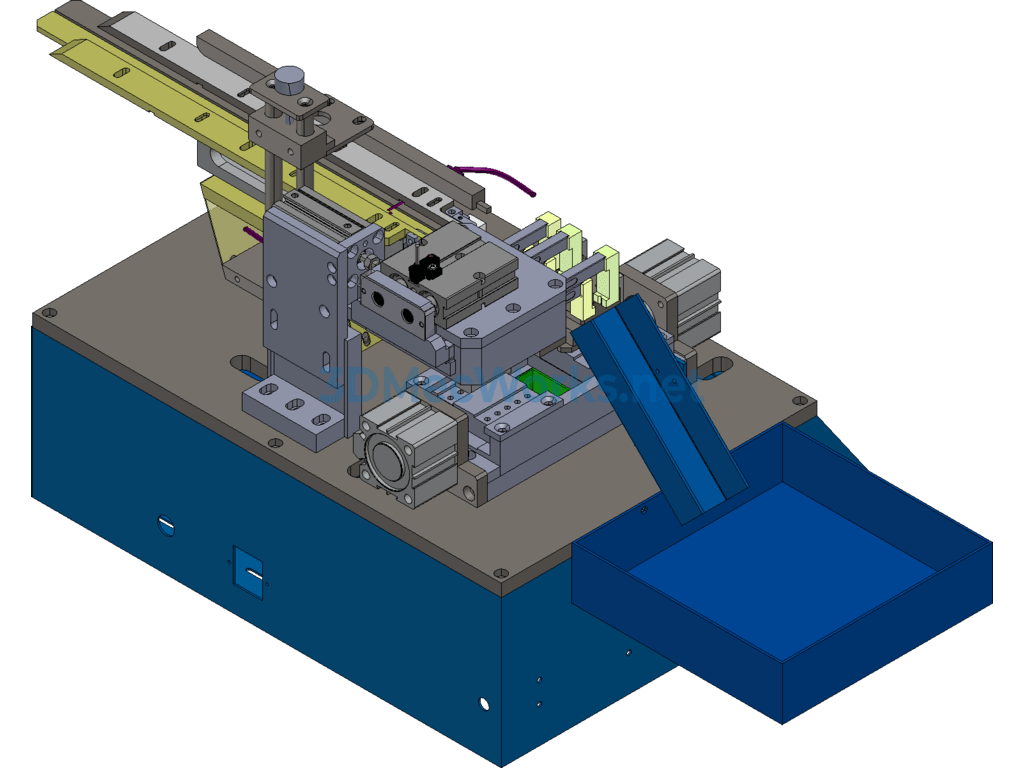

Suitable for LED, electrolytic capacitors, transistors, safety capacitors, metallized film capacitors, and quartz radial components.

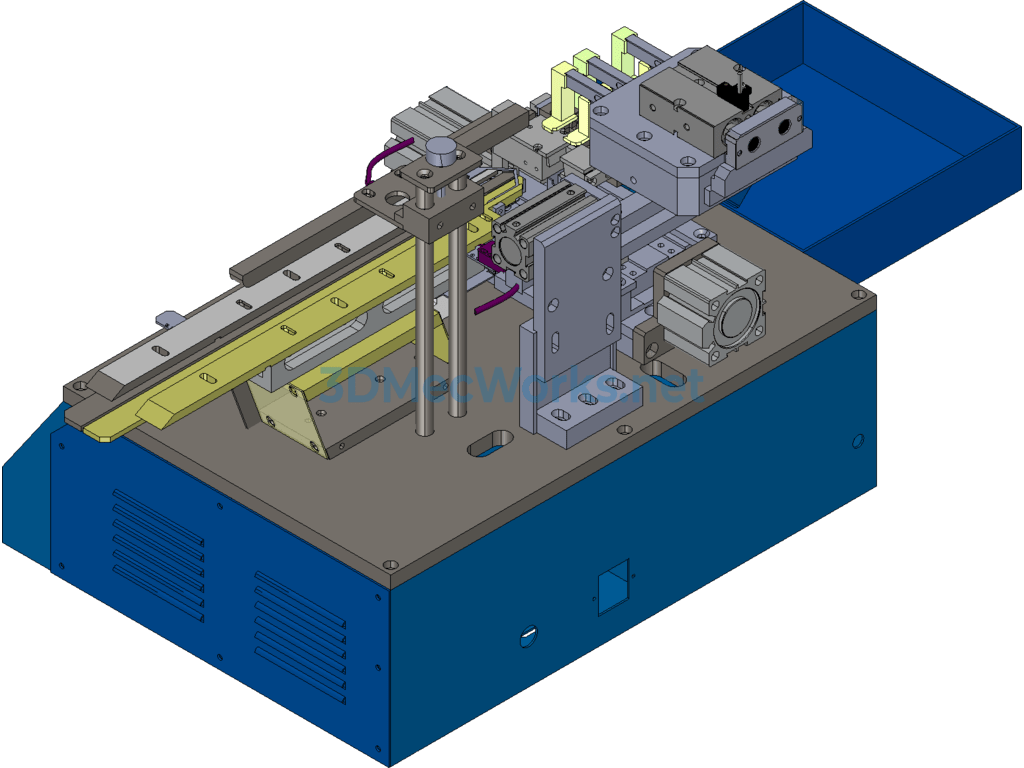

The imported cam transmission mechanism is precise, stable, durable, and low-noise. All parts are specially hardened for long service life.

Forming shapes: bend 90 degrees, inner bend, outer bend, forward and backward bend, punch K, long and short legs, etc., customizable based on customer requirements.

The vibrating tray automatically feeds the material, completing processes such as clamping, leg aligning, polarity testing, direction change, secondary testing, material discarding, leg cutting, and forming in one go. Additional processes can be added for special requirements.

The machine uses combination-type molds that allow for quick and easy changes; each set of molds is independently adjustable, and the tools and molds are made from imported Japanese steel.

Elastic rack pickup clamp ensures secure clamping without damaging the components themselves, and parts of similar sizes do not require changing the material clamp.

Specification: Pneumatic Bulk Capacitor Forming Machine

|

User Reviews

Be the first to review “Pneumatic Bulk Capacitor Forming Machine”

You must be logged in to post a review.

There are no reviews yet.