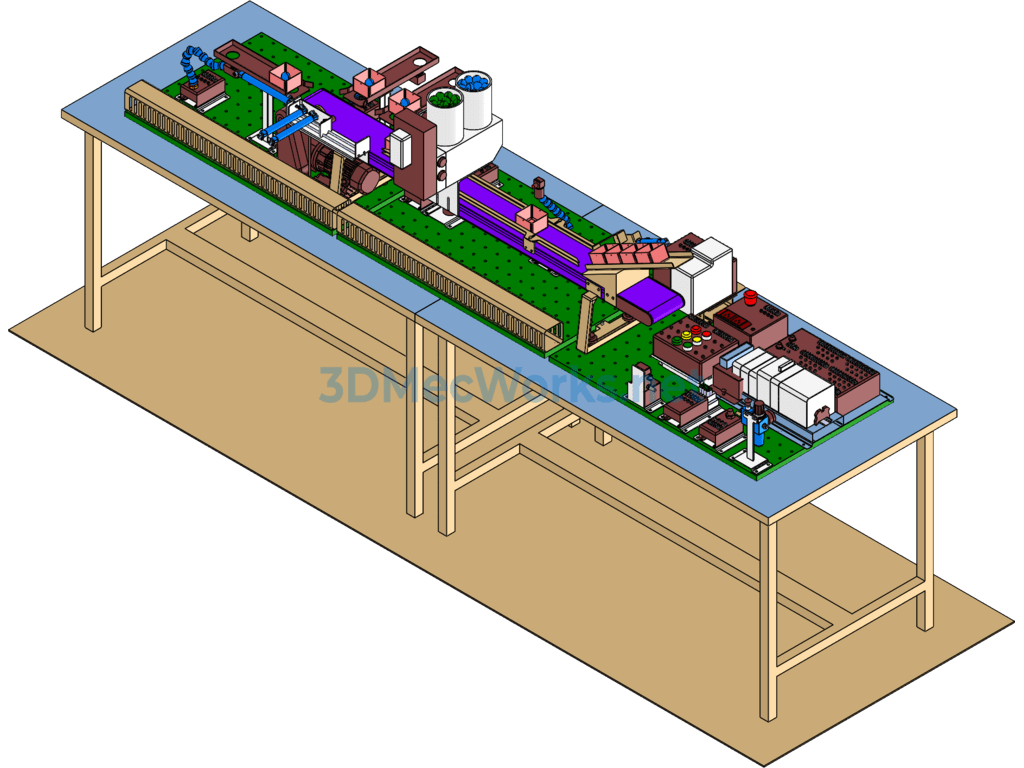

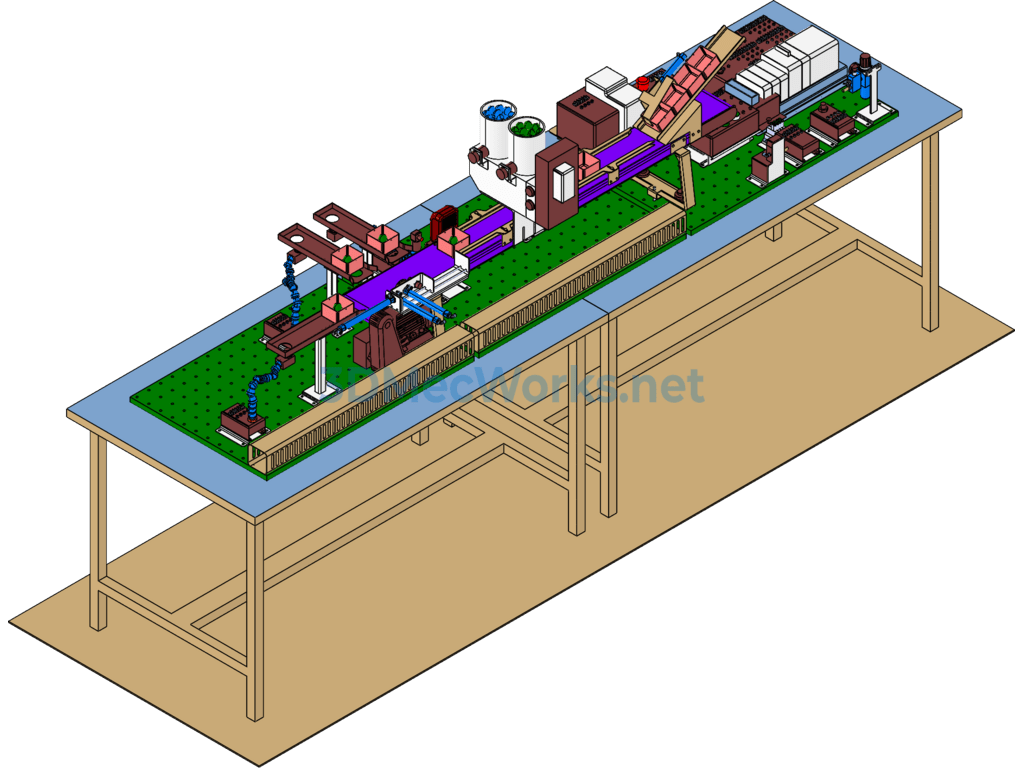

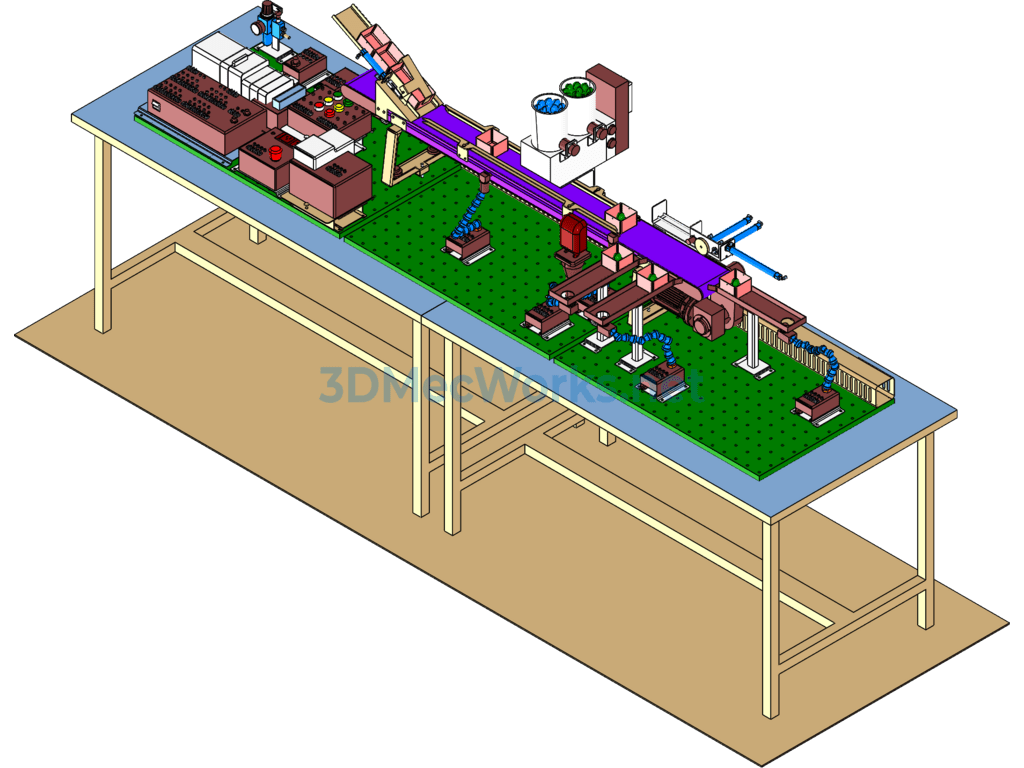

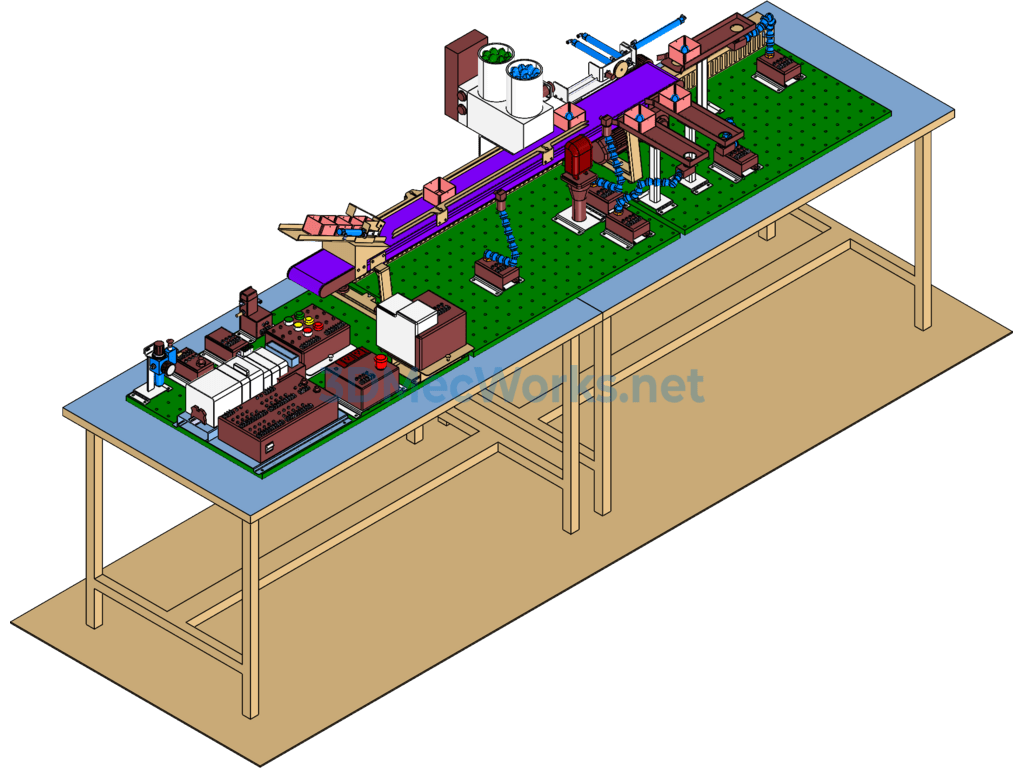

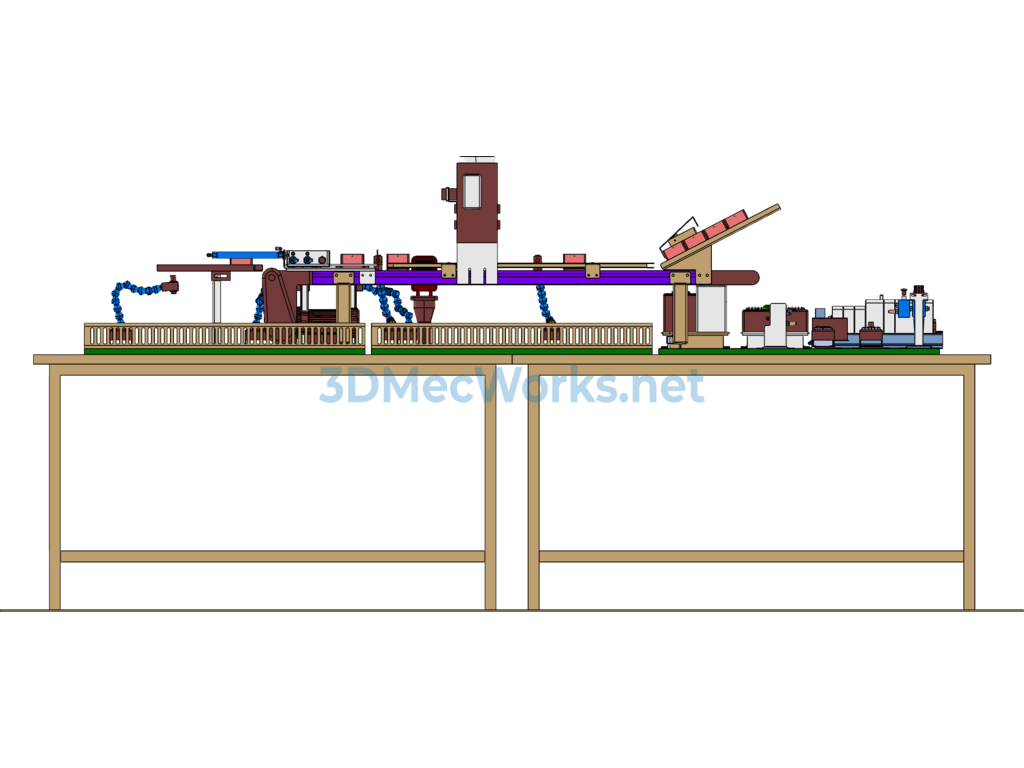

PCB Soldering Machine Equipment Design Model

This is a design drawing of equipment used for PCB circuit board soldering, employing high-energy laser pulses to locally heat small areas of material. The energy from laser radiation diffuses into the material through heat conduction, melting the material to form a specific molten pool. This is a new type of welding method. Laser welding primarily targets thin-walled materials and the welding of precision parts, capable of achieving spot welding, butt welding, overlap welding, and seal welding, among others. It features a high depth-to-width ratio, narrow weld seam width, small heat-affected zone, minimal deformation, fast welding speed, smooth and aesthetically pleasing weld seams, and requires no post-treatment or only simple post-treatment. The weld quality is high, with no porosity, precise control, small focus spot, high positioning accuracy, and is easily automated.

Specification: Pcb Soldering Machine Equipment Design Model

|

User Reviews

Be the first to review “Pcb Soldering Machine Equipment Design Model”

You must be logged in to post a review.

There are no reviews yet.