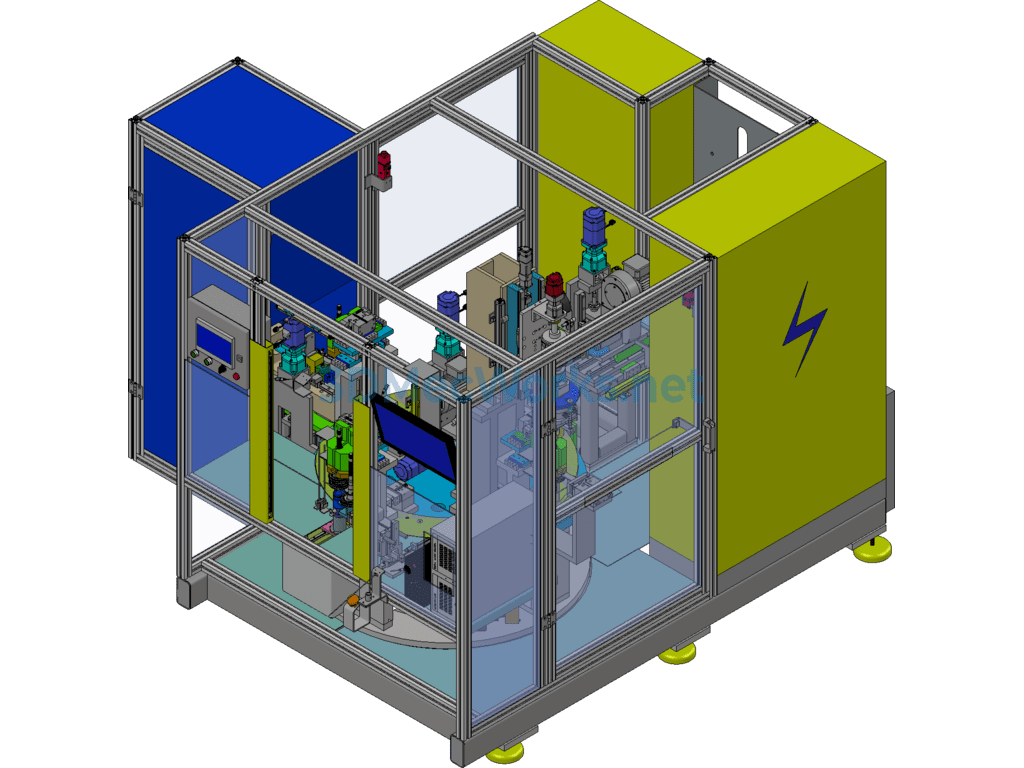

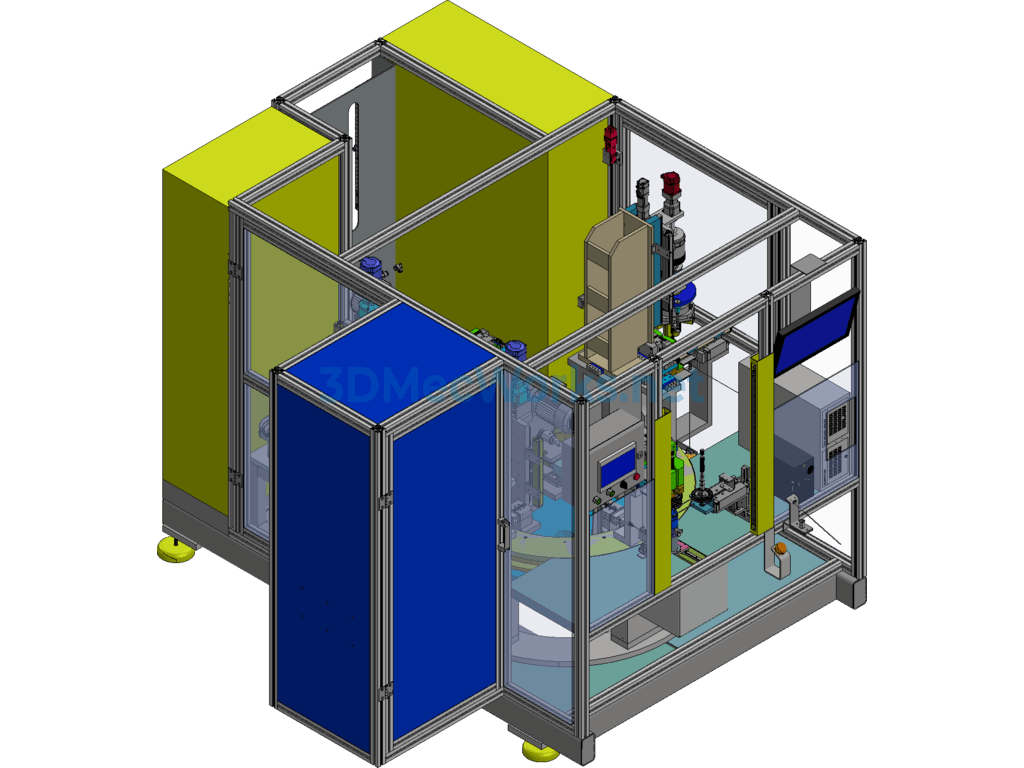

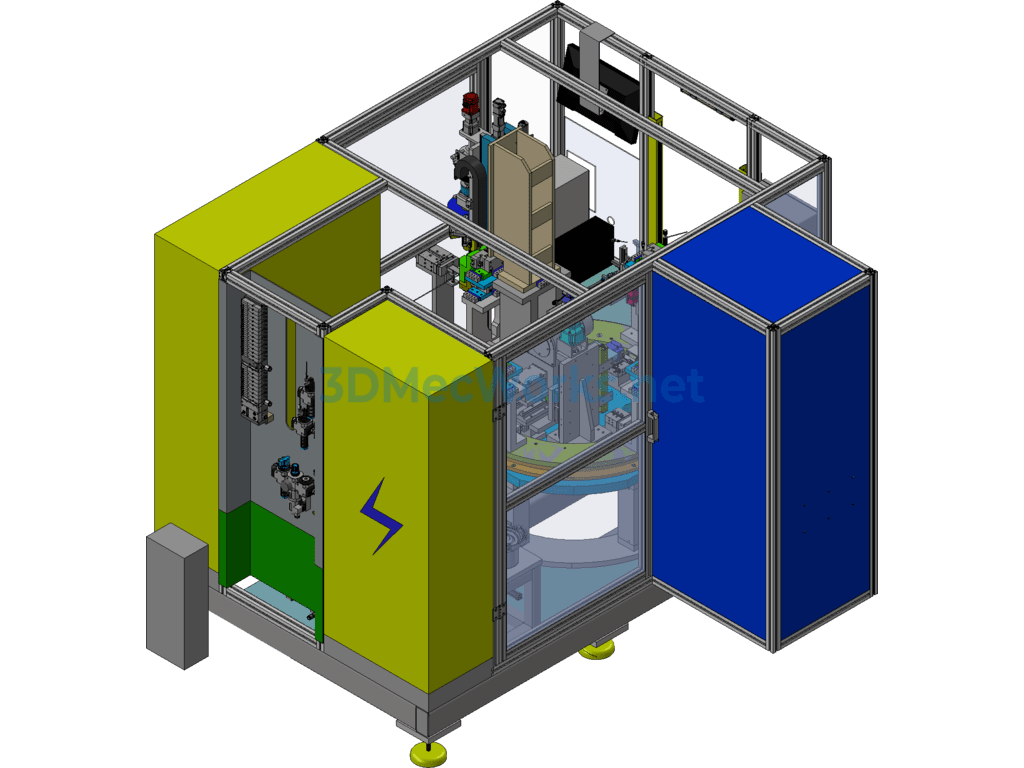

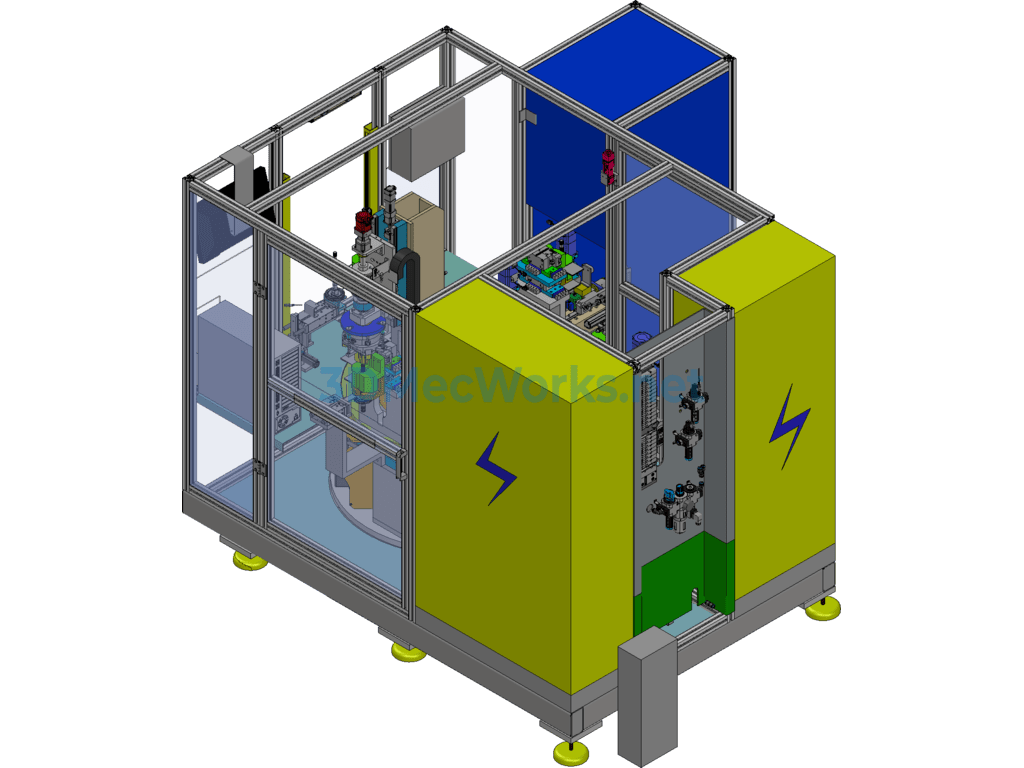

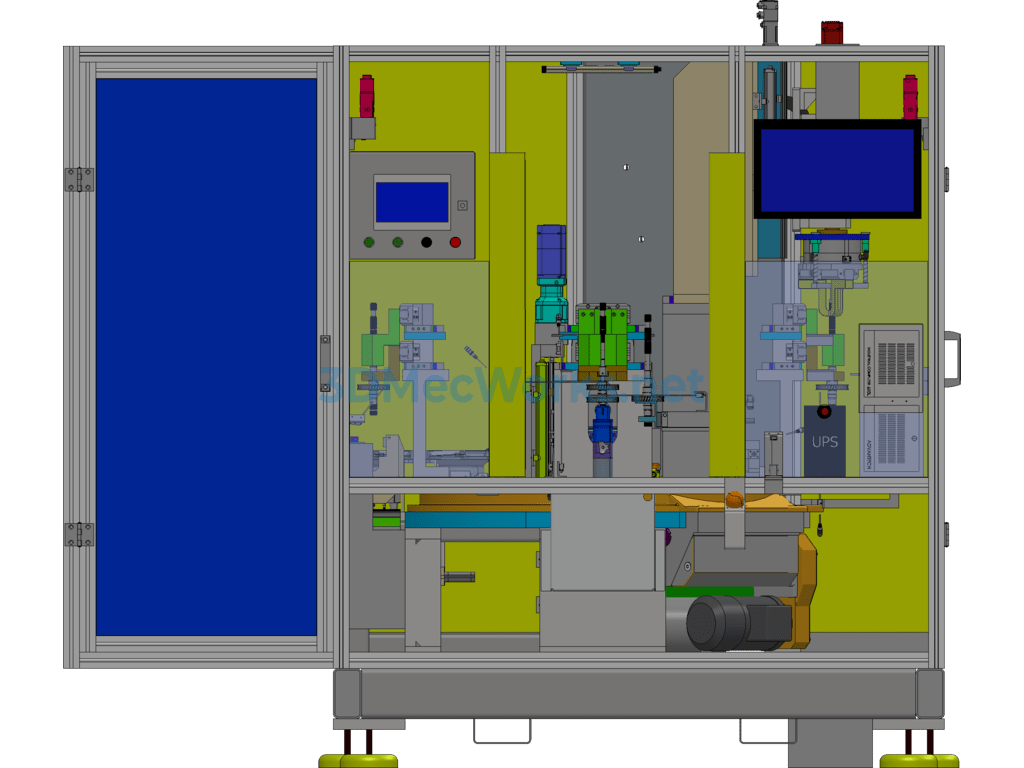

OP40 Output Shaft Drilling and Pinning

1. Purpose: Assemble the output shaft with the lower part of the input shaft, align, drill and ream the hole, insert the pin, and press fit;

2. Compatible Products:

3. Equipment Specifications: 2000mm(W)x2000mm(L)x 2000mm(Aluminum Profile H).

4. Equipment Color: RAL7035

5. Production Cycle Time: ≤ 45s

6. Equipment Technical Parameters

6.1 Equipment Power: 20kw;

6.2 Air Supply: ≥ 0.5Mpa clean, oil-free, and dry compressed air source. Air consumption: 10 liters/min.

6.3 Equipment Operation Mode: Loading/unloading performed by operator (manual), part positioning, drilling, pin insertion, and press fitting are automatically completed;

6.4 Pressing Force Monitoring: Range 30KN, precision 1% R.O; holding time not less than 3 seconds; bearing and lead screw lifespan ≥ 10 million times.

6.5 Press Depth Control: precision 0.02mm; includes displacement control and can connect to high-precision displacement sensor externally.

6.6 Press Fit Judgment: Whether pressure and displacement are within qualified range.

6.7 Model Changeover: Jigs and fixtures requiring replacement are placed below the equipment on a specially designed tray.

6.8 Calibration Standard Parts: Equipment is provided with special tools for correcting equipment coaxiality and displacement, stored in dedicated utensils, which are fixed on the equipment.

6.9 Equipment CPK ≥ 1.33

Specification: Output Shaft in Op40 With Drilled and Pinned Connection

|

User Reviews

Be the first to review “Output Shaft in Op40 With Drilled and Pinned Connection”

You must be logged in to post a review.

There are no reviews yet.