Sandblasting is the process of cleaning and roughening the surface of a substrate using the impact of a high-speed sand stream. Compressed air is used as the power to form a high-speed jet stream that sprays the abrasive materials (such as copper ore sand, quartz sand, emery, iron sand, and Hainan sand) at high speed onto the surface of the workpiece that needs to be treated, causing changes to the external surface or shape of the workpiece. Due to the impact and cutting action of the abrasive on the workpiece surface, the surface achieves a certain degree of cleanliness and a different level of roughness. This improves the mechanical properties of the workpiece surface, thereby enhancing its fatigue resistance, increasing adhesion between it and coatings, extending the durability of the coating film, and also benefiting the leveling and decorative properties of the coating.

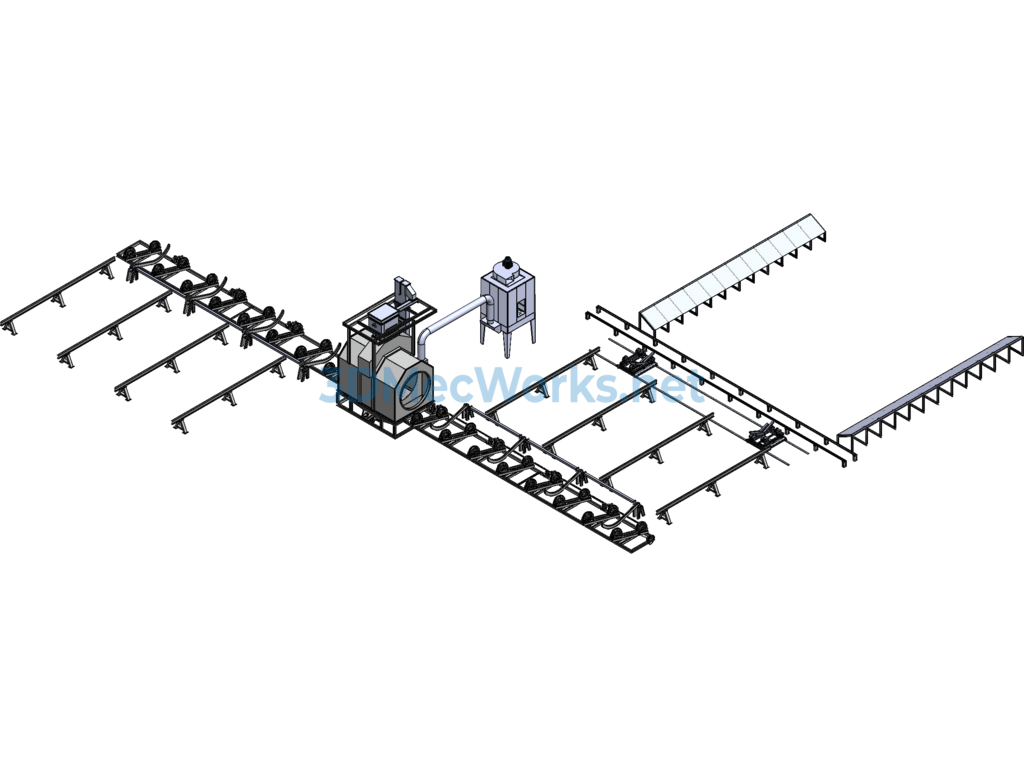

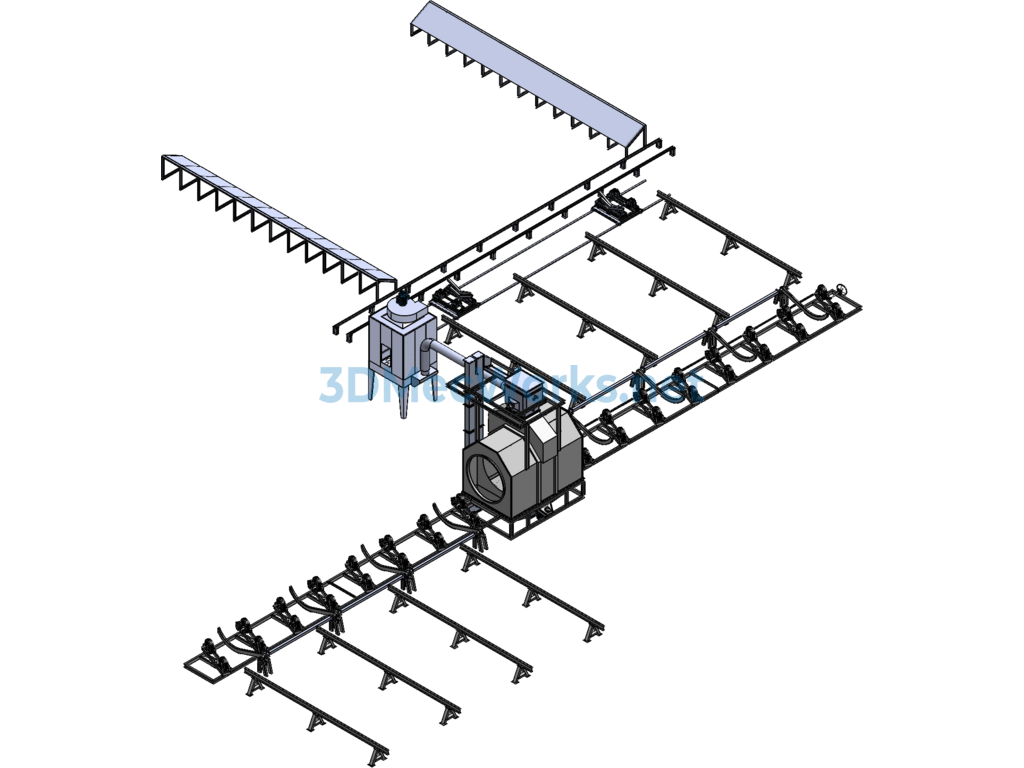

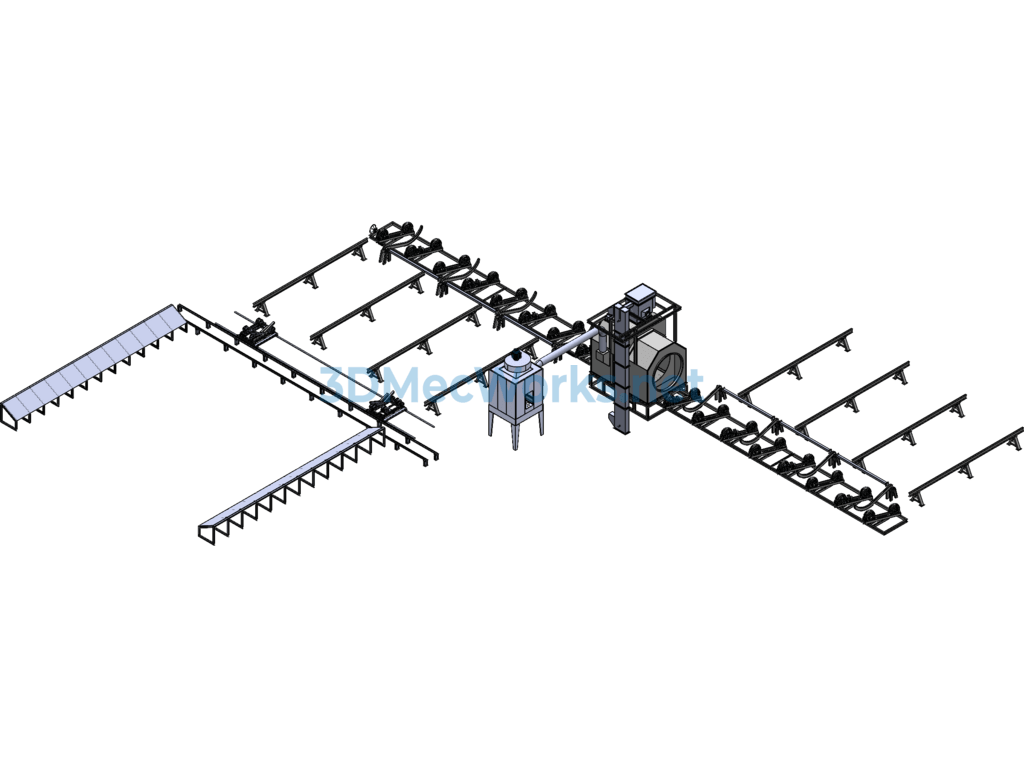

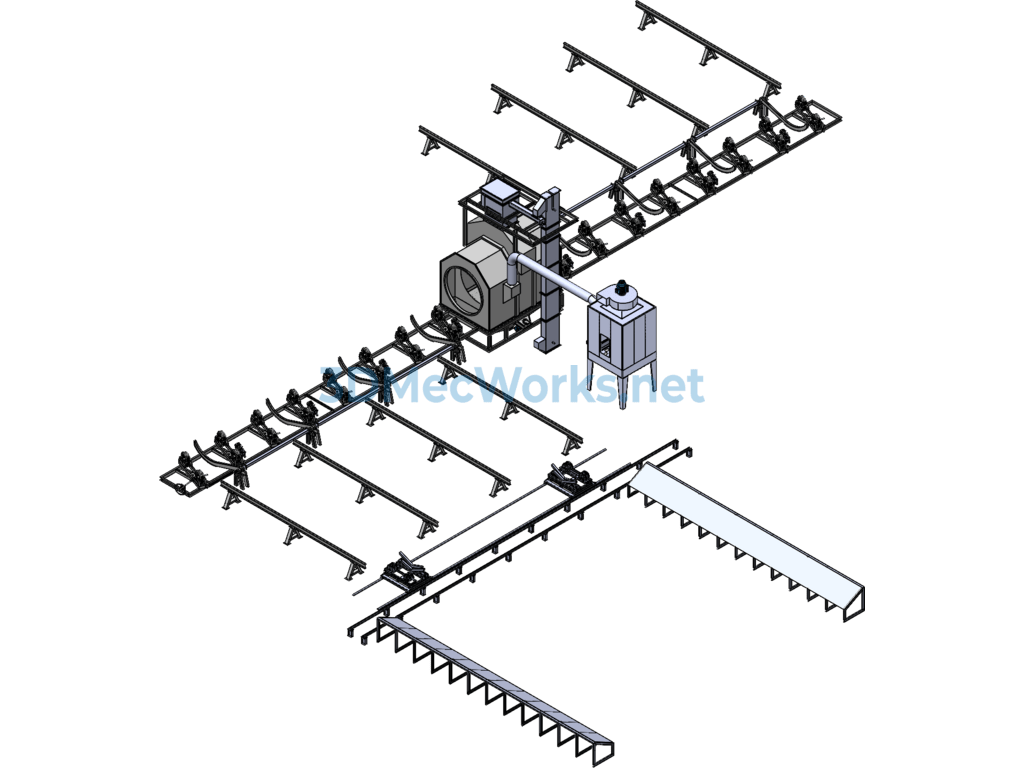

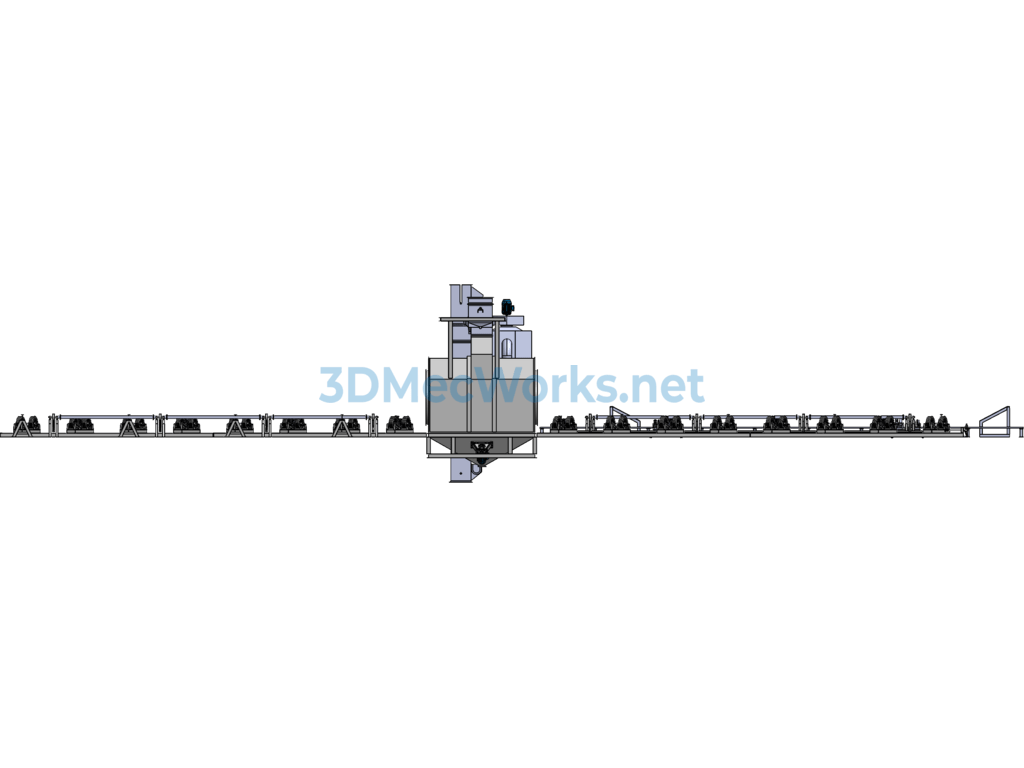

Specification: Outdoor Automatic Sandblasting Production Line

|

User Reviews

Be the first to review “Outdoor Automatic Sandblasting Production Line”

You must be logged in to post a review.

There are no reviews yet.