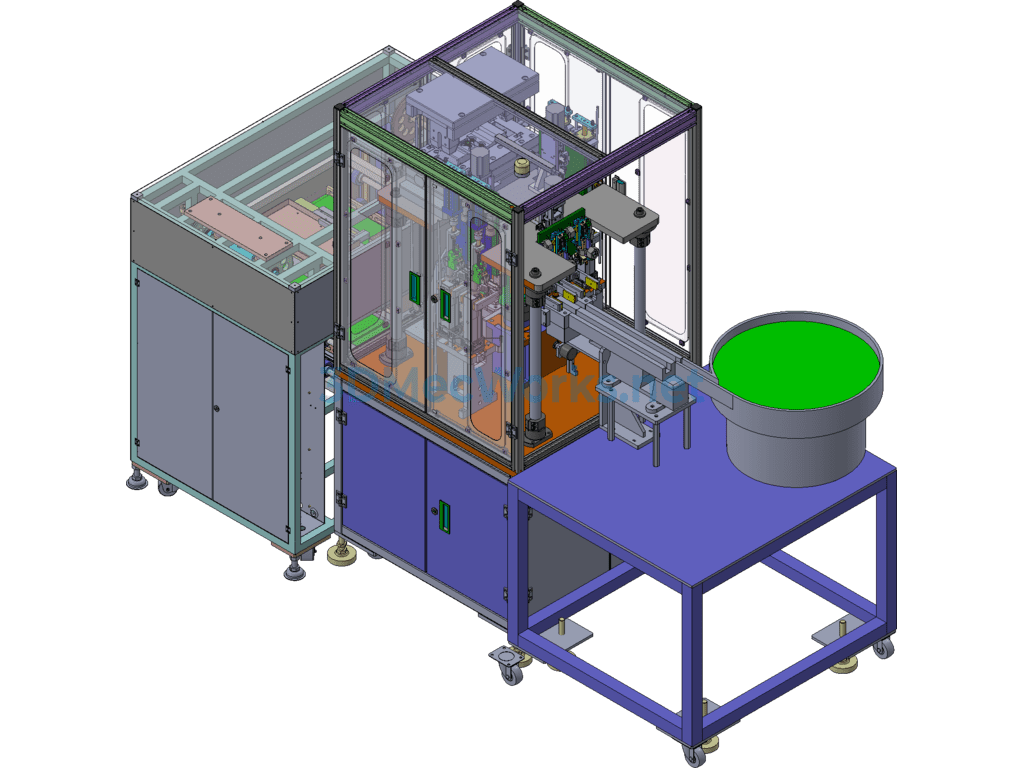

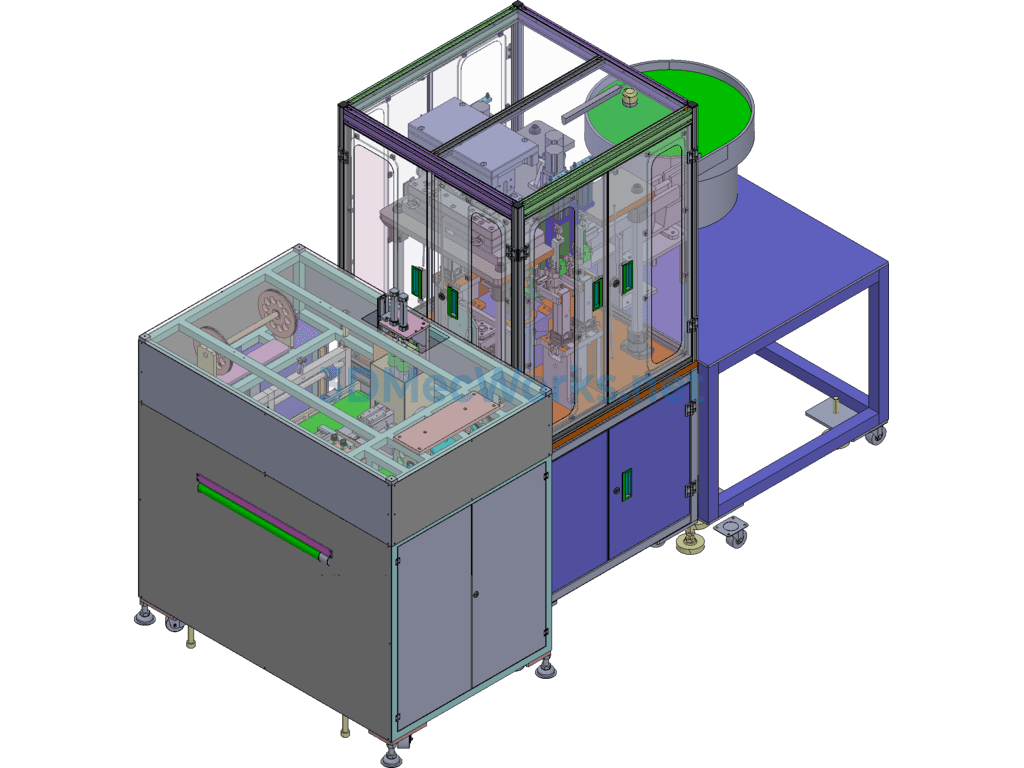

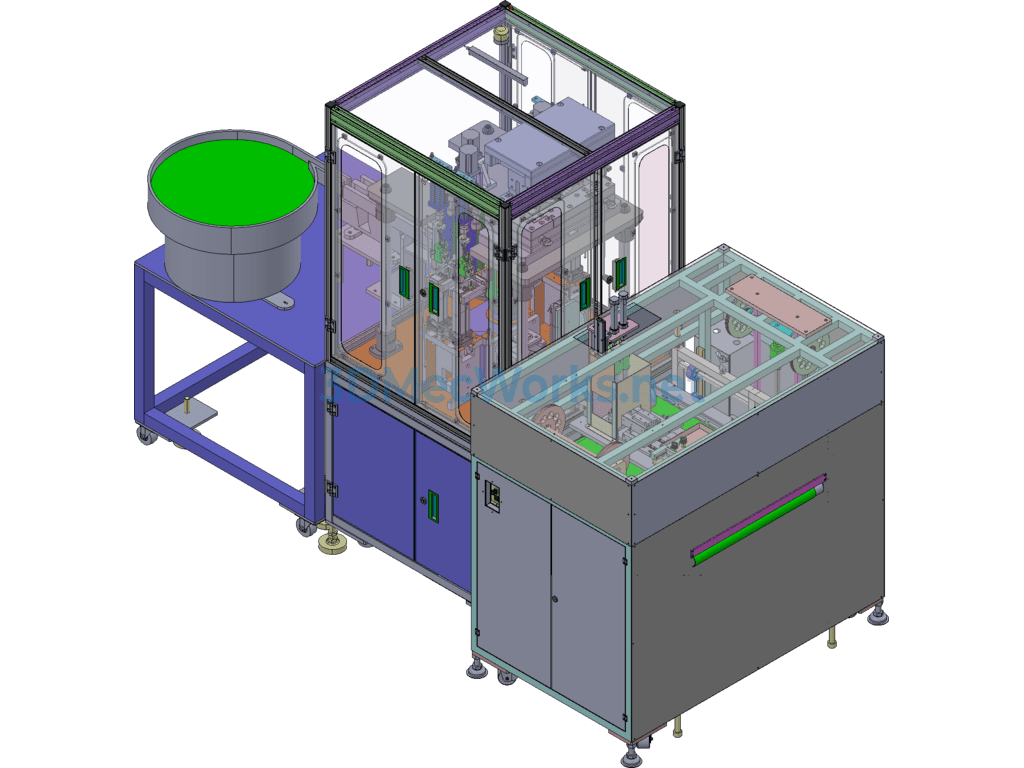

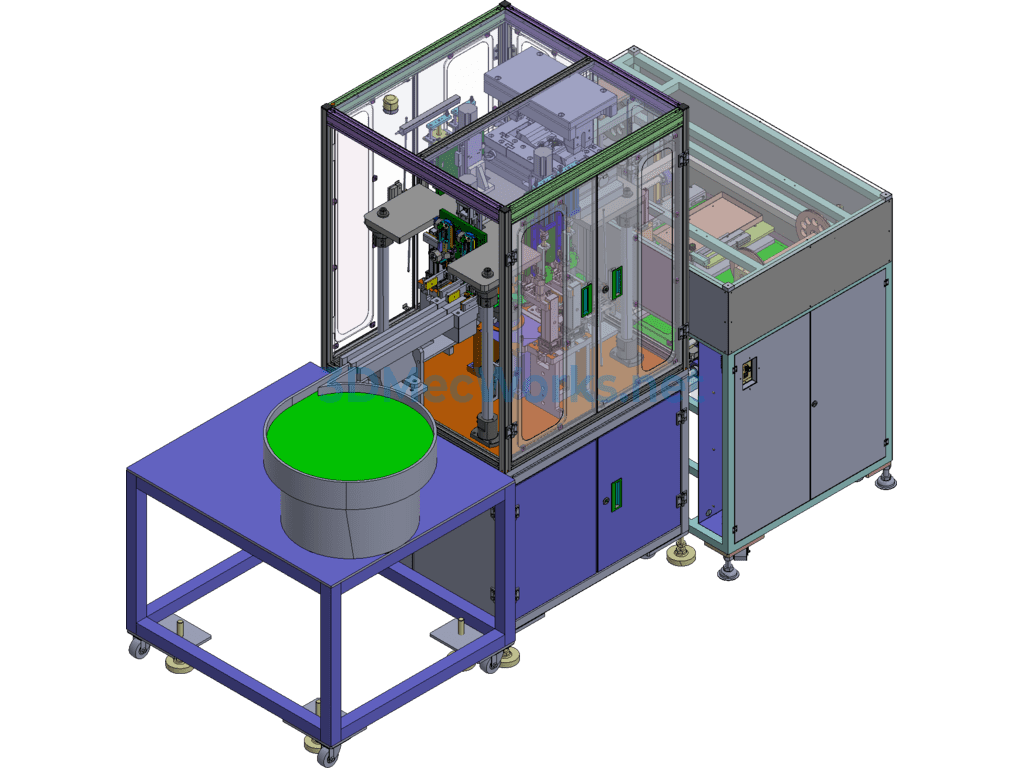

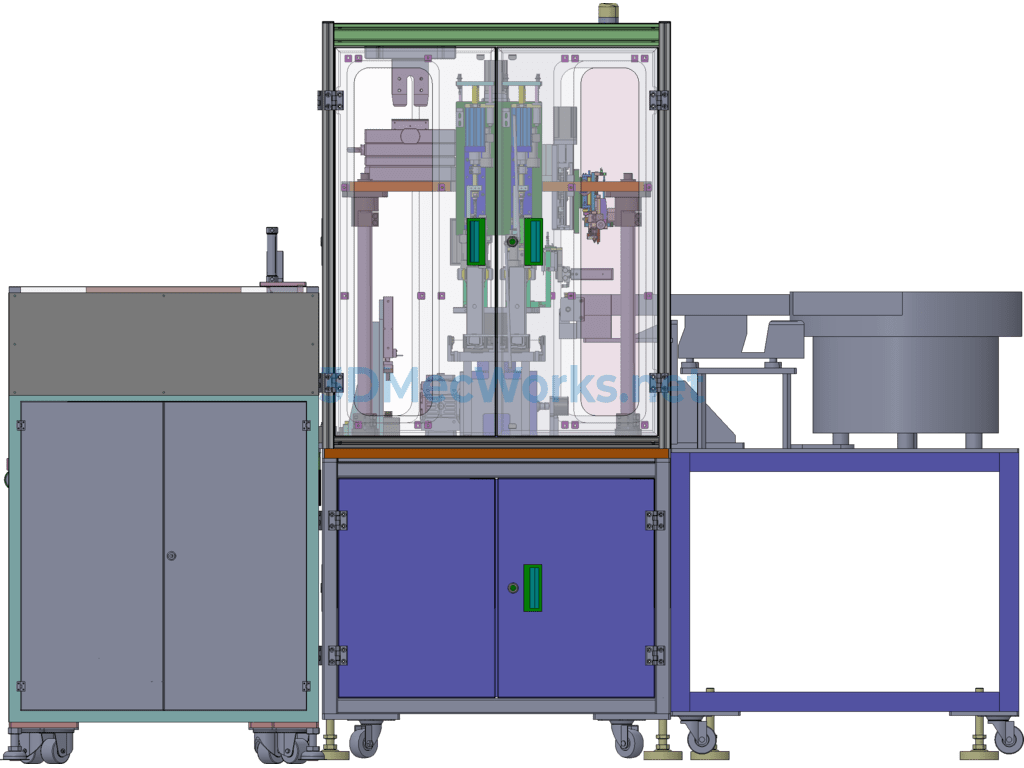

This equipment mechanism is designed with SW2016 and includes editable part features. The equipment requires high precision in angle and position for chip mounting, but efficiency requirements are not high. The entire machine generally has three cameras. Compared to traditional machines, besides the linear motion feature of the bonding head, there is an additional camera that can perform secondary positioning of the chip, preventing angle and position changes caused when the nozzle picks up the chip. Depending on the size of the chip, the mounting precision can be maintained within ±12~20μm, meeting the product quality requirements of TO packaging.

Weight and Power: approximately 800kg, 220 VAC; Power: 2000W; Pressure and dispensing method: 4bar ≤P≤6 bar, with air extrusion or adhesive type options; Chip: 0.2mm x 0.2mm ~1mm x 1mm; Chip feeding: 6-inch WAFER frame with expansion ring or TRAY plate; Visual System: 3 visual positioning systems for WAFER frames, 2 visual positioning systems for TRAY plates; Control method: industrial computer; UPH: 1000~2000 PCS; Mounting precision: ±20μm, within ±0.5°. Includes STP and UG general editable formats.

Specification: Optical Communication 128g Card Automatic Assembly Line

|

User Reviews

Be the first to review “Optical Communication 128g Card Automatic Assembly Line”

You must be logged in to post a review.

There are no reviews yet.