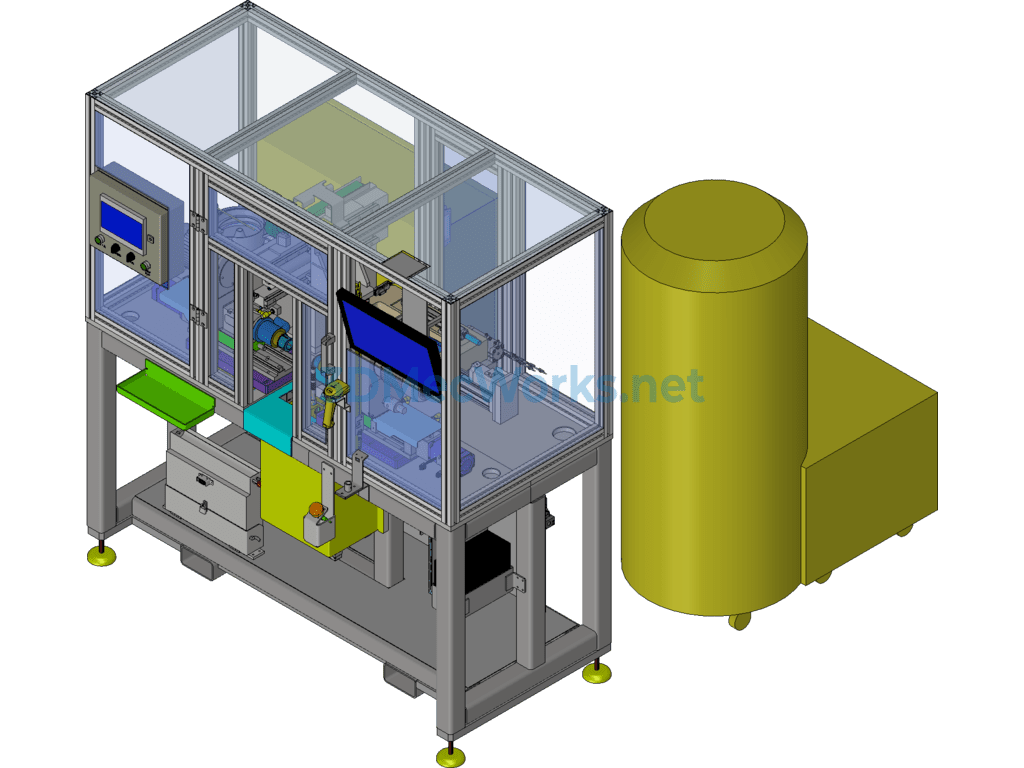

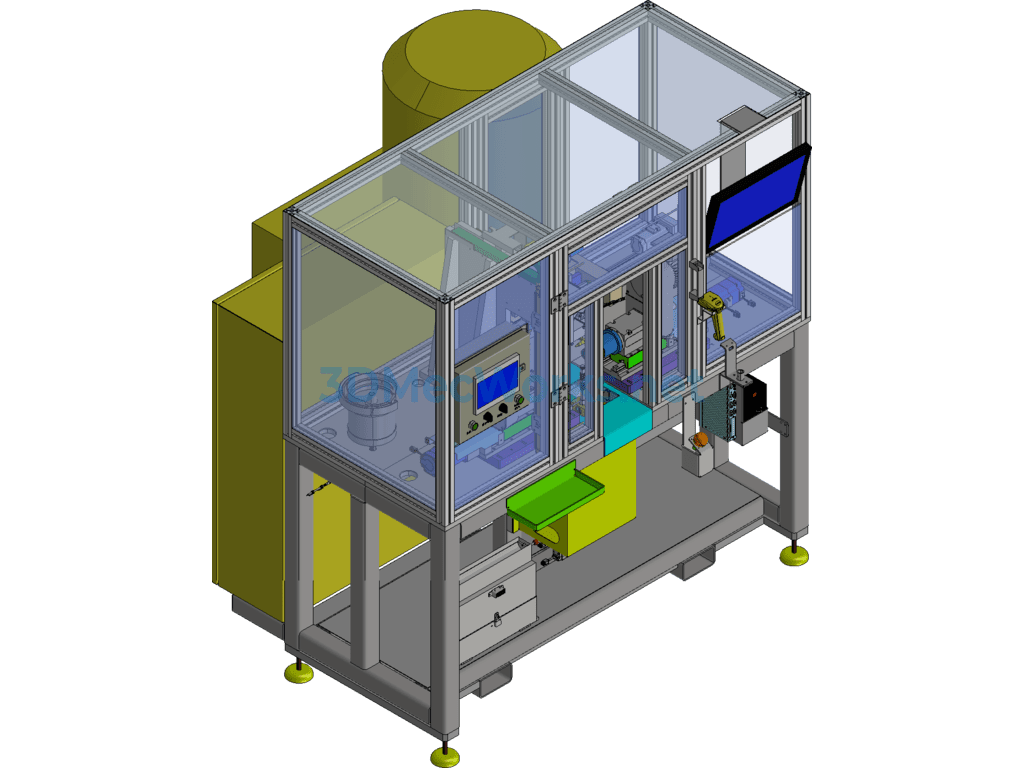

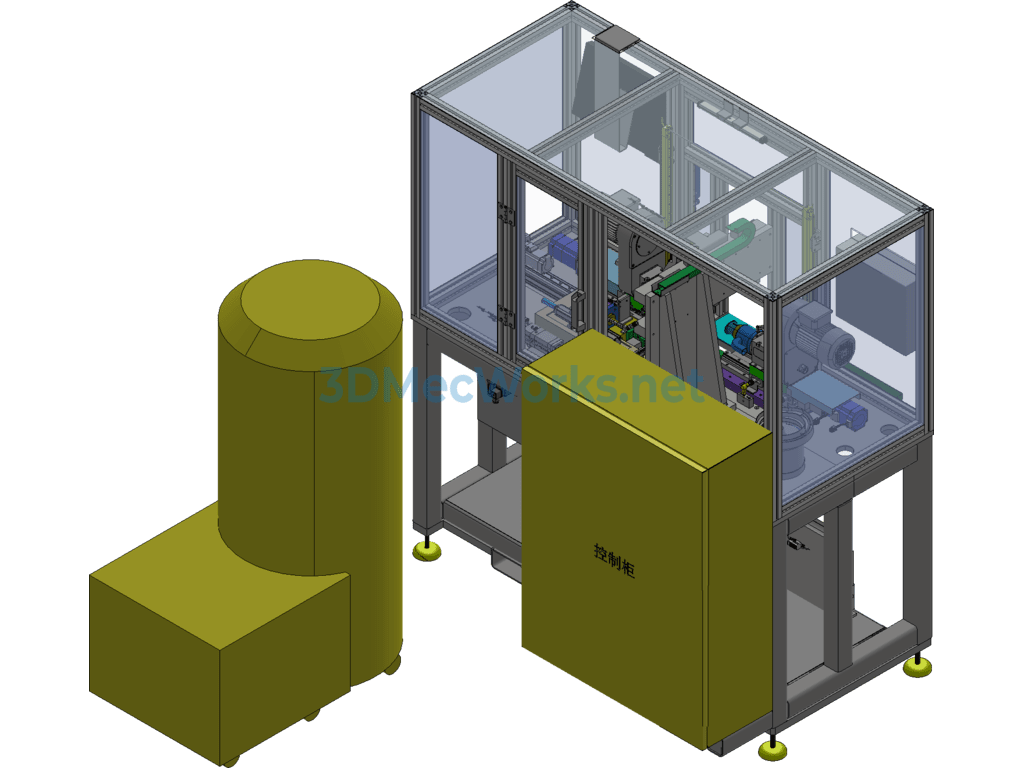

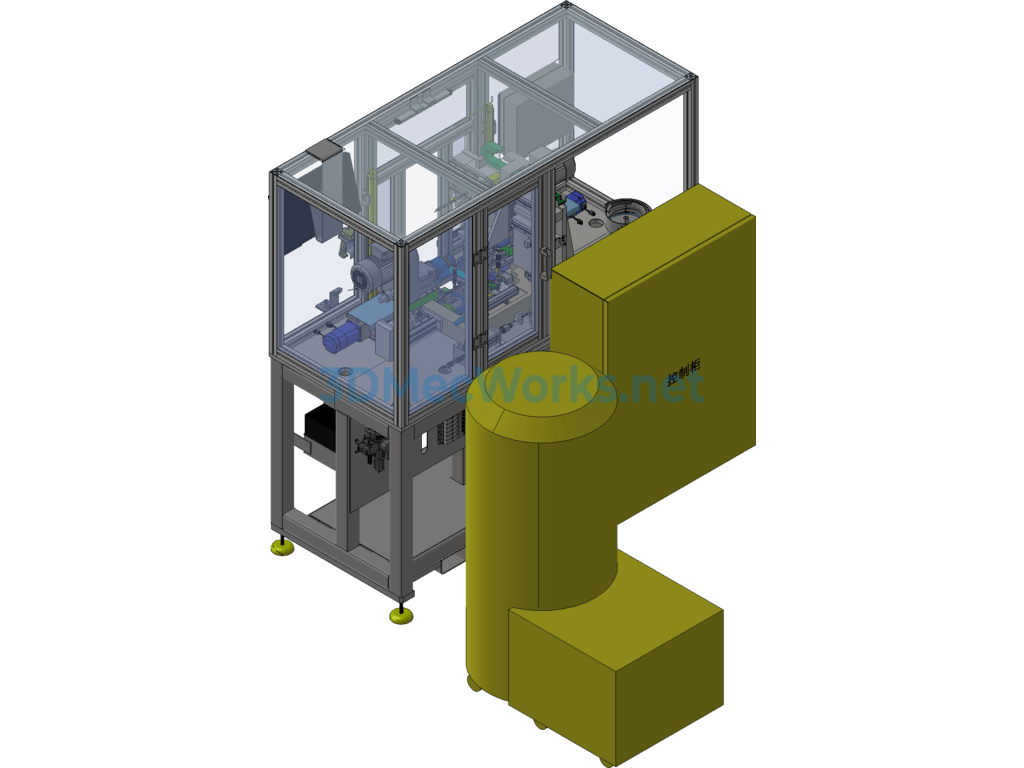

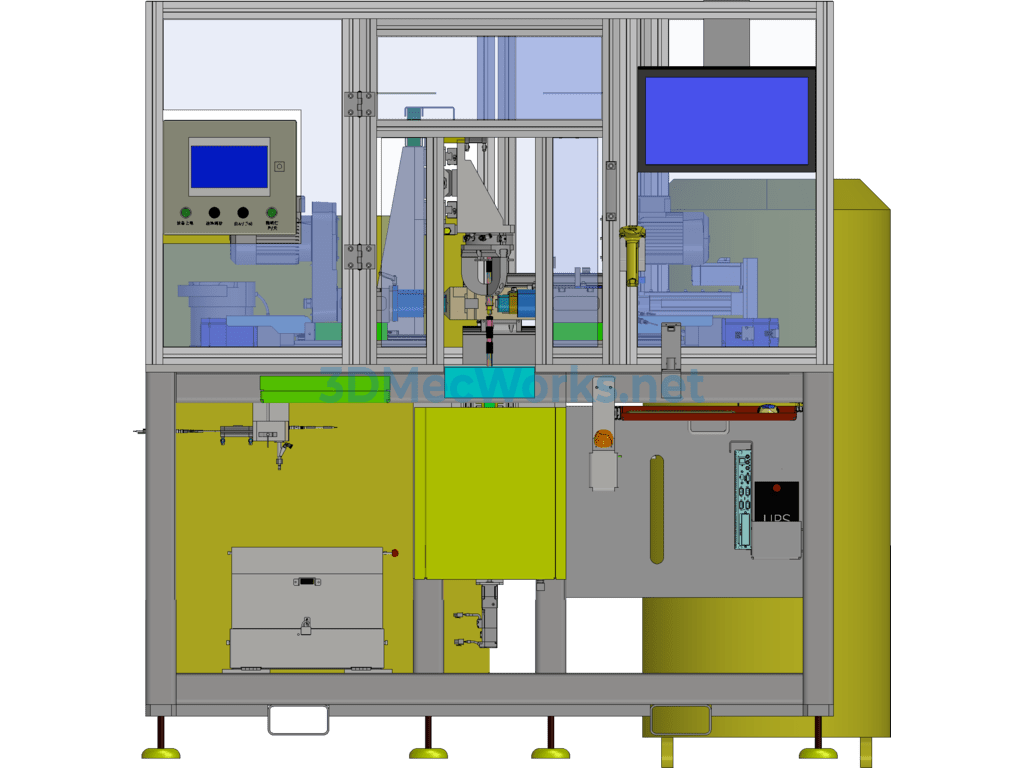

OP50 Input Shaft Drilling and Pinning

1. Purpose: To drill and pin the input shaft and torsion bar.

2. Compatible Products: XK507C, JLFC3C, SP232C.

3. Equipment Specifications: 1800mm(W) x 1600mm(L) x 2000mm(Aluminum Profile H).

4. Equipment Technical Parameters

4.1 Equipment Power: 20kw.

4.2 Air Source: ≥ 0.5Mpa Oil-free, Water-free Clean Compressed Air Source. Air Consumption: 10 liters/min.

4.3 Equipment Operation Mode: Product loading/unloading is performed by the operator (manual), automatic pin feeding, automatic completion of workpiece drilling, and pin insertion.

4.4 Press Force Monitoring: Range 30KN, Accuracy 1%R.O; Pressure retention time no less than 3 seconds; Bearing and screw lifespan ≥ 10 million cycles.

4.5 Press-in Depth Control: Accuracy 0.02mm; Equipped with self-displacement control and can be connected to a high-precision displacement sensor.

4.6 Press-Fit Judgment: Whether the pressure and displacement are within the qualified range.

4.7 Model Changeover: The tooling fixtures to be replaced are placed below the equipment, with a specially manufactured placement tray.

Specification: Op50 Input Shaft With Drilled and Pinned Hole

|

User Reviews

Be the first to review “Op50 Input Shaft With Drilled and Pinned Hole”

You must be logged in to post a review.

There are no reviews yet.