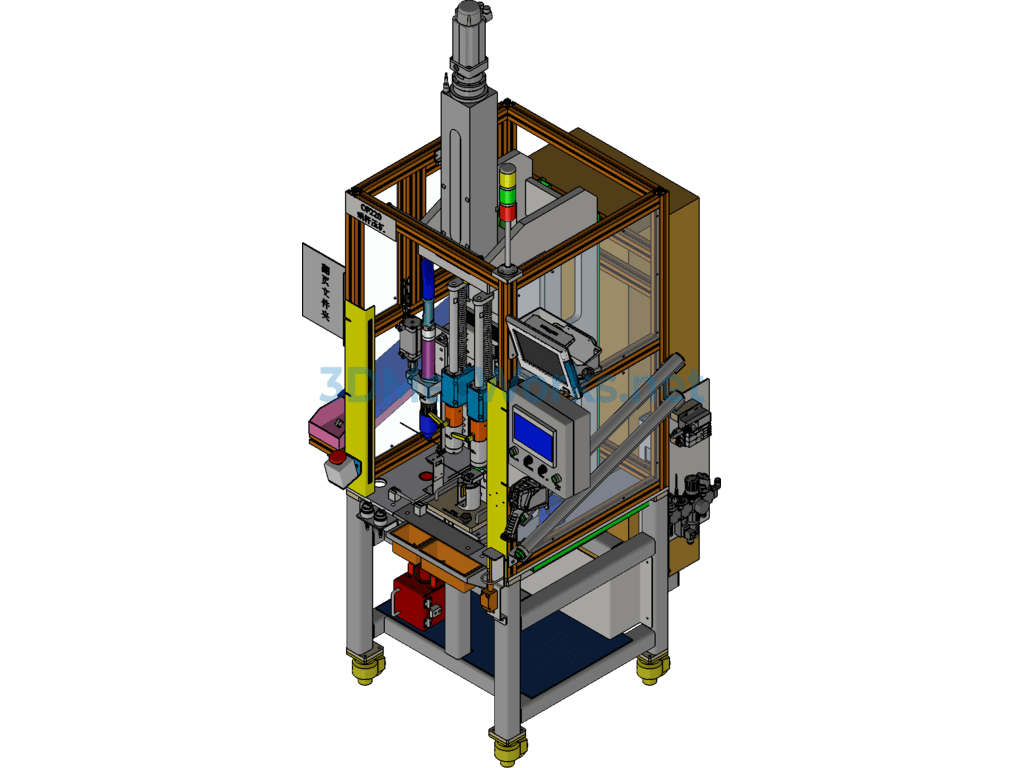

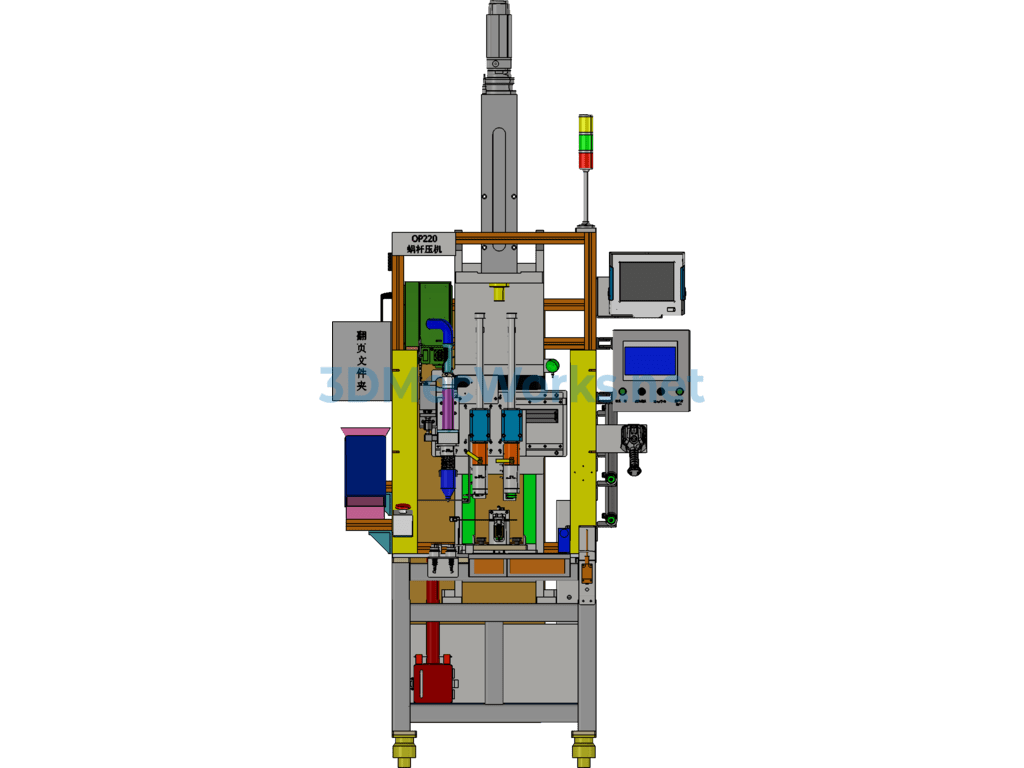

OP220 Worm Gear Assembly Synthesis

1. Purpose: Press the bearing assembly into the housing; Install O-ring on worm gear; Press-fit coupling onto worm gear; Lock the worm gear screws;

2. Compatible products: D571200;

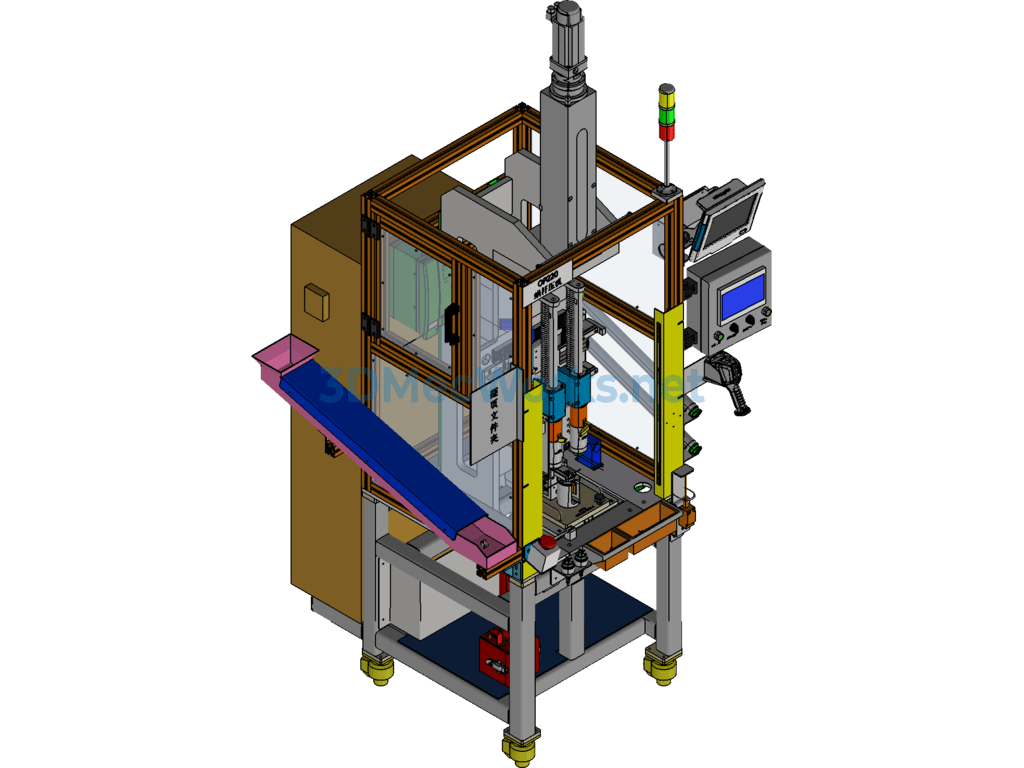

3. Equipment operation process

1) Take the worm gear, visually inspect for qualification, scan with a barcode reader (manual 3s)

2) Install the O-ring onto the worm gear, place the entire unit into the lower fixture, and the sensor detects its position (manual 3s)

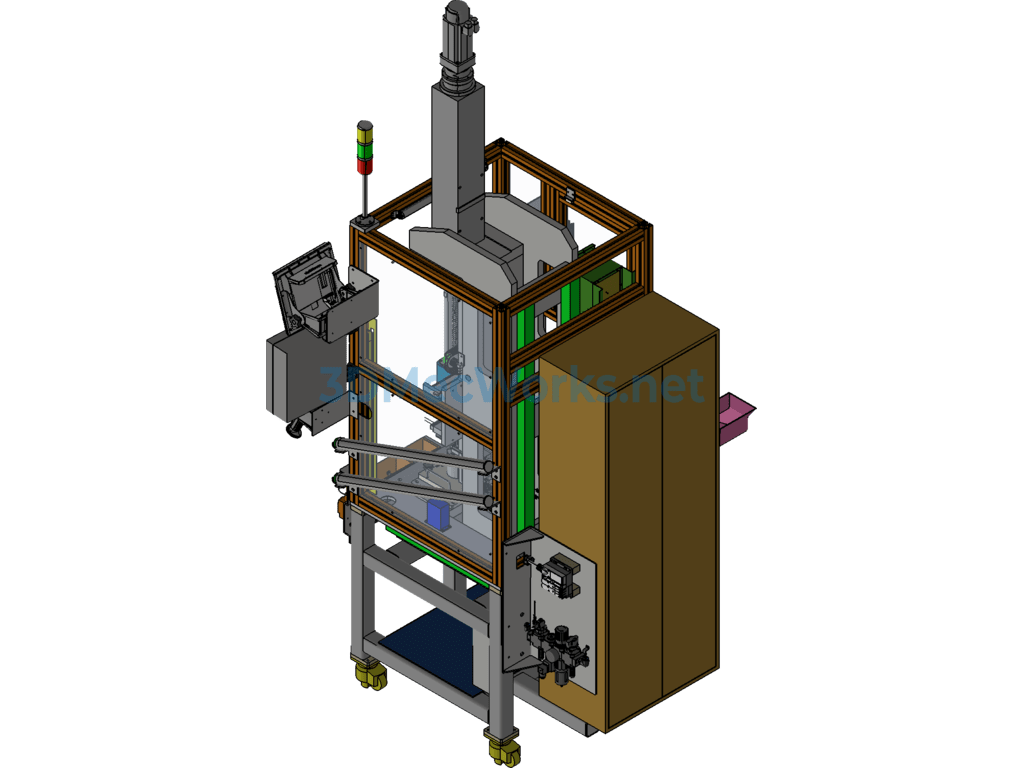

3) Press the start switch (manual 1s)

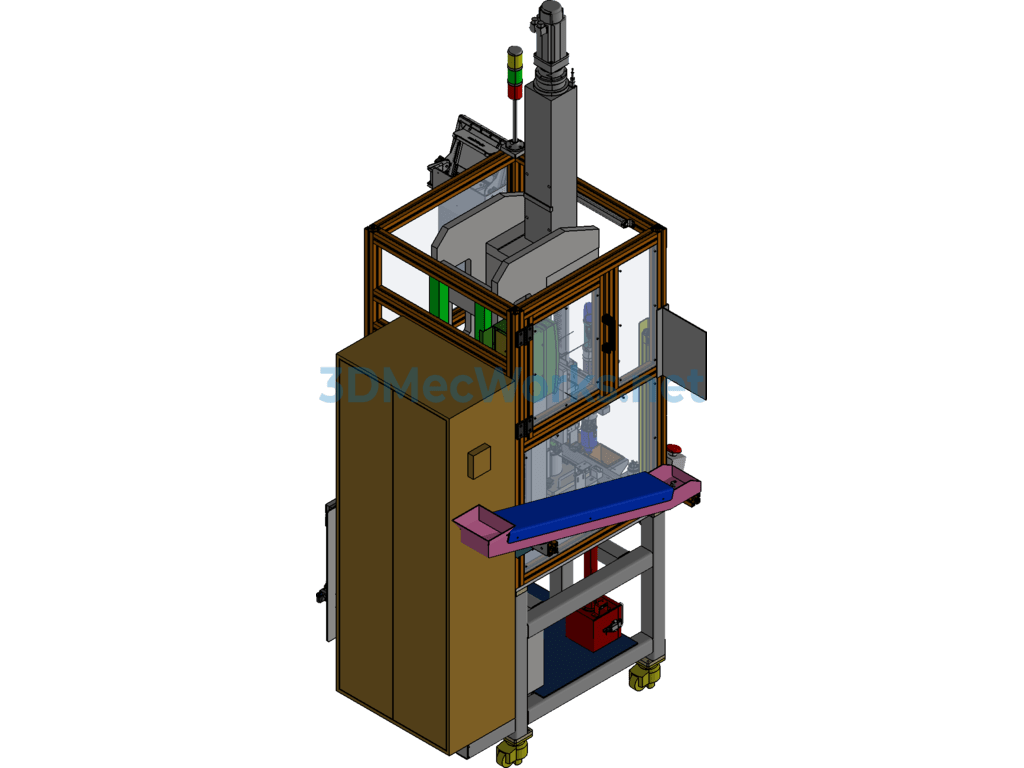

4) The moving door descends to a safe height, and the servo press drives the bearing press head downwards. (6s)

5) Once pressing is completed, the press head automatically retracts (2s)

6) The horizontal transfer mechanism moves the coupling press head above the press (2s)

7) The servo press drives the coupling press head downwards (6s)

8) Pressing is qualified, and the press head retracts automatically (2s)

9) The fixture transfer system moves the lower fixture under the tightening gun (2s)

10) The electric gun transfer mechanism drives the electric torque gun downwards (2s)

11) The electric gun tightens the locking screws to 15-20NM (5s)

12) The electric gun transfer mechanism retracts (2s)

13) The fixture transfer system moves the lower fixture under the tightening press (2s)

At the same time, the moving door opens

14) Manually remove the workpiece and transfer it to the next process (in case of non-conformance, the operator removes the non-conforming workpiece, places it in the NG box, triggers the NG photoelectric sensor, and resets the system) (manual 2s)

Specification: Op220 Worm Gear Assembly Synthesis

|

User Reviews

Be the first to review “Op220 Worm Gear Assembly Synthesis”

You must be logged in to post a review.

There are no reviews yet.