Currently, the methods of cleaning pulse bag dust collectors are divided into two types: row spray pulse jet cleaning and air box pulse cleaning. These two cleaning methods have the following characteristics:

Row Spray Pulse Jet Cleaning Method: This method has great cleaning kinetic energy, can thoroughly clean each filter bag inside the dust collector uniformly row by row, has low operational resistance, allows the filter bags to be longer (can exceed 6 meters) with a large length-to-diameter ratio, and has a small volume, requiring less floor space and is lightweight.

Air Box Pulse Cleaning Method: This method has relatively high cleaning kinetic energy. As it uses one to two pulse valves to clean a single bag compartment, to ensure thorough cleaning, the bag compartment cannot be too large, and the filter bag cannot be too long. Large air box pulse dust collectors have a large number of filter bags and require a large floor area. They use an offline cleaning method, but when there is high negative pressure inside the equipment, it is difficult to conduct non-stop online maintenance and bag replacement.

Typically, pulse jet cleaning is divided into high-pressure and low-pressure based on the air source pressure. In this project, the selected air source pressure range is 0.4–0.6Mpa, which is high-pressure pulse jet cleaning, based on the following reasons:

① High-pressure cleaning is more thorough, requiring fewer cleaning cycles, saving high-pressure air sources, introducing less external compressed air, reducing the load on the dust collector’s tail exhaust fan, resulting in lower energy consumption and operational costs.

② The pressure range of the compressed air source commonly used in cement plant dust collectors is 0.4–0.6Mpa, allowing for unified management, etc.

③ High-pressure cleaning uses the least compressed air to induce more filtered clean hot air for cleaning, which is beneficial for the equipment’s anti-condensation properties.

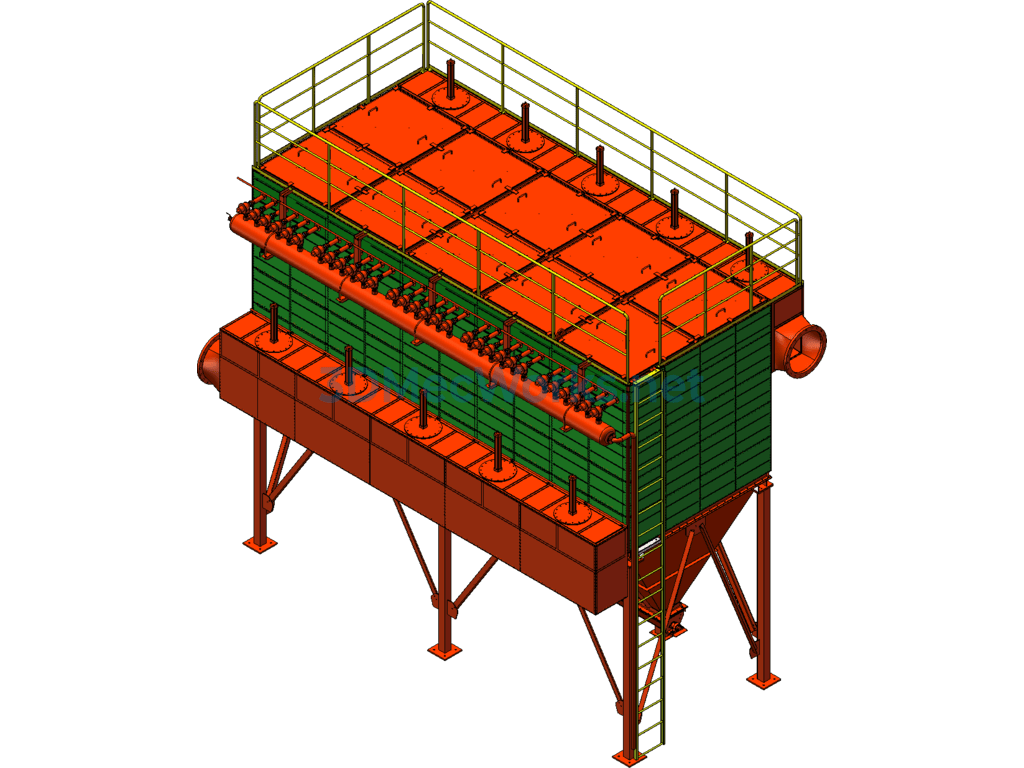

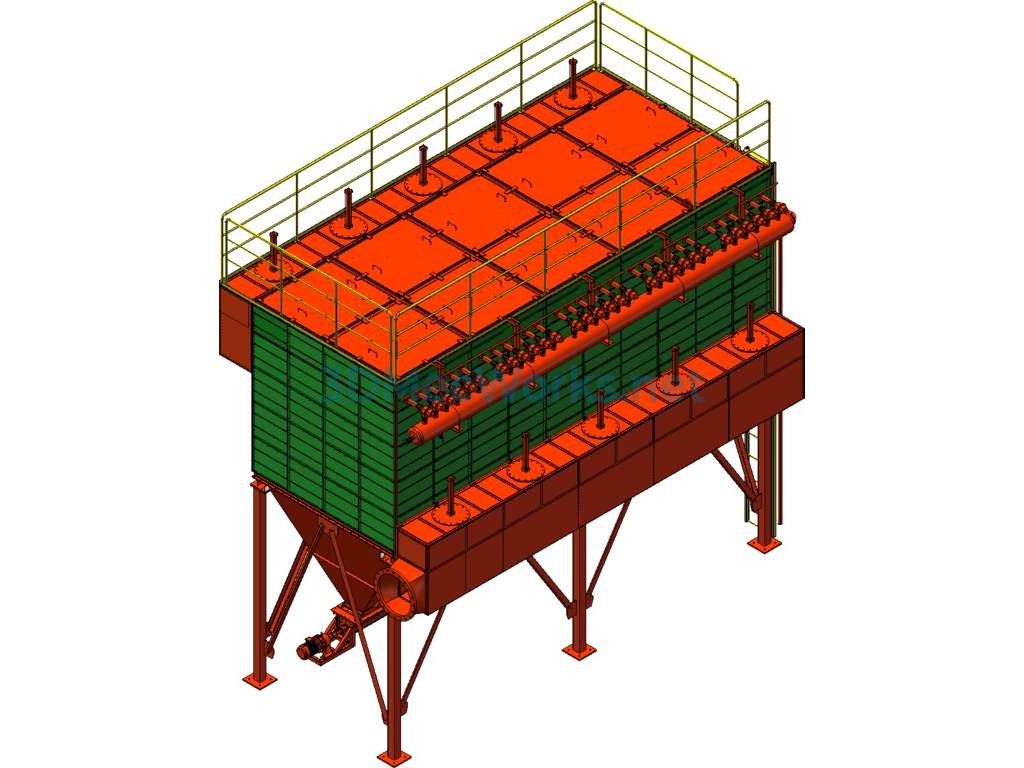

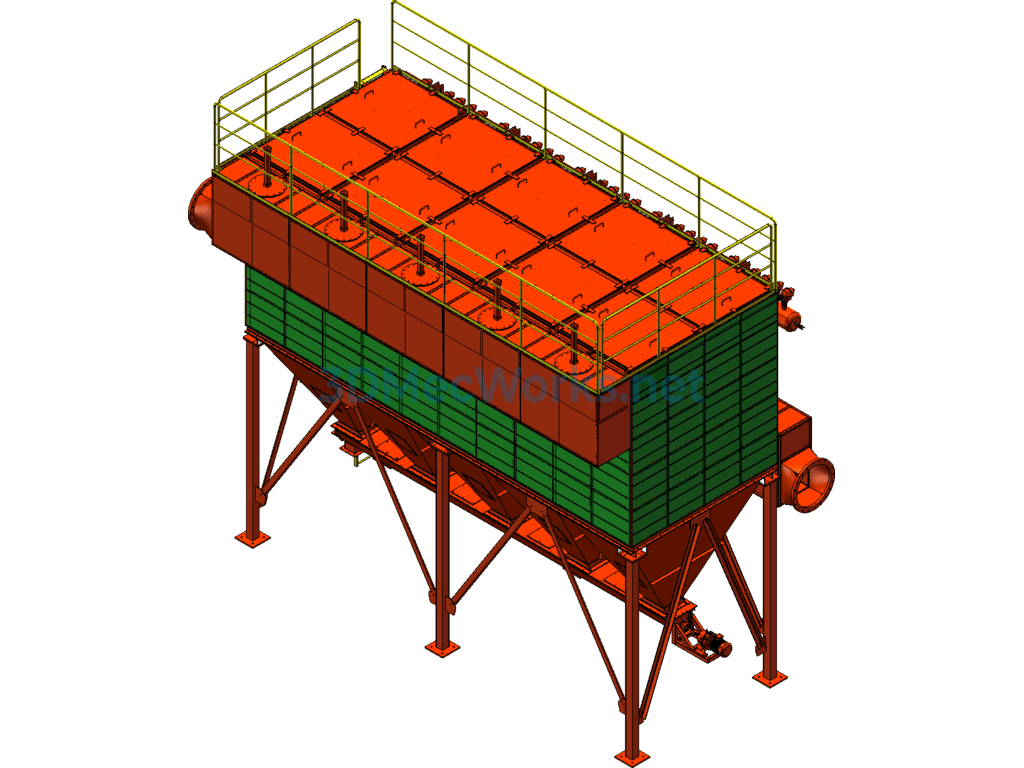

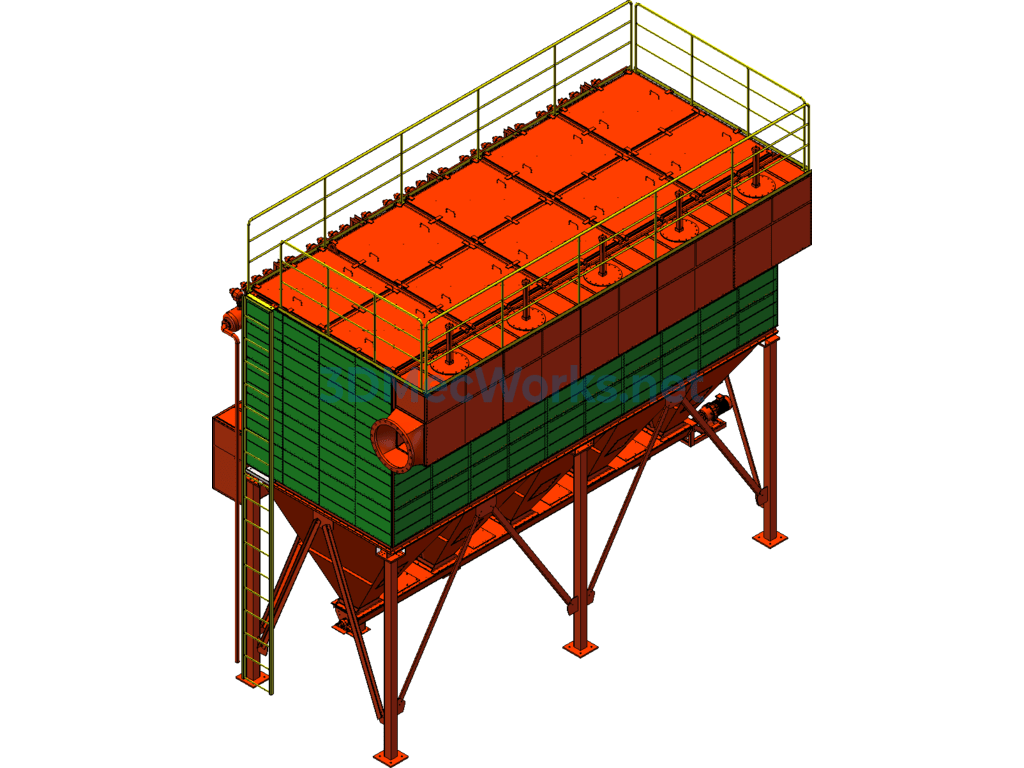

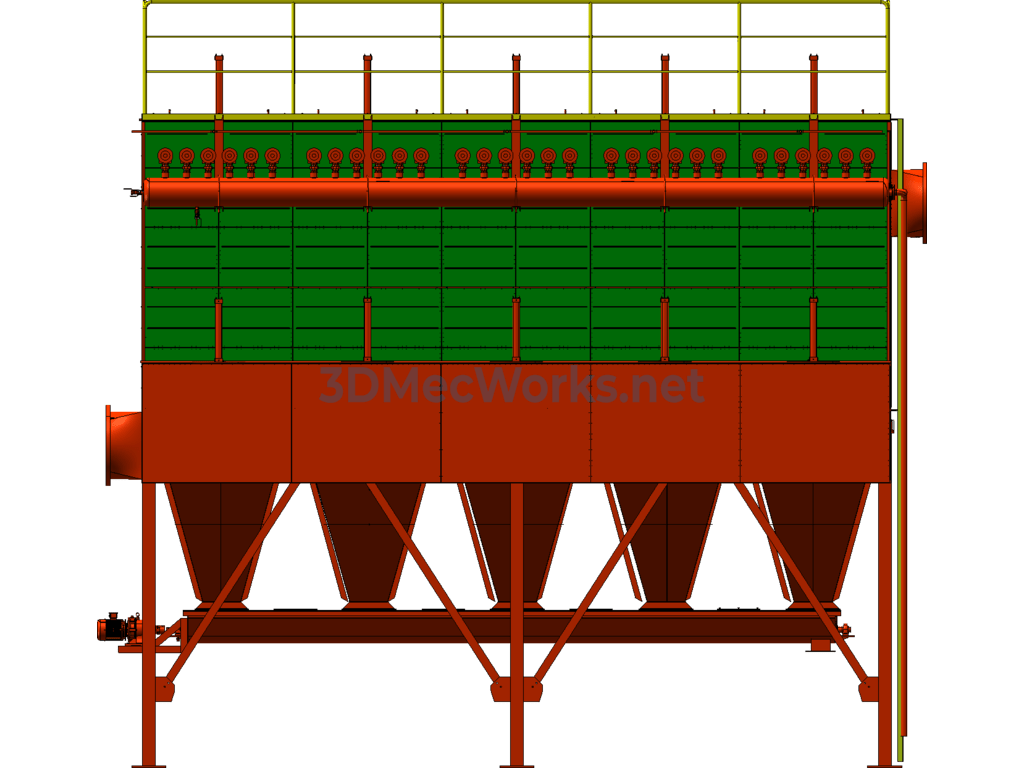

Specification: Offline Pulse Bag Dust Collector

|

User Reviews

Be the first to review “Offline Pulse Bag Dust Collector”

You must be logged in to post a review.

There are no reviews yet.