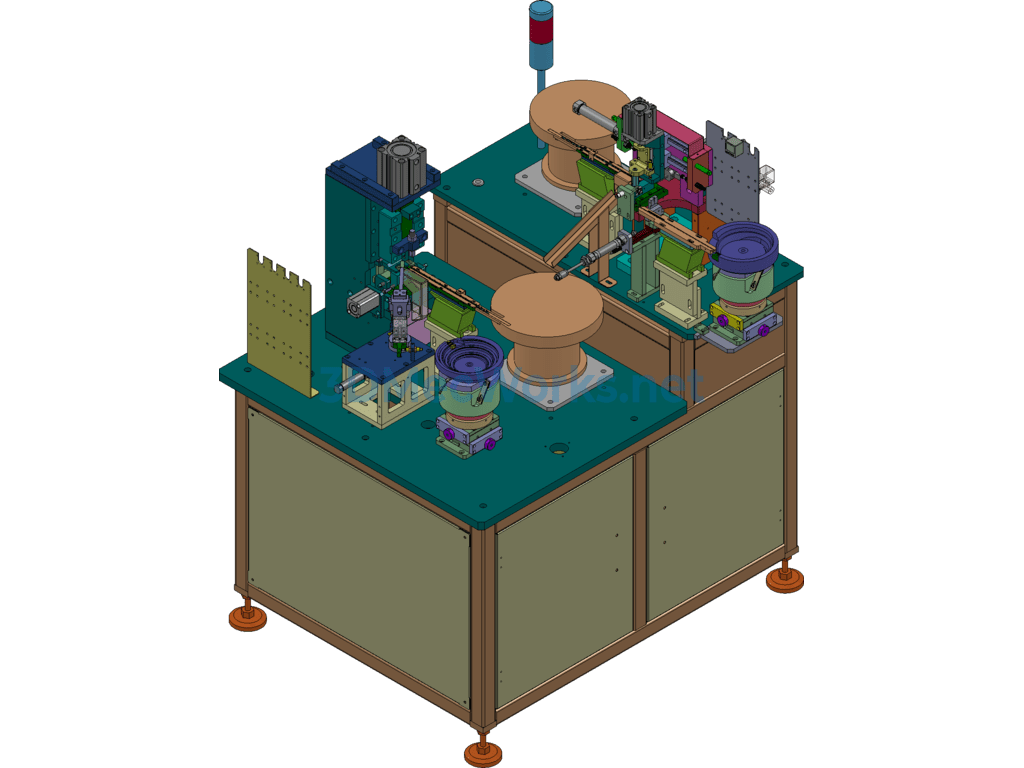

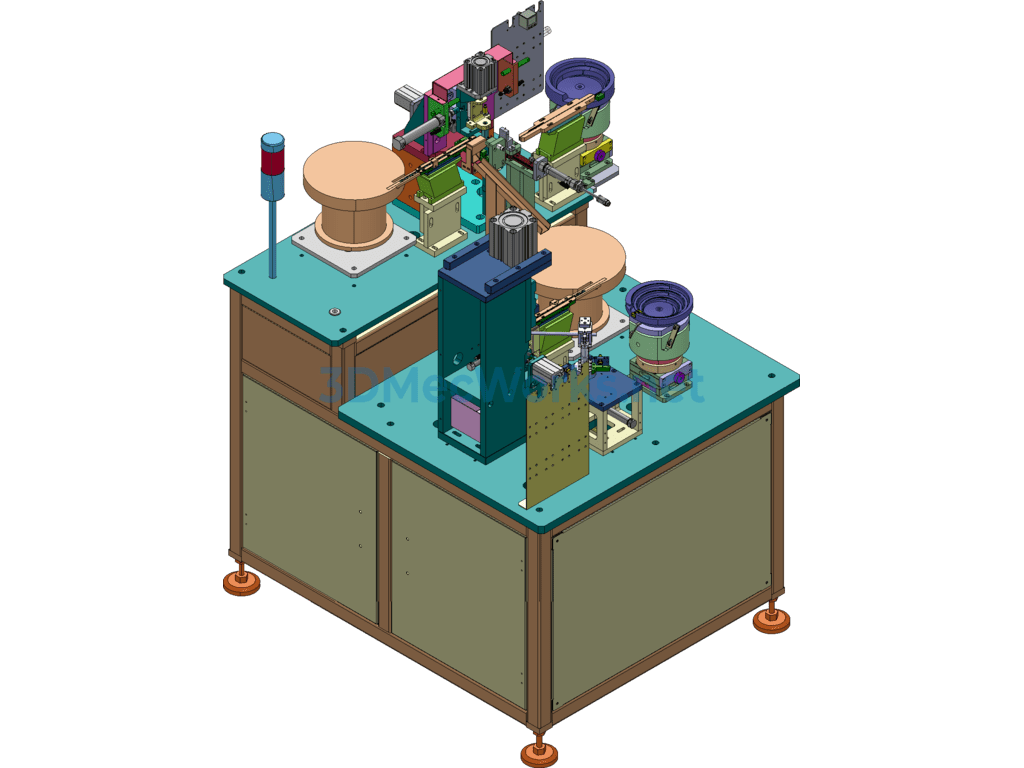

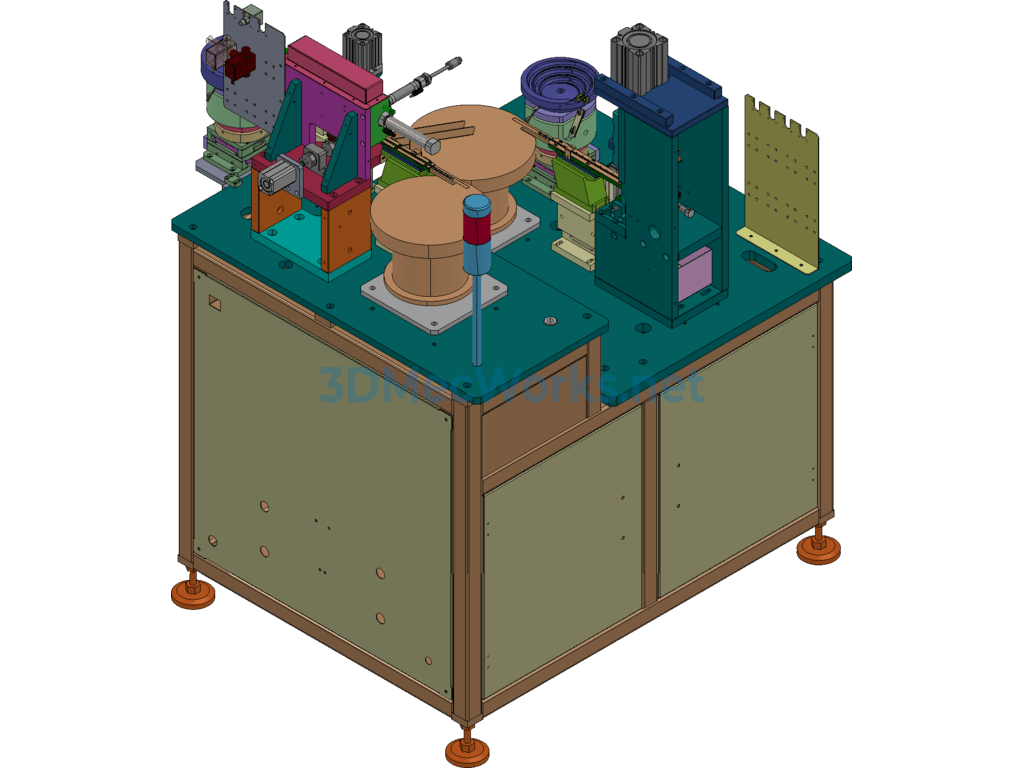

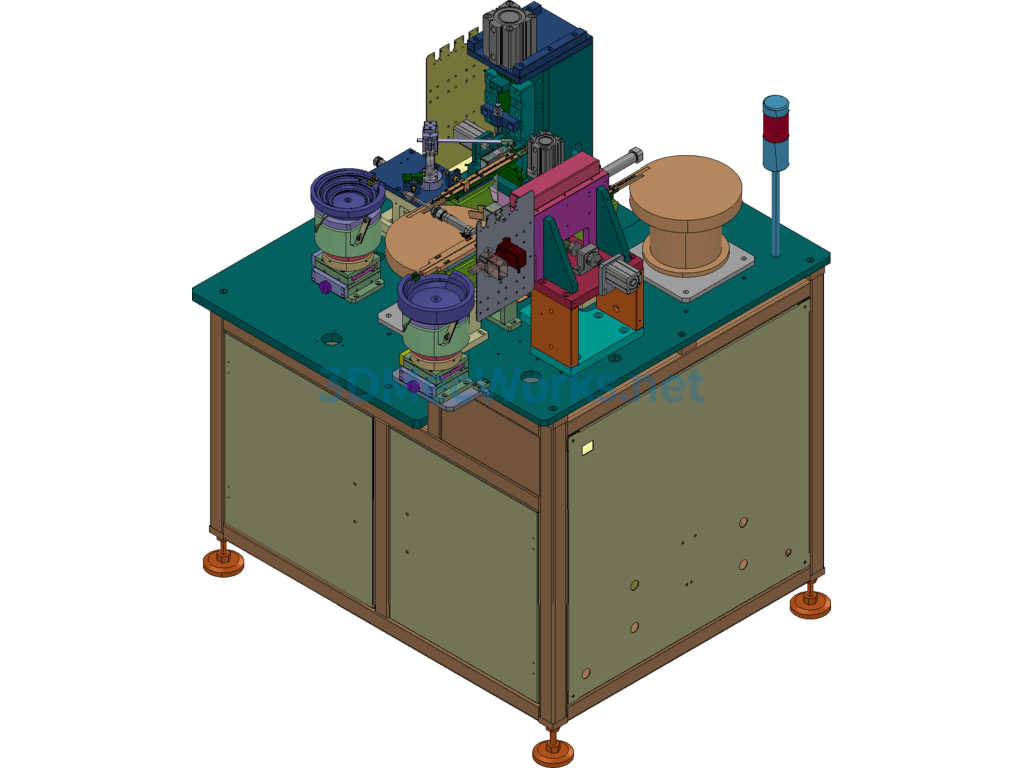

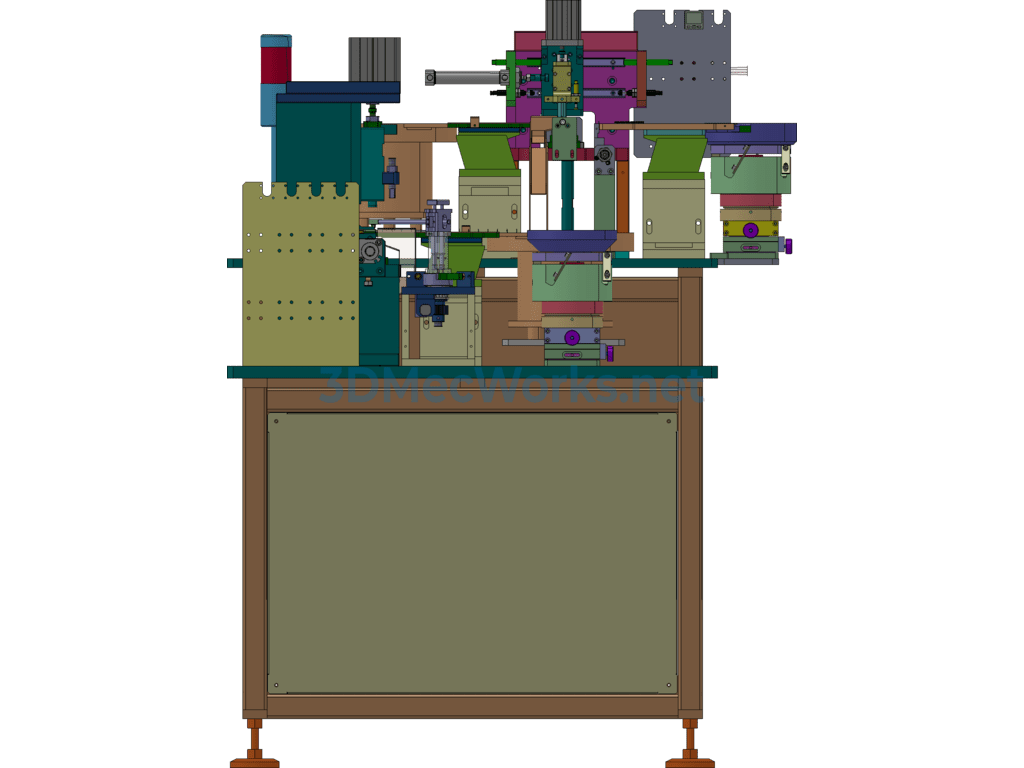

Non-standard precision clock and watch accessory fork piece pin assembly machine 3D model drawings sharing. This is a set of precision clock and watch accessory fork piece pin assembly machine, mainly used for the gear assembly of timepieces. The equipment is responsible for feeding and assembling four components, and the fork piece and fork pin are precision transmission parts in watches and clocks. This equipment is designed and developed specifically for the assembly of these precision accessories, characterized by high efficiency and low cost as a new type of non-standard assembly equipment. The fork piece is fed by a vibrating plate and a linear vibrating feeder. Firstly, the fork piece and the positioning pin are assembled together. After assembly, they enter another vibrating plate for the precise assembly of the pinion fork pin. The precision of the entire product after assembly has been verified to be within 0.01MM. The diameter of this fork pin is 0.5MM and the length is 5MM. It is fed by a small vibrating plate and is uprighted by vacuum adsorption, then picked and placed into the fork for precise assembly by a rotary pin picking structure. The punch head fully combines the fork and the gear piece in one go. It is precisely because the gears of watches are very precise and the parts are relatively small that it greatly increases the difficulty of assembly. In order to develop this equipment, our engineers initially brainstormed extensively to come up with a good and reasonable structure to realize it. Now, the complete assembly equipment drawings are uploaded here for those who need to study. Detailed structure insights can only be truly discovered by slowly researching after downloading.

Specification: Non-Standard Precision Clock and Watch Component Fork and Pin Assembly Machine

|

User Reviews

Be the first to review “Non-Standard Precision Clock and Watch Component Fork and Pin Assembly Machine”

You must be logged in to post a review.

There are no reviews yet.