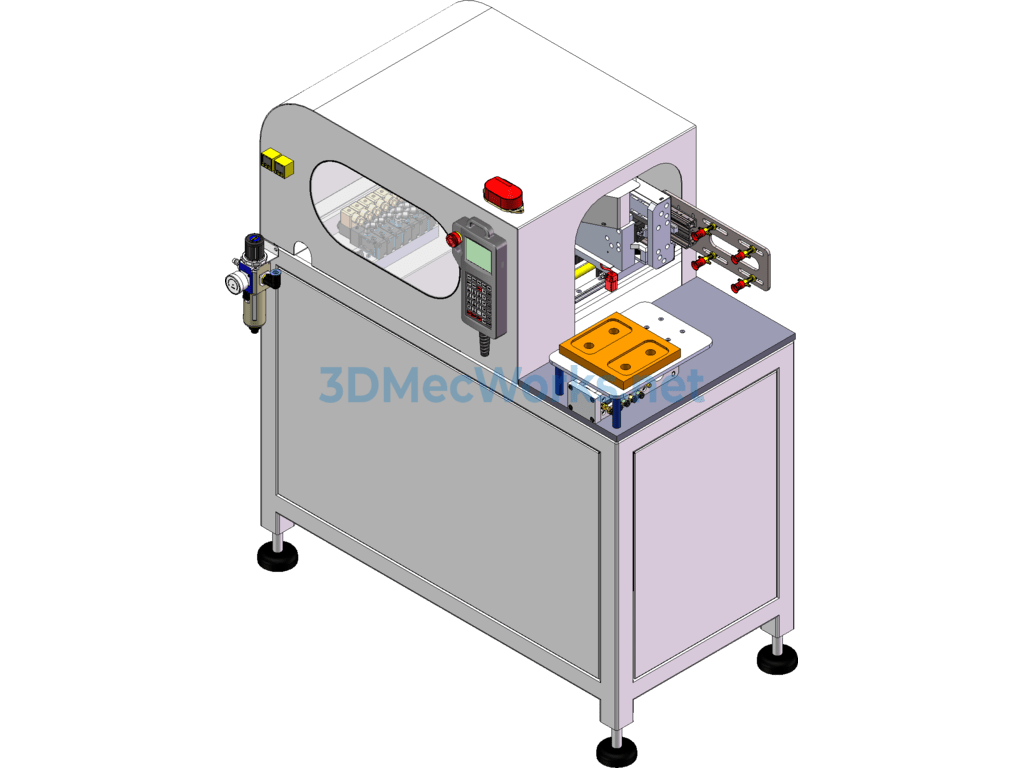

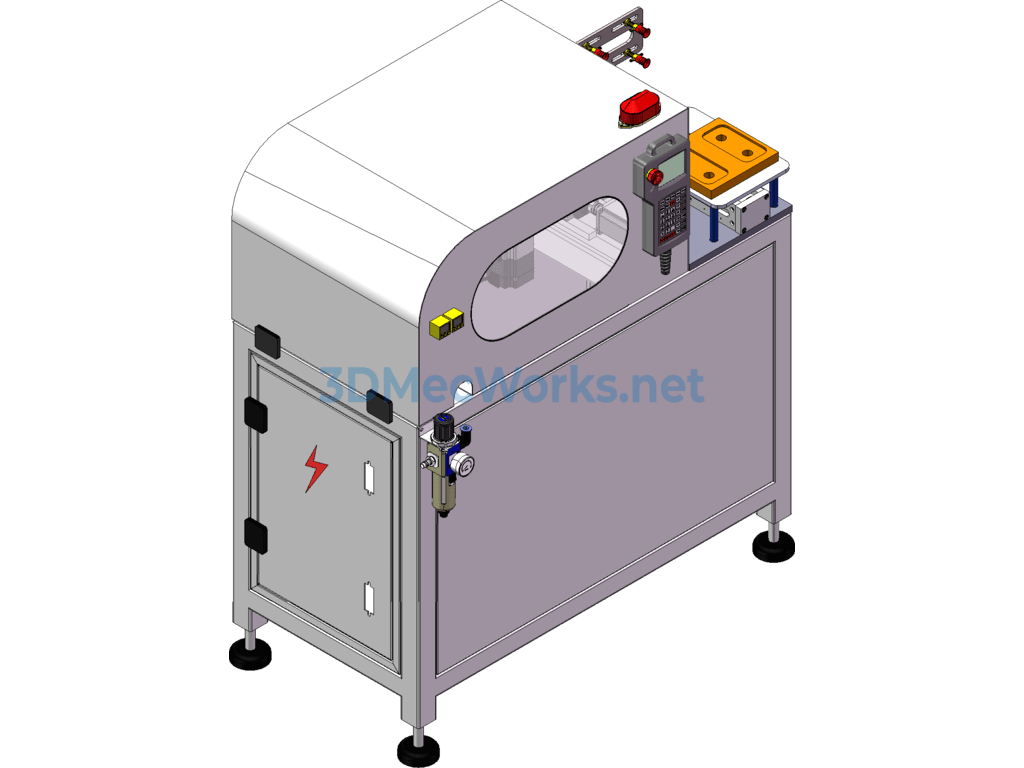

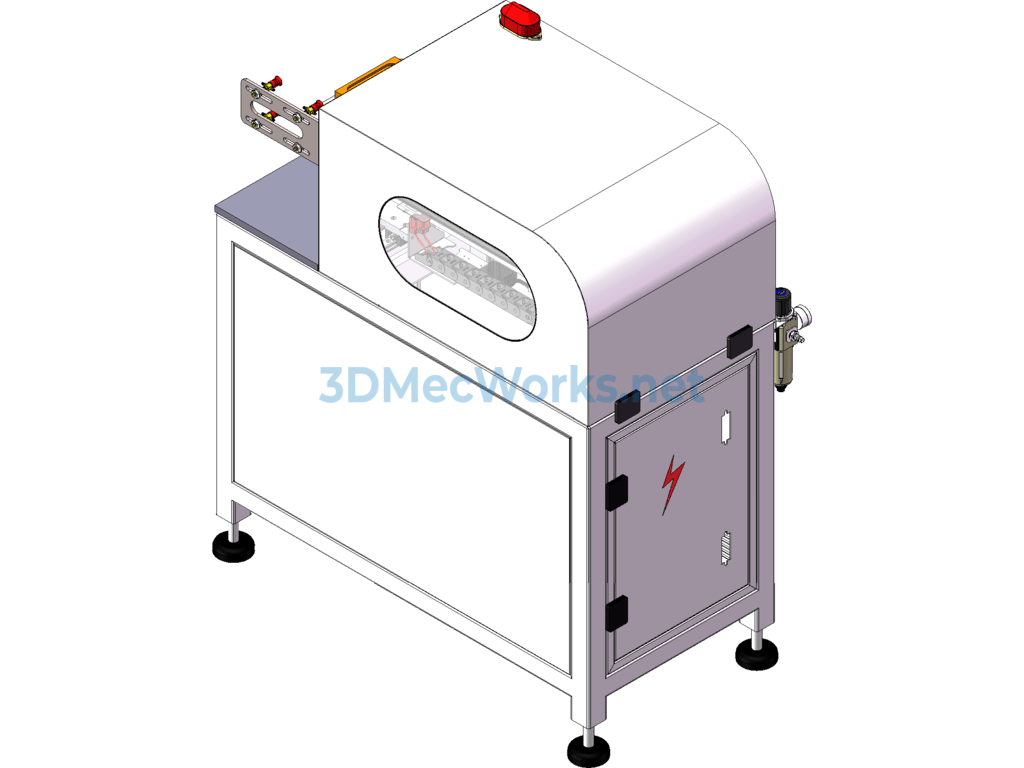

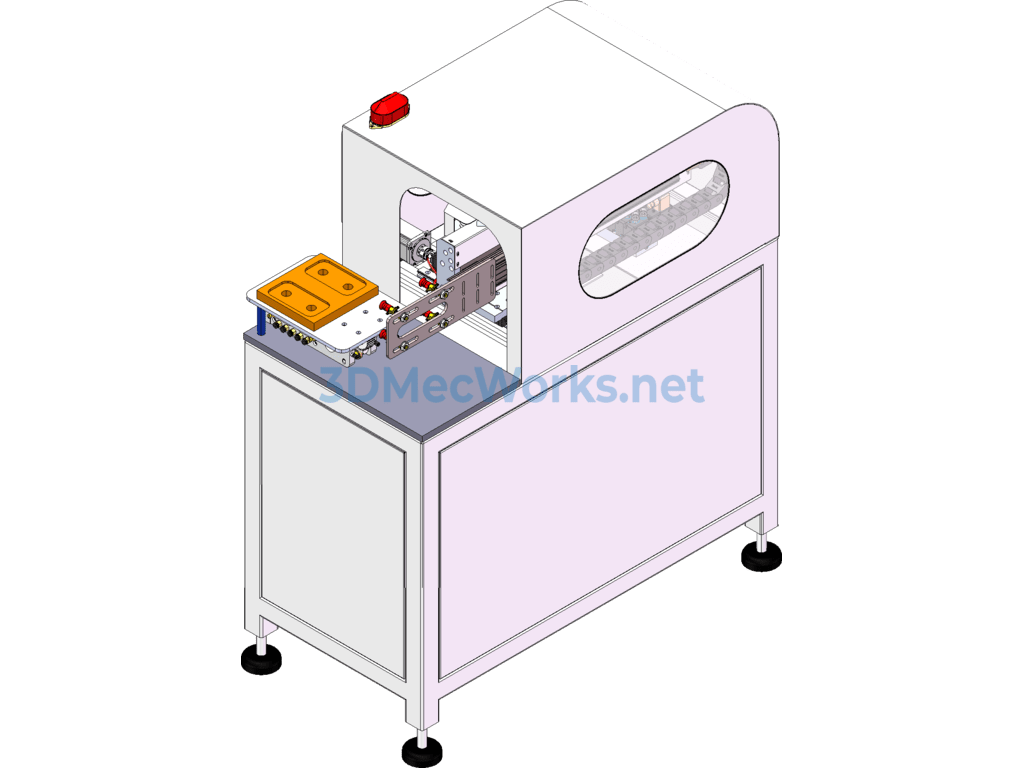

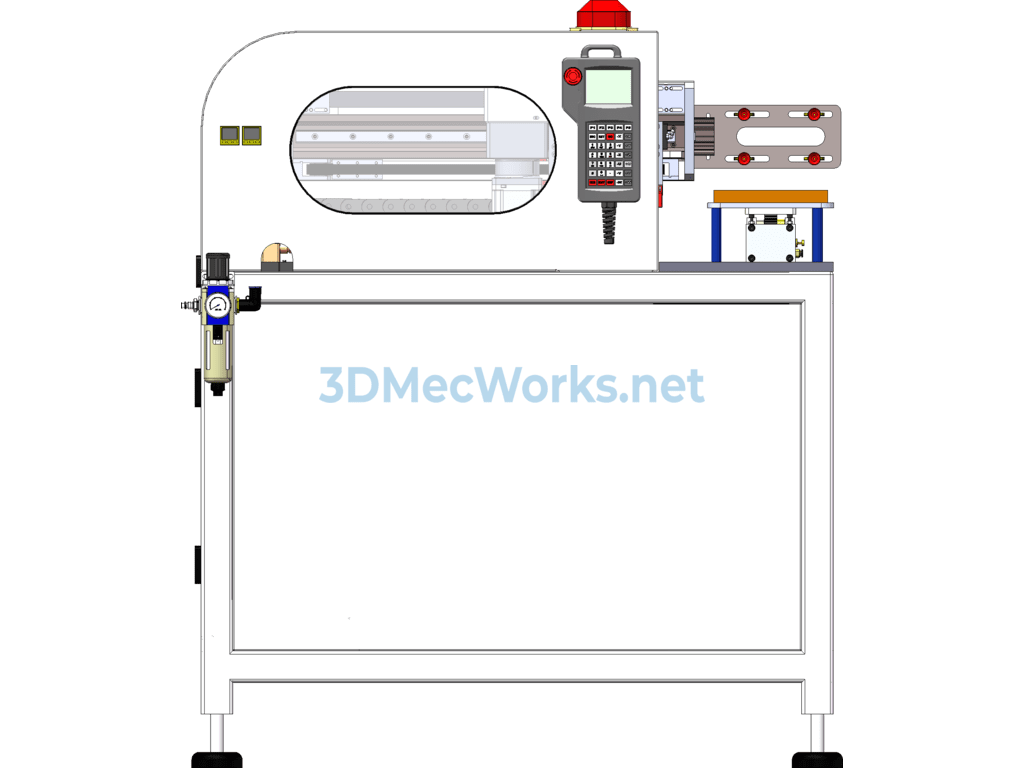

Non-standard Automated In-Mold Labeling Robot

Introduction to In-Mold Labeling Technology

Advantages of In-Mold Labeling and Solutions to Process Issues:

Abroad, in-mold labeling technology has already been widely applied, and it has gradually emerged in our country in recent years. This new technology is not only recognized by industry insiders but also quickly gains widespread use.

In-mold labeled products are produced by using specialized mechanical equipment to deliver printed composite material labels into specially structured injection molds. The process involves using the temperature of injected plastic to integrate the label with the plastic, primarily applicable to plastic packaging products made from PE and PP materials.

Advantages of In-Mold Labeling:

1. Acts as an Anti-counterfeiting Measure

The high technology content of in-mold labeling serves as an effective defense against counterfeiting. It requires tightly coordinated processes, from selecting high-quality materials, making the in-mold labels, to label production equipment and mold design structure and production technology, thus increasing the difficulty of forgery.

2. In-Mold Labeling Can Enhance Product Grade

Compared to products with silk-screen printing or outside-labeling, in-mold labeled products are more aesthetically pleasing, with more vibrant colors and a smoother feel.

Design increasingly pursues the aesthetics and fun of goods as a societal trend.

Attracting with beauty and manifesting the age with simplicity, brightness, and elegance in practical application.

In-mold labeled products have strong practicality and low loss. Compared to silk-screen and outside-labeled products, they do not have issues like ink dropping, labels lifting, peeling, or damaging. They offer resistance to extrusion, water, oil, mold, friction, acids, and alkalis and can withstand cooling and heat, making the labels less prone to damage and staining under special conditions.

The price of in-mold labeled products is similar to that of self-adhesive and silk-screen printed products. Using in-mold labeling can improve efficiency without needing manual labeling, eliminating the need for additional labeling production processes.

Specification: Non-Standard Automation In-Mold Labeling Robot

|

User Reviews

Be the first to review “Non-Standard Automation In-Mold Labeling Robot”

You must be logged in to post a review.

There are no reviews yet.