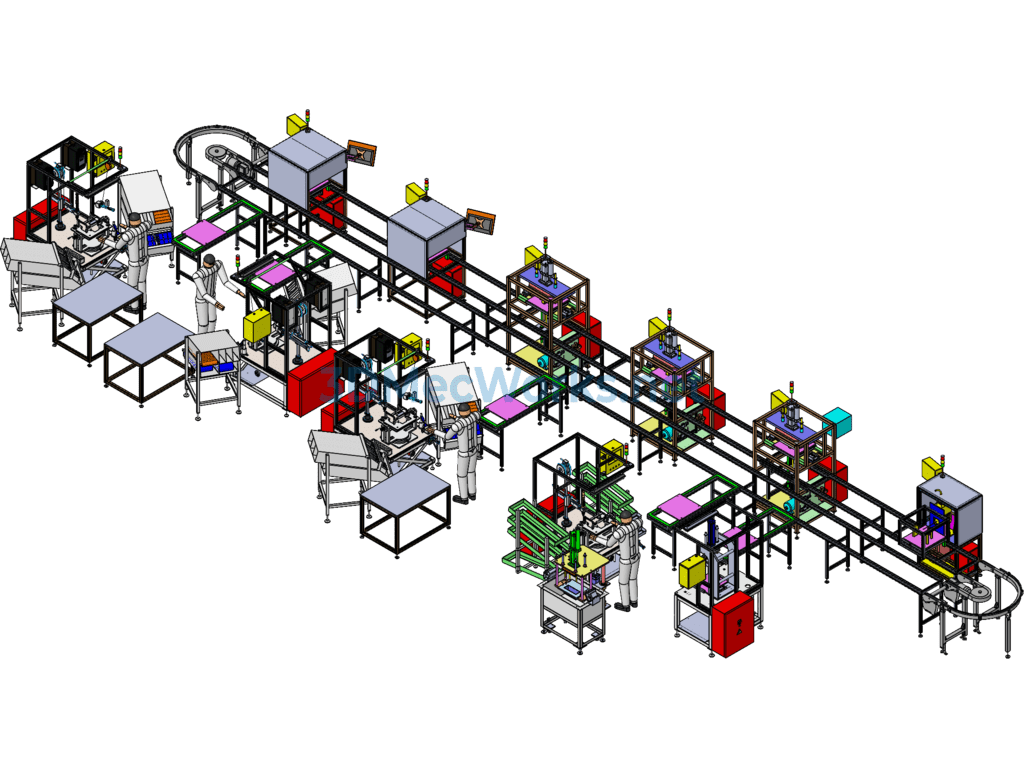

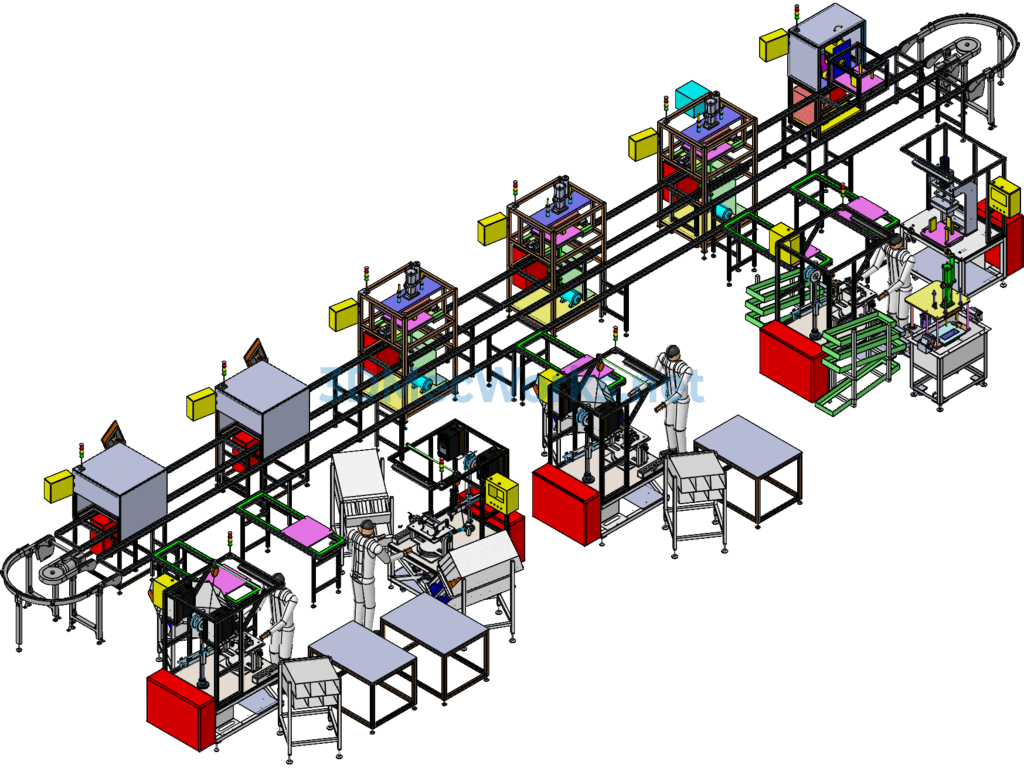

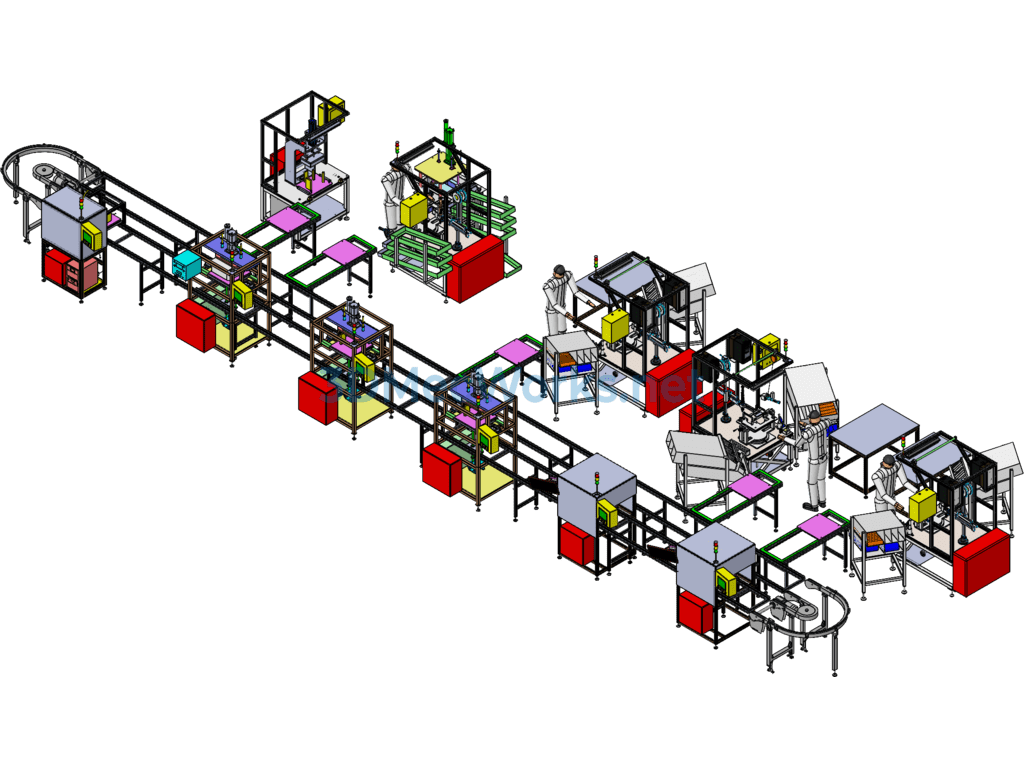

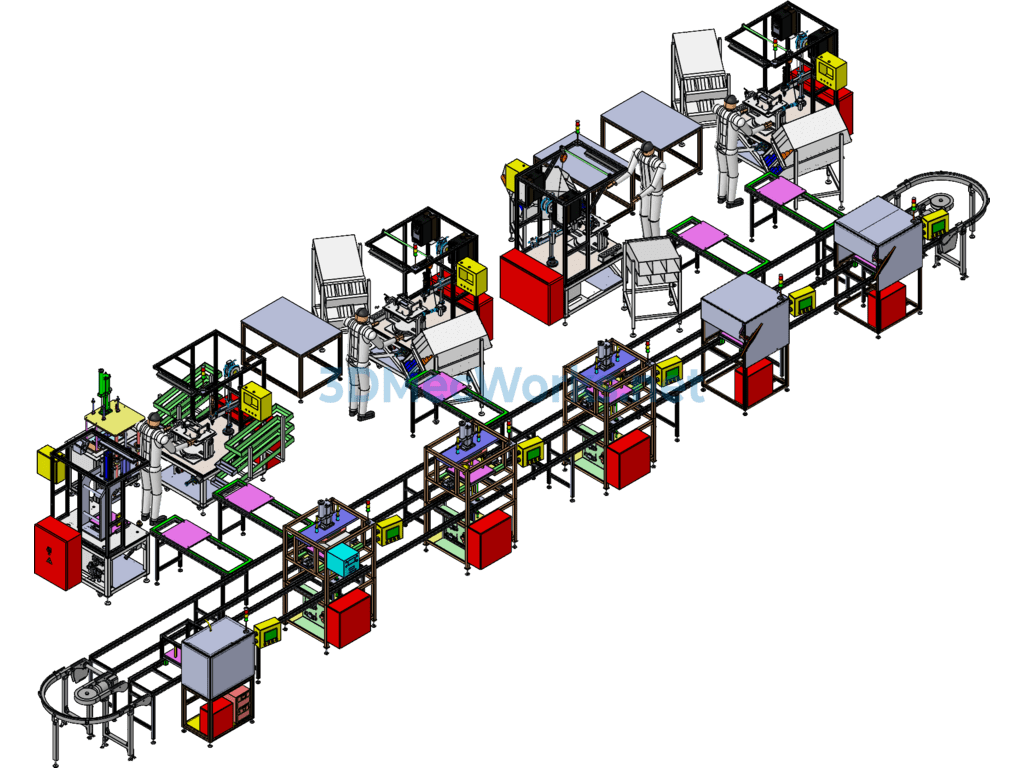

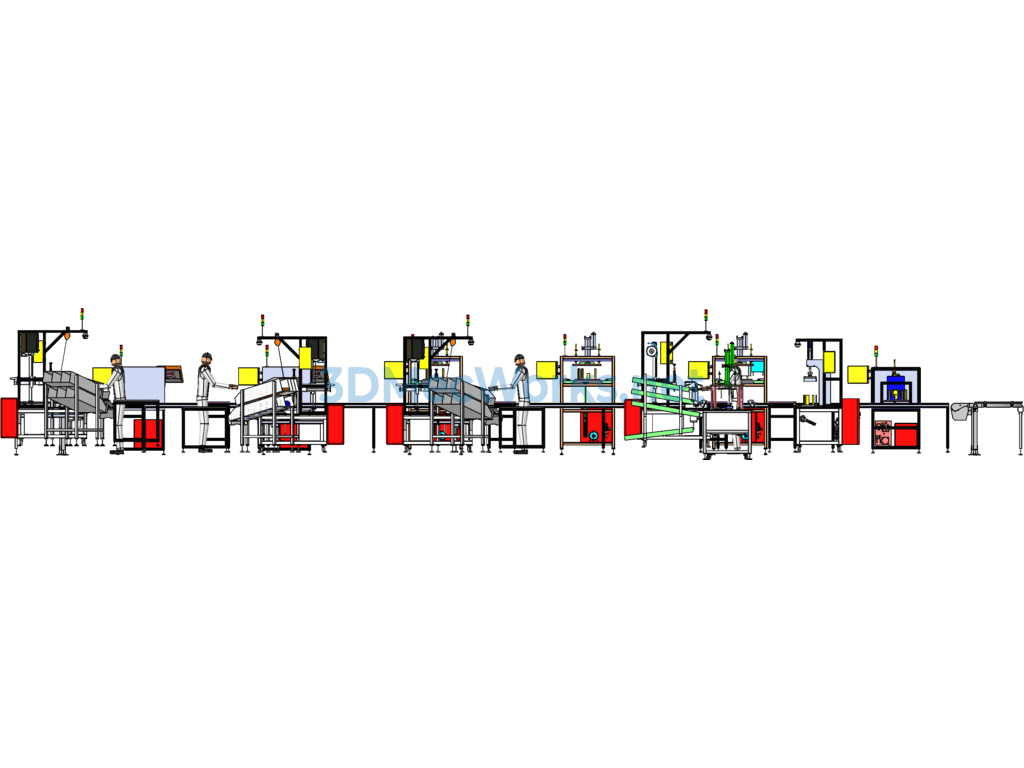

The functions of non-standard automated assembly lines and integrated inspection equipment include assembly machines, conveyors, and inspection devices. The equipment is highly robust, with advantages such as high speed, stable product quality, and a one-time investment. The subsequent costs are primarily maintenance and upgrade expenses, and it can enhance the overall operational capabilities of workers: it reduces the number of manual steps workers need to be directly involved in during production.

Disadvantages of non-standard automated assembly and inspection integrated equipment include slow results, high initial investment, and the initially developed equipment may not fully meet production requirements, necessitating continuous improvement and optimization.

3D models and source files (sldasm, sldprt) for non-standard automated assembly lines and integrated inspection equipment are available, providing nearly 600 files. They are worth referencing and available for download.

Specification: Non-Standard Automated Assembly Line and Integrated Testing Equipment

|

User Reviews

Be the first to review “Non-Standard Automated Assembly Line and Integrated Testing Equipment”

You must be logged in to post a review.

There are no reviews yet.