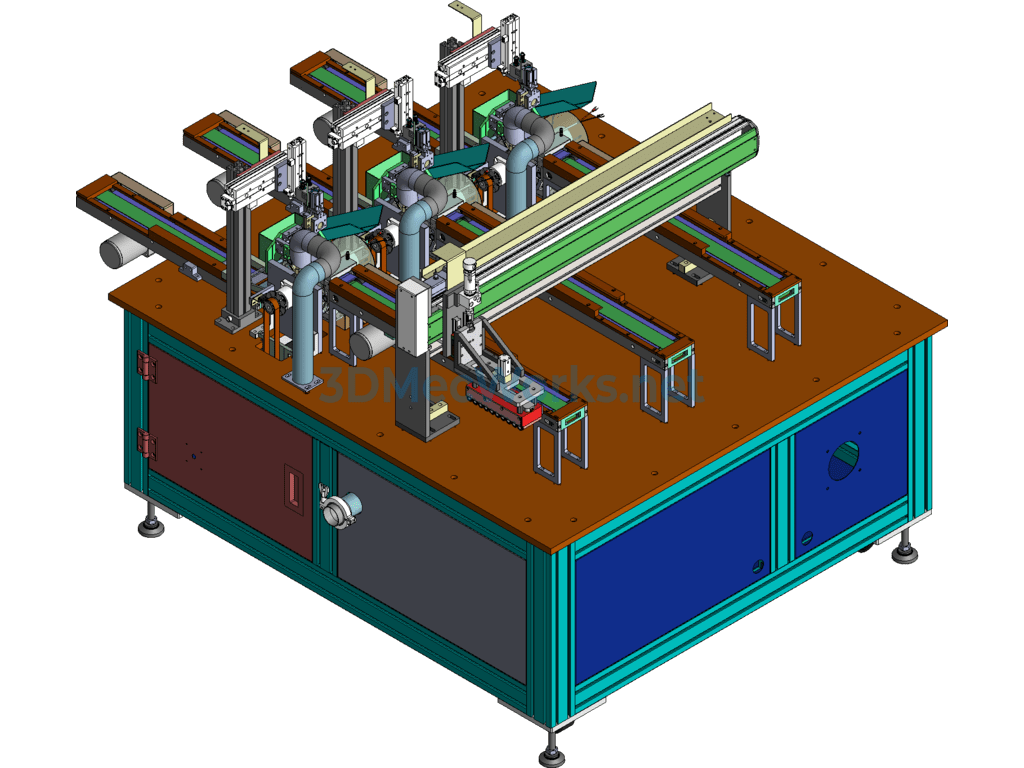

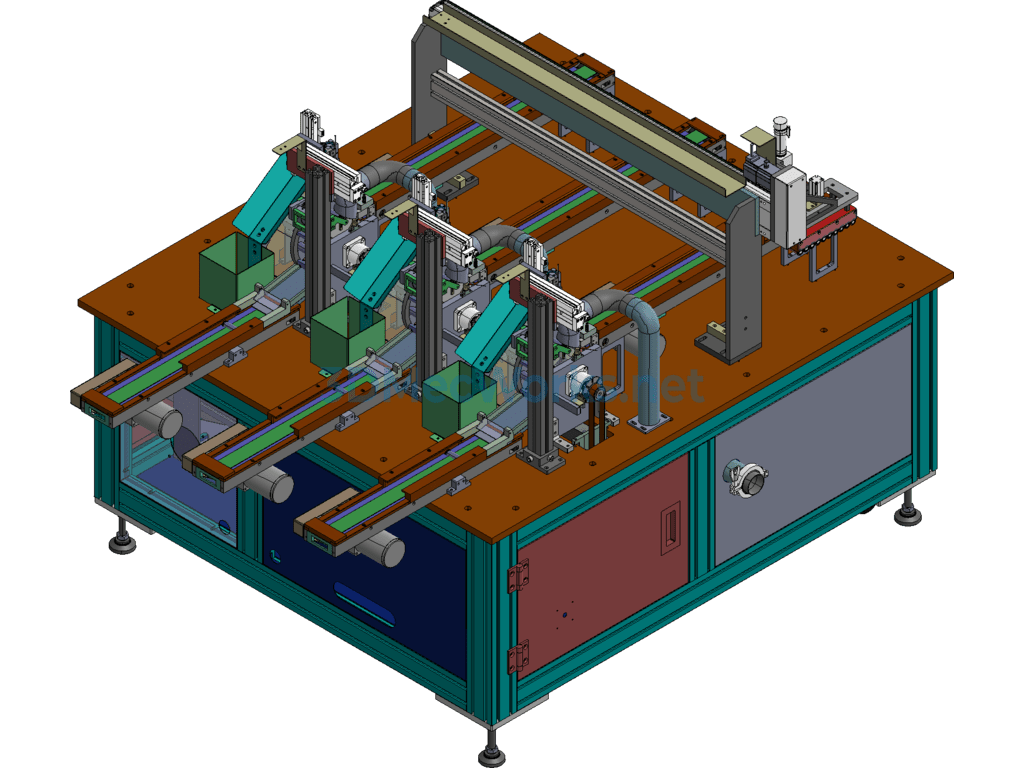

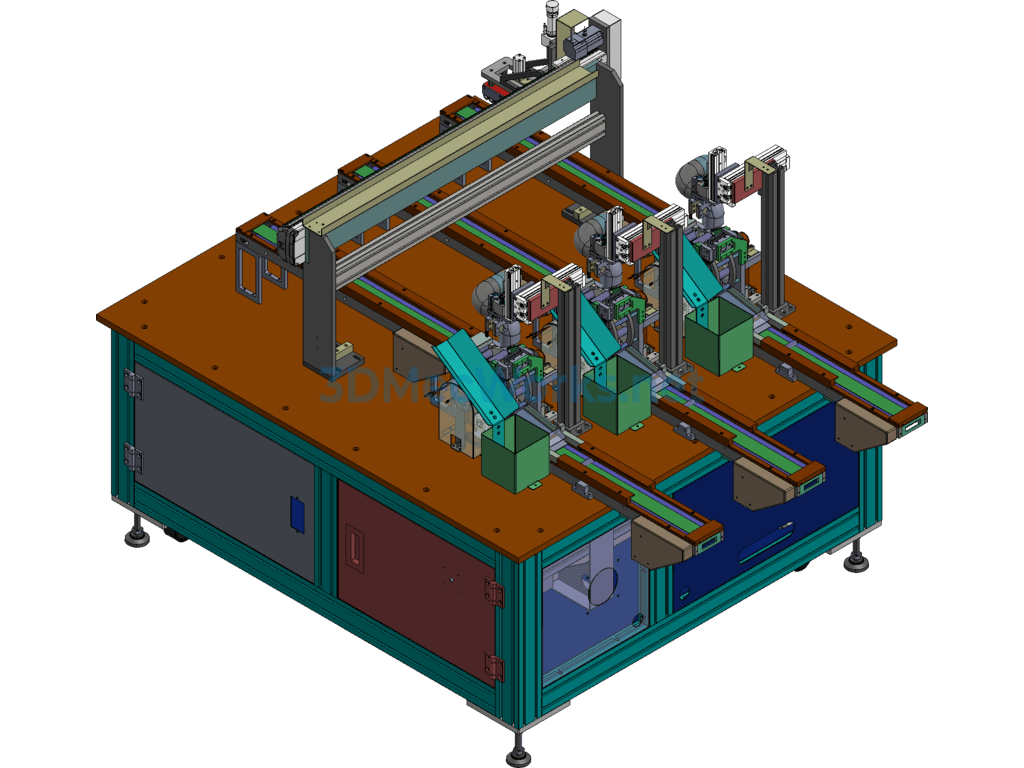

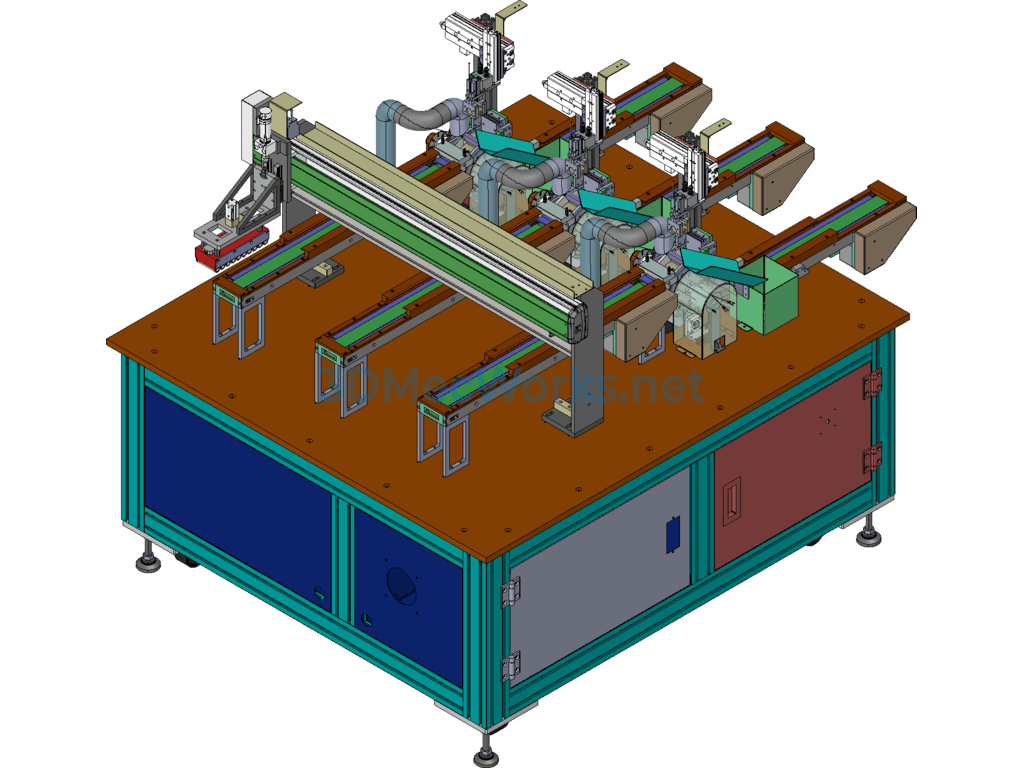

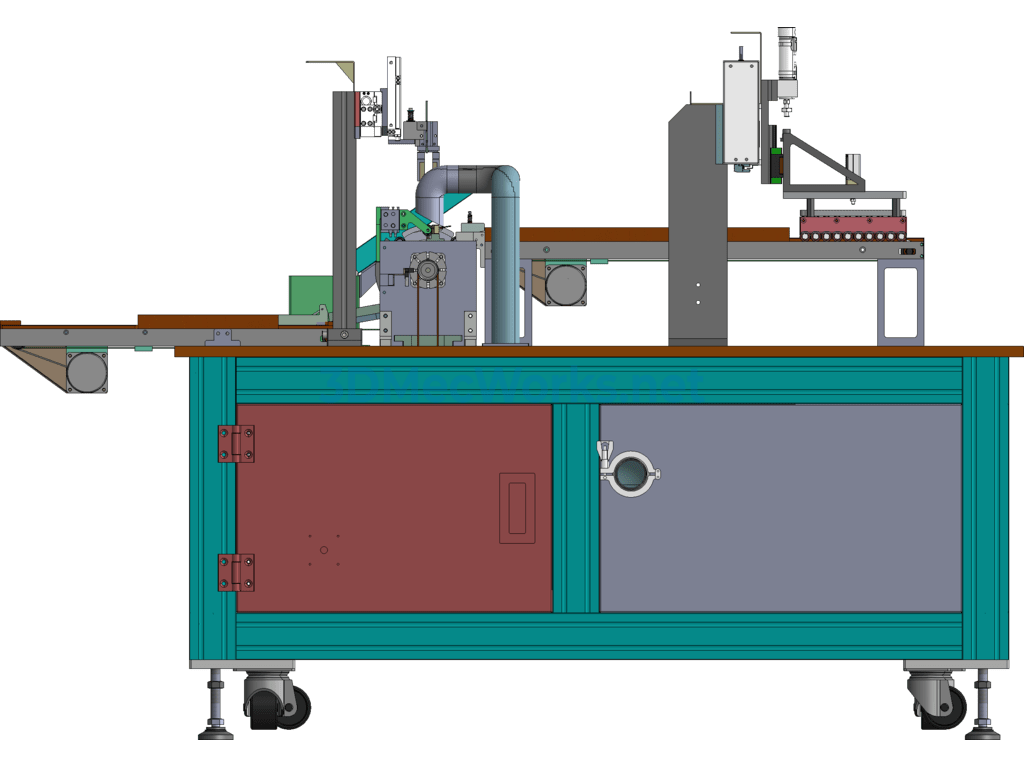

Machine Name: 18650 Cylindrical Battery Cell Automatic Cutting and Stripping Equipment

Working Principle Introduction

This equipment is suitable for products such as: 18650 battery cells, 26650 cylindrical mobile power supply batteries, automotive power batteries, and other cylindrical battery cell stripping. This equipment primarily consists of an automatic stripping and loading/unloading device for new energy power batteries: the complete set of drawings decompressed is over 100 MB, and the main machine has over 200 parts. The equipment mainly strips cylindrical battery cells through hot cutting. Initially, the battery cells are manually placed into the feed conveyor belt, and a robotic arm grabs the cells and moves them into the stripping section conveyor belt. The choice of conveyor belt depends on the production speed. The battery cells enter the stripping fixture via the conveyor belt. When the battery enters the cutter fixture, the cutter rotates, clamping the battery cell so that the cutter can peel the skin of the battery cell. The robotic arm then grabs the stripped off Qingke paper, which we refer to as waste material. The stripped battery cells are automatically discharged via the output conveyor belt, and manual collection and boxing can be performed. The principle of stripping is that the battery cell remains stationary while a stepper motor drives the cutter fixture to rotate. The cutter remains in a heated state, rotating at high speed to cut the outer skin of the battery cell, with a cutting precision of 0.1 mm. This equipment has a capacity of about 7000-8000 per hour for the three channels, so this stripping structure and speed can generally meet the needs of most customers in the market. Automatic loading and unloading can be added at the front and rear ends of the equipment based on cost considerations, either manually or automatically. The internal cutter structure diagrams can be seen as relatively complex. Of course, if you want to understand the design in more detail, you would need to download and study it slowly. The full set of drawings is complete, and those who need it or are interested are welcome to download and learn. The above is the complete structure and working principle of this equipment.

IV. Main Technical Parameters:

Category Specifications

Overall Dimensions: 1350*1220*1700MM (L*W*H)

Input Voltage: AC-220V 50Hz or AC-380V 50Hz Optional

Maximum Power: 0.9KW (when at 220V)

Input Air Pressure: 0.4-0.6 Mpa

Air Consumption: 1.5 L/min

Production Efficiency (C/T): ≤1.0 S/each

Equipment Utilization Rate: ≥95%

Processing Method: Automatic detection, automatic stripping, automatic discharge

Feed/Replace Method: Manual feeding

Specification: Non-Standard 18650 Cell Automatic Peeling Machine, 18650 Cylindrical Battery Peeling Equipment

|

User Reviews

Be the first to review “Non-Standard 18650 Cell Automatic Peeling Machine, 18650 Cylindrical Battery Peeling Equipment”

You must be logged in to post a review.

There are no reviews yet.