In the manufacturing process of lithium-ion batteries, after the completion of the electrode sheets, the positive and negative electrode sheets and the separator are assembled together using winding or stacking methods, with the separator isolating the positive and negative electrode sheets. During battery charging and discharging, the separator isolates electron conduction between the positive and negative electrode sheets, while allowing lithium ions to pass through. After winding or stacking assembly, the bare cell undergoes hot pressing treatment to shape the electrode sheets and separator, ensuring closer contact and reducing lithium ion transport resistance. Simultaneously with hot pressing, the bare cell often undergoes an insulation voltage resistance test, which is crucial for determining whether there are any foreign particles inside the cell causing a short circuit.

The instrument applies a voltage to the cell, maintaining this voltage for a specified period of time, and then measures the leakage current to see if it remains within the specified range, determining if there is a short circuit between the cell’s positive and negative electrodes.

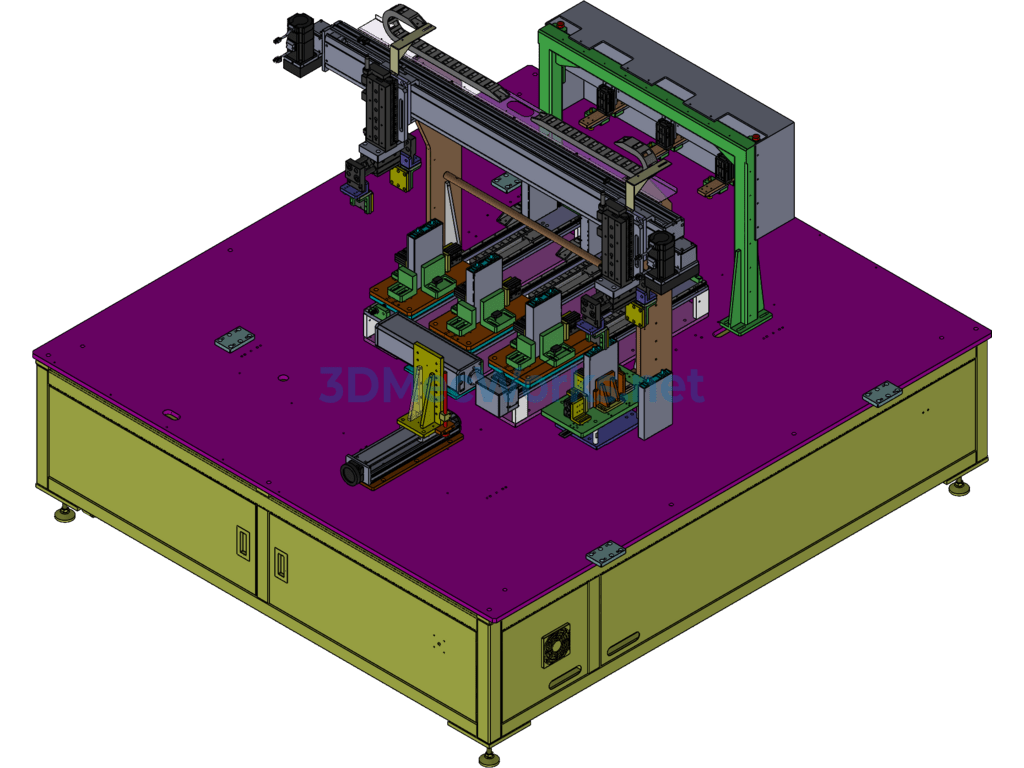

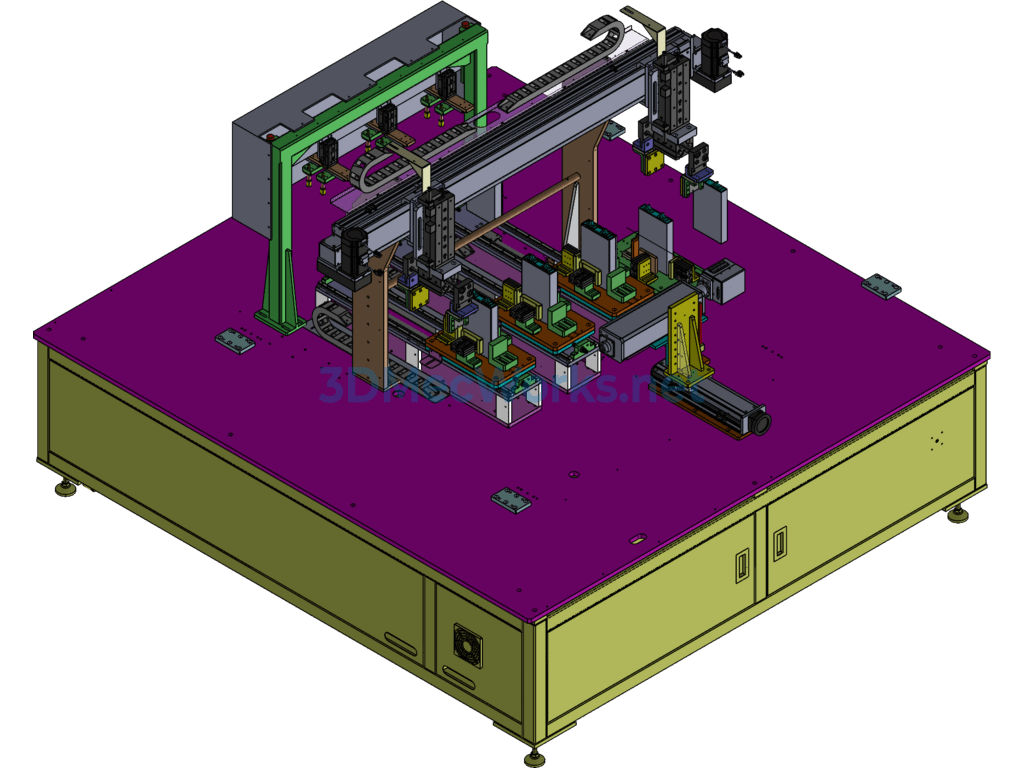

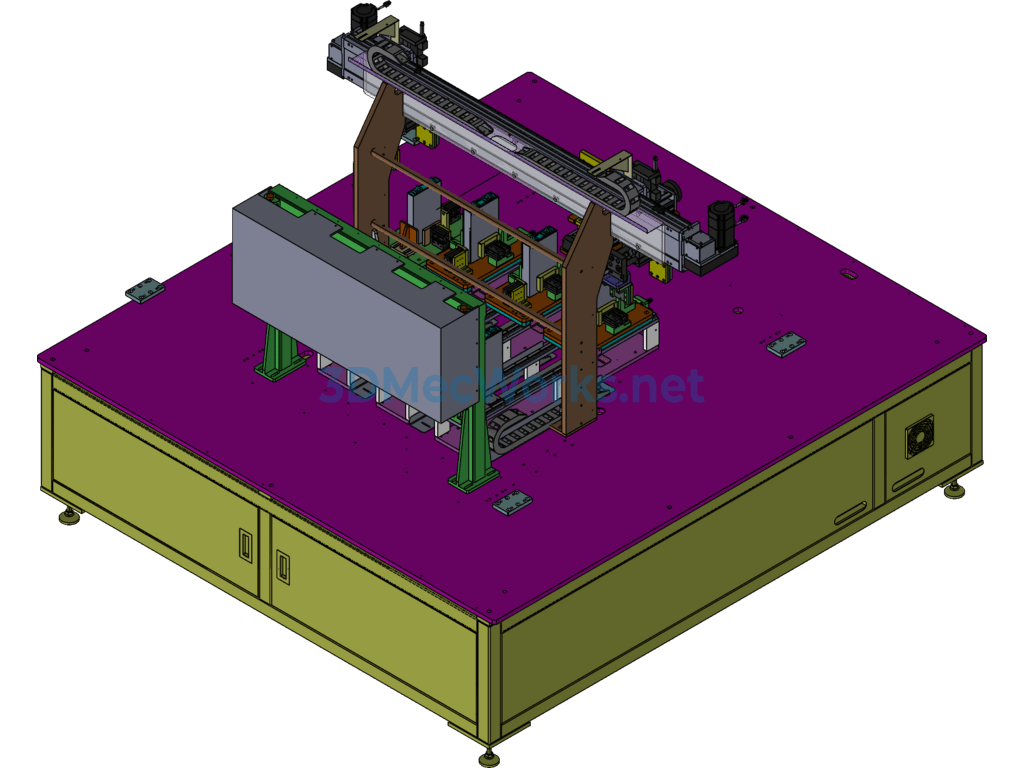

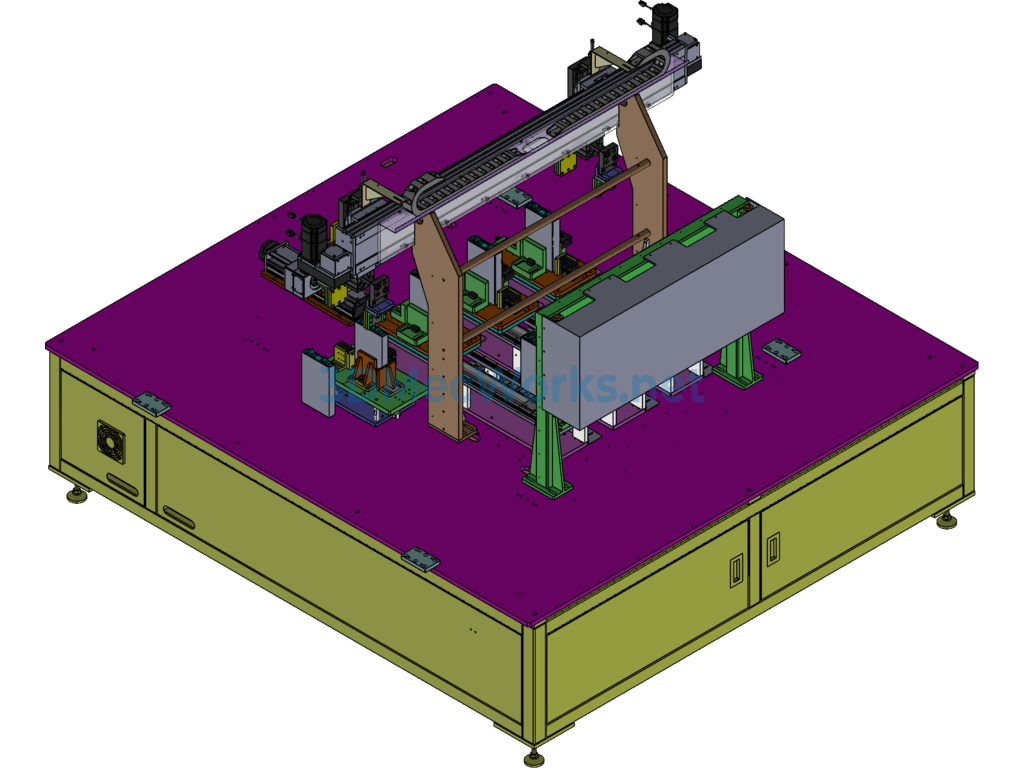

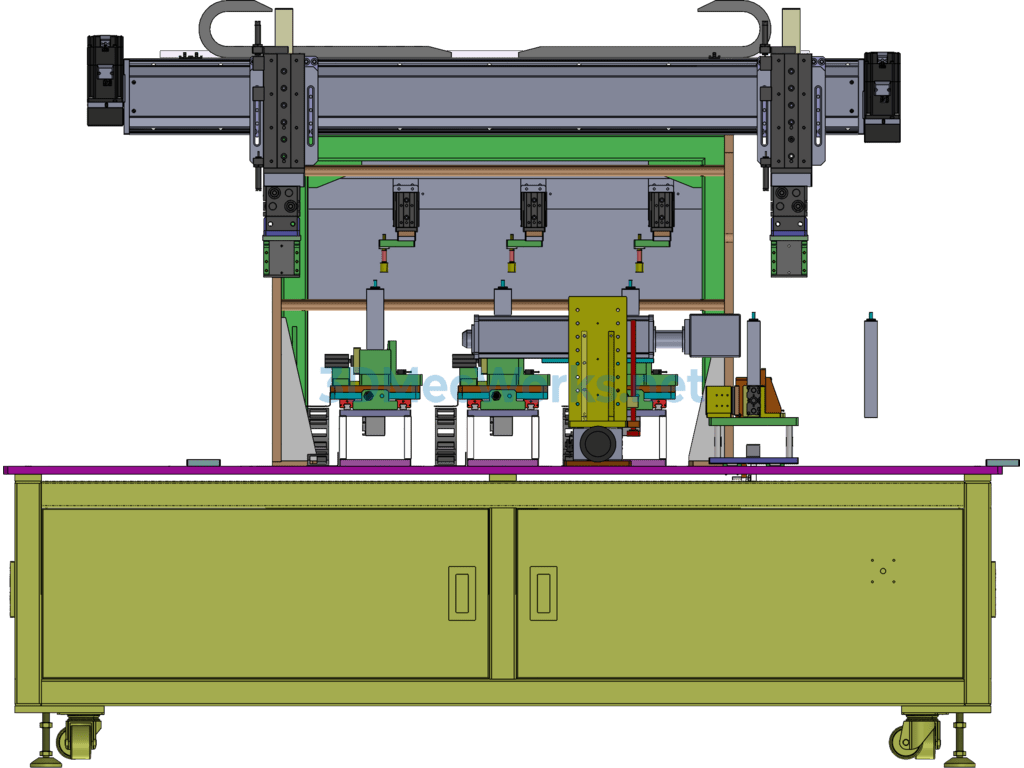

Specification: New Energy Power Battery Cell Insulation Tester

|

User Reviews

Be the first to review “New Energy Power Battery Cell Insulation Tester”

You must be logged in to post a review.

There are no reviews yet.