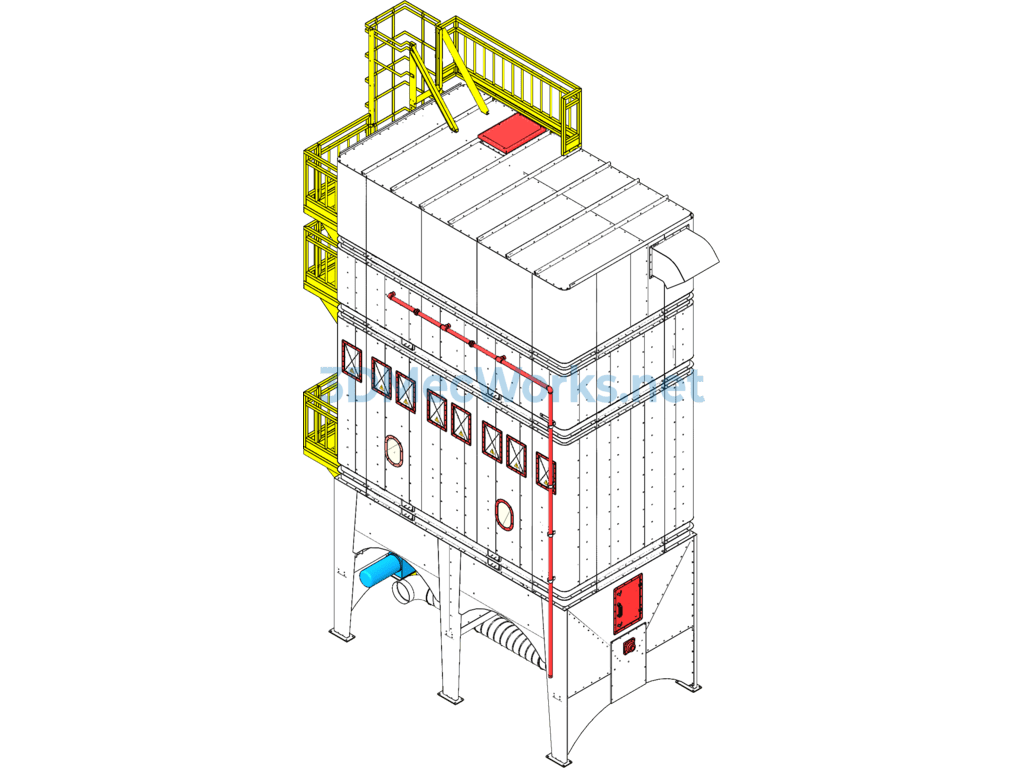

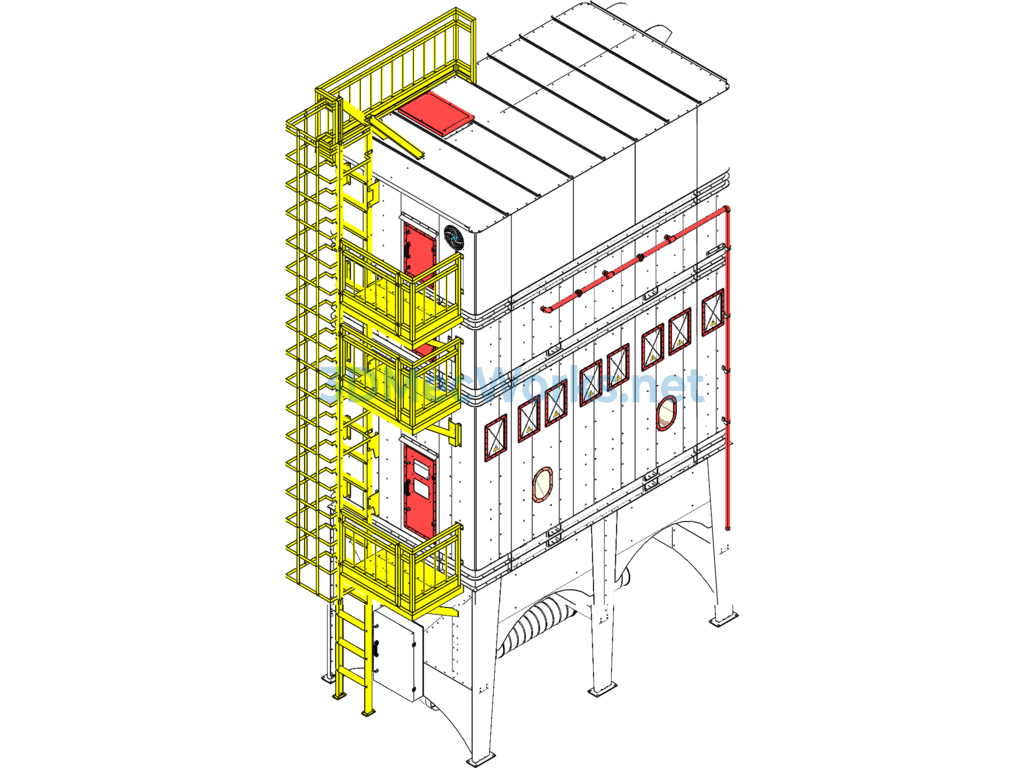

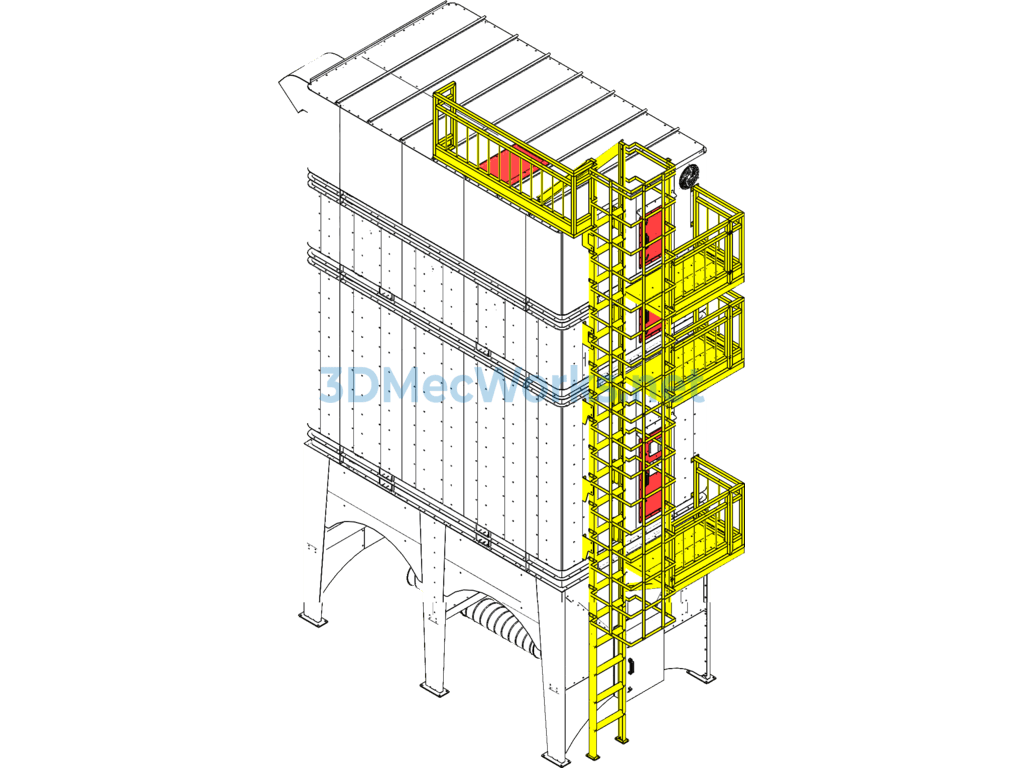

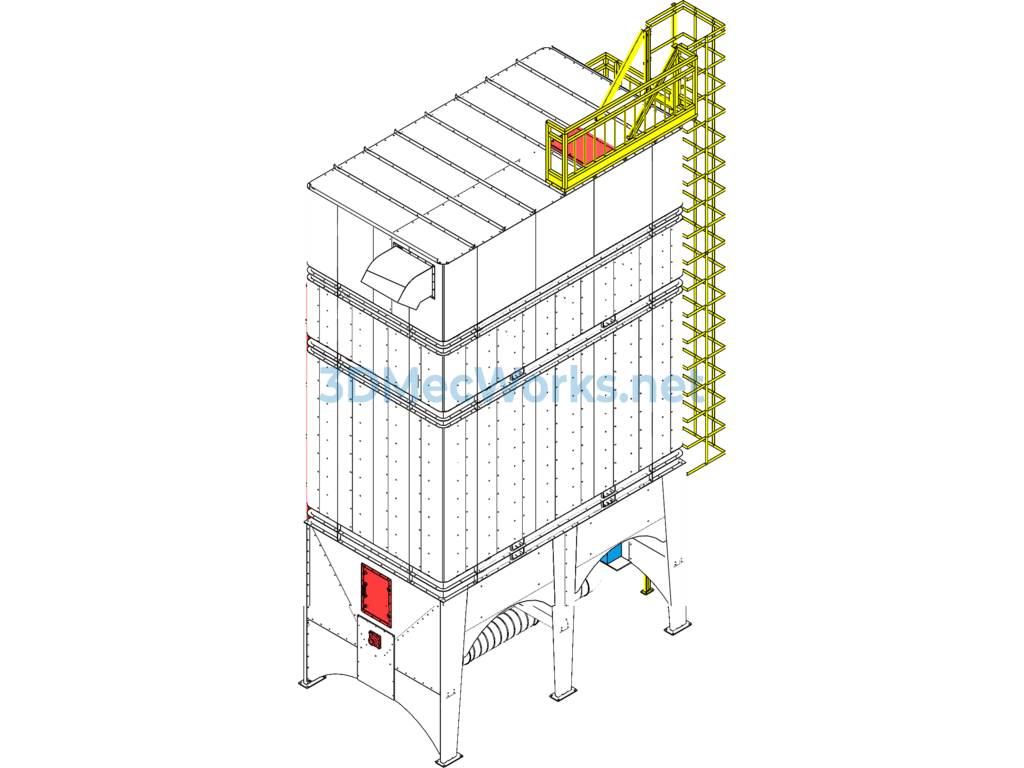

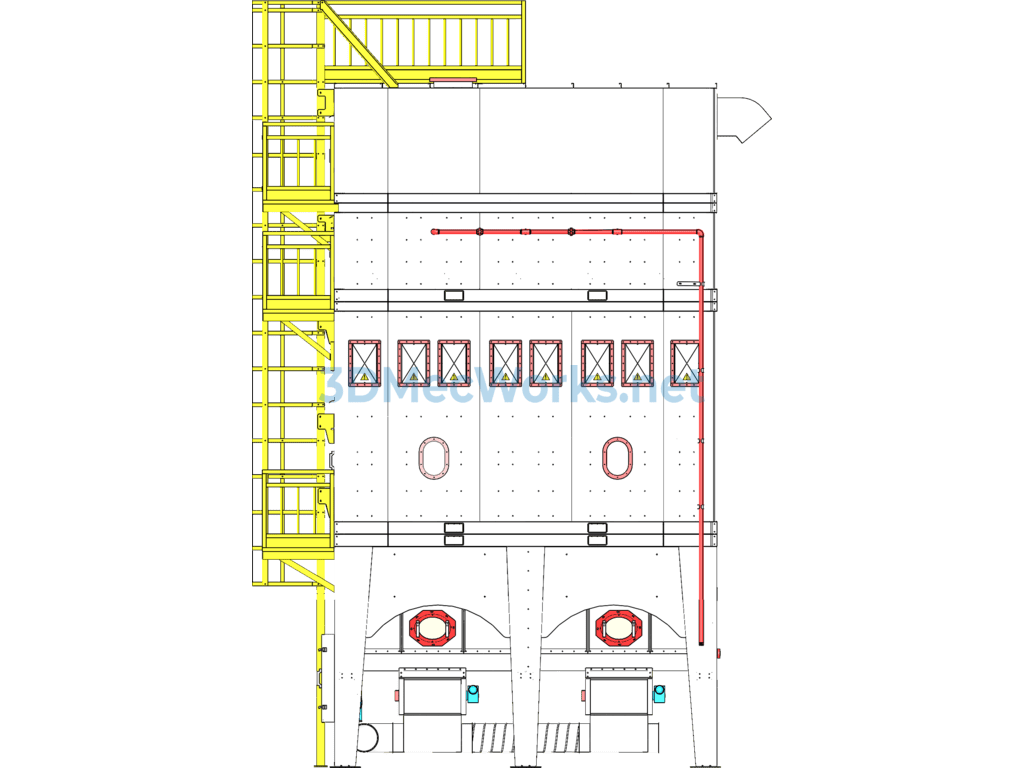

Woodworking Dust Collector: A specialized device composed of ductwork, fans, and filters used in woodworking shops, sanding workshops, and painting workshops to remove particles like sawdust and paint dust generated during processing. All parts are drawn using SolidWorks sheet metal feature at a 1:1 scale. Working principle: The airstream containing wood particles is drawn into the dust hopper by the fan, where heavier wood particles fall to the bottom under the influence of gravity and are discharged into the dust bin through the ash discharge valve. Other lighter and finer dust particles are adsorbed onto the outer surface of the filter bags as they flow upwards with the airstream. After passing through the bag filter, the clean air enters the exhaust chamber and is discharged outside. As the filtration process continues, more dust accumulates on the outer surface of the filter bags, correspondingly increasing the operating resistance of the system and reducing the system’s dust removal efficiency. Therefore, this system is equipped with an automatic pulse cleaning device, consisting of a pulse controller, pulse valve, quick coupling, air tank, and jet pipe. According to the characteristics of wood particles, the pulse amplitude and pulse frequency can be set on the pulse controller. Once the pulse amplitude and frequency are set, the system will automatically complete the cleaning of the filter bags during operation, thereby greatly enhancing filtration efficiency and extending the service life of the filter bags. The file includes three-dimensional design drawings and cutting drawings; all drawings are editable with parameters.

Specification: Multi-Unit Woodworking Dust Collector

|

User Reviews

Be the first to review “Multi-Unit Woodworking Dust Collector”

You must be logged in to post a review.

There are no reviews yet.