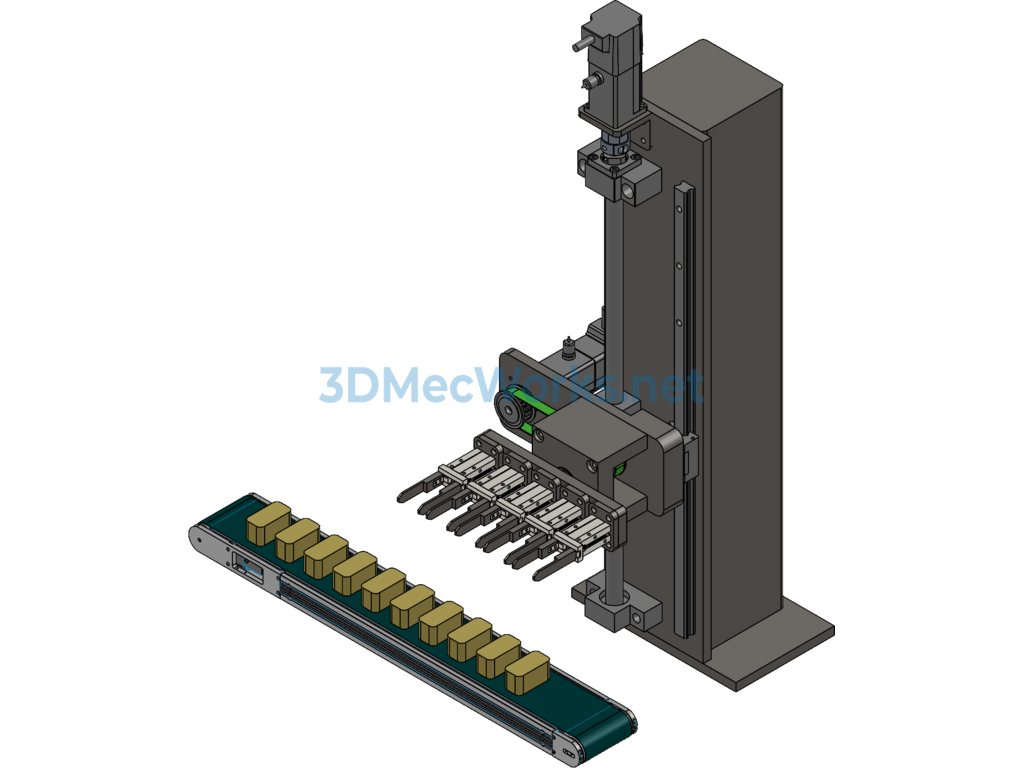

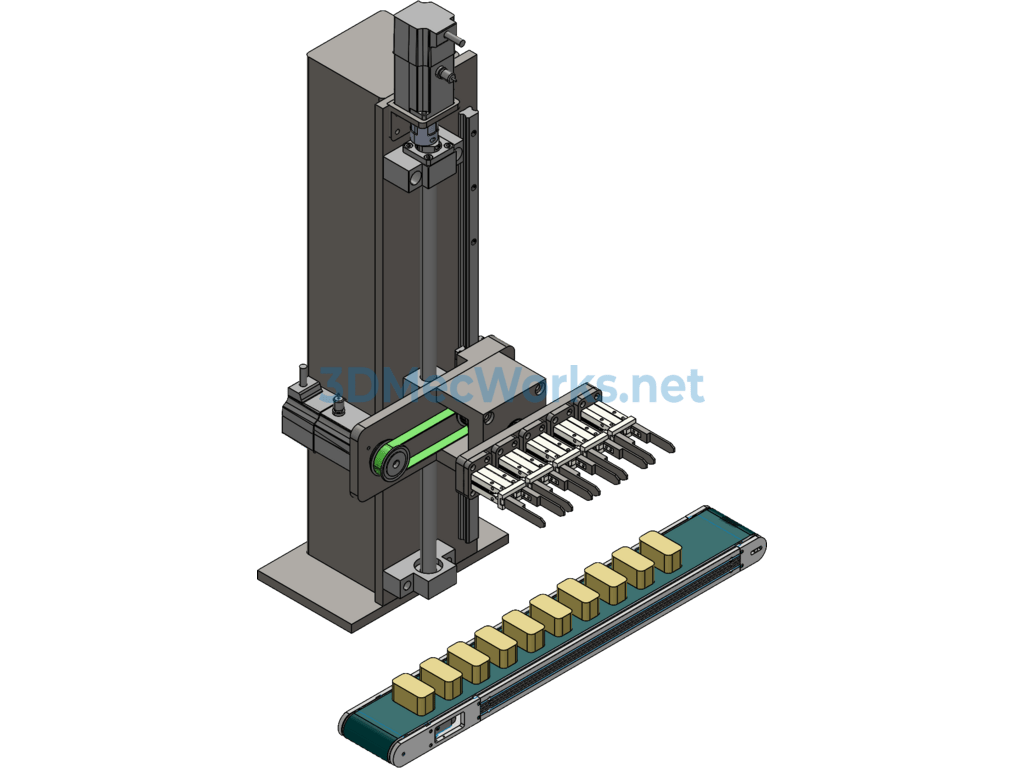

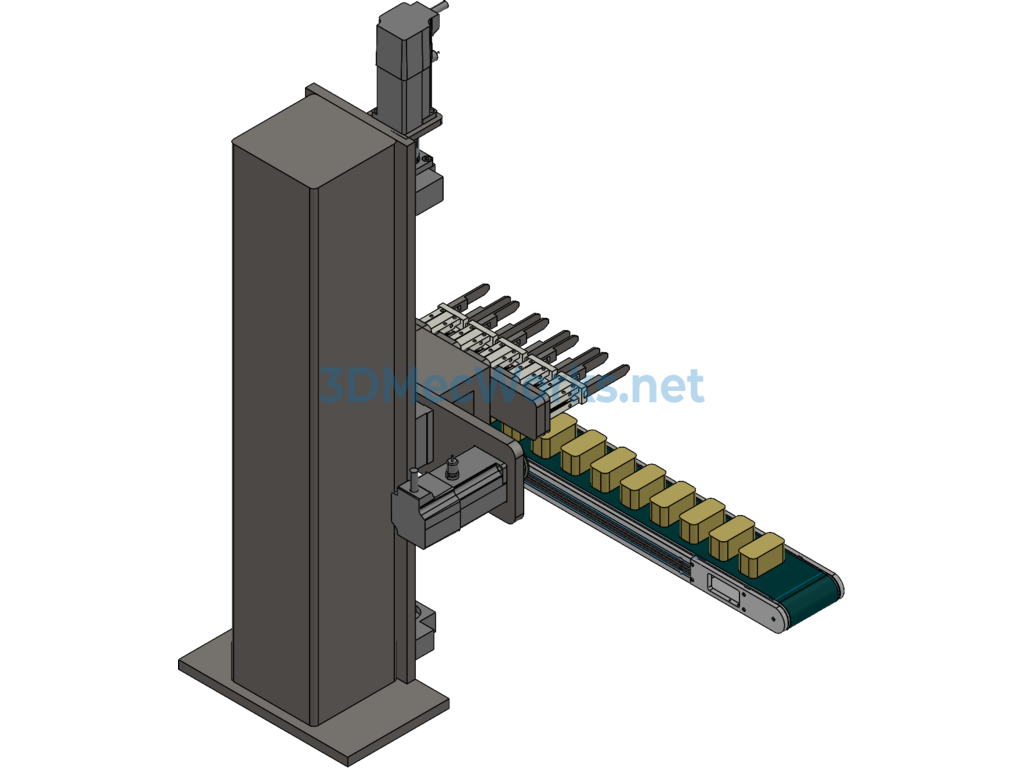

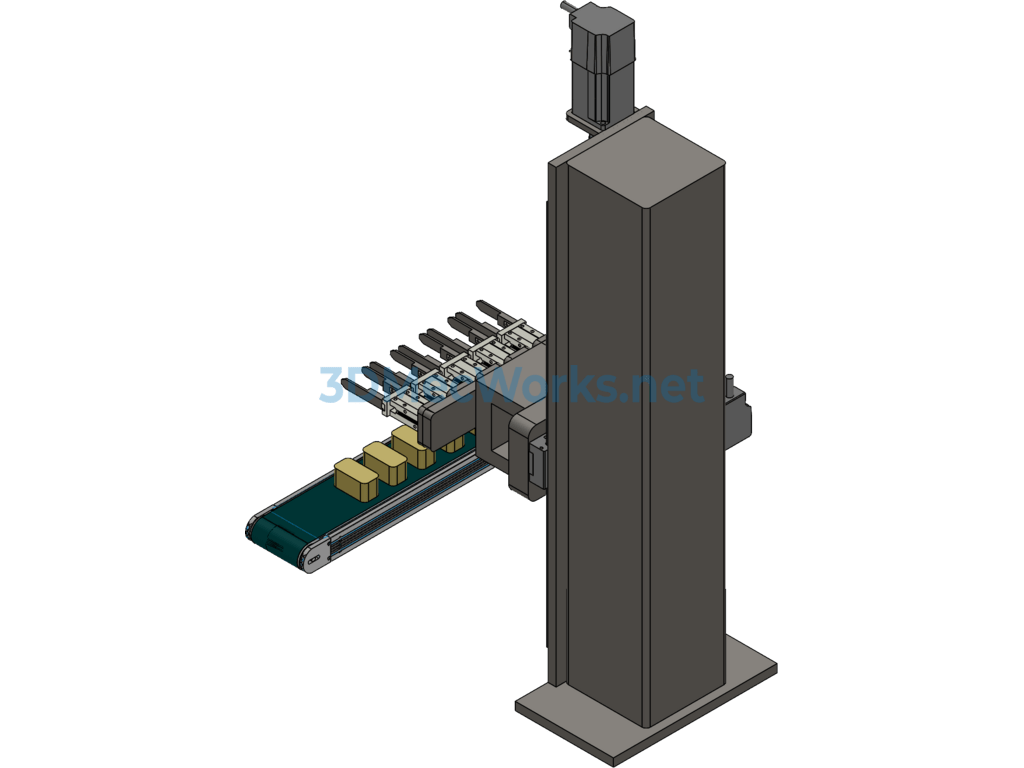

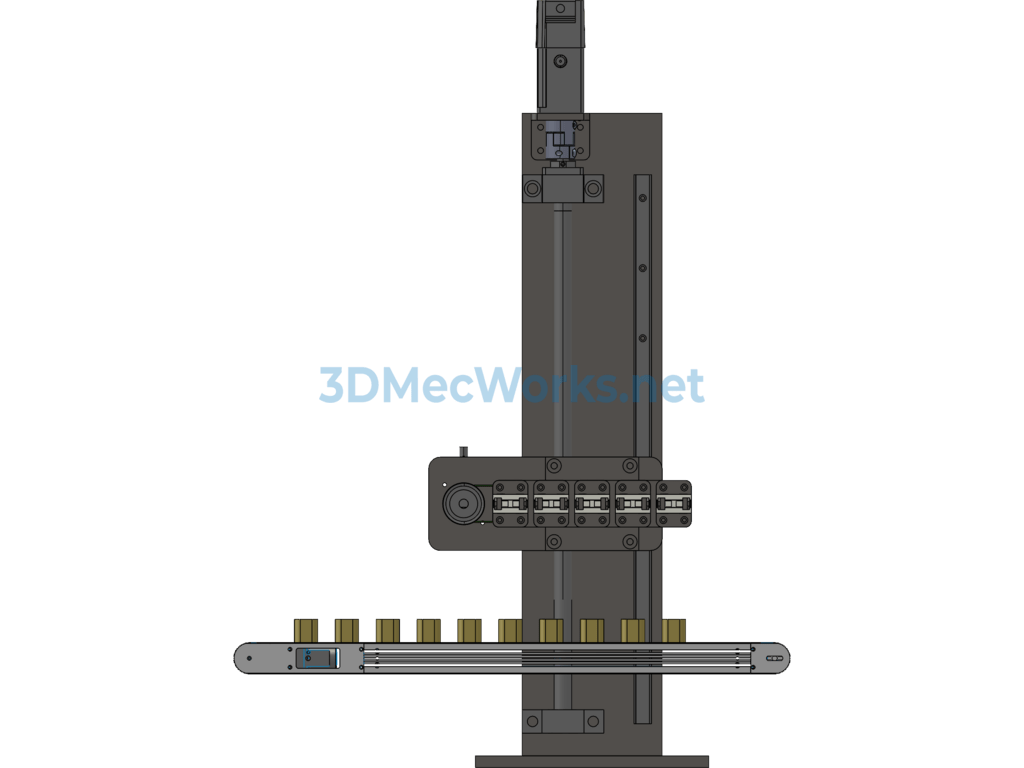

In factory production operations, we often encounter processes that require machining on both the top and bottom surfaces of a product, such as laser marking QR codes or inkjet printing on both surfaces. The conventional methods involve manual flipping, or using a manipulator when the equipment poses a risk to human operators. Manual operations are inefficient, prone to fatigue and errors, and labor costs are high, while manipulator operations require space for installation, take up a lot of space, and are costly. This proposal effectively solves the above problems and has the following advantages:

1. It can flip 5 products simultaneously, resulting in high efficiency;

2. The entire mechanism takes up little space and is easy to install;

3. Simple structure, easy to manufacture, low cost, and low maintenance expenses;

4. Strong applicability, suitable for both standalone equipment and assembly line operations;

5. The flip mechanism uses a synchronous belt drive, offering good flexibility, a compact structure, and easy installation. Both the synchronous belts and pulleys are standard parts, making them easy to procure and cost-effective.

Specification: Multi-Product Simultaneous 180° Flipping Mechanism

|

User Reviews

Be the first to review “Multi-Product Simultaneous 180° Flipping Mechanism”

You must be logged in to post a review.

There are no reviews yet.