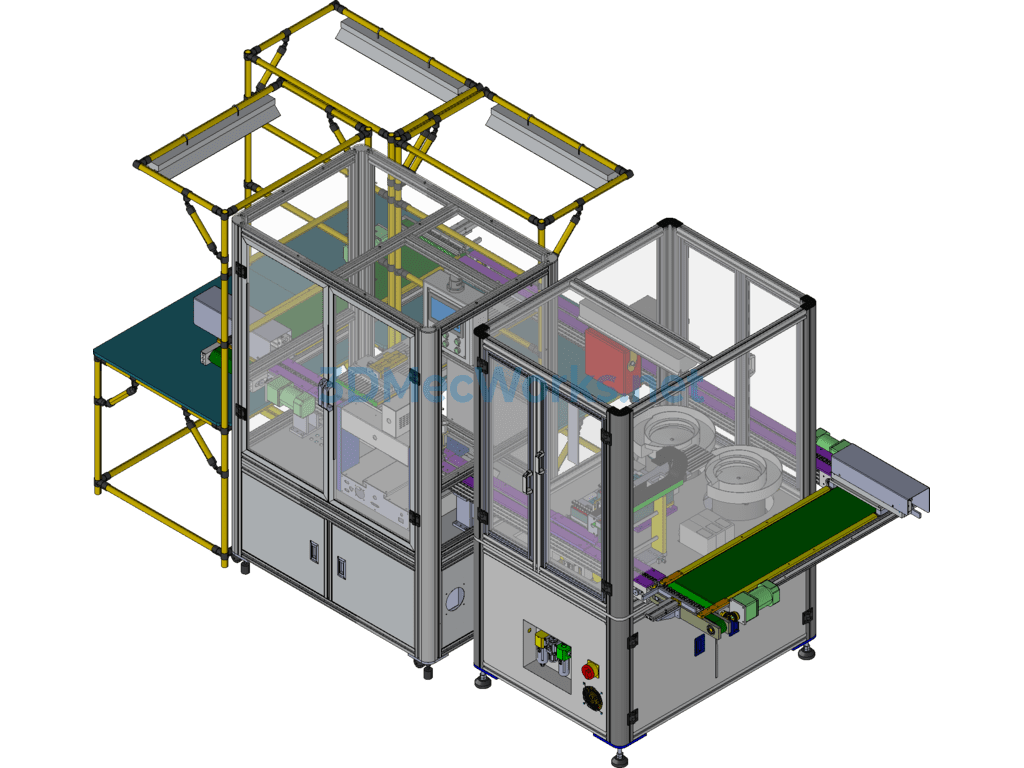

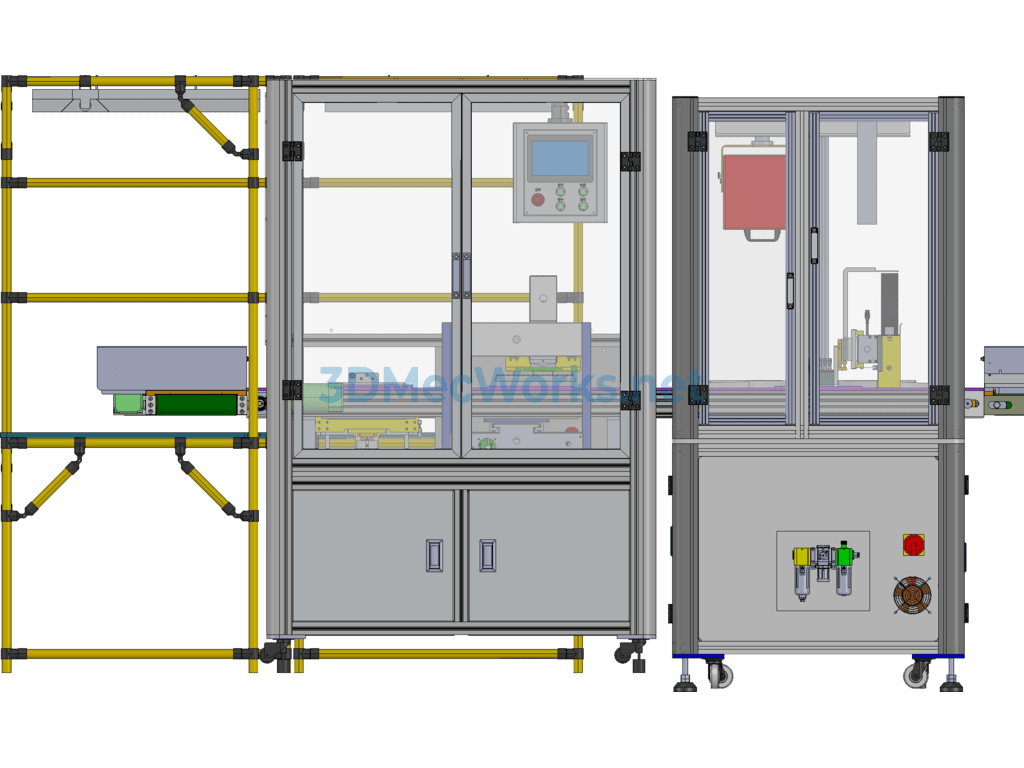

Assembly equipment, used for sorting and dispensing materials, assembly

The dispensing and assembly machine is divided into the following parts:

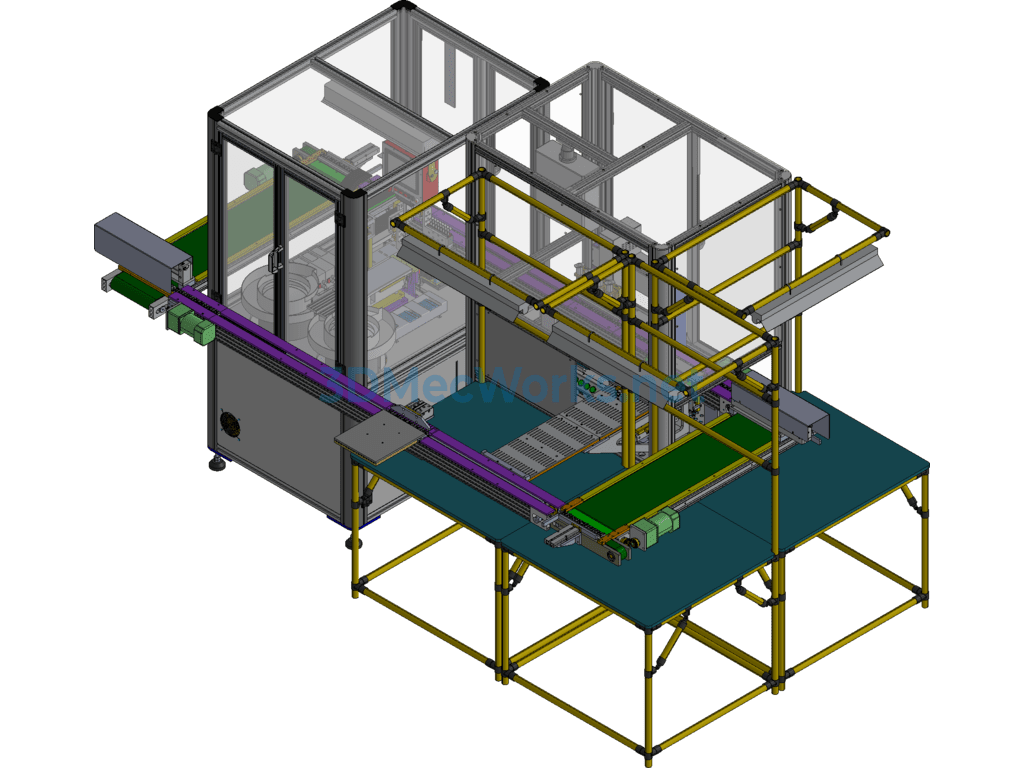

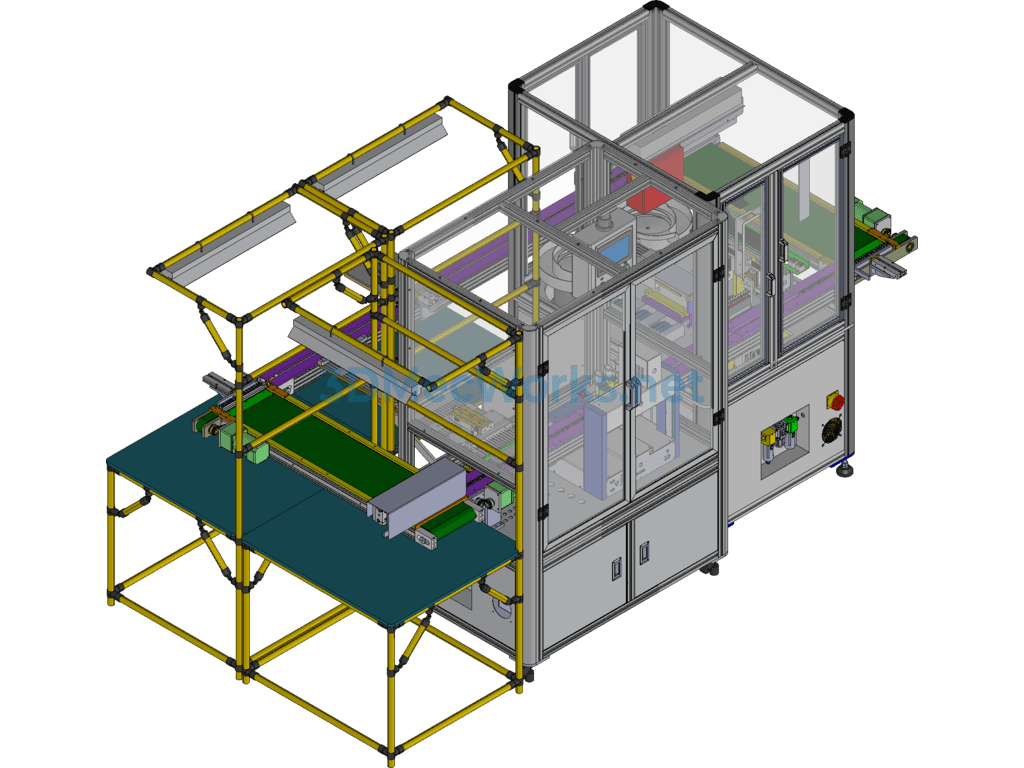

Clamping mechanism: Uses a side groove combined with a cylinder to lead into the groove, then the cylinder pushes down to achieve the unloading function.

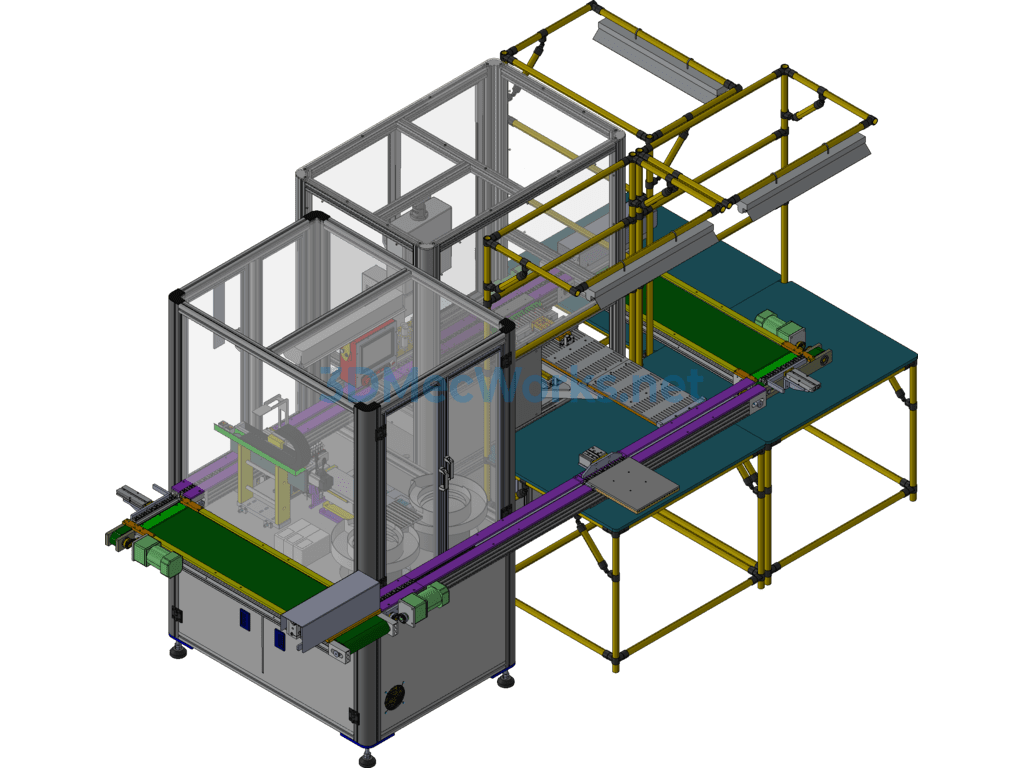

Fixture positioning mechanism: Achieves positioning of the fixture by using three cylinders to lift from below.

Discharge push-out mechanism: Uses a cylinder to drive a push needle to push the product out of the fixture.

Rodless cylinder misalignment receiving mechanism: Uses a rodless cylinder to drive two fixtures to achieve the function of exchanging material reception and unloading from both sides.

Iron core assembly equipment motion process:

Step 1: The fixture is moved into position by a conveyor belt, then lifted for positioning by a cylinder;

Step 2: The manipulator clamping mechanism moves to the left side for receiving, the left discharge push-out mechanism operates to push the product from the fixture into the clamping mechanism;

Step 3: The manipulator moves above the fixture, the cylinder pushes the magnet into the fixture;

Step 4: The manipulator clamping mechanism moves to the right side for receiving, the right discharge push-out mechanism operates to push the product from the fixture into the clamping mechanism;

Step 5: The push cylinder returns, the manipulator places the product on the fixture, the fixture positioning cylinder moves down and the fixture flows away;

Step 6: The product fills the fixture, the manipulator withdraws, the cylinder moves the fixture to the other side, cycling in sequence;

Specification: Magnet Sorting and Dispensing Assembly Equipment

|

User Reviews

Be the first to review “Magnet Sorting and Dispensing Assembly Equipment”

You must be logged in to post a review.

There are no reviews yet.