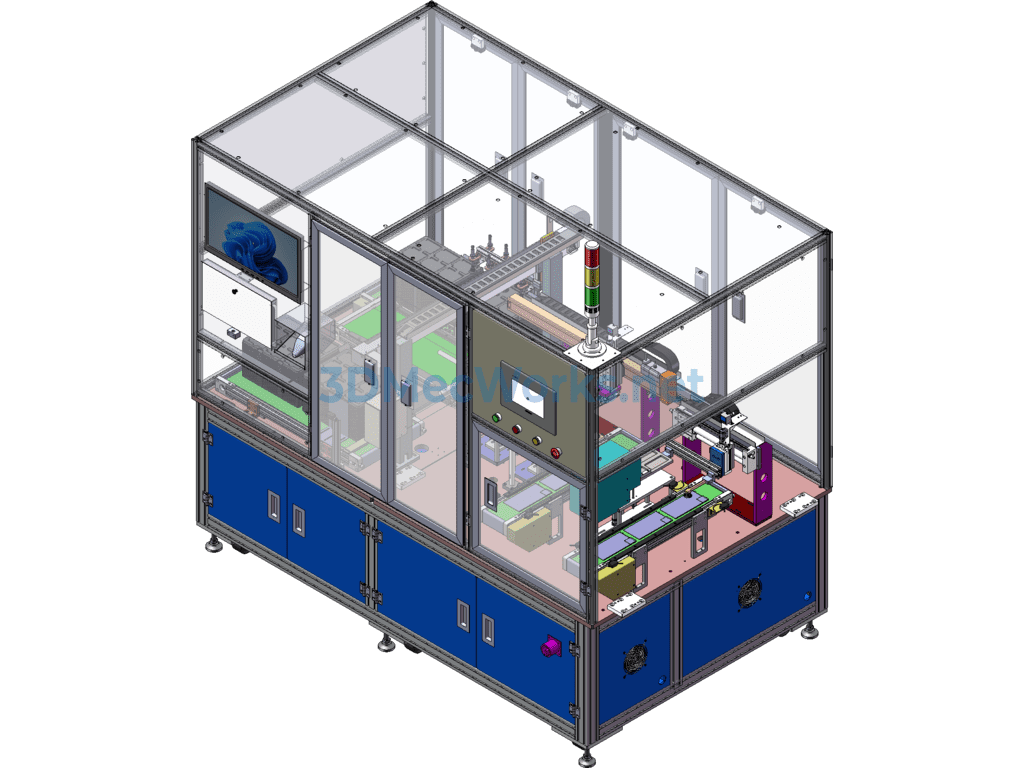

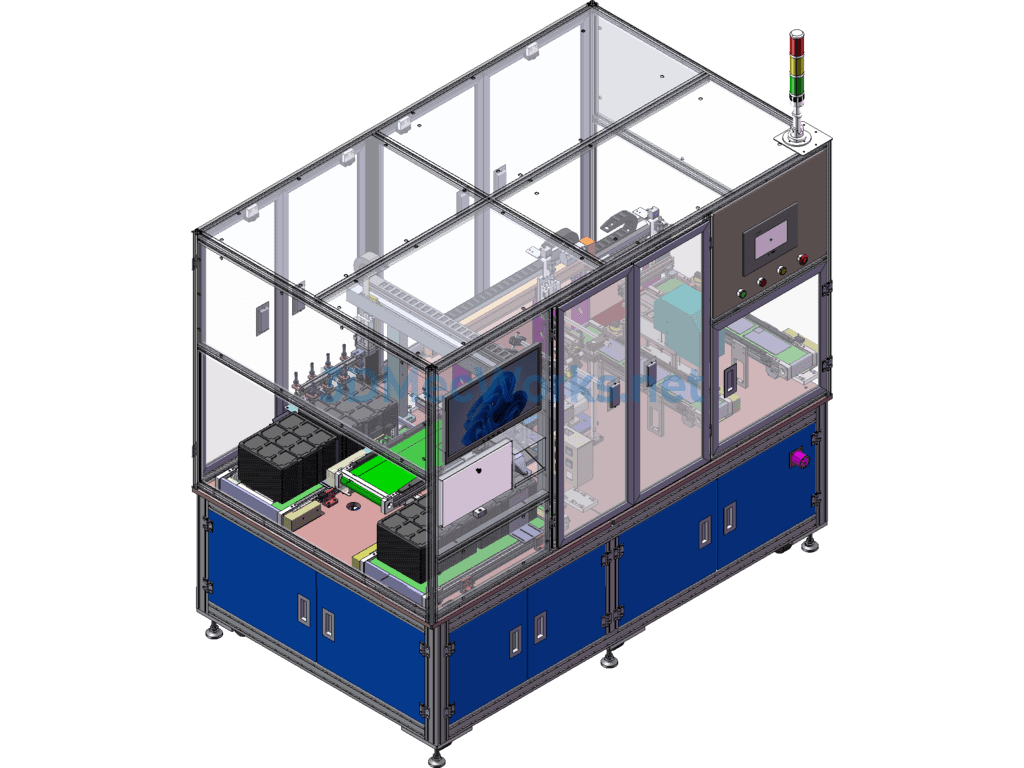

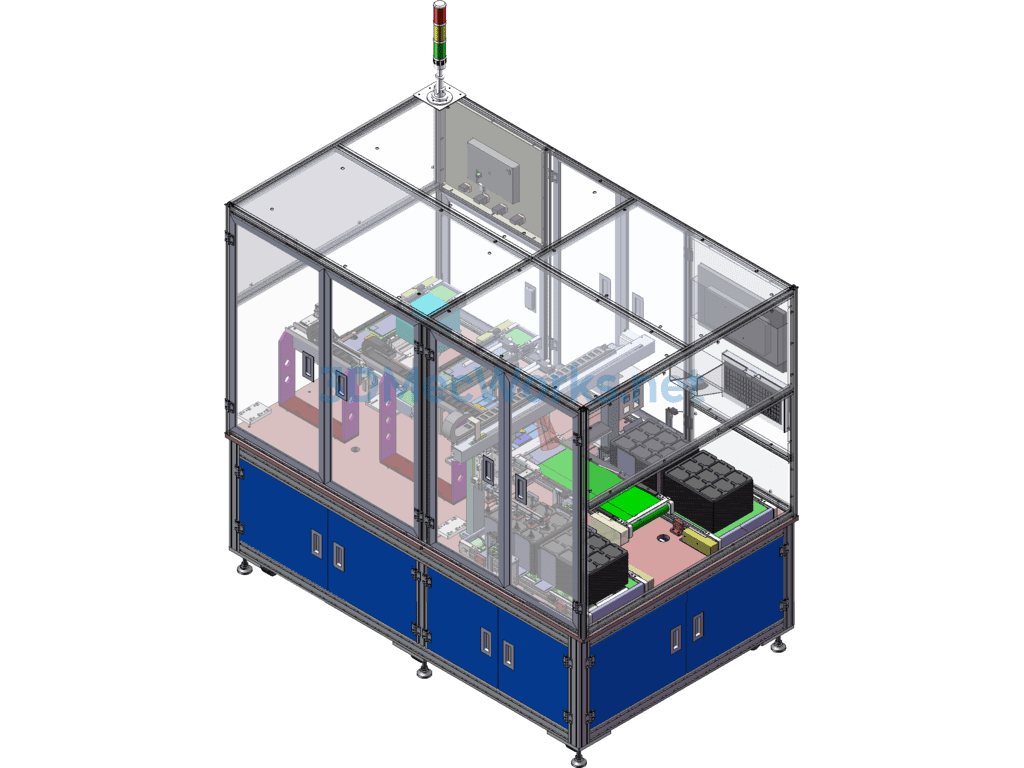

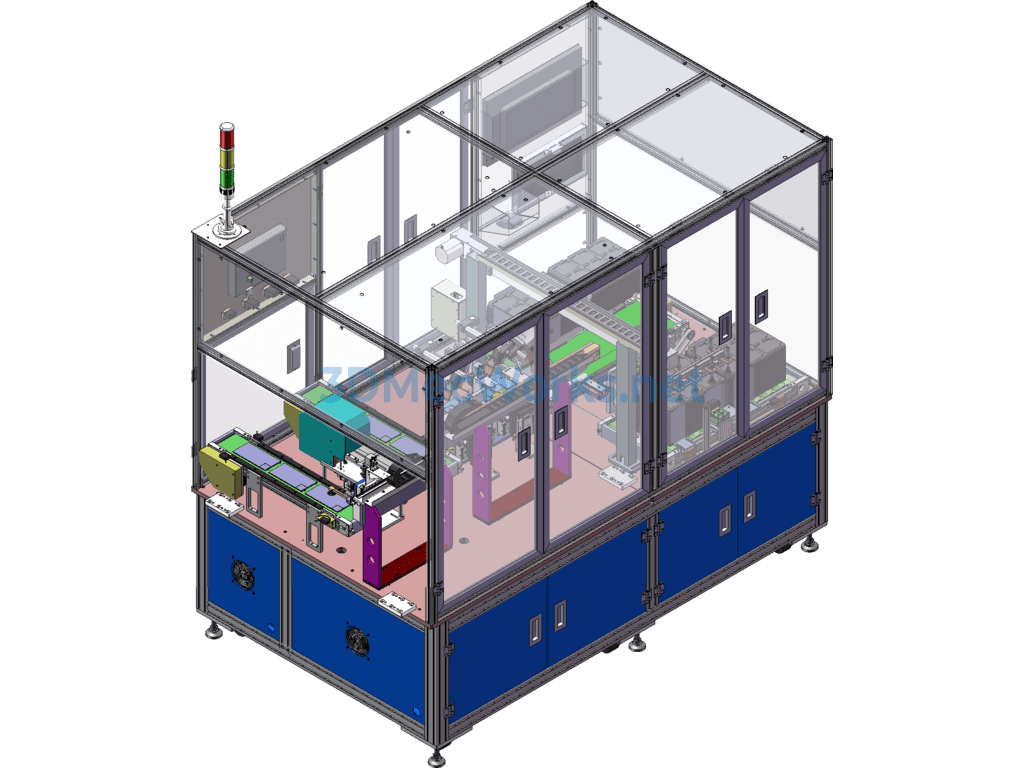

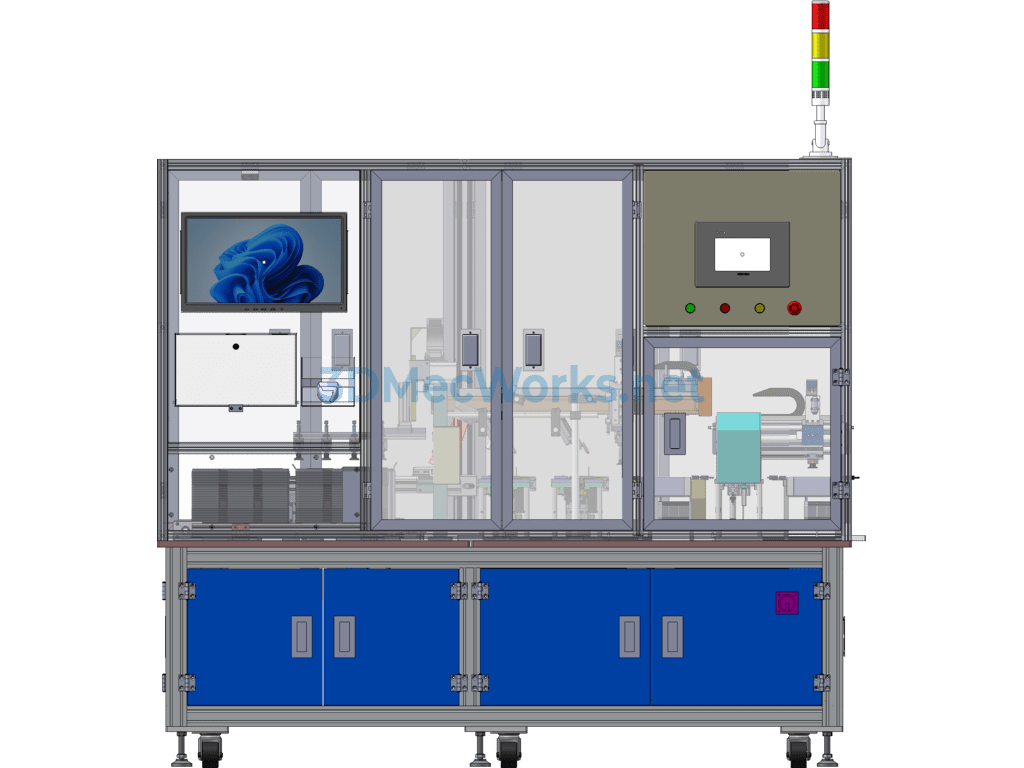

This machine is a device for testing the edge voltage and thickness of battery PACK. The drawings of this device are 300MB, with almost 500 small and large parts combined. The device’s 3D model is designed using SolidWorks 2012 software, and the entire set of drawings is original design. The quality of these drawings is superior to other members’ drawings and can be directly opened with SolidWorks after downloading. This device is a soft pack battery edge voltage and thickness testing equipment, mainly used for edge voltage and thickness testing of batteries. Finally, the inspected batteries are picked and placed at the unloading station, while defective ones are directed to the reject conveyor belt. The equipment operates fully automatically, with its main structural components including: 1. Automatic elevating loading tray assembly 2. Automatic handling robot 3. Feeding belt module 4. Battery edge voltage testing 5. Automatic battery scanning module 6. Battery leakage detection module 7. Battery handling robot 8. Defective product reject conveyor belt 9. Battery thickness testing module 10. Battery thickness testing reject and unloading robot.

Operation principle introduction: The battery feeding uses a blister tray which can stack many trays at once, allowing it not to require frequent material changes. Trays are conveyed by the feeding belt line. Once detected in position, the bottom lifting mechanism raises one tray at a time, and the robot then takes the batteries from the tray for loading. After battery picking is completed, the empty tray is grasped by the robot to another side for recycling, then the next tray is raised and the process repeats. The batteries are transported by the robot to the feeding belt where they undergo secondary positioning at the loading station. This positioning mechanism uses a cylinder and sensor at the rear of the feed belt to complete the material pushing and positioning action. Then, the next robot picks the battery for edge voltage and leakage testing; defective ones are placed onto the defect conveyor belt, and those testing OK are transported to the thickness testing station for thickness measurement. Upon completion of testing, the robot picks the battery to the unloading station, and similarly, defective products are discharged directly, while good products proceed to the next station for packaging and receipt. This is the complete introduction of the mobile battery pole edge voltage thickness testing machine. Due to the extensive nature of the drawings, a detailed understanding of structure and details requires downloading the drawings. This equipment is used in soft-pack battery PACK processing lines, so feel free to download them for reference and learning, all of which are excellent.

Specification: Lithium Battery Edge Voltage and Thickness Measurement Machine

|

User Reviews

Be the first to review “Lithium Battery Edge Voltage and Thickness Measurement Machine”

You must be logged in to post a review.

There are no reviews yet.