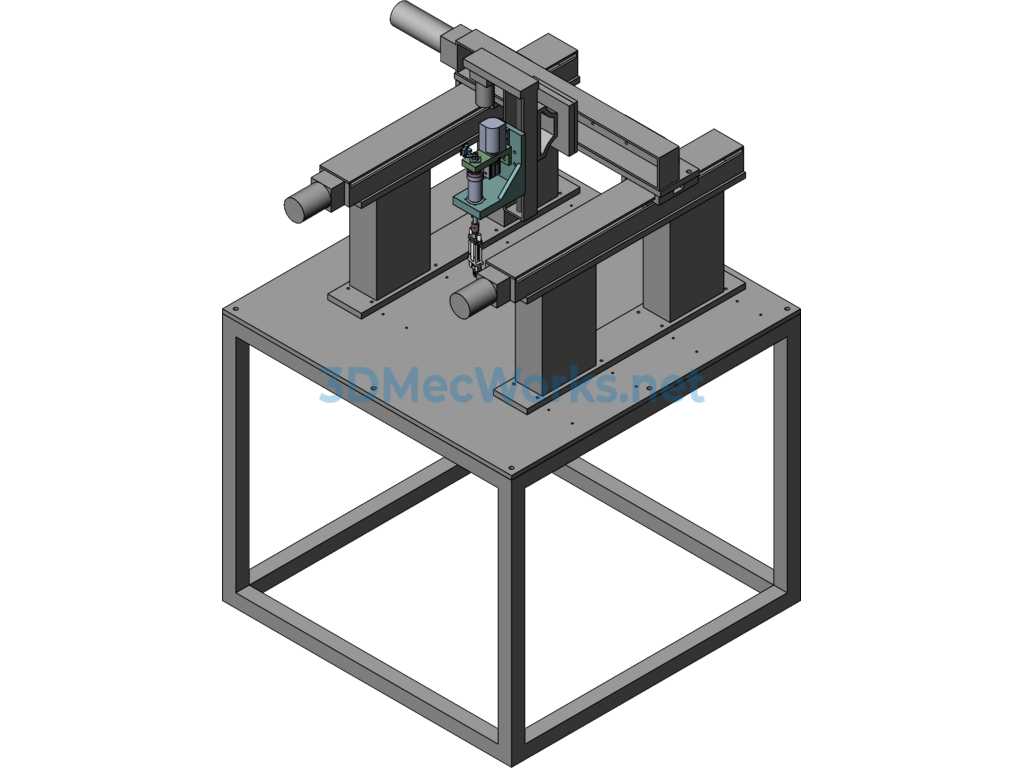

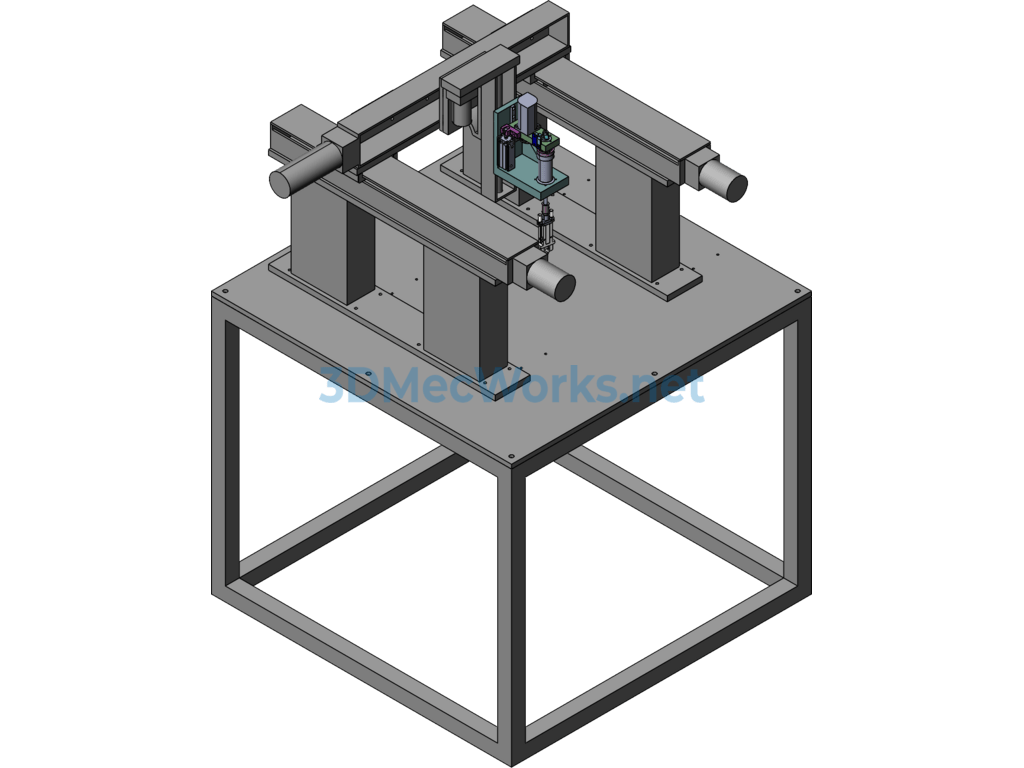

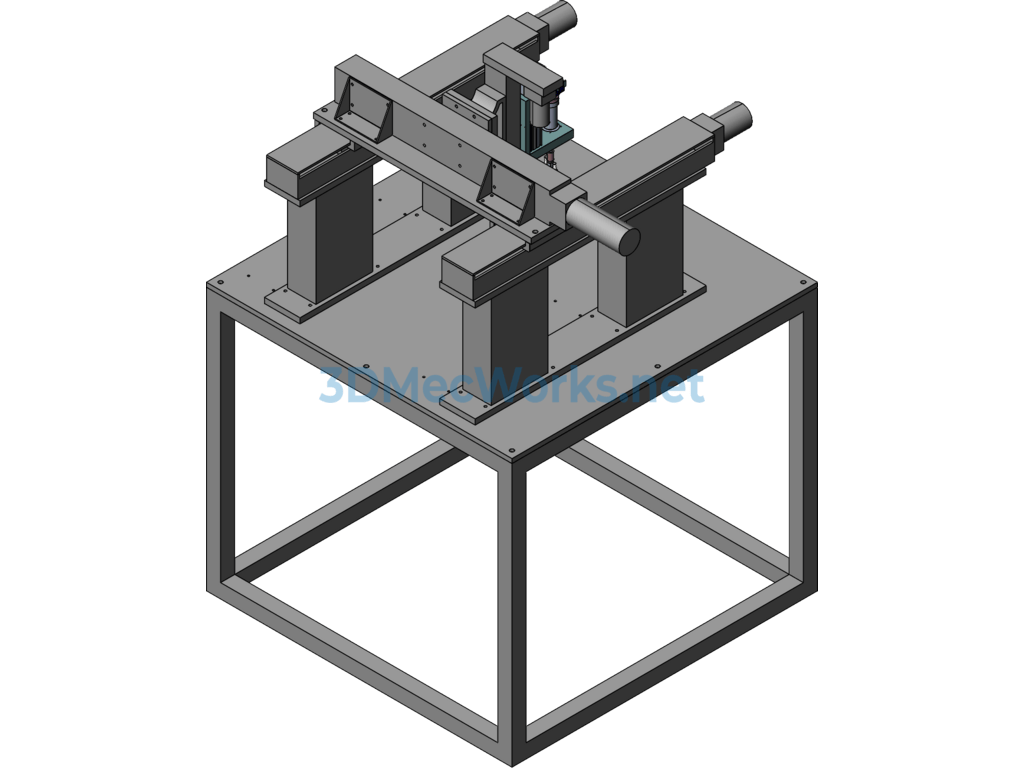

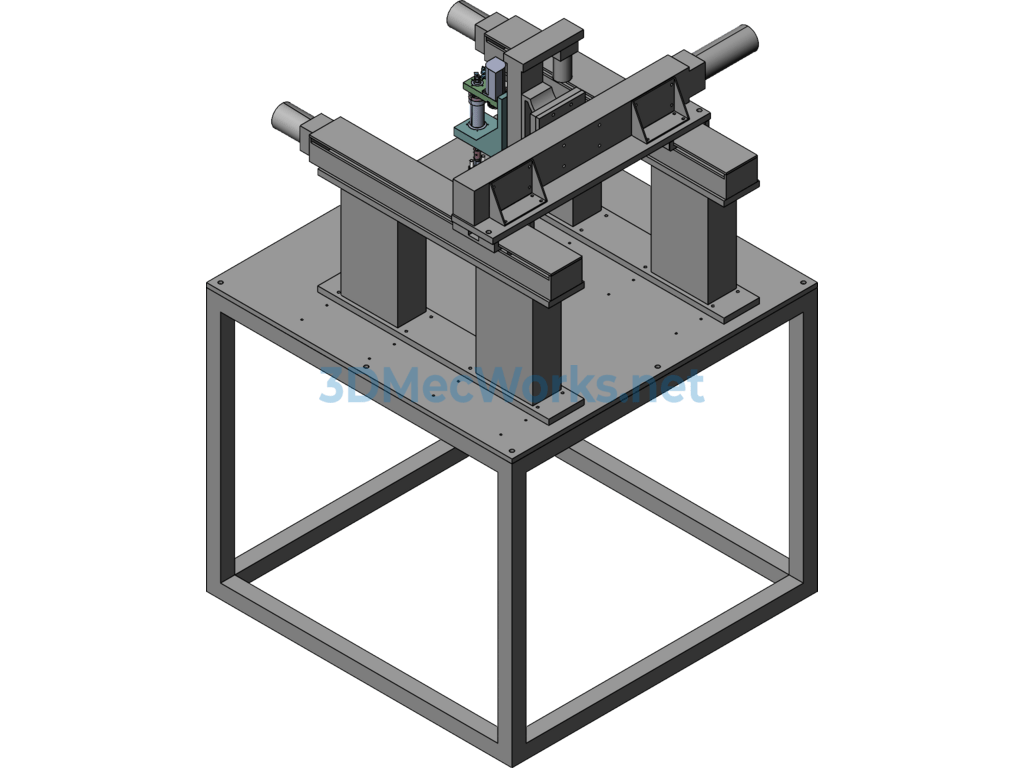

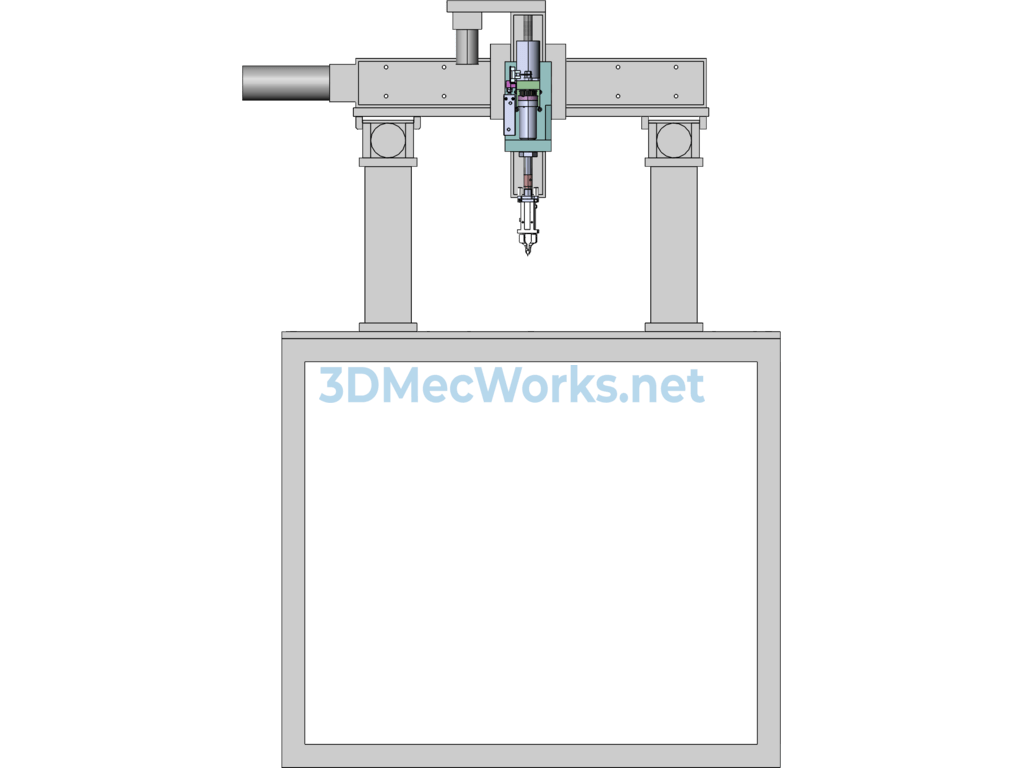

This project addresses the issues of high labor costs, poor reliability, and time-consuming efforts associated with manual operations in the plugin process of LED display production. It aims to develop an automated replacement device. The LED automatic plugin device is required to sort, adjust polarity, straighten, and precut the pins of individual diodes, and then transport them to the plugin device. The plugin PCB board is installed on an X-Y worktable, which should be capable of rotating around the Z-axis. When the control system directs the worktable to the position of the next hole to be plugged, the plugin device picks up a diode and completes the plugin action. The control system then moves the worktable to the next hole for the subsequent plugin. After completing the plugin for a PCB board, the worktable rotates, and the next PCB board moves into the plugin position. The entire plugin device achieves continuous plugin without the need for stopping for manual board exchange. The main focus of this project is the design of the mechanical structure system for the LED plugin machine, specifically designing the X-Y worktable and the plugin mechanism.

There are no reviews yet.