Laser marking uses a laser beam to make permanent marks on various material surfaces. The effect of marking is achieved by evaporating the surface material to reveal deeper material, or by using light energy to cause chemical and physical changes in the surface material to “engrave” traces, or by using light energy to burn off part of the material to display desired etched patterns or text.

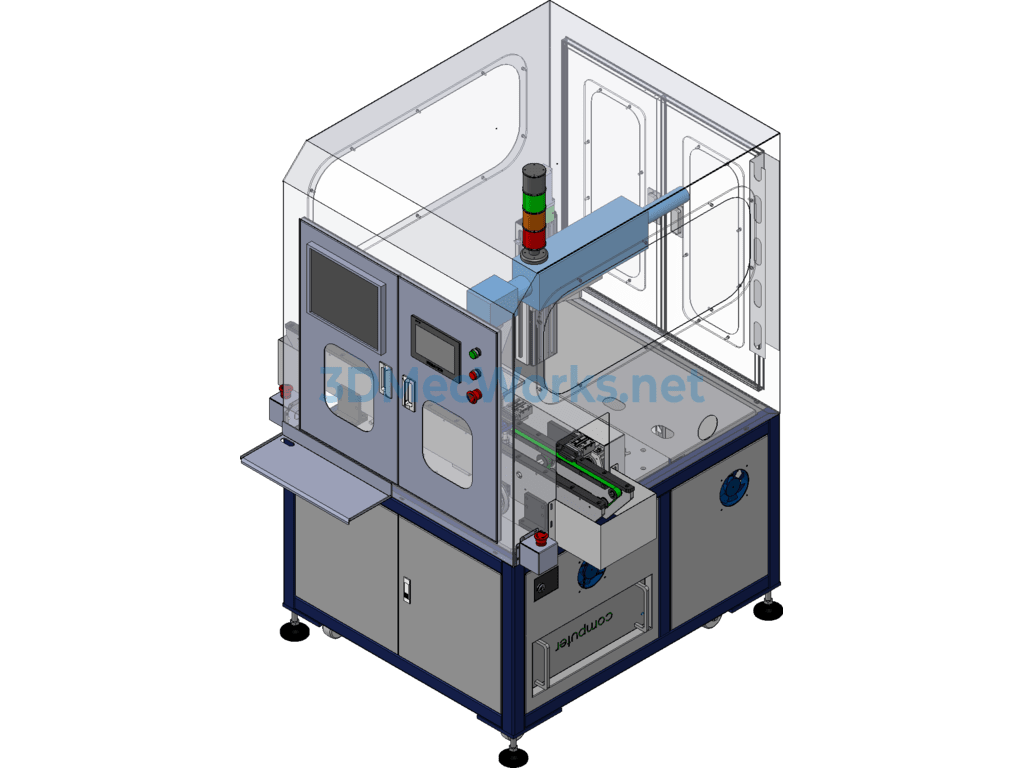

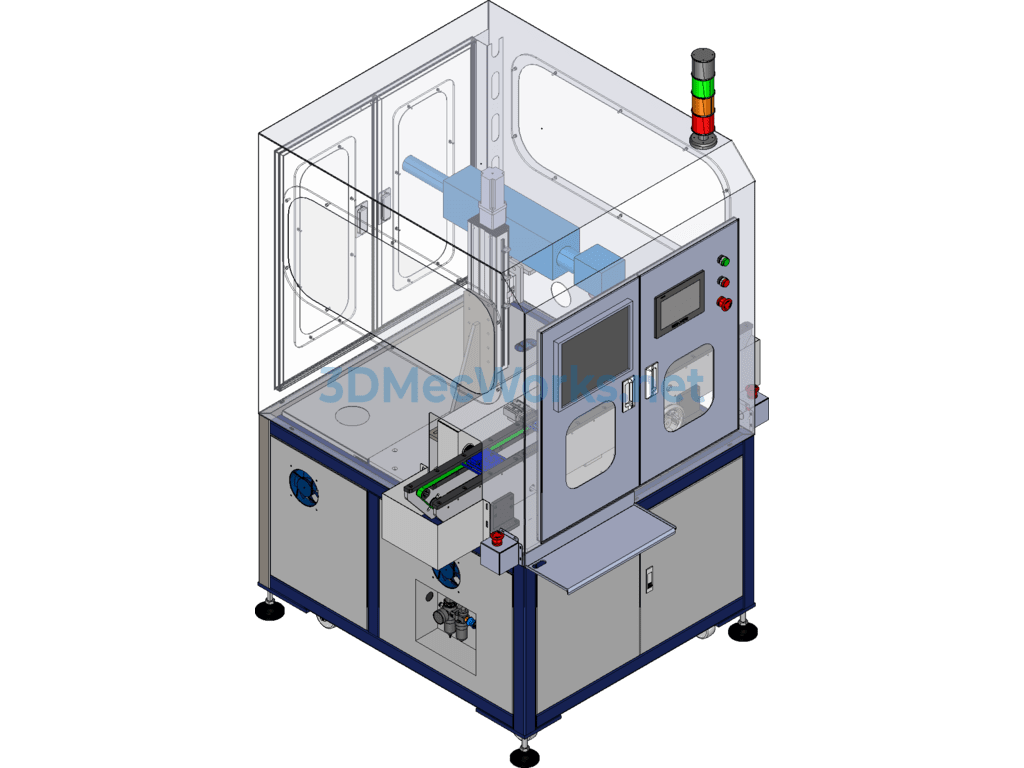

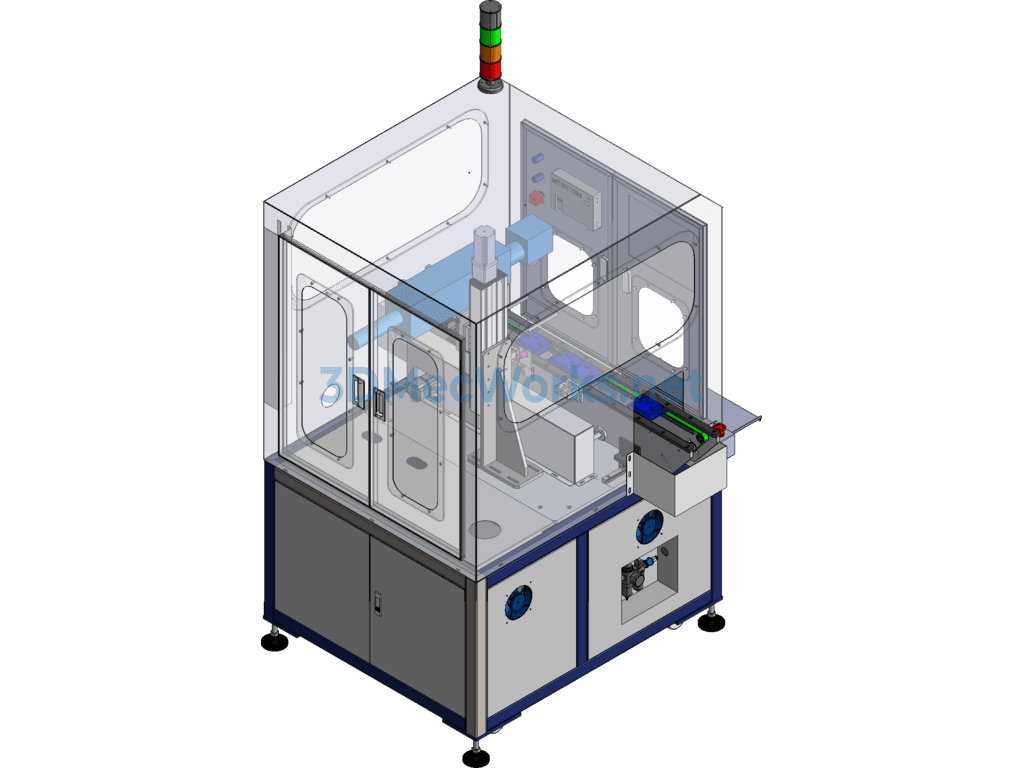

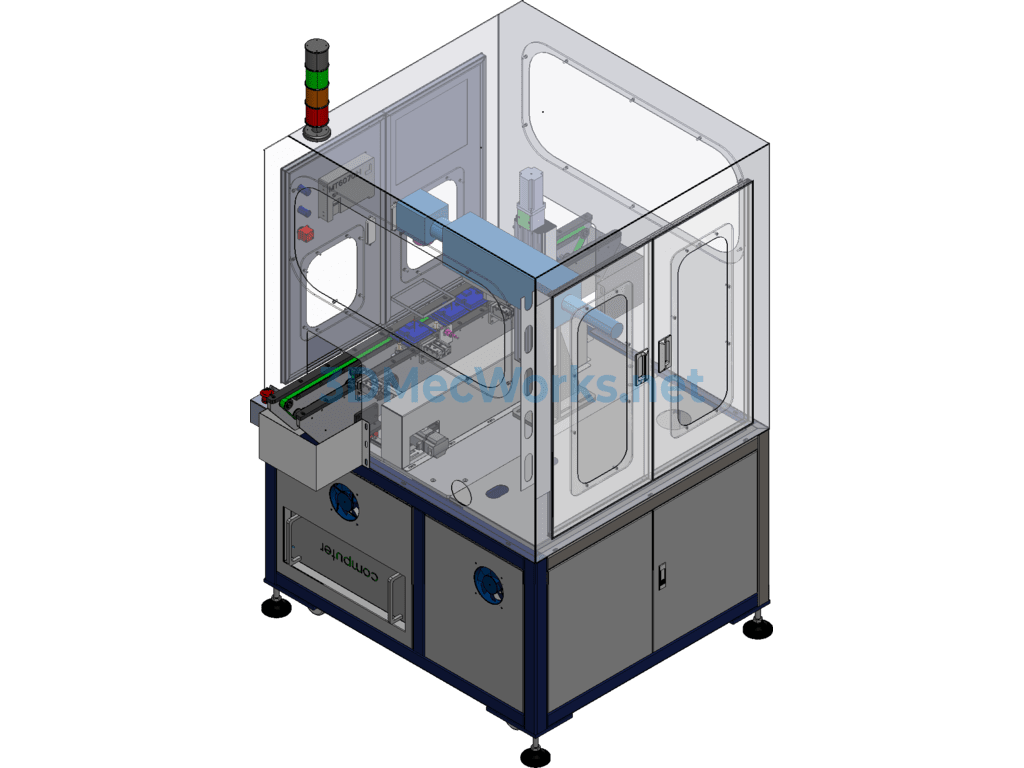

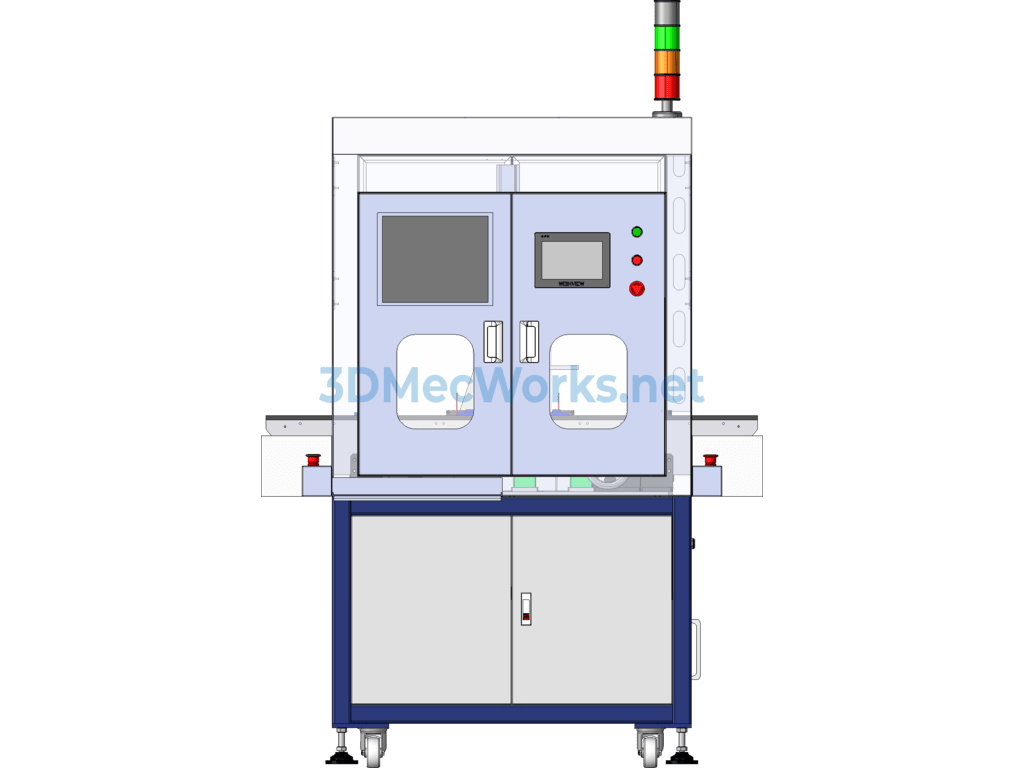

This equipment is used for marking controller panels, with servo adjustment for marking distance. Products are manually placed on the production line and flow to the marking position, where a cylinder positions them, completes marking, and then they flow out.

This line can adjust its width to accommodate products of different sizes. Products can be placed side by side during feeding, and the line can automatically retract and extend to allow products to flow through sequentially.

There are no reviews yet.