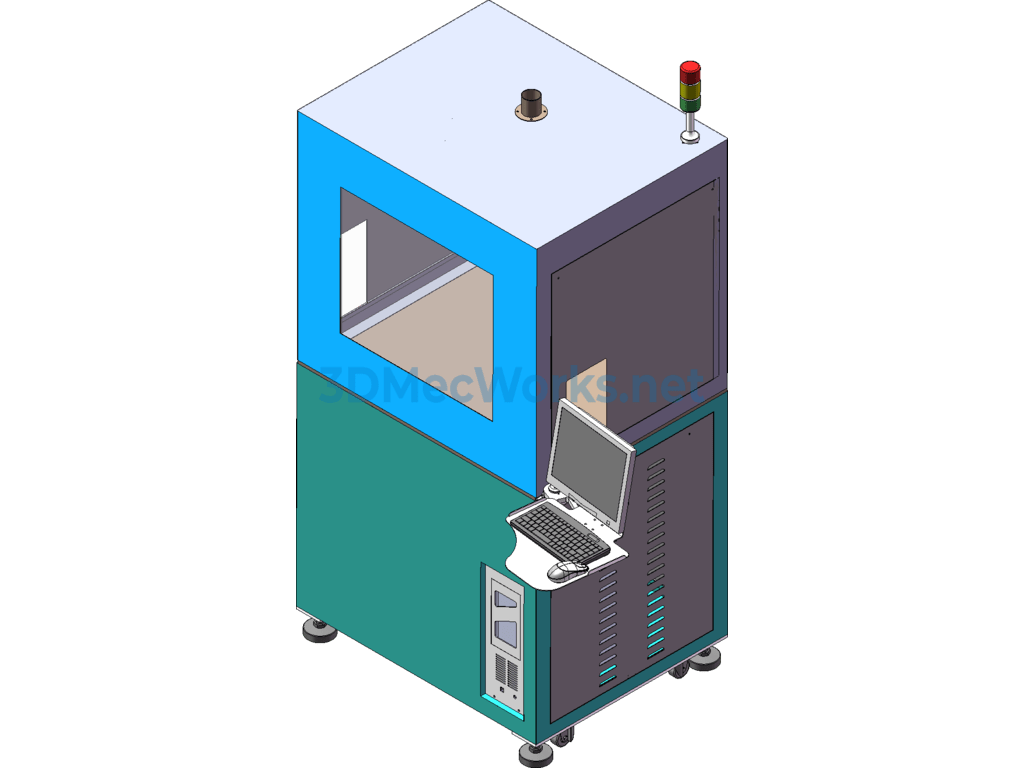

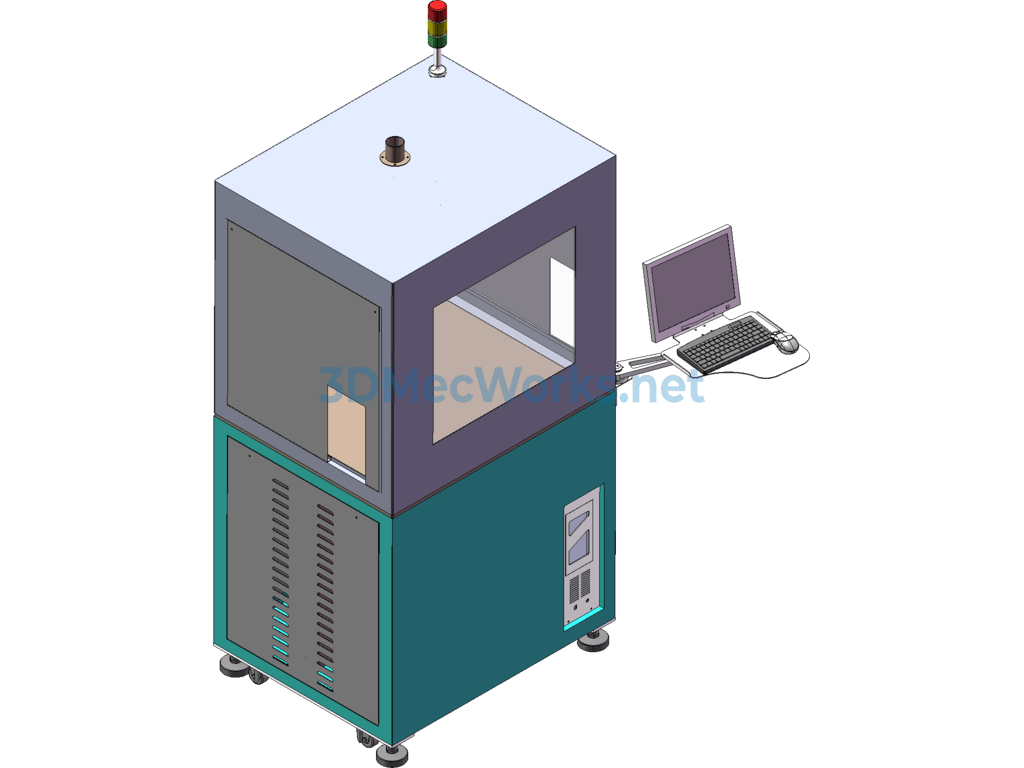

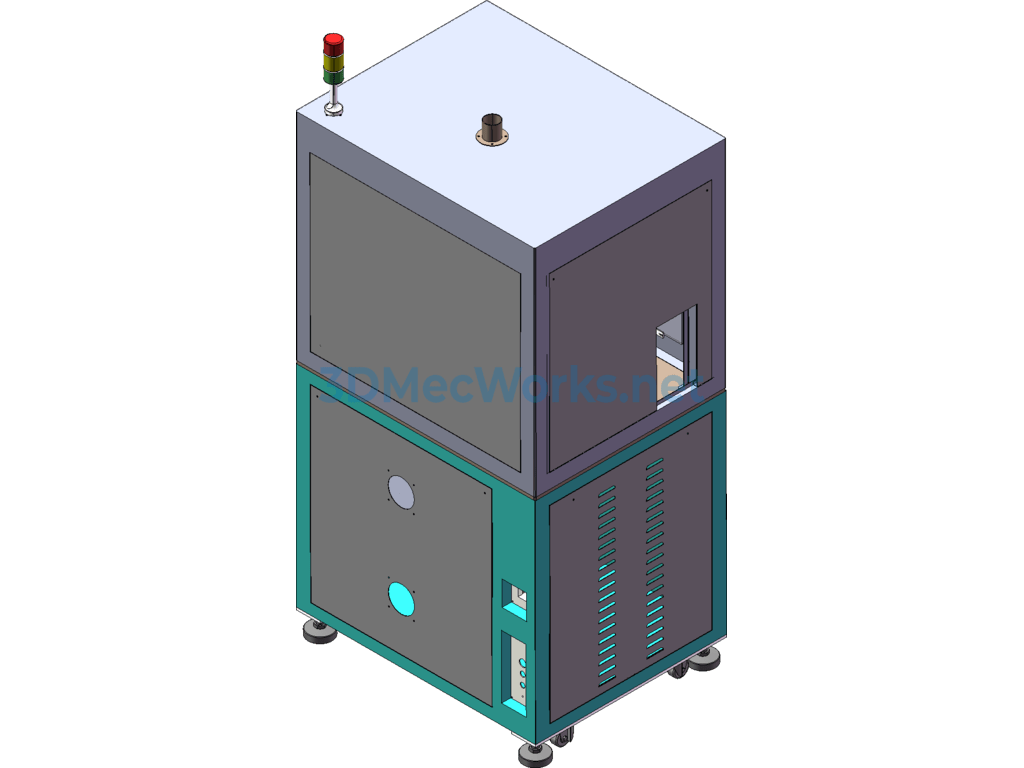

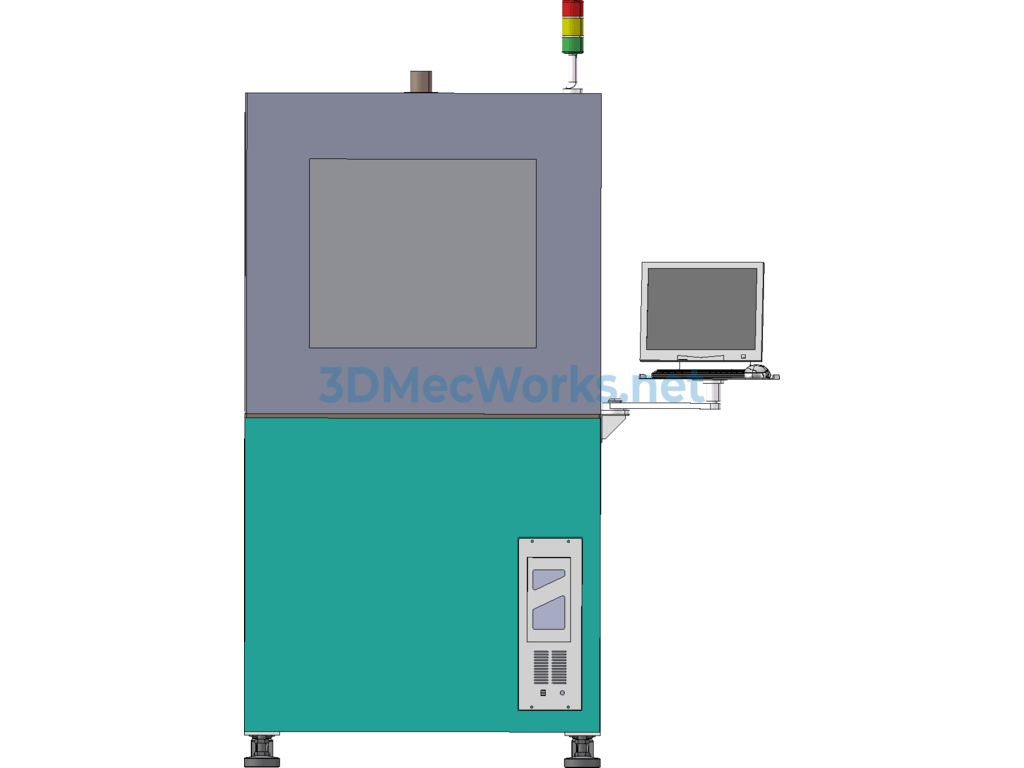

Laser Marking Equipment Operation Process:

1. Manually place the product on the left side of the equipment.

2. The product enters the interior of the equipment for automatic marking on both sides.

3. The marked product is collected from the conveyor belt on the right side of the equipment.

4. Manually place products sequentially on the left side.

5. Once a sensor detects that the first six products are fully arranged, the gripper cylinder grabs the products.

6. The stopper cylinder prevents the gripper from colliding with the seventh product when gripping the first six products.

7. The electric cylinder drives two sets of grippers to perform synchronized actions, simultaneously grabbing and collecting materials.

8. Gripper 1 grabs 6 products on the left, then places them at the marking position, where the machine automatically marks both sides.

9. Gripper 2 grabs finished products and places them on the right-side conveyor belt. Once the sensor detects that the product is in place, the conveyor belt runs and collects the products.

Specification: Laser Marking Equipment

|

User Reviews

Be the first to review “Laser Marking Equipment”

You must be logged in to post a review.

There are no reviews yet.