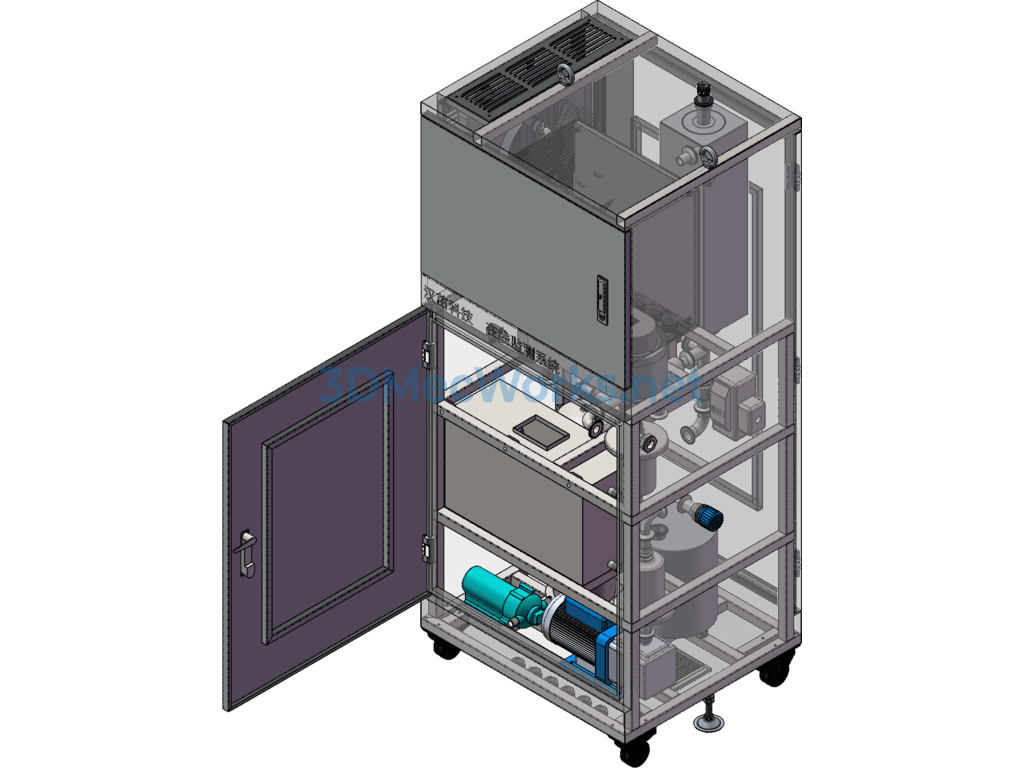

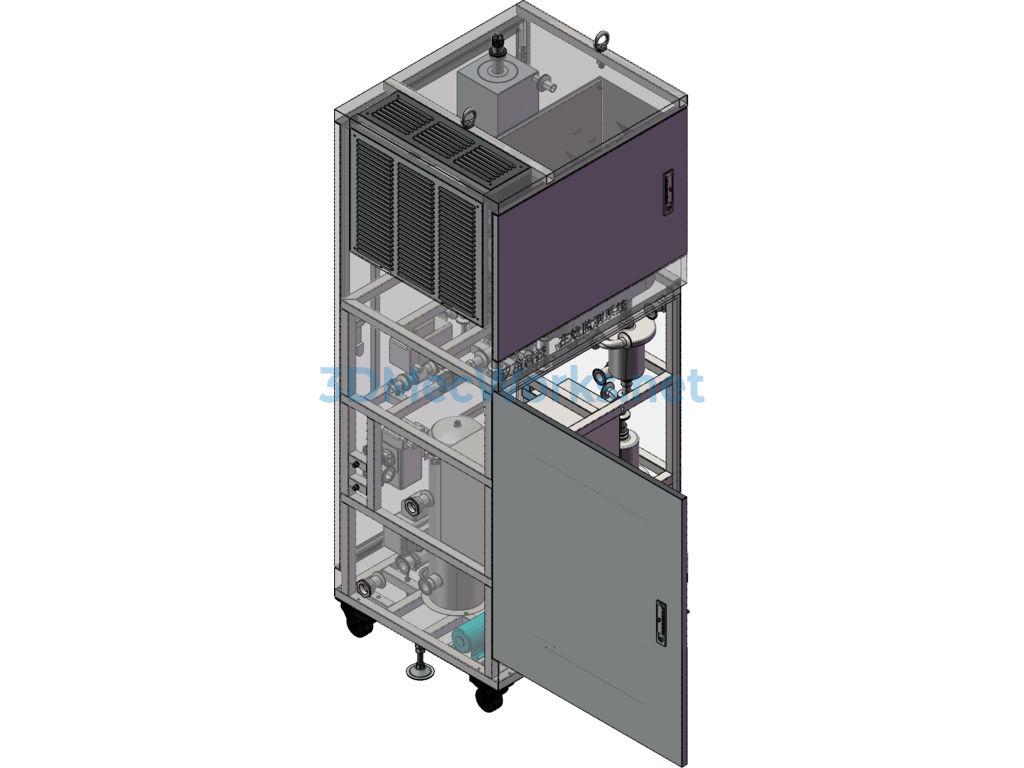

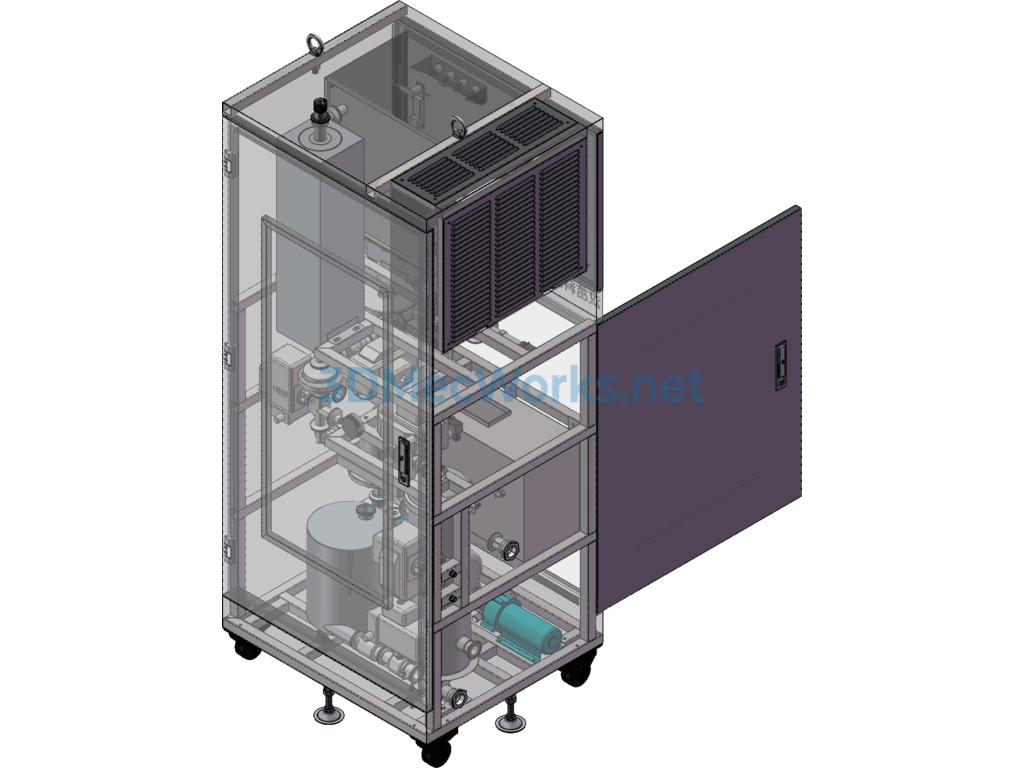

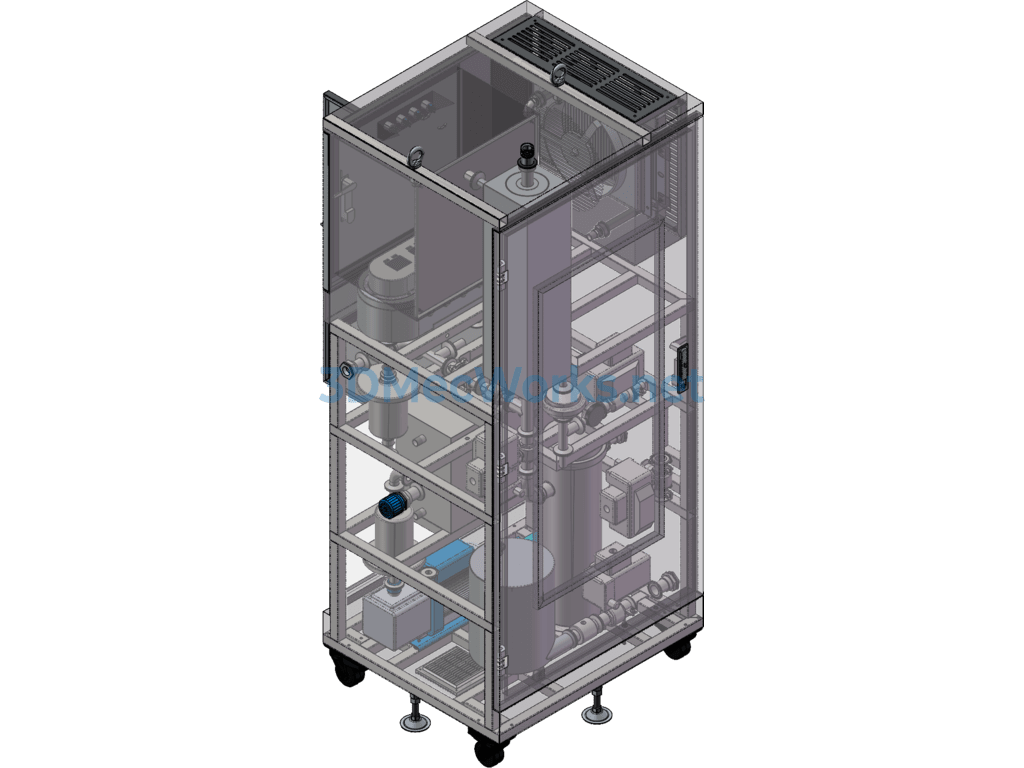

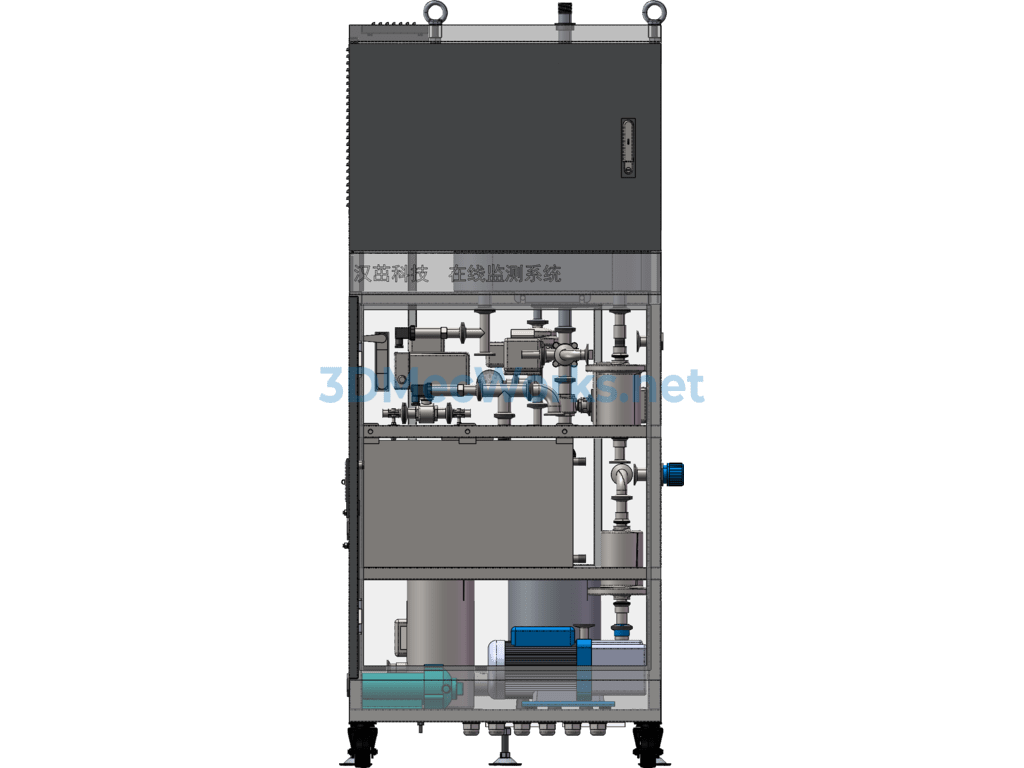

The kiln flue gas continuous online monitoring system uses extractive condensation sampling, backscatter particulate matter concentration measurement, Pitot tube flue gas velocity measurement, and computer network communication technology to achieve continuous online monitoring of pollutant emission concentration and total emissions from stationary pollution sources. Additionally, technical improvements have been made to address the domestic issues of varied coal types, significant coal quality changes, high pollutant emission concentrations, and high flue gas humidity. The system is designed and modeled according to standards, providing Chinese operational platforms and report functions, multiple sets of analog and switch input/output interfaces, enabling field bus connections and the selection of various communication methods, making system operation convenient and flexible.

The continuous flue gas online monitoring system is mainly composed of the following subsystems:

1. Solid particulate matter continuous monitoring subsystem, using laser backscatter single-point monitoring.

2. Gaseous pollutants continuous monitoring subsystem multi-component gas analyzer (SO2, NOX, CO, CO2, HCL, HF, NH3)

3. Continuous monitoring subsystem for flue gas oxygen content, flue gas flow, pressure, temperature, humidity, and other flue gas parameters

4. Data processing and remote communication system

Specification: Kiln Exhaust Online Monitoring System

|

User Reviews

Be the first to review “Kiln Exhaust Online Monitoring System”

You must be logged in to post a review.

There are no reviews yet.