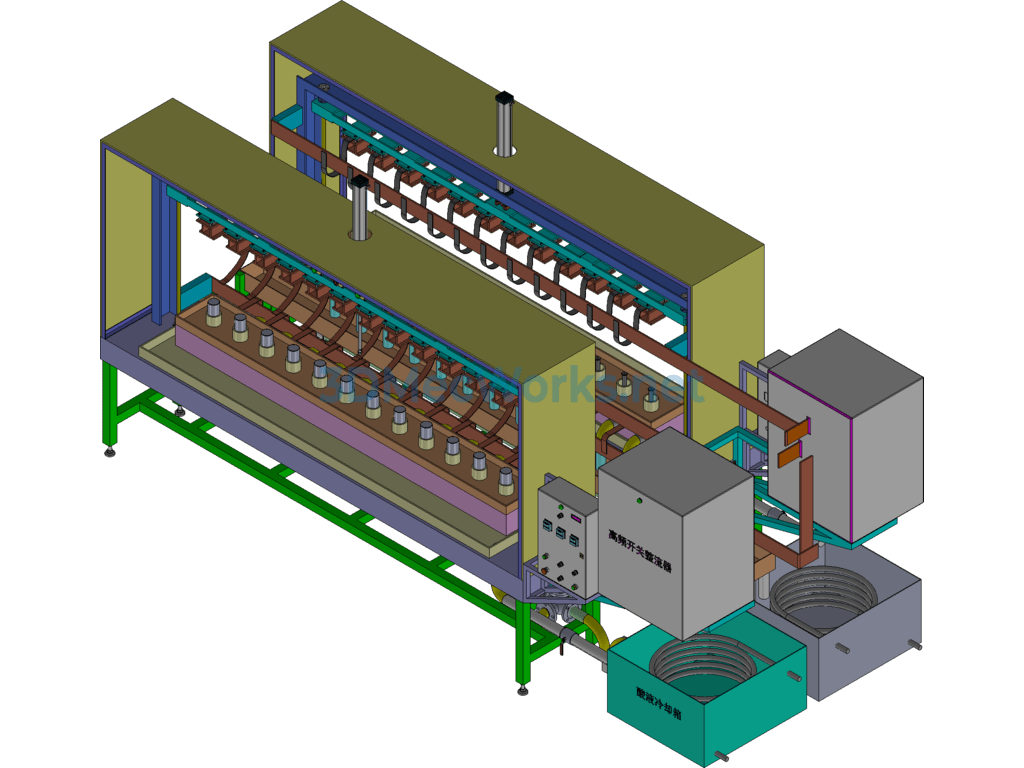

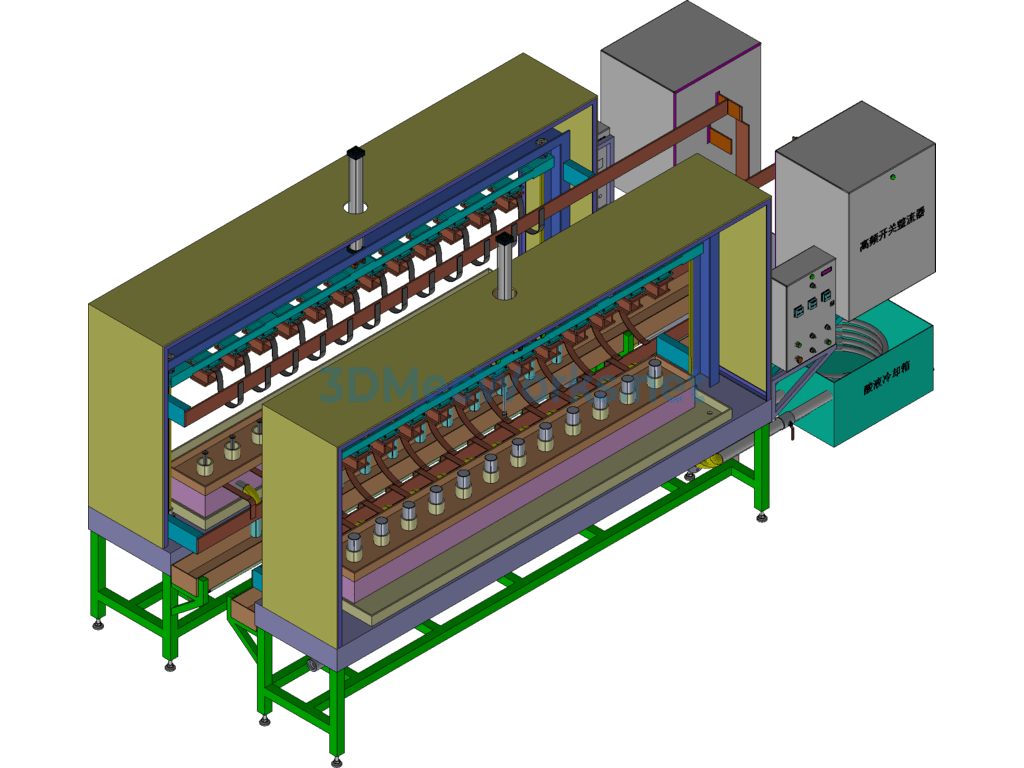

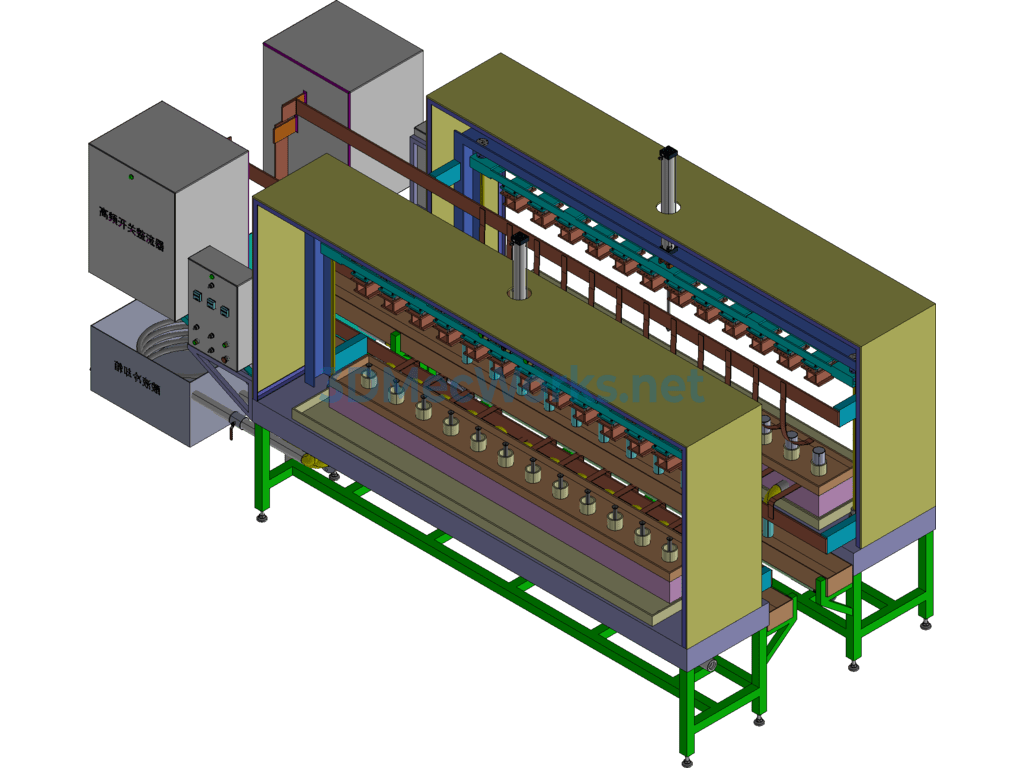

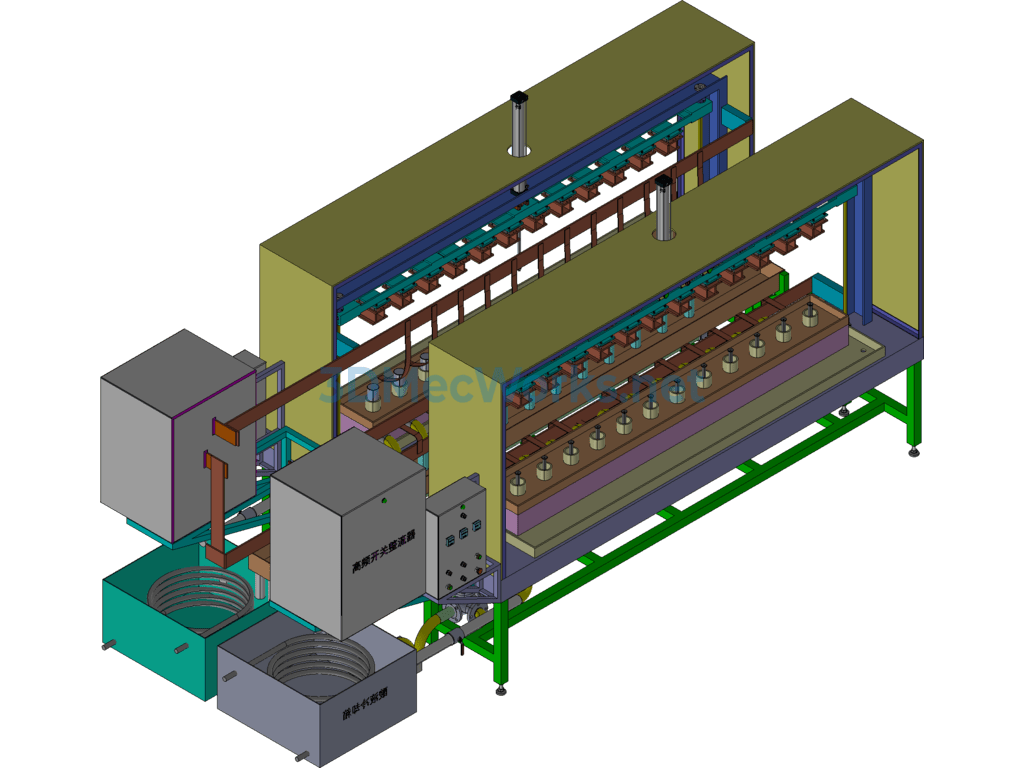

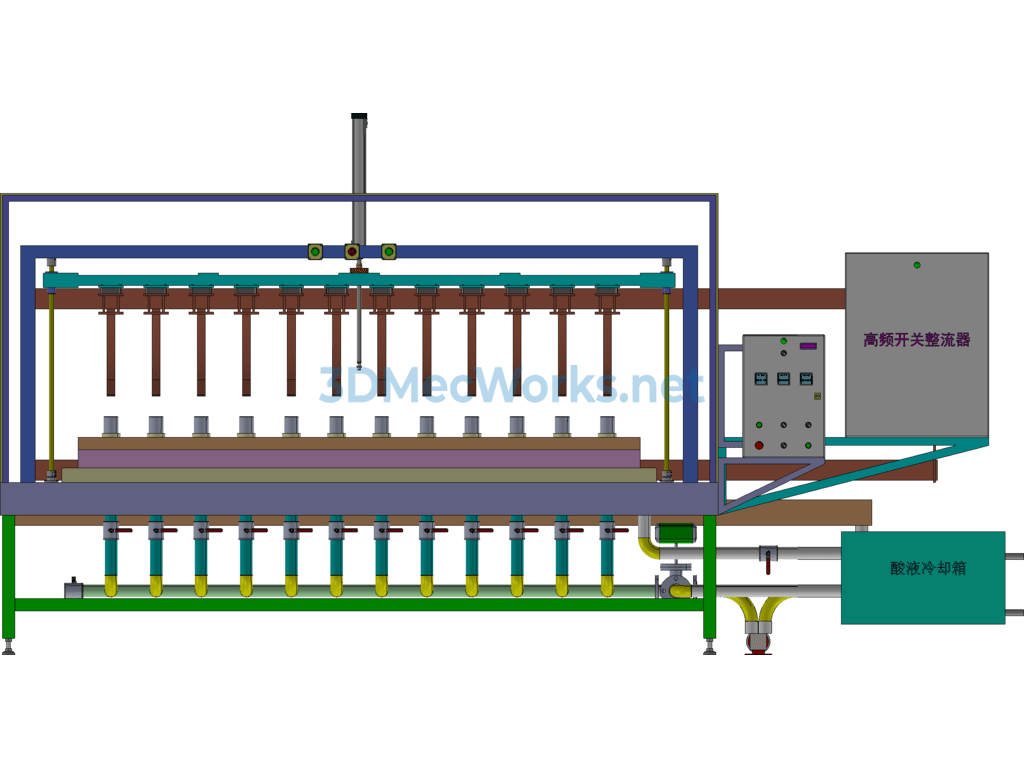

Thermal Cup Electrolytic Machine Solution – Automatically cleans the inner wall of the thermal cup, ensuring the inner and outer surfaces are smooth

1. This equipment has 24 stations (12 stations on one side);

2. Liquid flushing method (backflush);

3. Temperature control for acid tank (default circulating cooling water recommended flow rate of 70L/min), (customers can choose to use a chiller that can control ±5℃);

4. Blowing device added for residual acid in the thermal cup;

5. High-frequency switching rectifier (3000A);

6. Some parts of the equipment are made of stainless steel SUS316L and other corrosion-resistant materials with thicknesses of 5mm and 3mm;

7. Positioning accuracy, ±5mm;

8. Acid tank exhaust pipeline (excluding purification equipment);

9. The equipment comes with 5 types of thermal cup fixtures (requires the client to provide thermal cup dimension drawings);

10. Acid pump and acid valve (imported and domestic premium customers can choose imported);

Specification: Insulated Cup Electrolytic Machine Plan-

|

User Reviews

Be the first to review “Insulated Cup Electrolytic Machine Plan-”

You must be logged in to post a review.

There are no reviews yet.