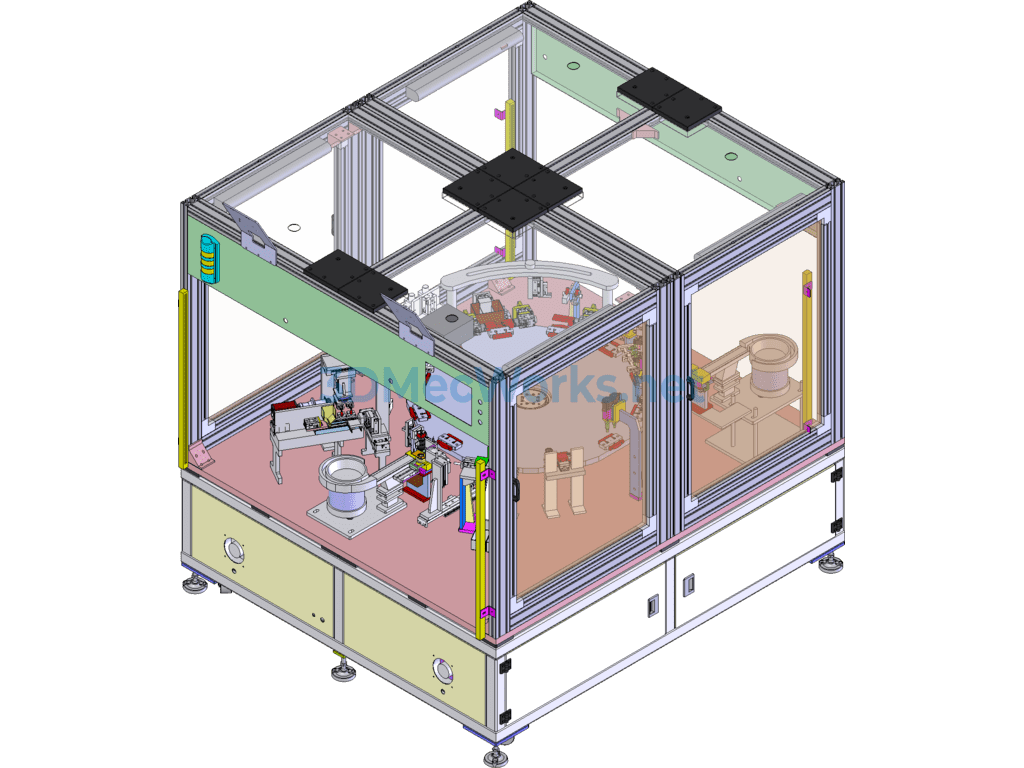

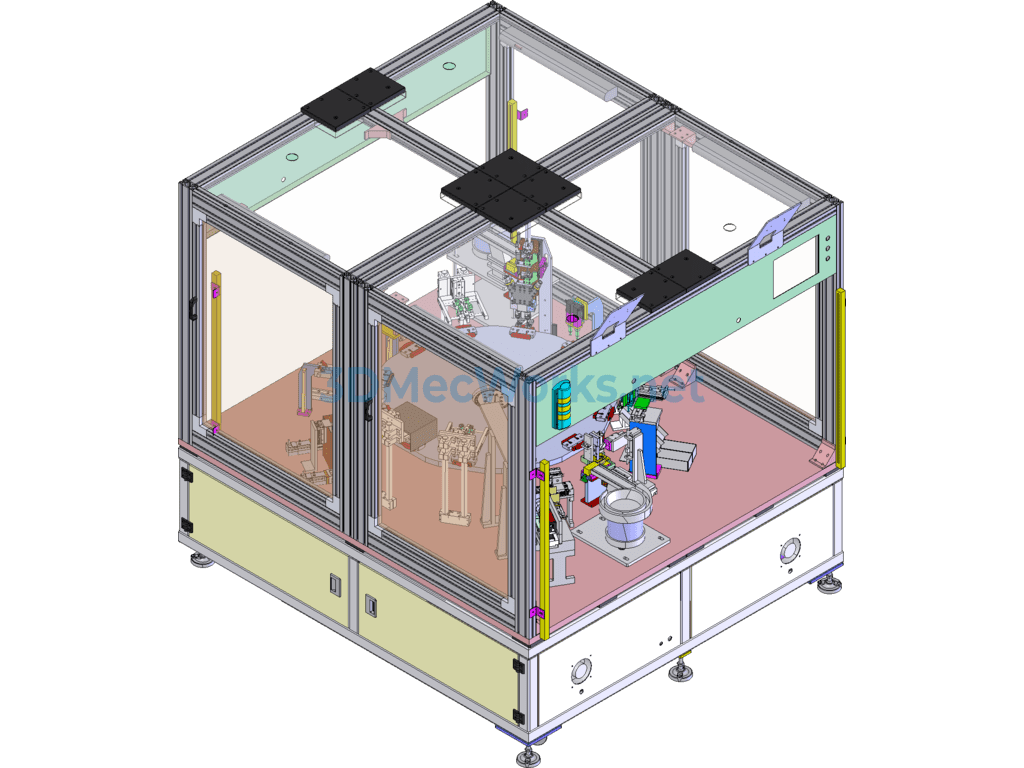

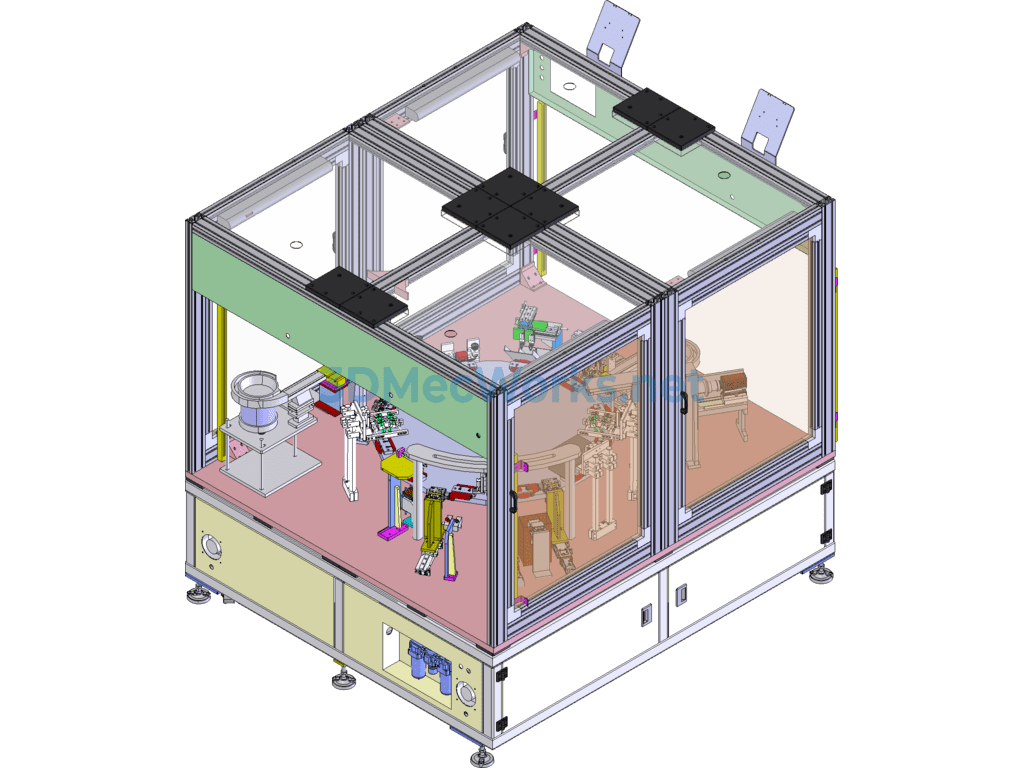

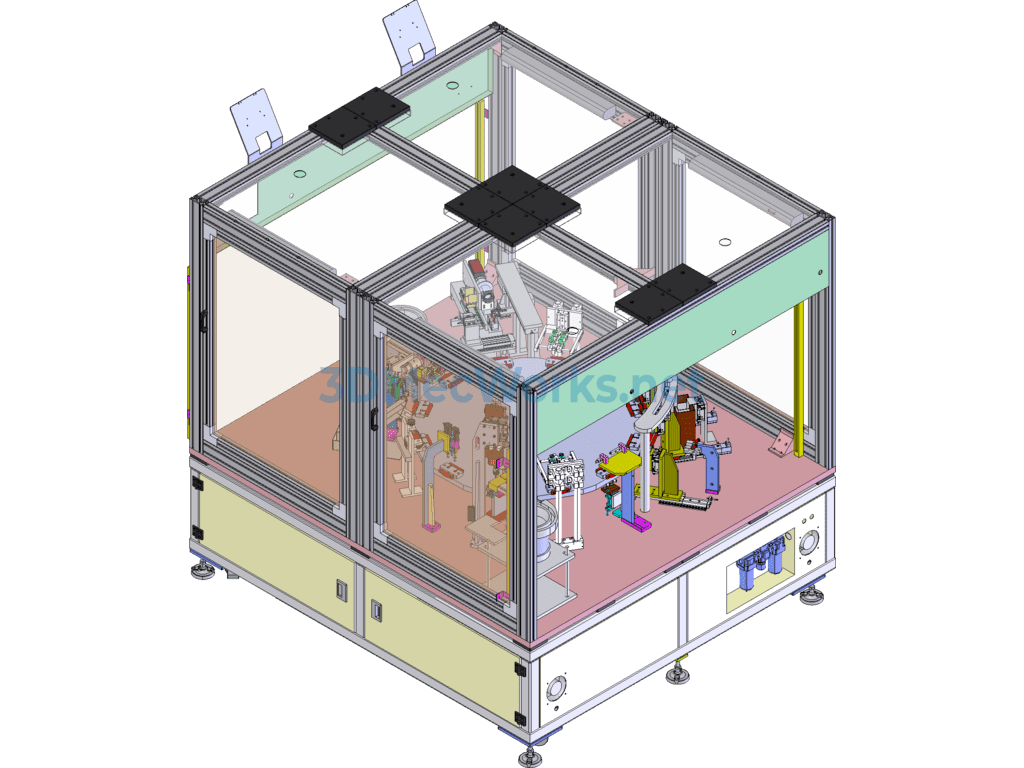

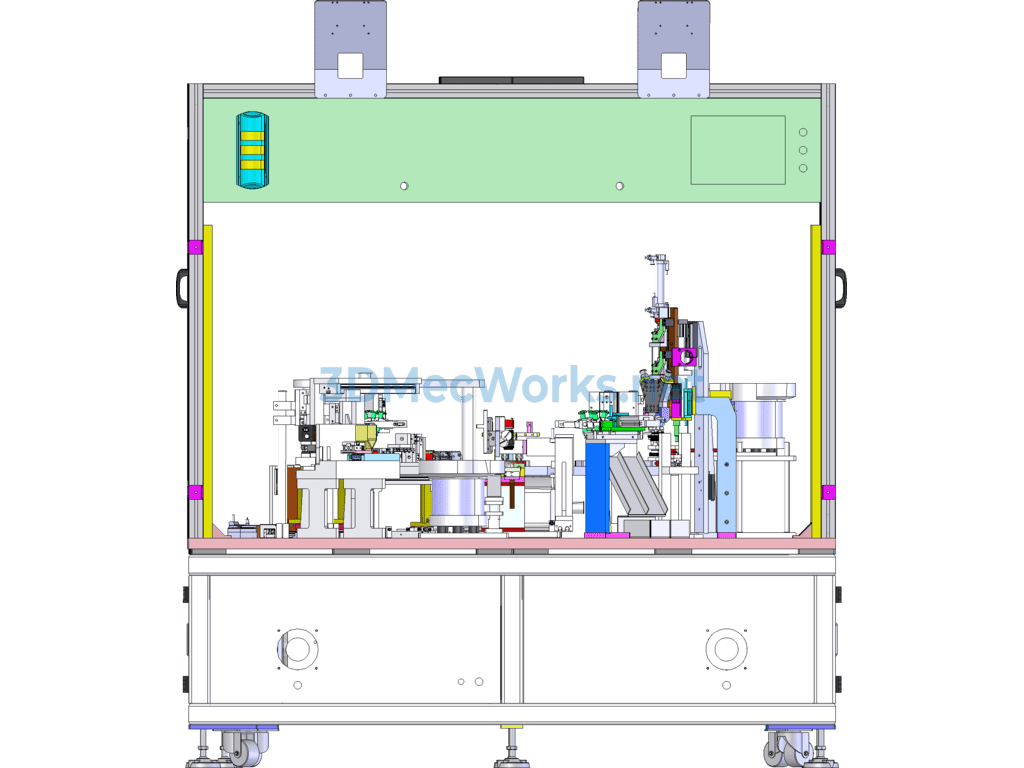

Automatic Injection Needle Assembly and Dispensing Machine Action Description:

Step 1: Base material is fed via vibrating bowl, with CCD checking for the correct orientation of the Base.

Step 2: First needle tube is inserted, with CCD checking for the correct orientation and any defects.

Step 3: Second needle tube is inserted, with CCD checking for the correct orientation and any defects.

Step 4: Apply UV adhesive.

Step 5: UV curing.

Step 6: Apply airtight adhesive.

Step 7: Strong air drying.

Step 8: Apply silicone to the tube opening.

Step 9: Pre-assemble the Cover.

Step 10: Press-fit the Cover.

Step 11: Discharge finished product (automatically distinguishing between OK & NG).

Step 12: Repeat the above actions.

Purpose of the Needle Assembly Machine: The machine automatically feeds materials (needle, Base, and Cover) and assembles them automatically.

Operation Method: Rotary table operation.

Brief Action Flow:

Base feeding / insert first needle tube -> insert second needle tube -> apply UV adhesive -> UV curing -> apply airtight adhesive -> strong air drying -> apply silicone to tube opening -> pre-assemble Cover -> press-fit Cover -> discharge finished product.

4. C/T: Estimated at 2pcs/5sec.

4. Estimated machine size: 2000(L)*1800(W)*1800(H)mm.

Specification: Injection Needle Assembly Dispensing Equipment

|

User Reviews

Be the first to review “Injection Needle Assembly Dispensing Equipment”

You must be logged in to post a review.

There are no reviews yet.