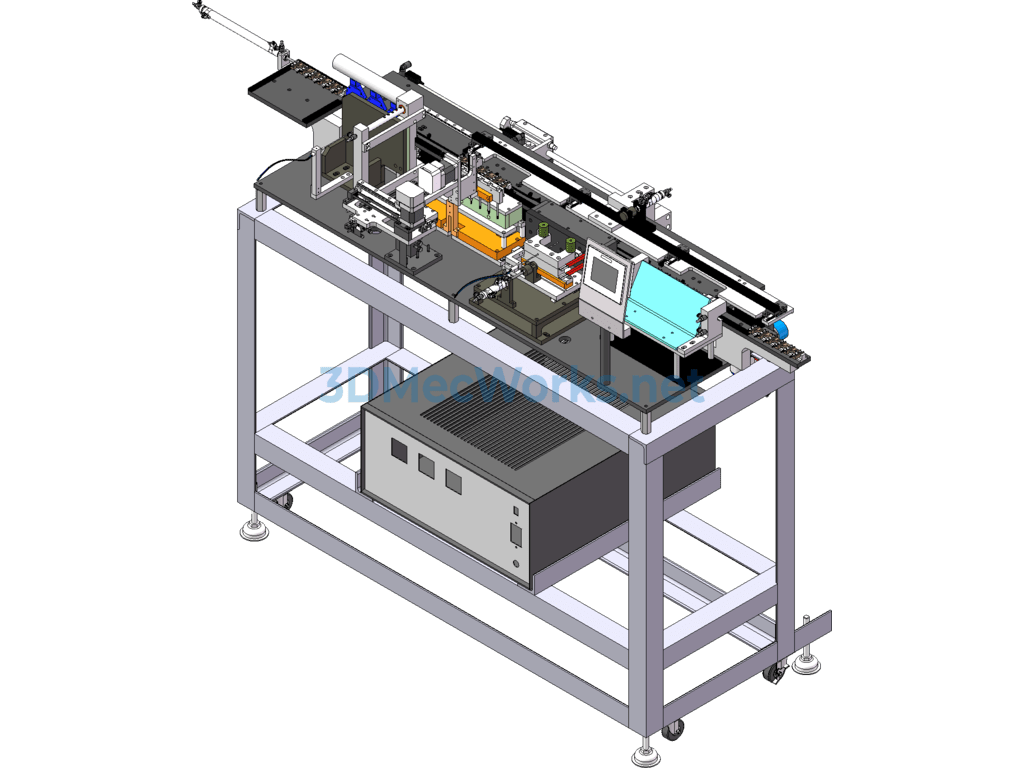

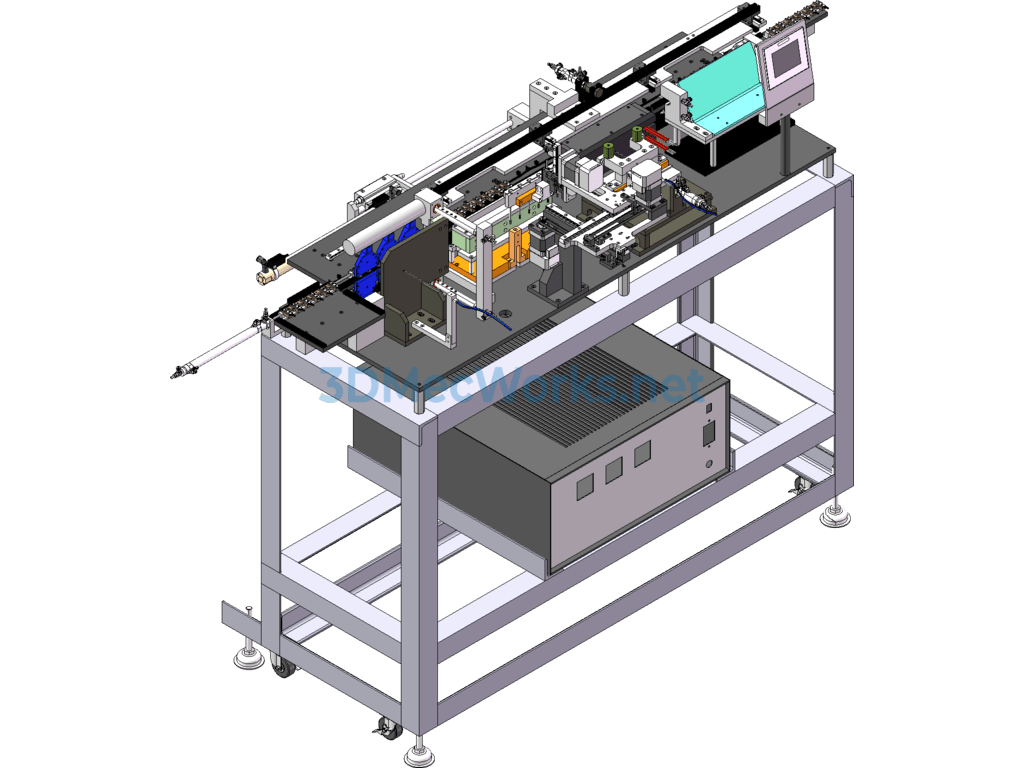

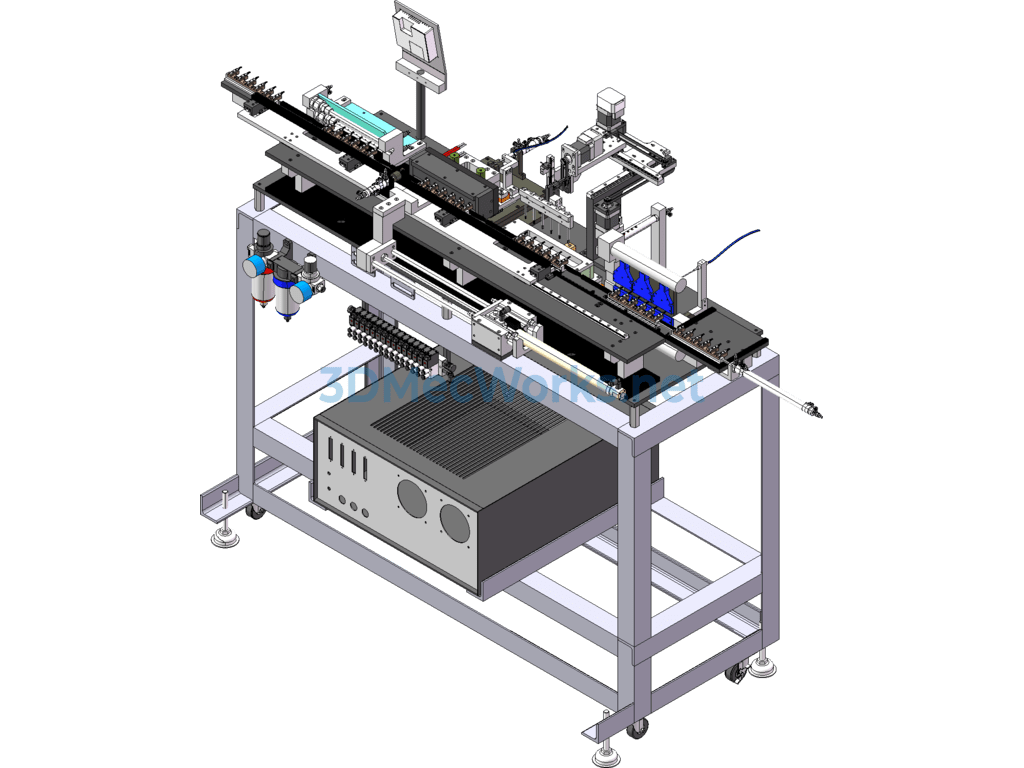

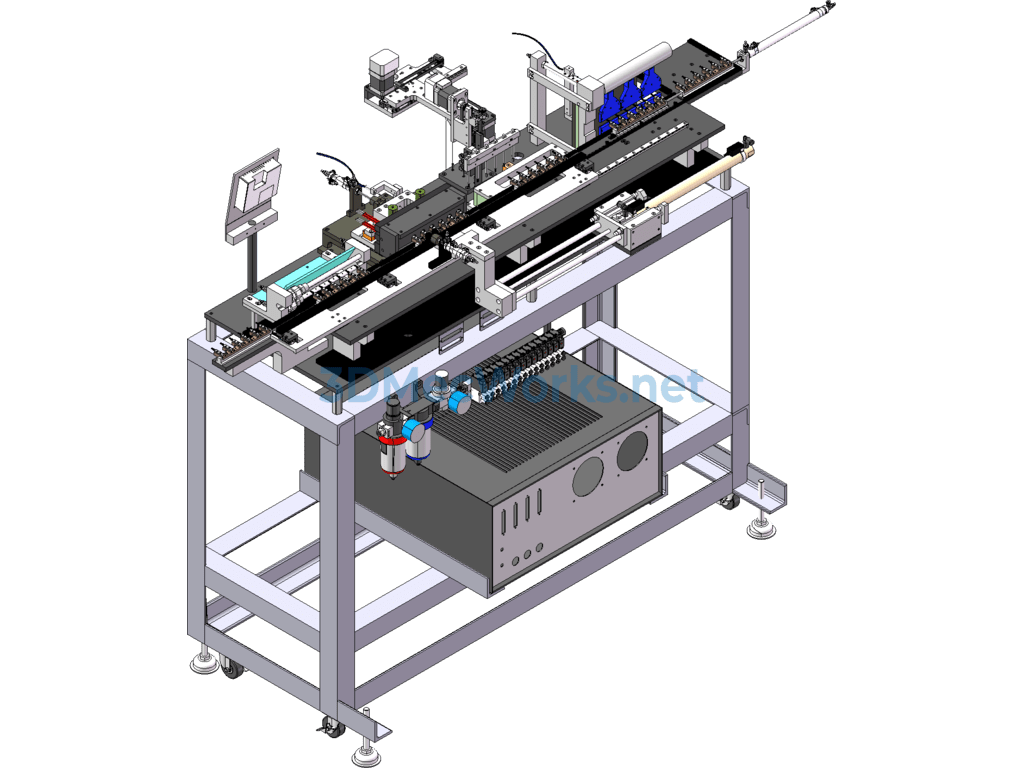

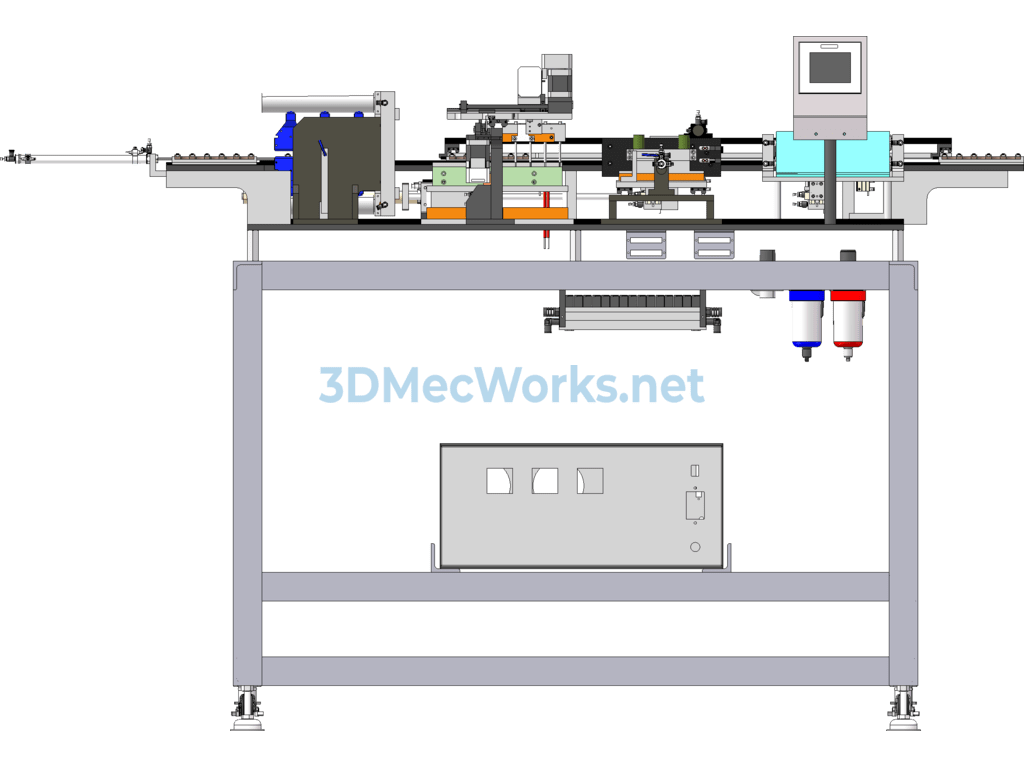

The automatic inductor soldering and inspection machine is a classic, mature, and stable equipment in the electronics industry. It is used for automatic soldering and electrical performance inspection of inductor parts. The equipment uses a tray-style automatic feeding, manipulator handling mechanism for material transfer, and a linear layout of the overall structure of the equipment. The manipulator grabs the inductor parts to the soldering slot for soldering, followed by moving to the next station for electrical performance inspection. After inspection, the handling manipulator discharges the parts. The equipment employs an industrial control single-chip microcomputer system, offering high automation efficiency. Feel free to download for comprehensive reference! The automatic waxing machine model for inductor parts contains 228 part drawings and 21 assemblies. It is recommended to open this model with SW2011 or later versions! For friends using other 3D software, this compressed package also includes STP documents!

Specification: Inductor Automatic Soldering and Testing Machine (automatic Waxing Machine)

|

User Reviews

Be the first to review “Inductor Automatic Soldering and Testing Machine (automatic Waxing Machine)”

You must be logged in to post a review.

There are no reviews yet.