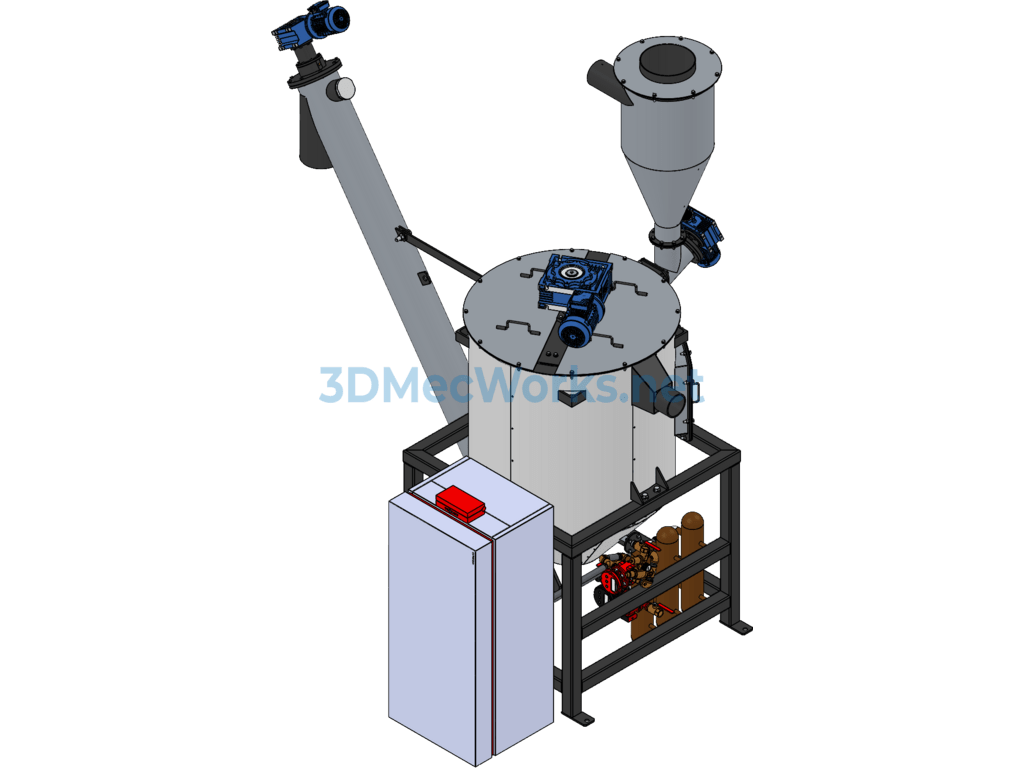

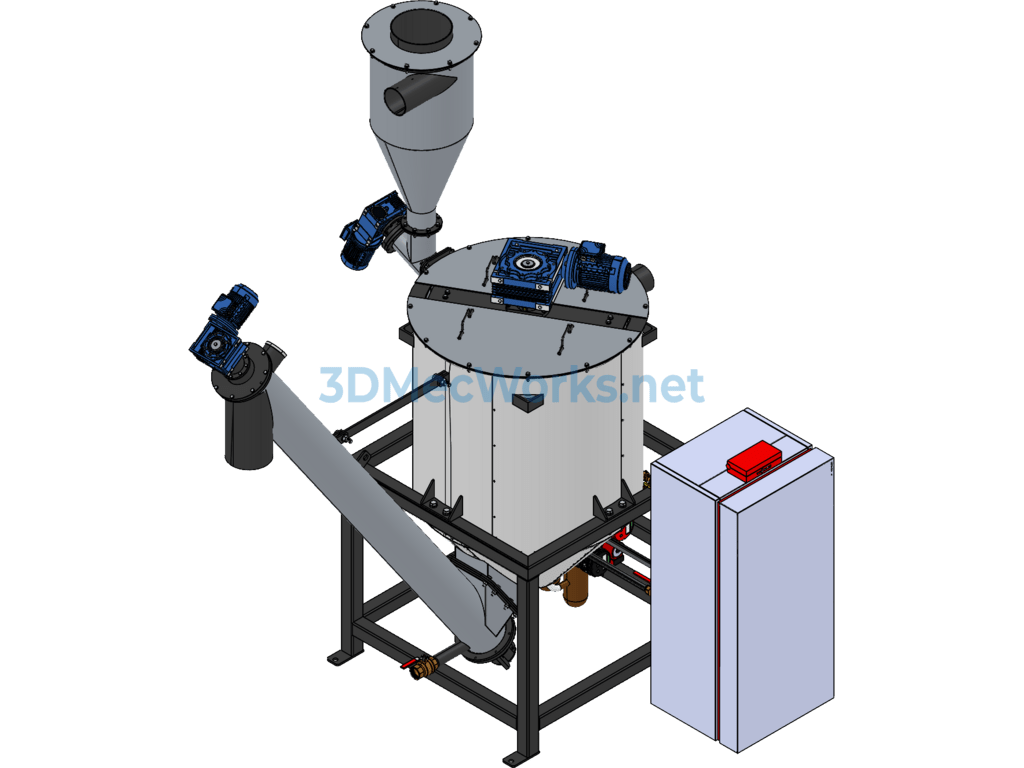

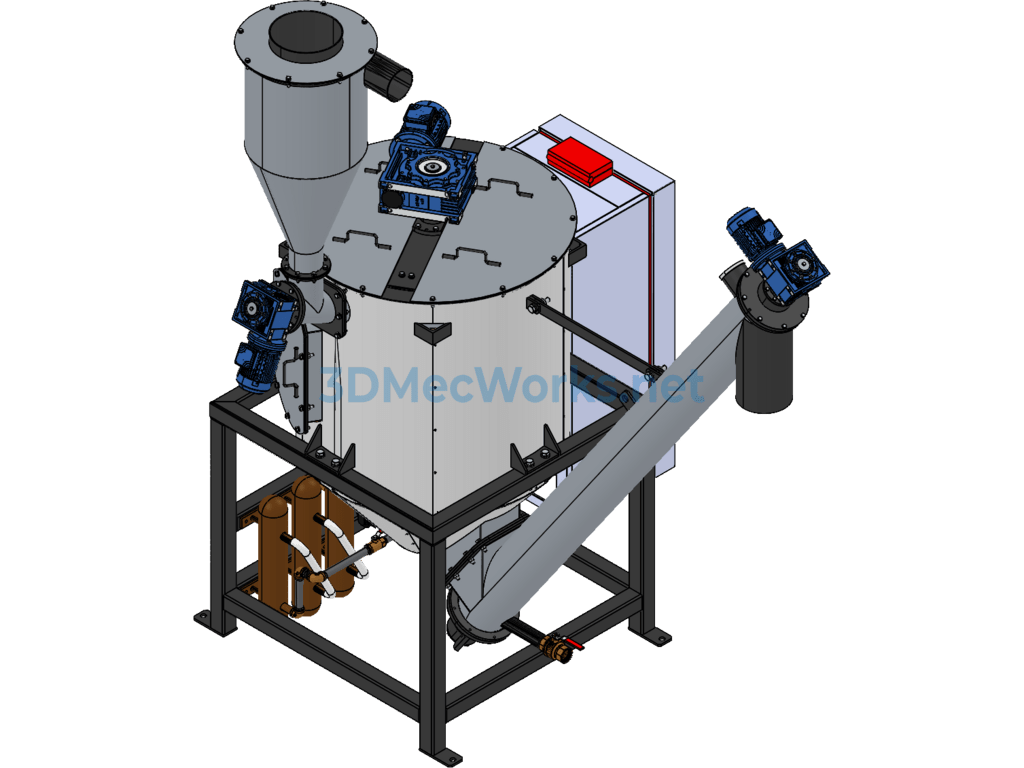

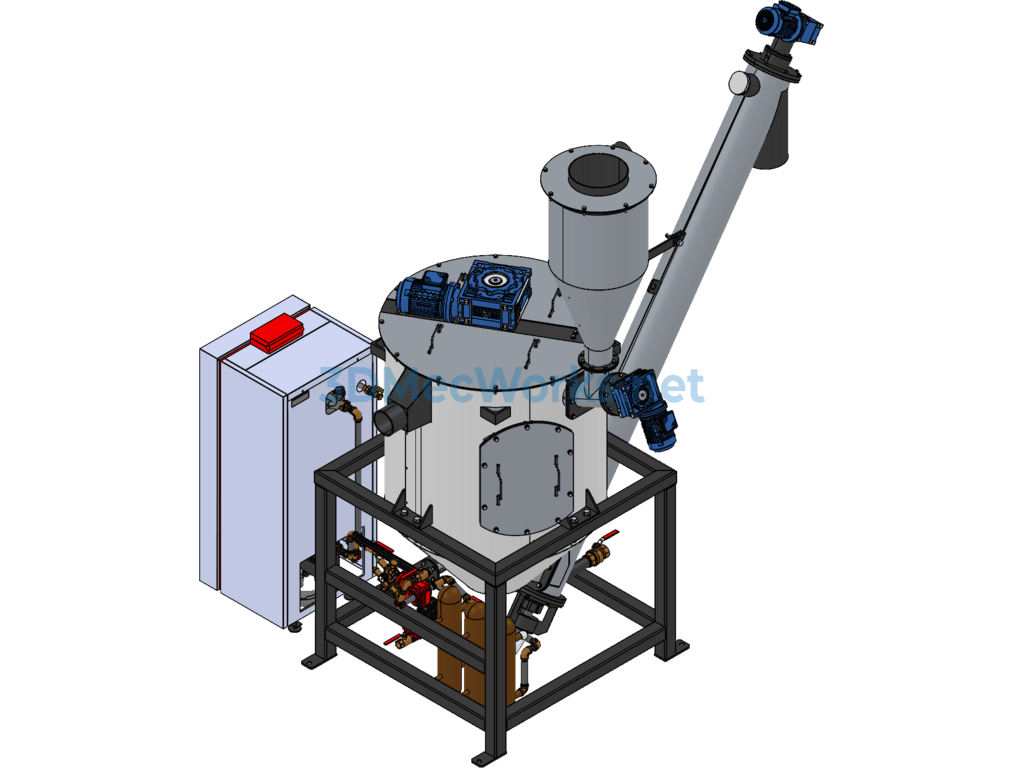

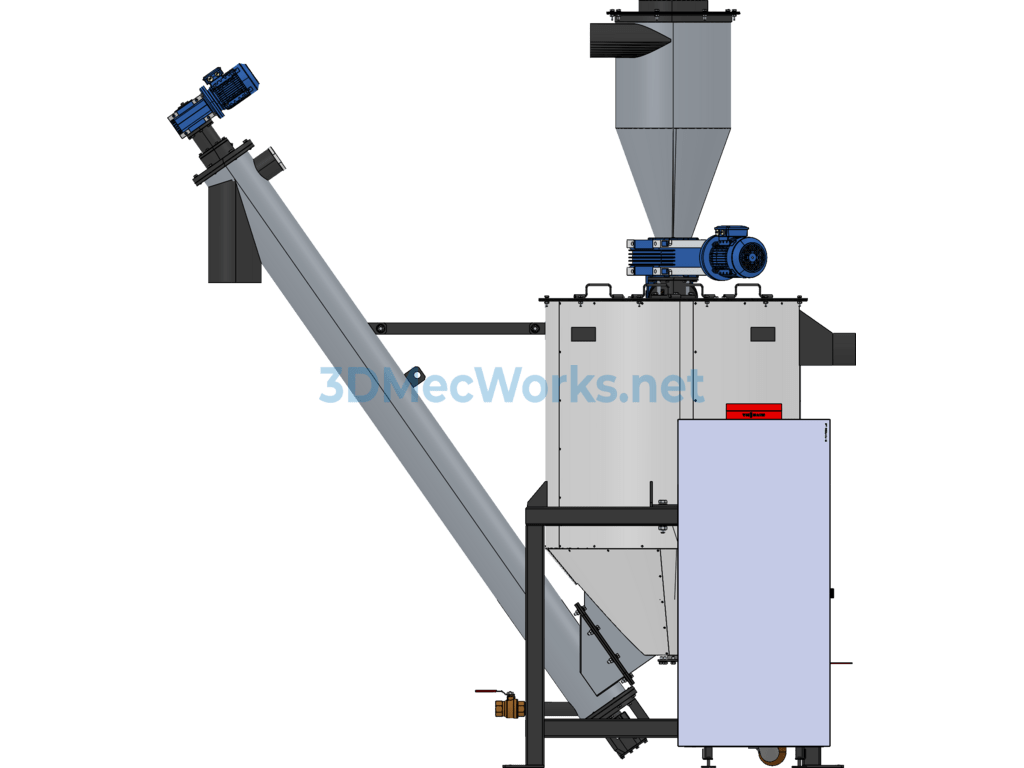

During the work process, this is a tank filled with water (with a special cleaning agent). The water/solution is at a temperature between the polymerization temperature and the boiling point. Hot water can soften the adhesive, allowing it to maintain contact with the surface of the polymer. Ground parts are continuously loaded and unloaded. In this process, the unit is designed in such a way that the parts remain for the maximum possible duration and obtain the most heat from the hot water. This is an insulator that can reduce electricity consumption in hot water. The heated water in the polymer can be driven by different energy sources selected by the user. By default, we will include a water tower and a ring heater.

Process Features:

There is a device on the market similar to the one we developed, however, we have some constructional and technical features that must be noted when making comparisons:

This is not just a container of water, it is a system that introduces water directly. Unlike other manufacturers, our equipment is equipped with a disc brake system, which provides as much time as possible in the hot solution, while the operation remains continuous.

Specification: Impregnation Washing Machine

|

User Reviews

Be the first to review “Impregnation Washing Machine”

You must be logged in to post a review.

There are no reviews yet.